Patents

Literature

39results about How to "To achieve thermal insulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based transparent heat-insulating paint used for energy-saving doors and windows and preparation method thereof

ActiveCN103351757AReduce usageRich varietyPolyurea/polyurethane coatingsWater basedAluminum doped zinc oxide

The invention discloses a water-based transparent heat-insulating paint used for energy-saving doors and windows. The paint comprises the following components by weight: 50 to 60% of an aqueous base latex, 20 to 30% of aqueous nanometer heat-insulating slurry, 0.5 to 1% of a defoaming agents, 1 to 5% of a thickening agent, 0.5 to 1% of a film forming auxiliary agent and 0.5 to 1% of a leveling agent, with the balance being deionized water, wherein the aqueous base latex is an aqueous acrylic resin emulsion with solid content of 30 to 60 wt% or an aqueous polyurethane resin emulsion with solid content of 30 to 60 wt%, and the aqueous nanometer heat-insulating slurry contains the two functional particles consisting of fluorine-doped tin oxide and aluminum-doped zinc oxide. The invention further discloses a preparation method for the paint. The paint prepared in the invention can be coated on the surface of door and window glass to form a transparent film; and the film can absorb the vast majority of ultraviolet light and obstruct more than 60% of infrared light and has average transmittance of more than 70% in a visible light area.

