Wrapping powder

A technology for coating flour and modified starch, which is applied in the field of food processing, can solve the problems of inability to meet performance and particle state, large oil absorption of flour, and reduced product taste, etc., and achieves the effects of good appearance, reduced oil absorption, and reduced intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

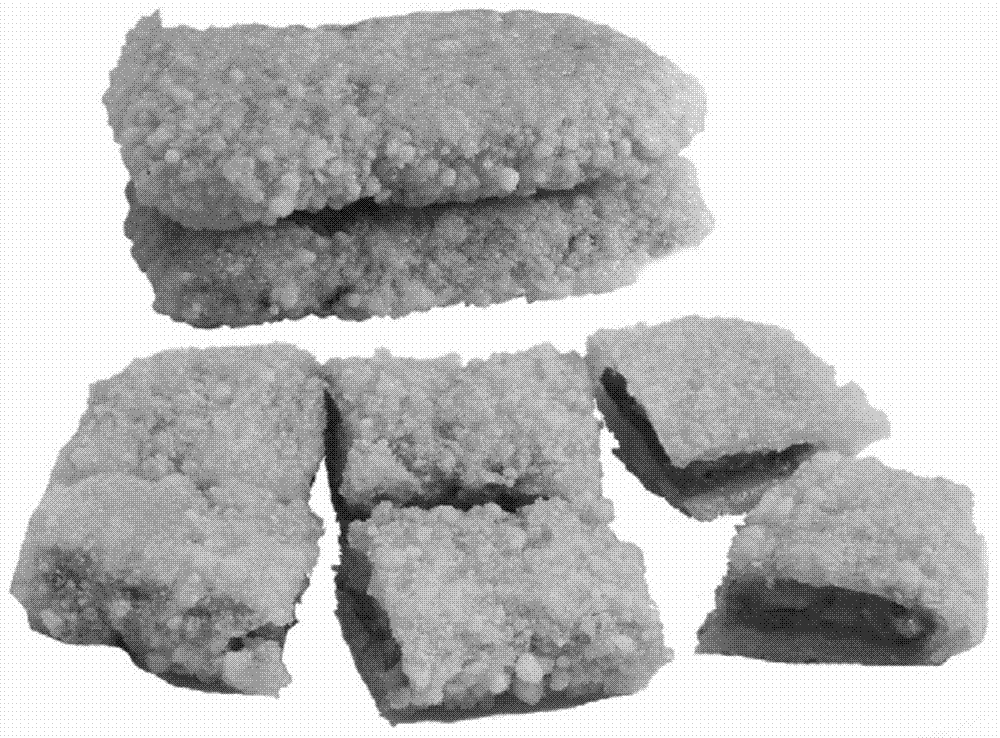

Image

Examples

Embodiment 1

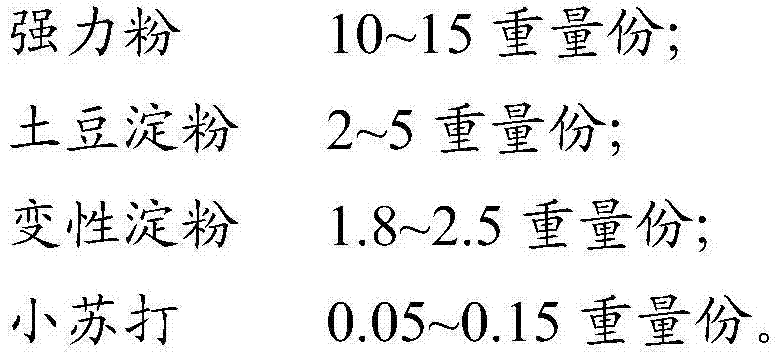

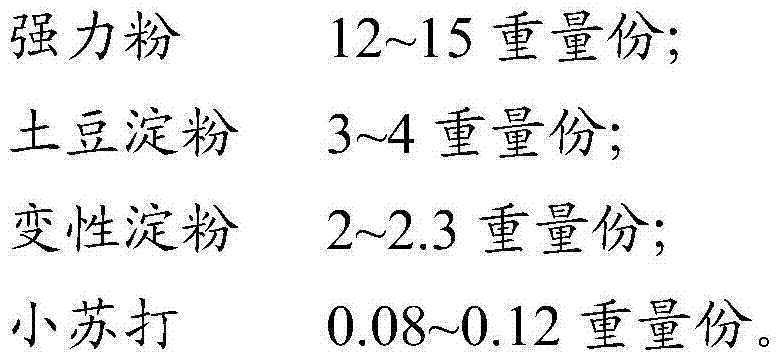

[0033] 1.1 Mix 10 parts by weight of strong powder, 2 parts by weight of potato starch, 1.8 parts by weight of modified corn starch and 0.05 parts by weight of baking soda to obtain the coating powder.

[0034] 1.2 The chicken breast of 100 parts by weight, the salt of 2 parts by weight, the white granulated sugar of 1 part by weight, the monosodium glutamate of 0.3 parts by weight, the cumin powder of 0.4 parts by weight, the garlic powder of 0.12 parts by weight, the seasoning capsicum of 0.2 parts by weight , 0.1 parts by weight of heat-reactive chicken essence, 0.3 parts by weight of composite water-retaining agent, 4 parts by weight of starch mixed with 30 parts by weight of water, vacuum tumbling pickled, vacuum degree -0.09MPa, 8 rpm, tumbling for 40min , and then mix it with 25 parts by weight of the slurry (the slurry is 12 parts by weight of the powdered powder obtained in 1.1 and 13 parts by weight of water), after fully mixing it, lightly mix it with the powdered po...

Embodiment 2

[0037] 2.1 Mix 12 parts by weight of strong powder, 4 parts by weight of potato starch, 1.8 parts by weight of modified corn starch and 0.1 part by weight of baking soda to obtain the coating powder.

