Sludge fast heat drying treating device and sludge fast heat drying treating method

A treatment device and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of nozzle wear and lower production efficiency, and achieve the effects of avoiding sticking to the wall, fast heat and mass transfer speed, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

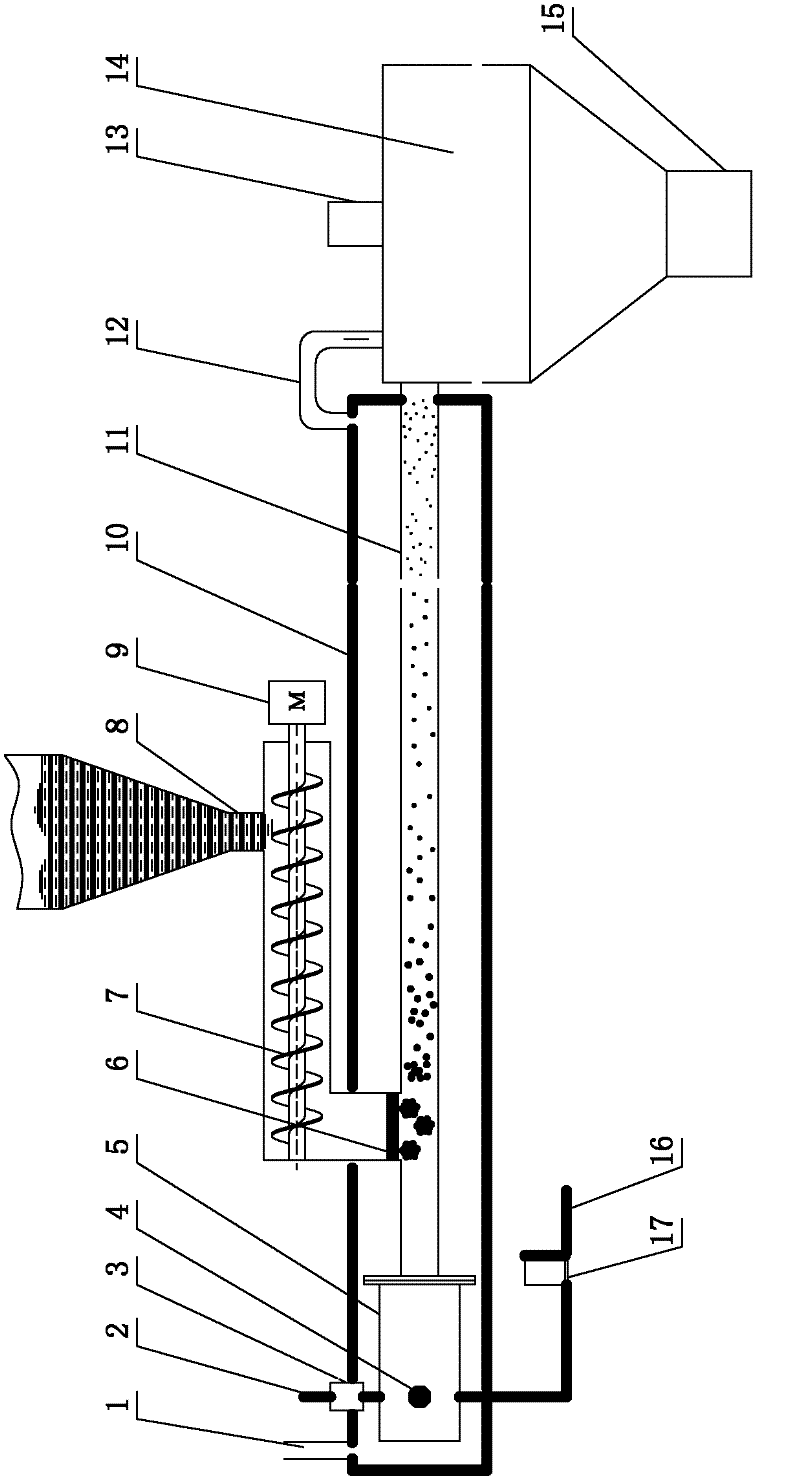

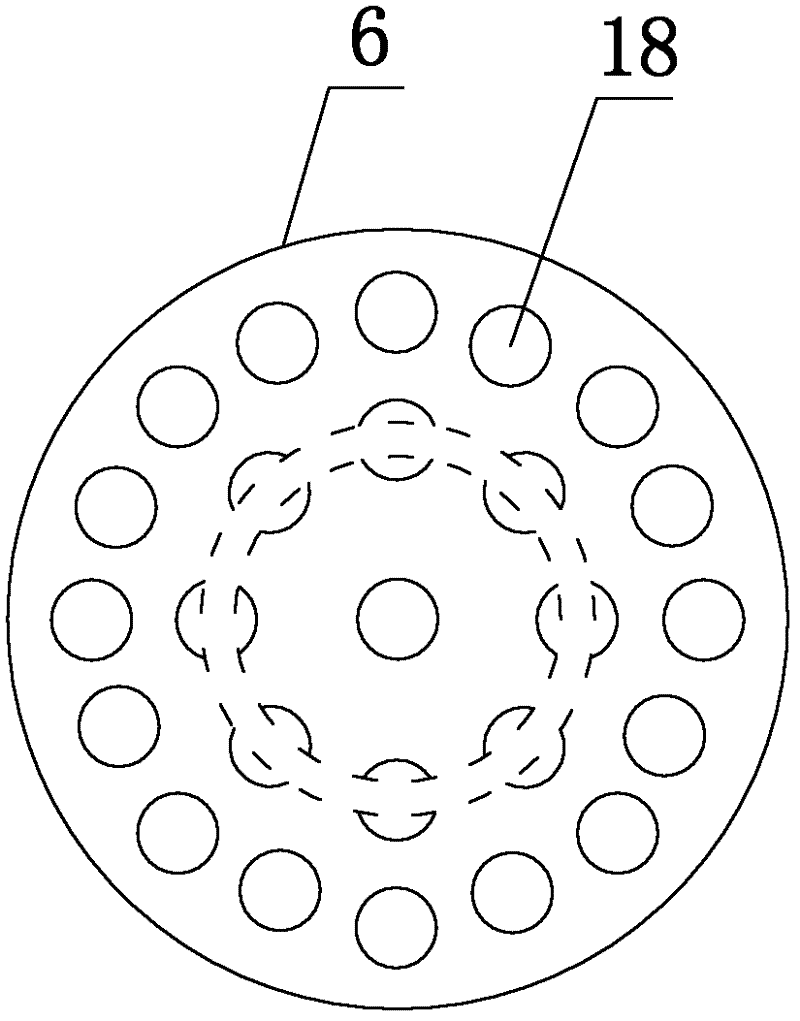

[0031] A sludge rapid thermal drying treatment device, which consists of a controllable explosion burner, a sludge conveying mechanism, and a post-dryer 14. The controllable explosion burner consists of a combustion chamber 5, an igniter 4, an air intake pipeline 2, Composed of gas intake pipeline 16, tail pipe 11 and jacket 10, the combustion chamber is fixed in the jacket, the combustion chamber is fixed with gas intake pipeline, air intake pipeline and igniter, and the tail pipe is fixed in the jacket Inside, one end communicates with the combustion chamber, and one end extends out of the jacket to communicate with the post-dryer. The sludge conveying mechanism is fixed above the outside of the jacket, and the end of the sludge conveying m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com