Owner:ZHEJIANG UNIV

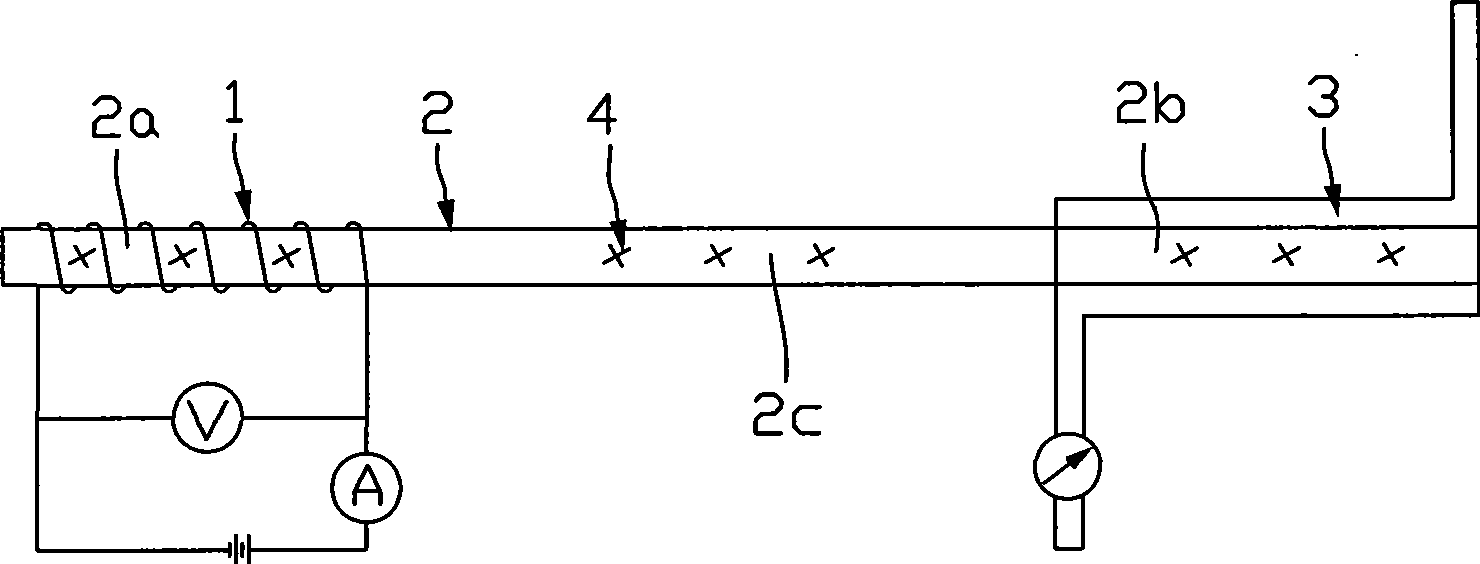

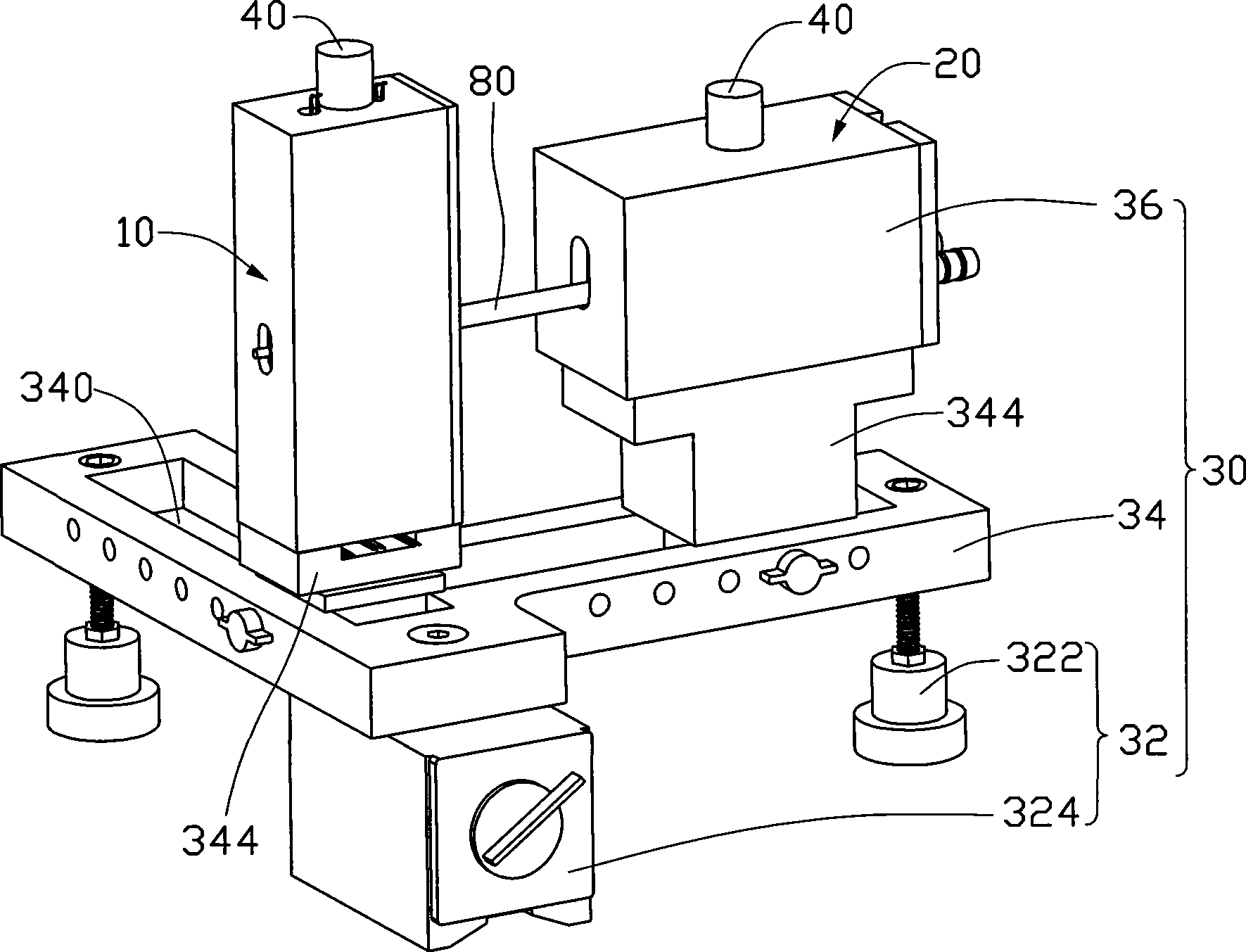

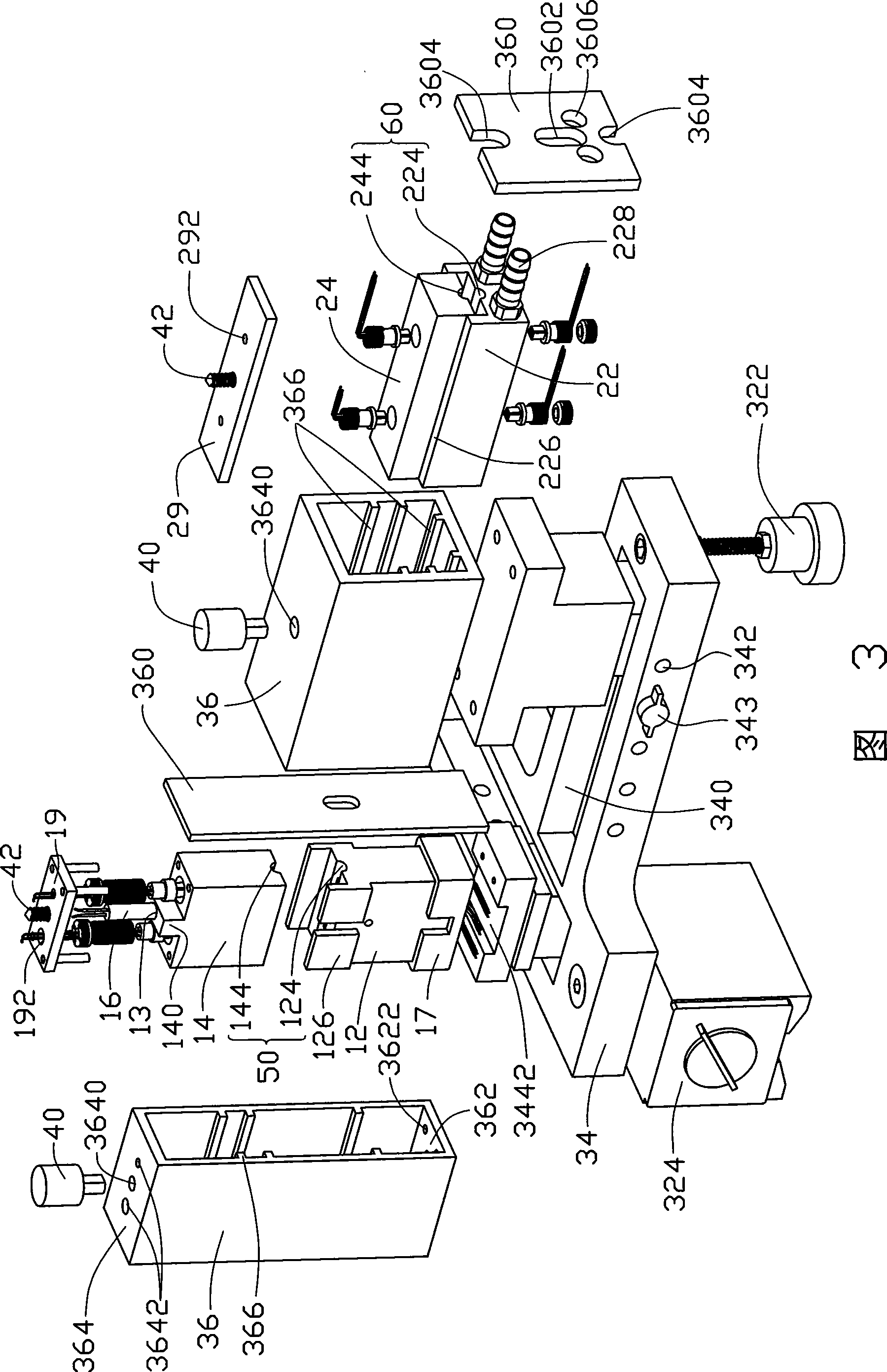

Hot pipe performance detecting device

InactiveCN101435786AMeet the requirements of mass production testingImprove consistencyMaterial heat developmentThermometers using electric/magnetic elementsEngineeringHeating element

The invention discloses a performance detecting device for heat tubes, which comprises a heating component, a heat dissipation component and a load bearing part, wherein the heating component and the heat dissipation component comprise a fixed part and a movable part respectively; the movable part and the fixed part can be disengaged or engaged; at least one measurement holding part capable of holding a to-be-detected heat tube is arranged between the opposite surfaces of the fixed part and the movable part; at least one temperature sensor is arranged in the measurement holding part; at least one heating element is arranged in the fixed part and the movable part of the corresponding heating component; at least one cooling structure is arranged in the fixed part and the movable part of the corresponding heat dissipation component; the load bearing part comprises a positioning seat and two clamping seats which are arranged on the positioning seat and can be slid and adjusted relative to the positioning seat; and the two clamping seats bear the heating component and the heat dissipation component respectively, adjust positions and position the two components.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Thermal insulation plaster bonding agent

A novel multifunctional heat preserving and insulating plaster adhesive has the components with the following weight content: cement 20-40%, silicon-aluminium glass hollow sphere material 15-35%, grinded high-calcium flyash 15-35%, water reducing agent 0.5-1.2%, air-entrainer 0.005-0.05%, modifier 1-5%, fiber 0.1-5%, and water-loss reducer 0.5-2%. In the adhesive the cement is common silicate 42.5 grade cement; the silicon-aluminum glass hollow sphere material has specific surface area 400-15000m<2> / kg, the sphere grain diameter is 0.5 mu m-60 mu m, and the content of silicon oxide is above 50%; the grained high-calcium flyash is obtained by grinding the common high-calcium flyash with the polarization grinder for 30min, the CaO content is above 18% and the fineness degree is 4000-6000m<2> / kg; the water reducing agent is alkali lignin water reducing agent; the fiber is the combination of one or a plurality of fibers in modified polypropylene fiber, alkali-resistant glass fiber, nylon fiber, animal and vegetable fibers; the air-entrainer is the colophony pyrolytic polymer series air-entrainer; and the modifier is cellulose or the derivative of the cellulose. The adhesion promoter is sodium group or potassium-group alta-mud.

Owner:武汉科华高新材料发展有限公司

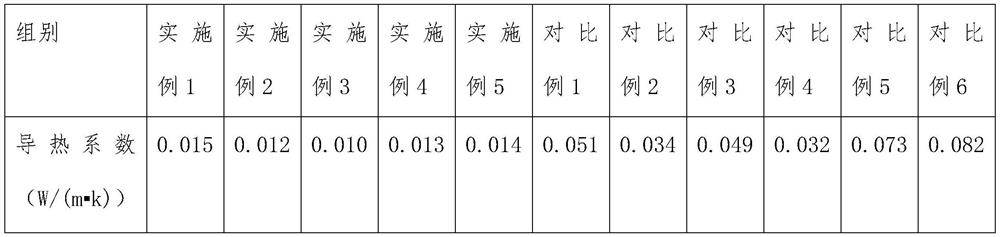

Composite architectural heat-insulation coating and preparation method thereof

InactiveCN105199520AEfficient fillingImprove liquidityRadiation-absorbing paintsReflecting/signal paintsEmulsionMicrosphere

The invention discloses a composite architectural heat-insulation coating and a preparation method thereof. The composite architectural heat-insulation coating is formed by mixing the following ingredients by mass: 25 to 40 parts of water, 0.3 to 0.9 part of a thickening agent, 0.1 to 0.3 part of a multifunctional additive, 0.3 to 1.2 parts of an ageing resistant additive, 0.2 to 0.5 part of a wetting agent, 0.5 to 2.0 parts of a dispersing agent, 0.4 to 1.3 parts of a mold inhibitor, 0.2 to 0.5 part of an antifoaming agent, 2 to 5 parts of a film-forming additive, 8 to 20 parts of a pigment, 6 to 13 parts of a heat-insulation functional additive formed by mixing two or three of phase change microcapsules, hollow glass microspheres and polymeric microspheres, and 38 to 52 parts of an emulsion. The composite architectural heat-insulation coating is favorable in appearance, excellent in storage stability, equal to or lower than 1.06 g / cm<3> in density, equal to or lower than 0.065 W / (m.k) in heat conductivity, larger than 10 DEG C in heat-insulation temperature difference, favorable in washability and brushability, and excellent in heat-insulation effect.

