Bread crumbs and preparation method thereof

A production method and technology of bread crumbs, which are applied in the field of food additives, can solve the problems of affecting health, poor taste of food, greasy food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

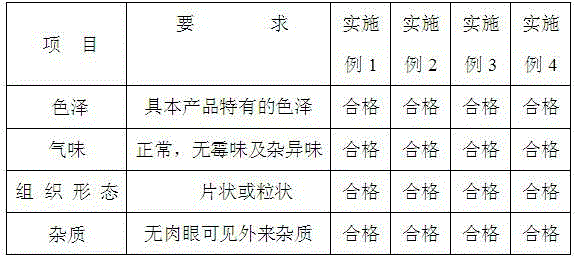

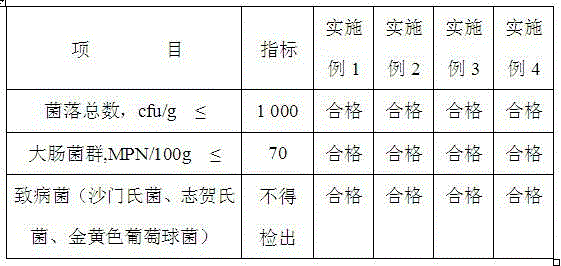

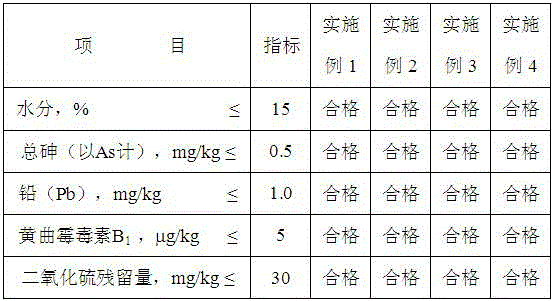

Examples

Embodiment 1

[0054] A bread bran is composed of the following raw materials in parts by weight: 70 parts of high-precision flour, 8 parts of starch, 5 parts of water, 5 parts of rice, 3 parts of salt, 1 part of sugar and 1 part of emulsifier.

[0055] The bread crumbs of the invention have less oil absorption, crispy, crispy and soft taste after frying, and high nutritional value.

[0056] The production method of the bread crumbs comprises the following steps: (a) preparation of raw materials: weighing the raw materials according to the above weight parts; (b) mixing and stirring: mixing the raw materials with high-precision flour, starch, water, rice, salt, sugar, emulsifying (c) Expansion: Put the mixture obtained in step (b) into a twin-screw extrusion extruder for expansion treatment to obtain the primary product. The expansion treatment is divided into three stages, They are the former stage, the middle stage, and the latter stage respectively. The temperature of the former stage is ...

Embodiment 2

[0059] A bread bran is composed of the following raw materials in parts by weight: 75 parts of high-precision flour, 10 parts of starch, 8 parts of water, 8 parts of rice, 5 parts of salt, 3 parts of sugar and 2 parts of emulsifier.

[0060] The bread crumbs of the invention have less oil absorption, crispy, crispy and soft taste after frying, and high nutritional value.

[0061] The production method of the bread crumbs comprises the following steps: (a) preparation of raw materials: weighing the raw materials according to the above weight parts; (b) mixing and stirring: mixing the raw materials with high-precision flour, starch, water, rice, salt, sugar, emulsifying (c) Expansion: Put the mixture obtained in step (b) into a twin-screw extrusion extruder for expansion treatment to obtain the primary product. The expansion treatment is divided into three stages, They are the former stage, the middle stage, and the latter stage respectively. The temperature of the former stage ...

Embodiment 3

[0064] A bread bran is composed of the following raw materials in parts by weight: 80 parts of high-precision flour, 10 parts of starch, 8 parts of water, 5 parts of rice, 3 parts of salt, 2 parts of sugar and 1 part of emulsifier.

[0065] The bread crumbs of the invention have less oil absorption, crispy, crispy and soft taste after frying, and high nutritional value.

[0066]The production method of the bread crumbs comprises the following steps: (a) preparation of raw materials: weighing the raw materials according to the above weight parts; (b) mixing and stirring: mixing the raw materials with high-precision flour, starch, water, rice, salt, sugar, emulsifying (c) Expansion: Put the mixture obtained in step (b) into a twin-screw extrusion extruder for expansion treatment to obtain the primary product. The expansion treatment is divided into three stages, They are the former stage, the middle stage, and the latter stage respectively. The temperature of the former stage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com