Meat balls with soft and crisp mouth feel and preparation method of meat balls

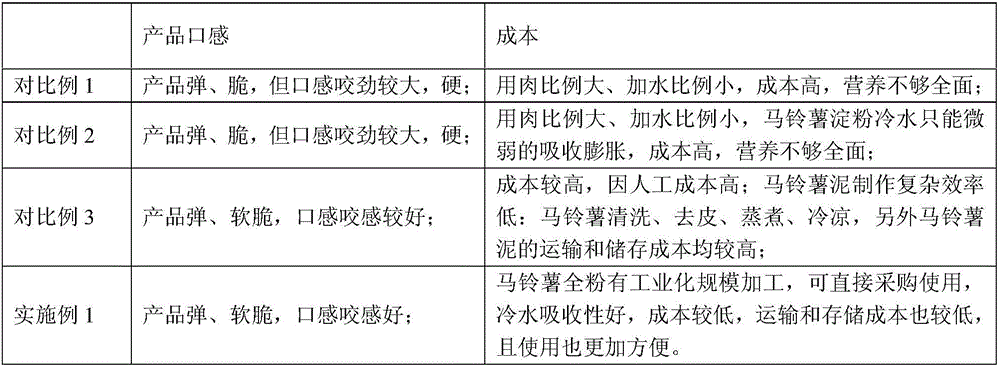

A meatball, soft and crispy technology, which is applied in the field of meatballs with soft and crispy taste and its preparation field, can solve the problems of high raw material cost and production cost, not suitable for people's consumption habits, complicated production of mashed potatoes, etc., and achieves increased softness and crispness. Taste, product taste is soft and tender, and the effect of improving taste palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A soft and crispy meatball made of the following raw materials by weight:

[0039] 50 parts of pork hind leg, 15.5 parts of fat, 17 parts of ice water, 1.5 parts of soybean protein isolate, 3 parts of tapioca hydroxypropyl starch, 4 parts of whole potato powder, 3 parts of onion, 7 parts of carrot, 0.35 part of compound phosphate , 1.15 parts of salt, 2.5 parts of white sugar, 0.4 parts of rice wine, 0.8 parts of dark soy sauce, 1.2 parts of chicken juice, 0.1 parts of pork extract, 0.4 parts of monosodium glutamate, 1.2 parts of chicken powder, 0.1 parts of white pepper powder, 0.8 parts of black pepper powder share.

[0040] The preparation method of the soft and crisp meatball of above-mentioned mouthfeel comprises the following steps:

[0041] (1) Thaw the pork hind leg meat and fat to a semi-thawed state, the surface of the meat piece will become soft at 2-3cm, cut into large pieces and put them in a meat grinder to grind the pork hind leg meat and fat fat to 8mm ...

Embodiment 2

[0050] A soft and crispy meatball made of the following raw materials by weight:

[0051] 40 parts of chicken breast, 20 parts of fat, 15 parts of ice water, 2 parts of soybean protein isolate, 2 parts of tapioca hydroxypropyl starch, 6 parts of whole potato powder, 1 part of onion, 10 parts of carrot, 0.5 part of compound phosphate, 0.9 part of salt 2 parts of white sugar, 0.2 part of rice wine, 1.0 part of dark soy sauce, 1.0 part of chicken juice, 0.14 part of pork extract, 0.2 part of monosodium glutamate, 1.5 part of chicken powder, 0.14 part of white pepper powder, and 0.4 part of crushed black pepper.

[0052] The preparation method of the soft and crisp meatball of above-mentioned mouthfeel comprises the following steps:

[0053] (1) Thaw the chicken breast and fat until it is semi-thawed, and the surface of the meat will be 2-3 cm soft. Cut it into large pieces and put it into a meat grinder to grind the chicken breast and fat into 6mm particles. Put it into a stirri...

Embodiment 3

[0062] A soft and crispy meatball made of the following raw materials by weight:

[0063] 60 parts of pork hind leg, 10 parts of fat, 22 parts of ice water, 1 part of soybean protein isolate, 5 parts of tapioca hydroxypropyl starch, 1 part of whole potato powder, 5 parts of onion, 5 parts of carrot, 0.2 part of compound phosphate , 1.4 parts of salt, 3 parts of white sugar, 0.6 parts of rice wine, 0.5 parts of dark soy sauce, 1.5 parts of chicken juice, 0.06 parts of pork extract, 0.6 parts of monosodium glutamate, 1 part of chicken powder, 0.07 parts of white pepper powder, 1.2 parts of crushed black pepper share.

[0064] The preparation method of the soft and crisp meatball of above-mentioned mouthfeel comprises the following steps:

[0065] (1) Thaw the pork hind leg meat and fat until it is semi-thawed, the surface of the meat piece will become soft by 2-3 cm, cut into large pieces and put it in a meat grinder to grind the pork hind leg meat and fat into 10mm particles,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com