Owner:东莞暨南大学研究院 +2

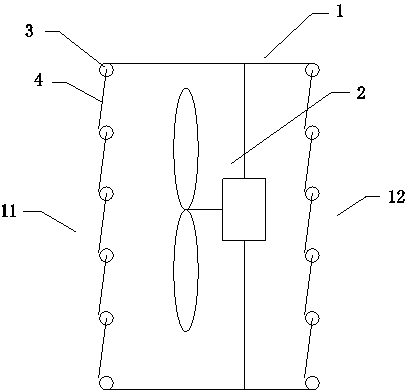

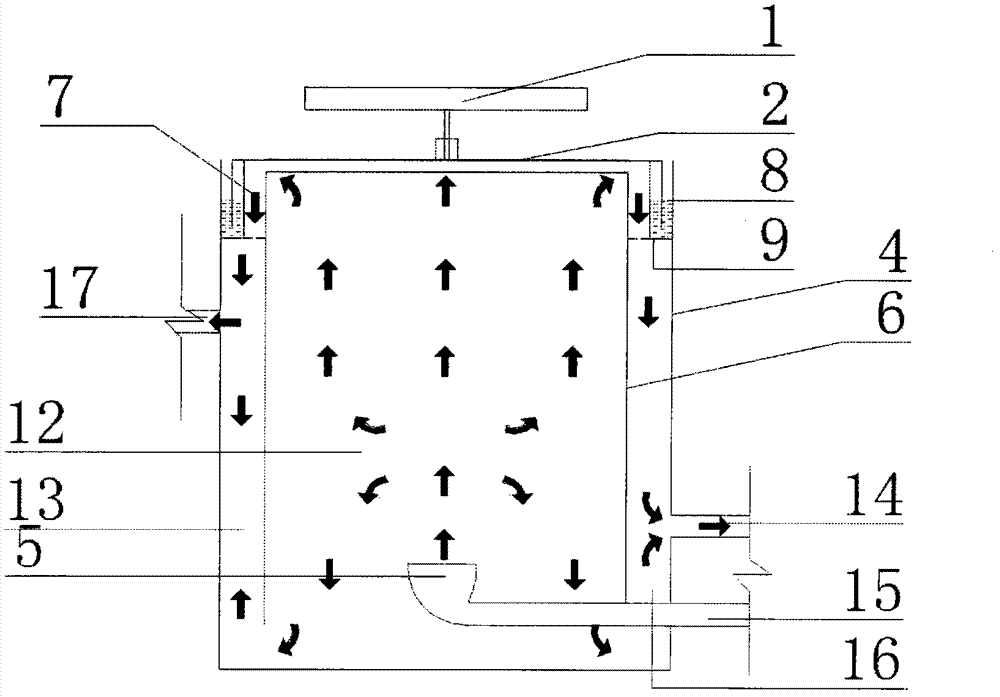

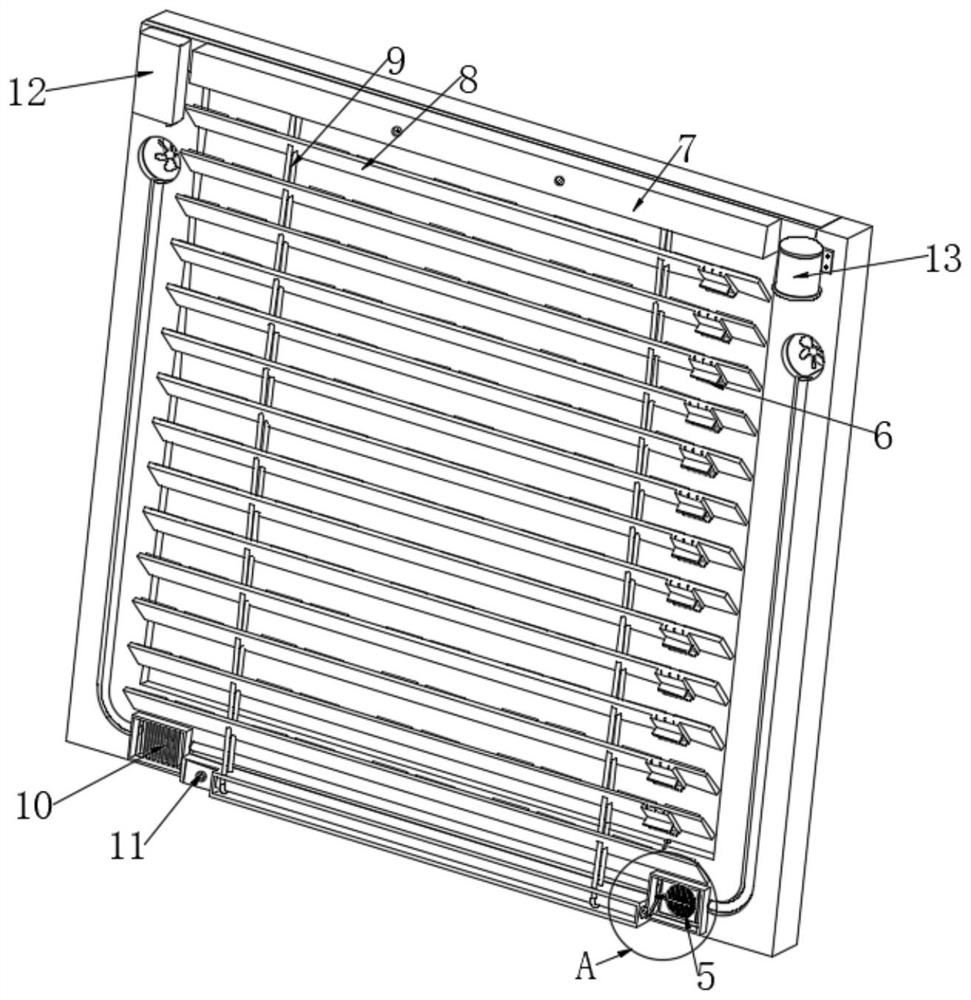

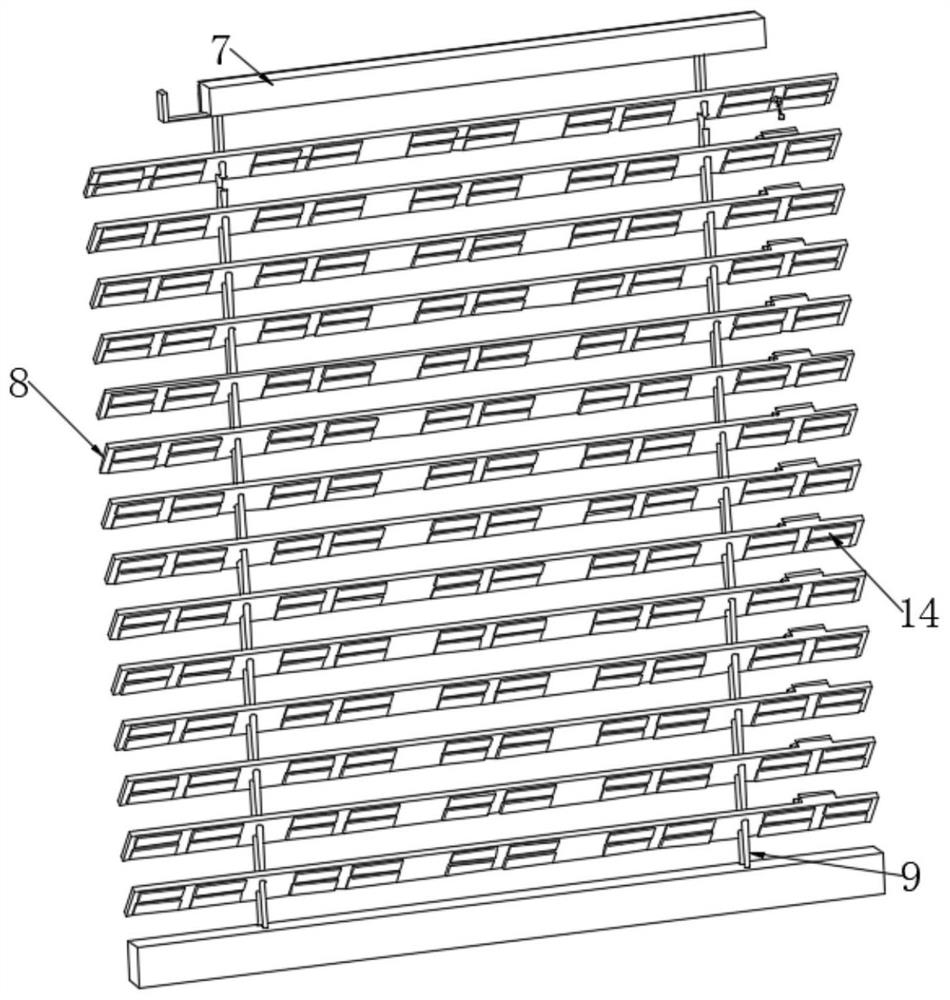

Indoor air conditioning ventilator

InactiveCN103644619ATo achieve the purpose of ventilationTo achieve thermal insulation effectLighting and heating apparatusAir-flow control membersEngineeringThermal protection

The invention discloses an indoor air conditioning ventilator. The indoor air conditioning ventilator comprises a casing and an air supply fan which is arranged inside the casing; an automatic shutter device is arranged at an air outlet of the casing; the automatic shutter device comprises screen plate units which are laminated; the screen plate units comprise pivot shafts which are arranged on the casing in a penetration mode and screen plates which are pivoted to the pivot shafts. According to the indoor air conditioning ventilator, when ventilation is needed, the air supply fan blows the screen plates to rotate around the pivot shafts when supplying air towards the air outlet, so that the air outlet is opened, indoor feculent air is discharged, and a ventilation purpose is achieved; when the ventilation is not needed, the screen plates freely droop to seal the air outlet due to the gravitational function, a thermal protection and heat insulation effect is achieved, the integral ventilation process does not need a hand to open an air channel, and the ventilation is convenient.

