Low-temperature grain depot heat insulation system and construction method thereof

A thermal insulation system and construction method technology, applied in thermal insulation, large-capacity bulk material storage, building components, etc., can solve the problems of pressure deformation of polyurethane sprayed foam layer, thermal insulation is easy to become a cold bridge, complex construction technology, etc., to achieve The construction quality is easier to guarantee, the service life is long, and the effect of wide selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

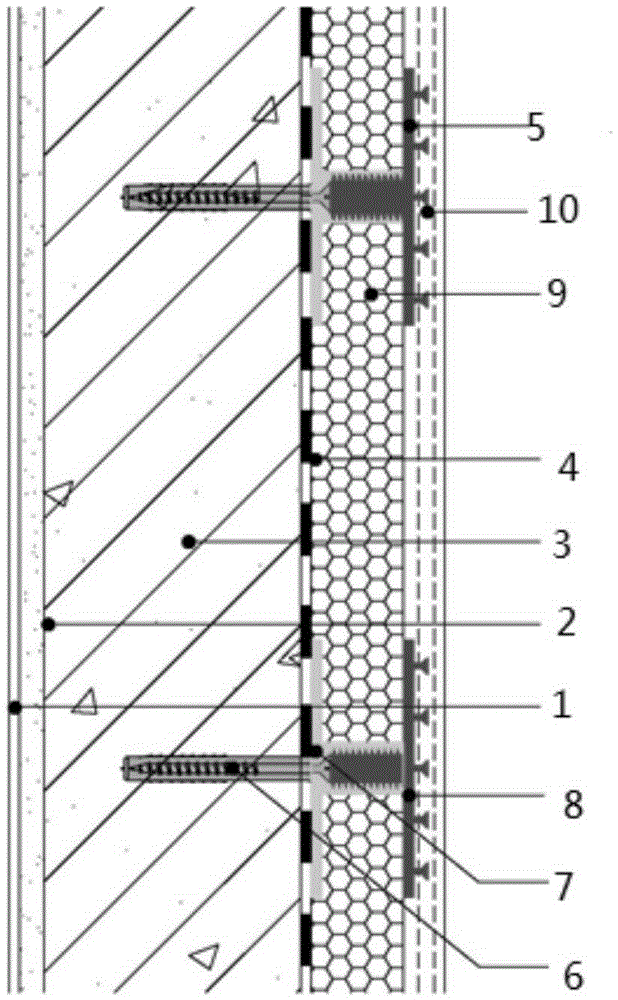

[0030] Example 1: Low Temperature Grain Depot Insulation System

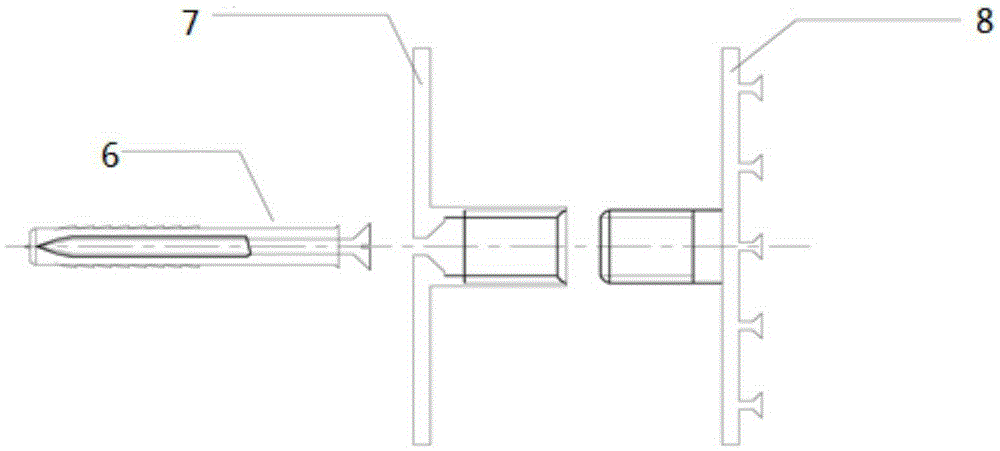

[0031] From outside to inside, they are: heat-reflective paint finishing layer (1); plastering layer (2); reinforced concrete or block warehouse wall (3); vapor barrier layer (4); fixing parts (5), including expansion nails (6), chassis (7) and top plate (8); thermal insulation layer (9); plastering protection layer (10), wherein, the outer side of painting layer (2) is coated with heat-reflective paint finishing layer (1), steam-proof The layer (4) is arranged between the insulation layer (9) and the warehouse wall (3), and the insulation layer (9) and the vapor barrier layer (4) are fixed on the warehouse wall (3) by a pressure-bearing