[0038] 2.2 The chicken breast of 100 parts by weight, the salt of 2 parts by weight, the white granulated sugar of 1 part by weight, the monosodium glutamate of 0.3 parts by weight, the cumin powder of 0.4 parts by weight, the garlic powder of 0.12 parts by weight, the seasoning capsicum of 0.2 parts by weight , 0.1 parts by weight of heat-reactive chicken essence, 0.3 parts by weight of composite water-retaining agent, 4 parts by weight of starch mixed with 30 parts by weight of water, vacuum tumbling pickled, vacuum degree -0.09MPa, 8 rpm, tumbling for 40min , then mix it with 25 parts by weight of the slurry (the slurry is 12 parts by weight of the powdered powder obtained in 2.1 and 13 parts by weight of water), after fully mixing it, lightly mix it with the powdered powder o...

Embodiment 3

[0040] 3.1 Mix 15 parts by weight of strong powder, 5 parts by weight of potato starch, 1.8 parts by weight of modified corn starch, and 0.05 parts by weight of baking soda to obtain the coating powder.

[0041] 3.2 100 parts by weight of chicken breast meat, 2 parts by weight of salt, 1 part by weight of white granulated sugar, 0.3 parts by weight of monosodium glutamate, 0.4 parts by weight of cumin powder, 0.12 parts by weight of garlic powder, 0.2 parts by weight of seasoning capsicum , 0.1 parts by weight of heat-reactive chicken essence, 0.3 parts by weight of composite water-retaining agent, 4 parts by weight of starch mixed with 30 parts by weight of water, vacuum tumbling pickled, vacuum degree -0.09MPa, 8 rpm, tumbling for 40min , then mix it with 25 parts by weight of the slurry (the slurry is 12 parts by weight of the powdered powder obtained in 3.1 and 13 parts by weight of water), after fully mixing it, lightly mix it with the powdered powder obtained in 3.1 Ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com