Owner:ZHONGSHAN LANSHUI ENERGY TECH DEV

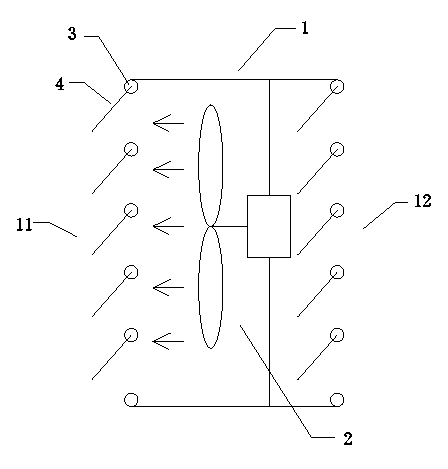

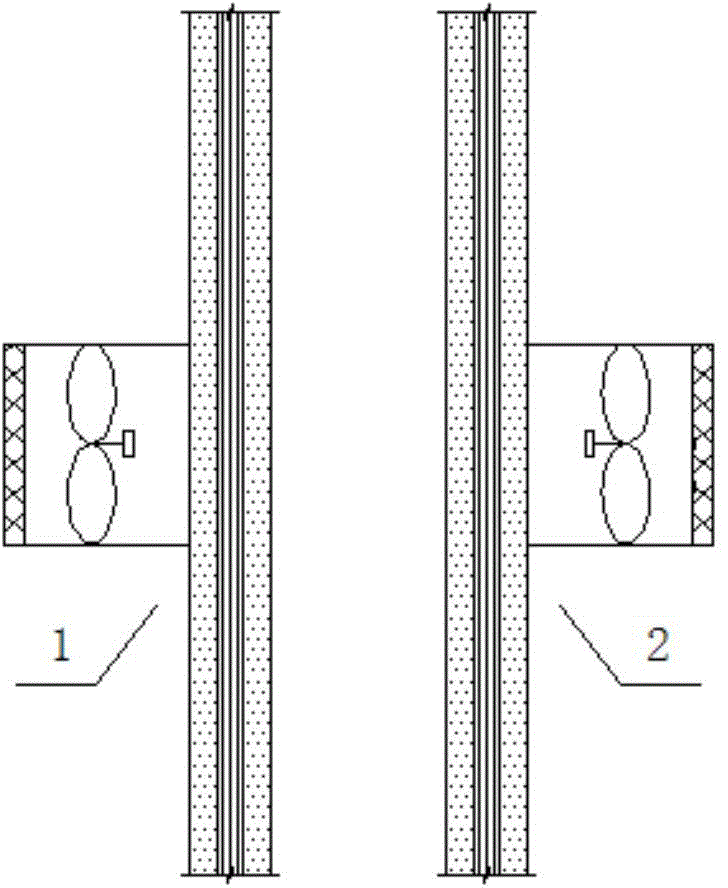

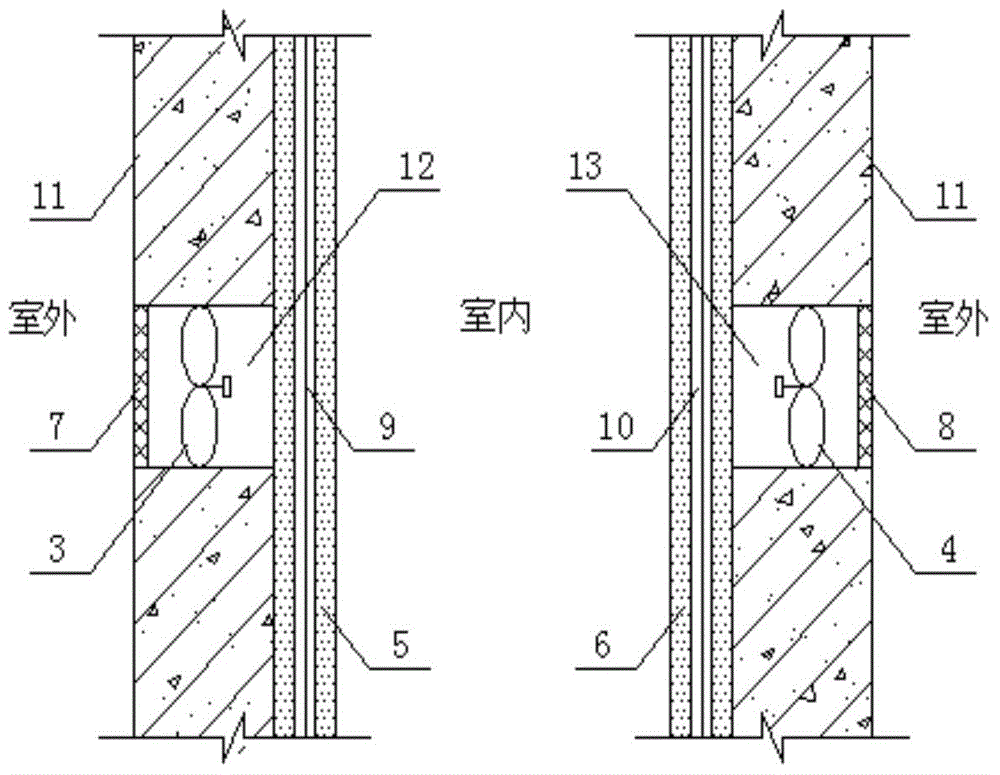

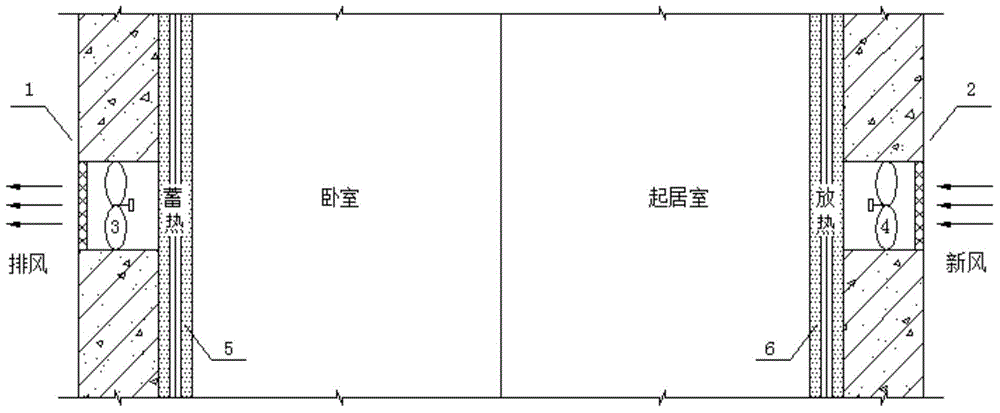

Self-temperature-regulation heat recovery type ventilation system

ActiveCN104676811ATo achieve thermal insulation effectIncreased ventilation energy consumptionEnergy recovery in ventilation and heatingHeat recovery systemsIndoor air qualityBuilding energy

The invention discloses a self-temperature-regulation heat recovery type ventilation system which is installed on a building outer wall. At least one set of vent holes are formed in the building outer wall. The ventilation system comprises at least one set of temperature regulation walls made of temperature regulation materials, and ventilators arranged at the vent holes, the temperature regulation walls are arranged on the sides, facing indoors, of the vent holes, and the ventilators are arranged in the middles of the vent holes. In the self-temperature-regulation heat recovery type ventilation system, the temperature regulation materials are led into a building envelope, heat storage and heat release are conducted through the temperature regulation walls so that heat or cold in exhaust air can be recovered when indoor ventilation is conducted, the indoor air quality can be improved, the influences of outdoor temperature fluctuation can be effectively delayed and reduced, building heating or air conditioning can not be used or less used, the capacity of air conditioner devices can be reduced, and the building energy consumption can be lowered.