fixing piece (5) On, the plastering protective layer (10) is painted on the outside of the insulation layer (9). Such as figure 1 shown. The plastic chassis (7) is fixed on the warehouse wall by expansion nails (6), and the other end penetrates the insulation layer (9) and is...

Embodiment 2

[0032] Example 2: Construction method of low temperature grain depot insulation system

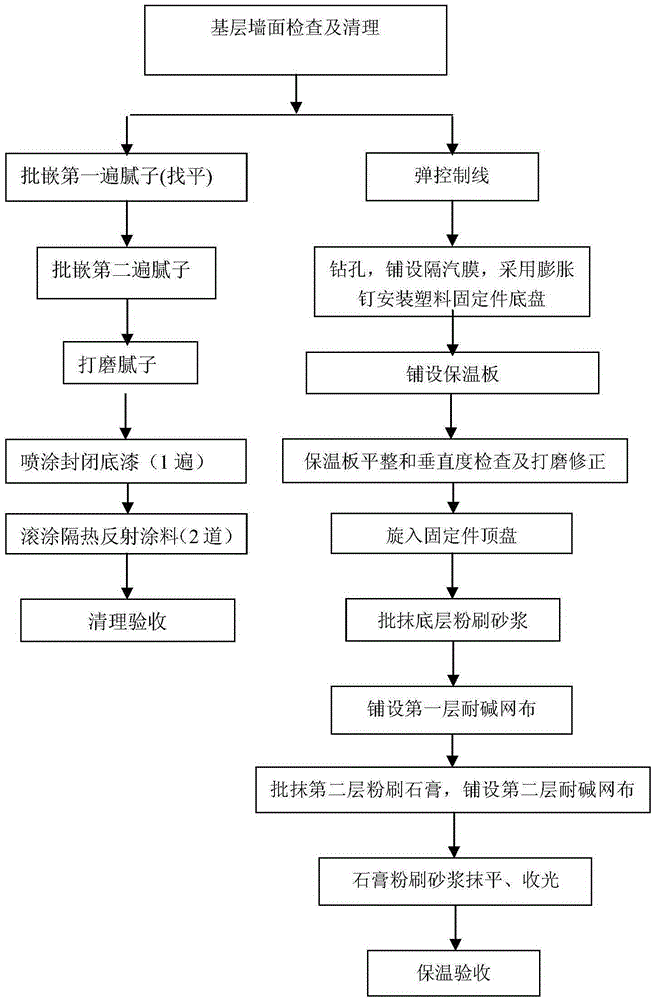

[0033] (1) Construction method of the external heat insulation system: first check and clean the wall of the warehouse, then batch putty inlay the bottom layer for leveling, then batch putty inlay 2 to 3 times, polish the putty to form a whitewash layer; then spray the sealing primer, and finally roll Apply heat-insulating reflective paint to form a heat-reflective paint finish layer, which is the external heat insulation system;

[0034](2) Construction method of the internal thermal insulation system: first check and clean the wall of the warehouse, play the control line, lay a vapor barrier layer on the inner side of the warehouse wall, use expansion nails to fix the chassis of the fixing part and the vapor barrier layer on the warehouse wall, and then Lay the insulation board through the tip of the fixing part on the warehouse wall to form an insulation layer, then align the top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com