Preparation method of vitamin C granules in Rosa roxburghii

A technology for granules and vitamins, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas. It can solve the problems of expensive natural vitamin C, laborious grinding and stirring, and decreased extraction rate. Achieve the effect of short preparation time, not easy to stick to the wall, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

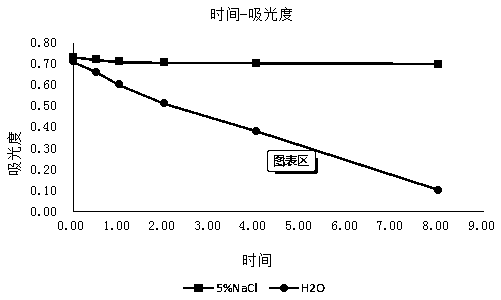

[0022] Configure an aqueous solution containing 0.2% oxalic acid and 5% sodium chloride as an extractant, weigh 2g of Rosa roxburghii dried fruit, add 100ml of extractant, and perform flash extraction of Rosa roxburghii dried fruit in an ultrasonic environment, wherein the extraction temperature is 30°C. The extraction time is 40min, the ultrasonic frequency is 60%, the extraction time of the flash extractor is 60s, and the voltage is 100V. After filtration, the filtrate is concentrated by rotary evaporation; take the above filtrate and add 100ml of 75% ethanol, let it stand for precipitation, and remove the insoluble ethanol. Sugar, such as chitosan, is filtered and the filtrate is rotovapped to obtain the extract concentrate.

[0023] With starch slurry as binder and maltodextrin as diluent, add an appropriate amount of the above-mentioned concentrated extract into the mortar, then add an appropriate amount of diluent, and mix uniformly by equal addition method (so that the t...

Embodiment 2

[0025] Configure an aqueous solution containing 0.2% oxalic acid as an extractant, weigh 2g of Rosa roxburghii dry fruit, add 100ml of extractant, and perform flash extraction on the Rosa roxburghii dry fruit in an ultrasonic environment, wherein the extraction temperature is 30°C, the extraction time is 40min, and the ultrasonic frequency 60%, the extraction time of the flash extractor is 60s, and the voltage is 100V. After filtration, the filtrate is concentrated by rotary evaporation; the above-mentioned filtrate is added to 100ml75% ethanol, left to settle, and sugars that are not compatible with ethanol, such as chitosan, are removed. After filtration, the filtrate was rotary evaporated to obtain the extract concentrate.

[0026] With starch slurry as binder and maltodextrin as diluent, add an appropriate amount of the above-mentioned concentrated extract into the mortar, then add an appropriate amount of diluent, and mix uniformly by equal addition method (so that the tho...

Embodiment 3

[0029] Configure an aqueous solution containing 0.2% oxalic acid and 5% sodium chloride as an extractant, weigh 2g of Rosa roxburghii dried fruit, add 100ml of extractant, and perform flash extraction of Rosa roxburghii dried fruit in an ultrasonic environment, wherein the extraction temperature is 30°C. The extraction time is 40min, the ultrasonic frequency is 60%, the extraction time of the flash extractor is 60s, and the voltage is 100V. After filtration, the filtrate is concentrated by rotary evaporation; take the above filtrate and add 100ml of 75% ethanol, let it stand for precipitation, and remove the insoluble ethanol. Sugar, such as chitosan, is filtered and the filtrate is rotovapped to obtain the extract concentrate.

[0030] Using starch slurry as a binder, using β-cyclodextrin, soluble starch, and maltodextrin as a diluent respectively, add an appropriate amount of the above-mentioned concentrated extract in a mortar, and then add an appropriate amount of diluent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com