Owner:CHINA ACAD OF BUILDING RES

Energy-saving brick prepared on basis of building waste and preparation method thereof

InactiveCN108264333AImprove stabilityImprove compactnessCeramic materials productionClaywaresFiberTO-18

The invention discloses an energy-saving brick prepared on the basis of building waste. The energy-saving brick is prepared from the following raw materials in parts by weight: 32 to 36 parts of modified building waste, 24 to 28 parts of modified flay ash, 14 to 18 parts of coal gangue, 12 to 14 parts of lithium bentonite, 8 to 12 parts of cotton fiber, 6 to 10 parts of wood fiber, 8 to 12 parts of glass beads, 8 to 12 parts of crushed crude pearlite, 4 to 6 parts of water reducers, 3 to 5 parts of anti-foaming agents, 3 to 5 parts of cement and 1 to 3 parts of filling materials. The inventionaims at providing the energy-saving brick prepared on the basis of building waste. The energy-saving brick has the advantages that the building waste is sufficiently utilized; meanwhile, the properties such as the intensity, the sound isolation and heat isolation performance and the like of the brick can be improved; high use value and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Recycled aggregate temperature controlled plastering mortar and preparation method thereof

InactiveCN107522431ATo achieve thermal insulation effectShorten the construction periodSolid waste managementEpoxyPrill

The invention discloses recycled aggregate temperature controlled plastering mortar and a preparation method thereof. The recycled aggregate temperature controlled plastering mortar comprises the following raw materials: a recycled aggregate, water, cement, coal ash, a heat-conducting phase change material particles and aqueous epoxy resin, wherein the recycled aggregate is pretreated small particle aggregate, the grain size of which is smaller than 4.75mm. The preparation method of the recycled aggregate temperature controlled plastering mortar comprises selection, weighing, stirring and mixing of the recycled aggregate. The temperature controlled plastering mortar produced by the recycled aggregate obtained by resourceful treatment of building wastes and other materials in a certain proportion has the effects of regulating temperature, controlling temperature, keeping temperature and isolating heat. The application range of the recycled aggregate made from the building wastes is expanded, the additional value of a product is increased, and harmony between man and nature is achieved.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

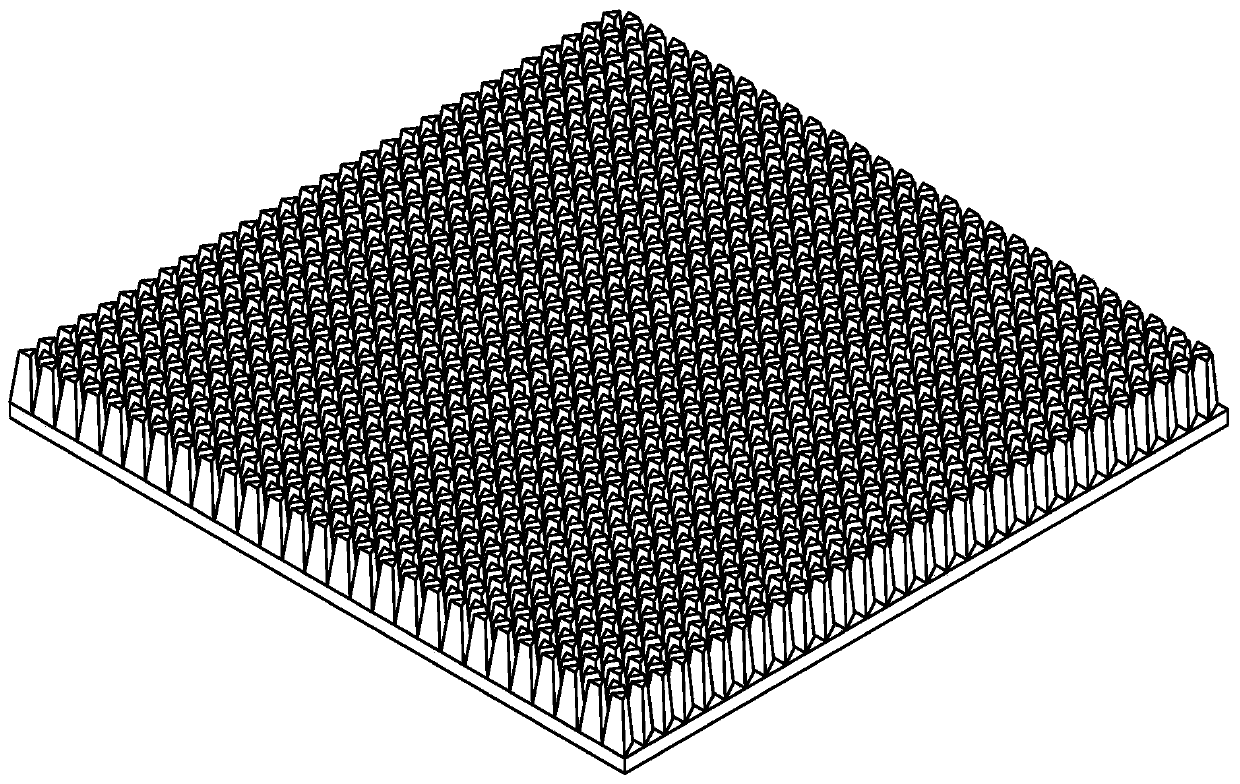

Vacuum honeycomb ceramic body

The invention discloses a vacuum honeycomb ceramic body, which is produced according to method with the following steps: adding various raw materials for formulating honeycomb ceramic proportionally into the ball mill for ball milling and forming into powder, kneading for forming into pug, ageing and pugging pug for forming into mud segment, adding mud segments into press for forming honeycomb ceramic wet blank, placing wet blank into drying room, drying and shaping at 60-120 DEG C for forming into semi-dried blank body, burning into honeycomb ceramic body at 1200-1500 DEG C, placing honeycomb ceramic body into a vacuum box with vacuum degree 4-9 KPa for executing vacuum treatment, using material identical to honeycomb ceramic under vacuum state for sealing two terminals of honeycomb ceramic body, and then drying, executing secondary burning for forming into a vacuum honeycomb ceramic body under 1200-1500 DEG C. The heat insulation and heat preservation performances of the vacuum honeycomb ceramic body provided by the invention increases to 50-80 times of that of cavity brick, and the mass reduces 50-70%. The product provided by the invention not only has the advantages of lower thermometric conductivity, but also has light quality, low cost, saving raw material, reduced building load and saving building items investment.

Owner:姚光纯

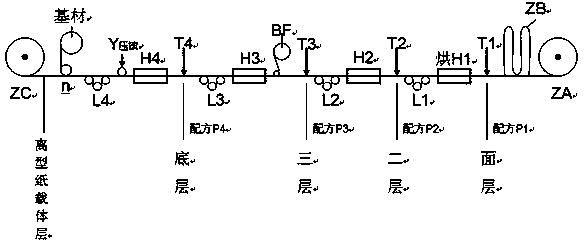

Multifunctional soft wall base material production process and formula

ActiveCN103375003AWith negative ion release functionGood flexibilityCovering/liningsFoaming agentThermal insulation

The invention relates to a multifunctional soft wall base material production process and formula. The multifunctional soft wall base material comprises T1, T2 and T3 (adhering layer) in the front. T1 is a PU (polyurethane) layer which is used for increasing surface anti-scratch strength, adding negative ion powder materials, and allowing the soft wall base material to have a negative ion releasing function. T2 is a support layer which is used for supporting embossed printing. Foaming agent is added to the adhering layer T3 to allow T3 to have the same foaming effect as T2, and weight of the soft wall base material is reduced and softness of the same is increased. Foaming ratio of T2 and T3 is controlled at 1.2-1.8 times according to different requirements of the soft wall base material. After cloth applying, a high-foaming material T3 layer is coated at the bottom of base cloth to increase internal space of the soft wall base material, achieve thermal insulation and softness, and facilitate wall adhering. Diatomaceous earth is added in the formula and one-step foaming is used to allow cells of the whole soft wall base material to be communicated so as to achieve breathability, and accordingly the soft wall base material has functions of breathability, moisture permeability, moisture adjusting by balancing moisture regain and water retention rate, and deodorization.

Owner:NINGBO CALLDE BIOMIMETICS MATERIALS CO LTD

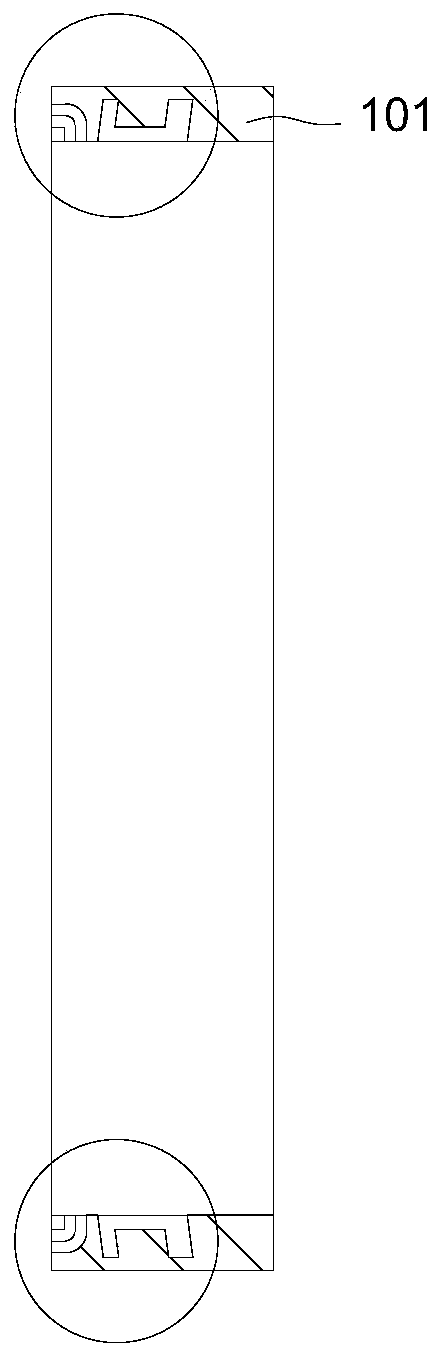

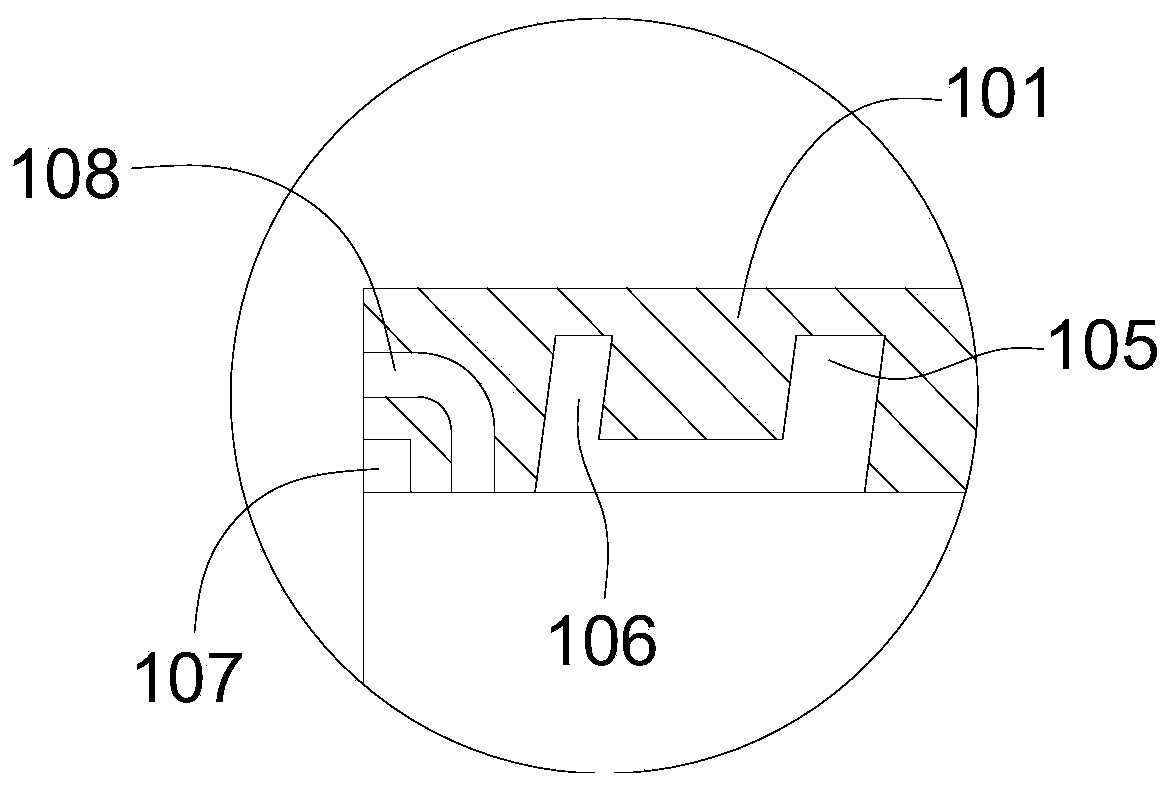

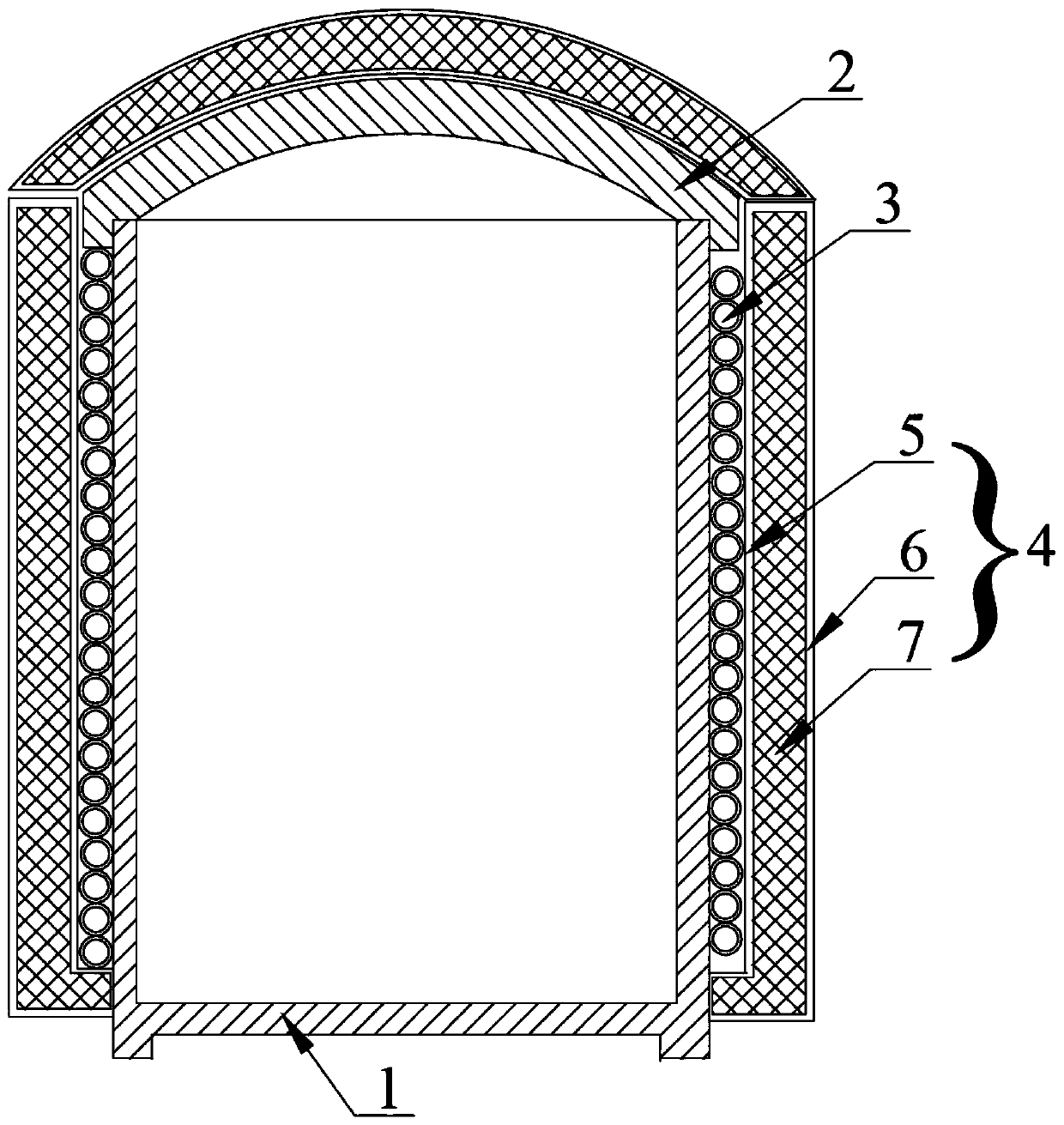

Heat-insulated aluminum alloy door and window

ActiveCN110485871AReduce heating rateAvoid heat exchangeRadiation protectionClimate change adaptationMaterials scienceAluminium alloy

The embodiment of the invention provides a heat-insulated aluminum alloy door and window. The heat-insulated aluminum alloy door and window comprises a window frame, a first window body, a second window body and a third window body, wherein the first window body, the second window body and the third window body are installed in a window body, the first window body is in an arc shape, the second window body is further in an arc shape, the sinking direction of the second window body is the same as the sinking direction of the first window body, the first window body sinks facing the second window body, a vacuum thermal insulating layer is formed between the second window body and the first window body, and an accommodating cavity is formed between the third window body and the second windowbody. According to the heat-insulated aluminum alloy door and window, the arc-shaped first window body and the second window body are used, rays of light can be dispersed, so that energy taken indoorsby sun illumination is reduced, speed of indoor warming is further slowed down, the vacuum thermal insulating layer formed between the first window body and the second window body can well prevent indoor and outdoor heat exchange, the accommodating cavity between the second window body and the third window body can accommodate liquid to cool indoors, and thus the effect of heat insulation is achieved.

Owner:SHENZHEN SIKANG SCI & TECH

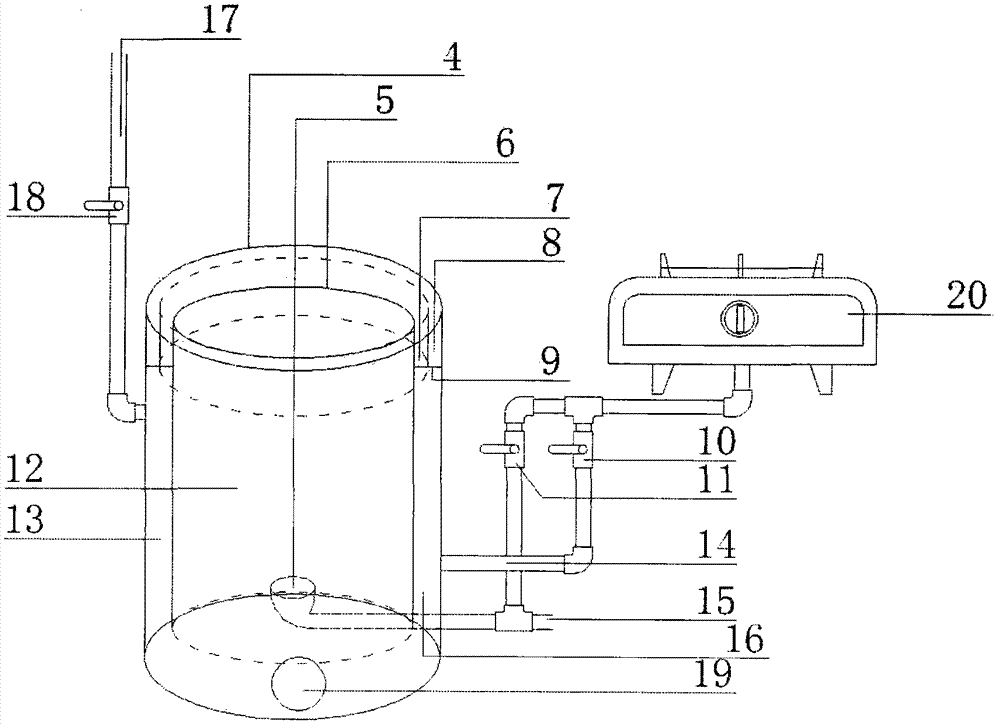

Straw gasification furnace

InactiveCN102901128AReduce carbon black productionIncrease productionDomestic stoves or rangesLighting and heating apparatusTarCoal tar

A double-liner and double-filtration design scheme of a straw gasification furnace is designed in the invention. The straw gasification furnace comprises a furnace inner liner, a furnace lid, an output tube, a gas discharge tube and a cooking stove, wherein a space between the furnace lid and the body of the furnace is sealed, the cooking stove is communicated with the inner liner, a furnace outer liner communicated with the gas discharge tube is arranged outside the furnace inner liner, the furnace inner liner forms a fuel chamber, a circulation chamber is formed between the furnace inner liner and the furnace outer liner, the furnace outer liner is communicated with the output tube and the gas discharge tube, and the connection of the furnace outer liner and the furnace inner liner is provided with crushed straws or a straw furnace ash layer. A heat insulation effect can be reached in the fuel combustion process, and a gas generated in the combustion can circulate in the two liners in a high temperature manner to make a tar high-temperature dissolving process return to the furnace bottom and the tar combine with the combusted furnace ash, so the furnace ash is diluted, there is no dust pollution in ash discharge, and simultaneously the discharged furnace ash can be reused, thereby a tar filtration effect is reached, and a recycle environment protection effect is also reached.

Owner:黄炉孝

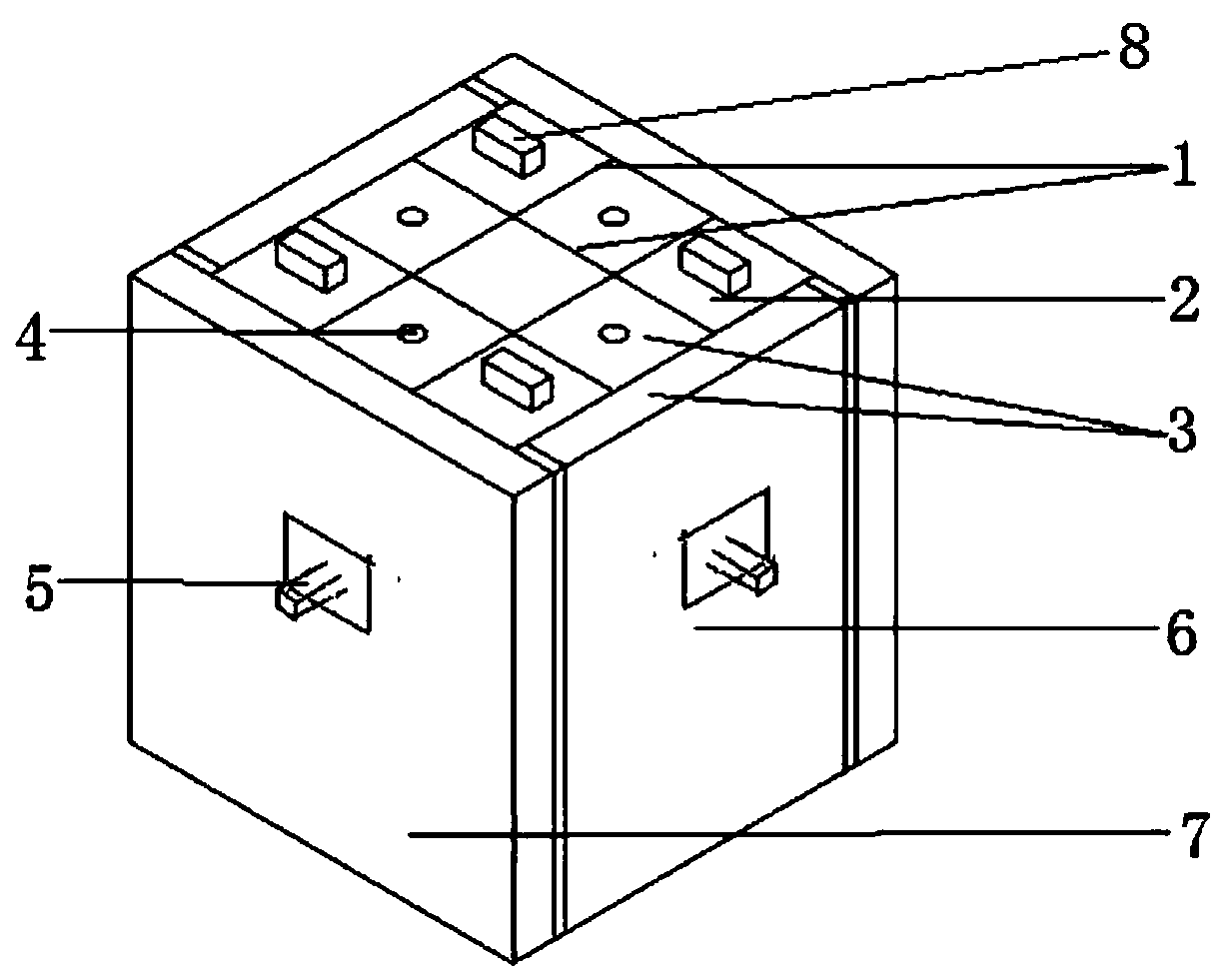

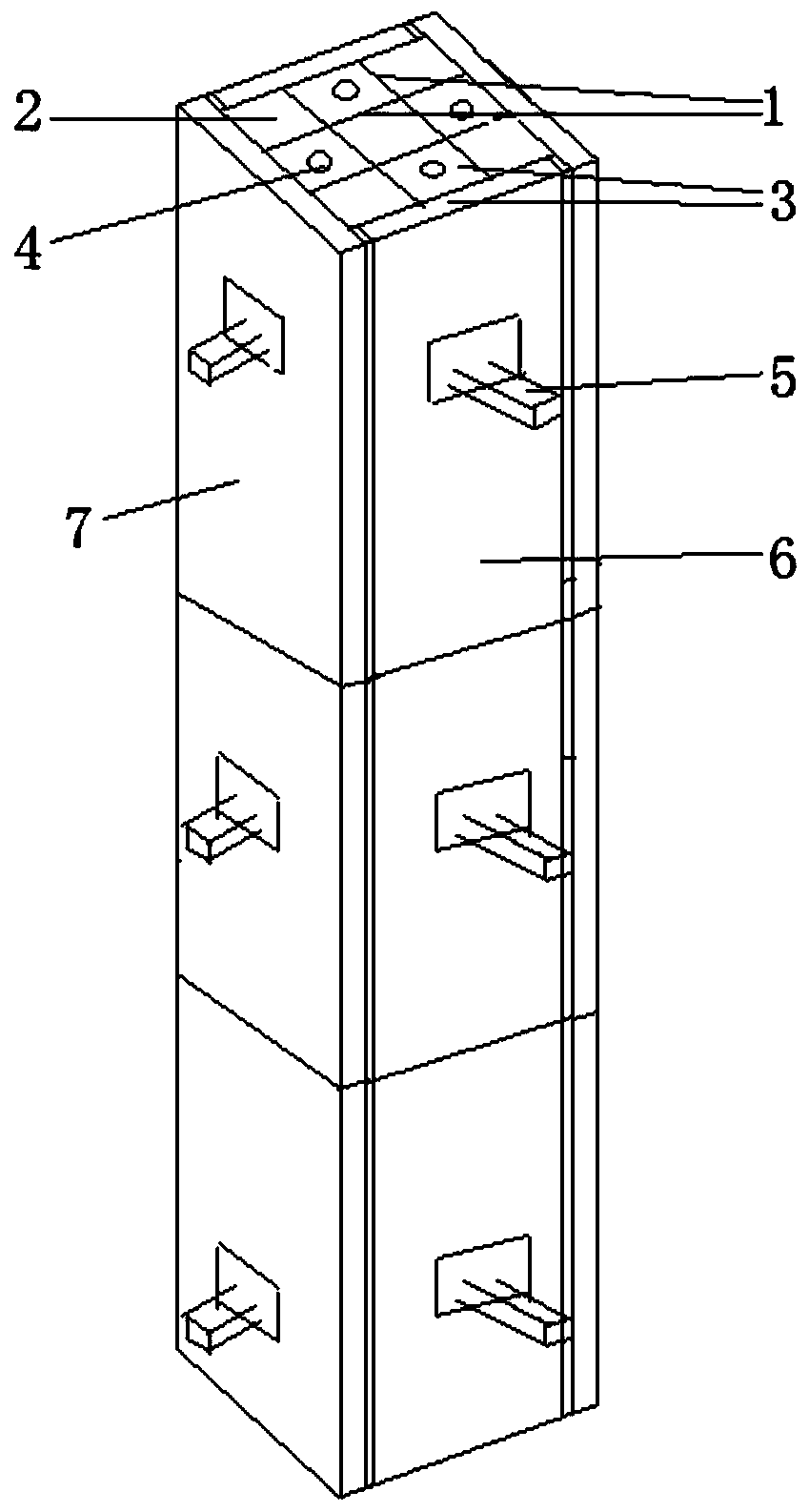

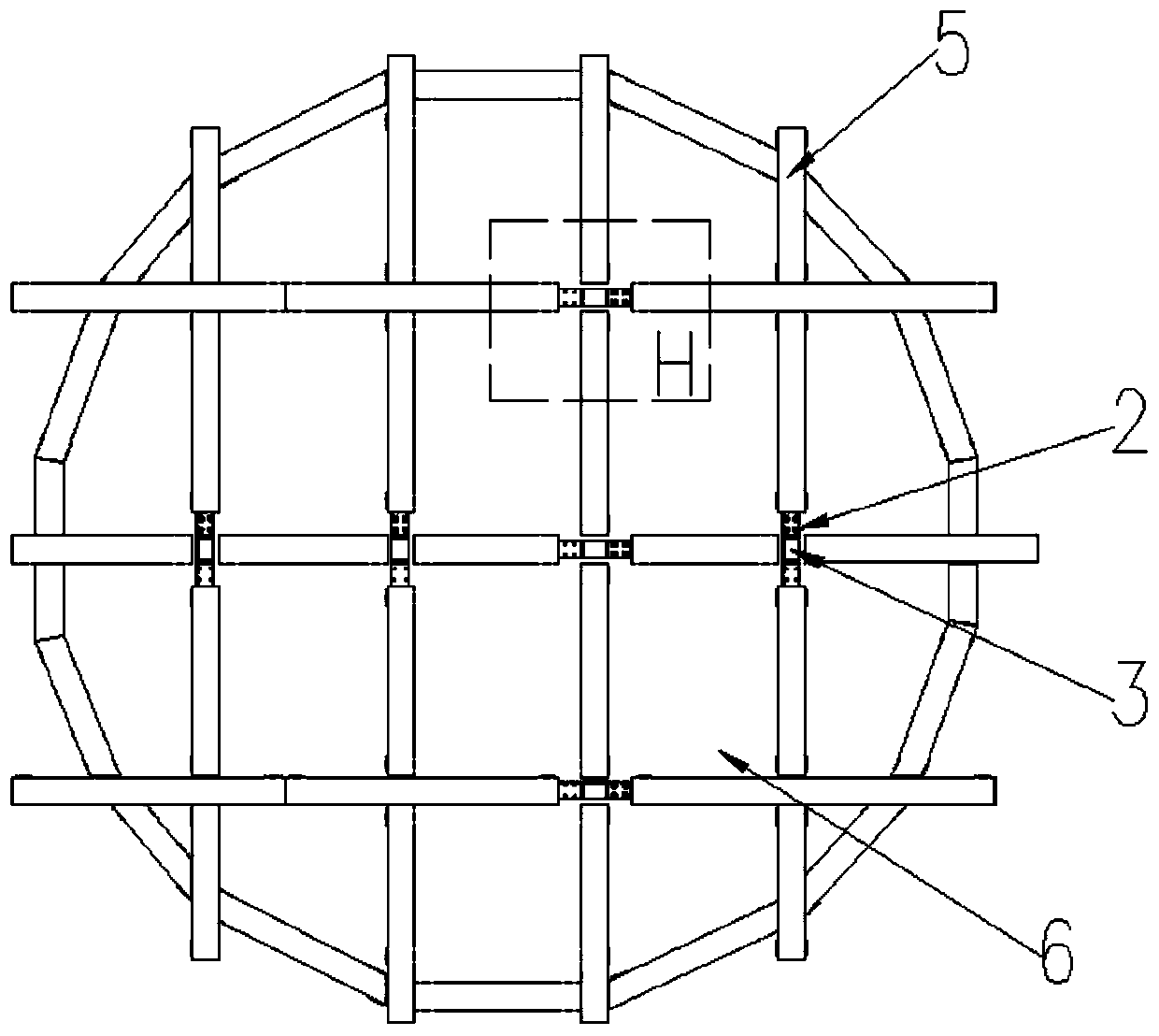

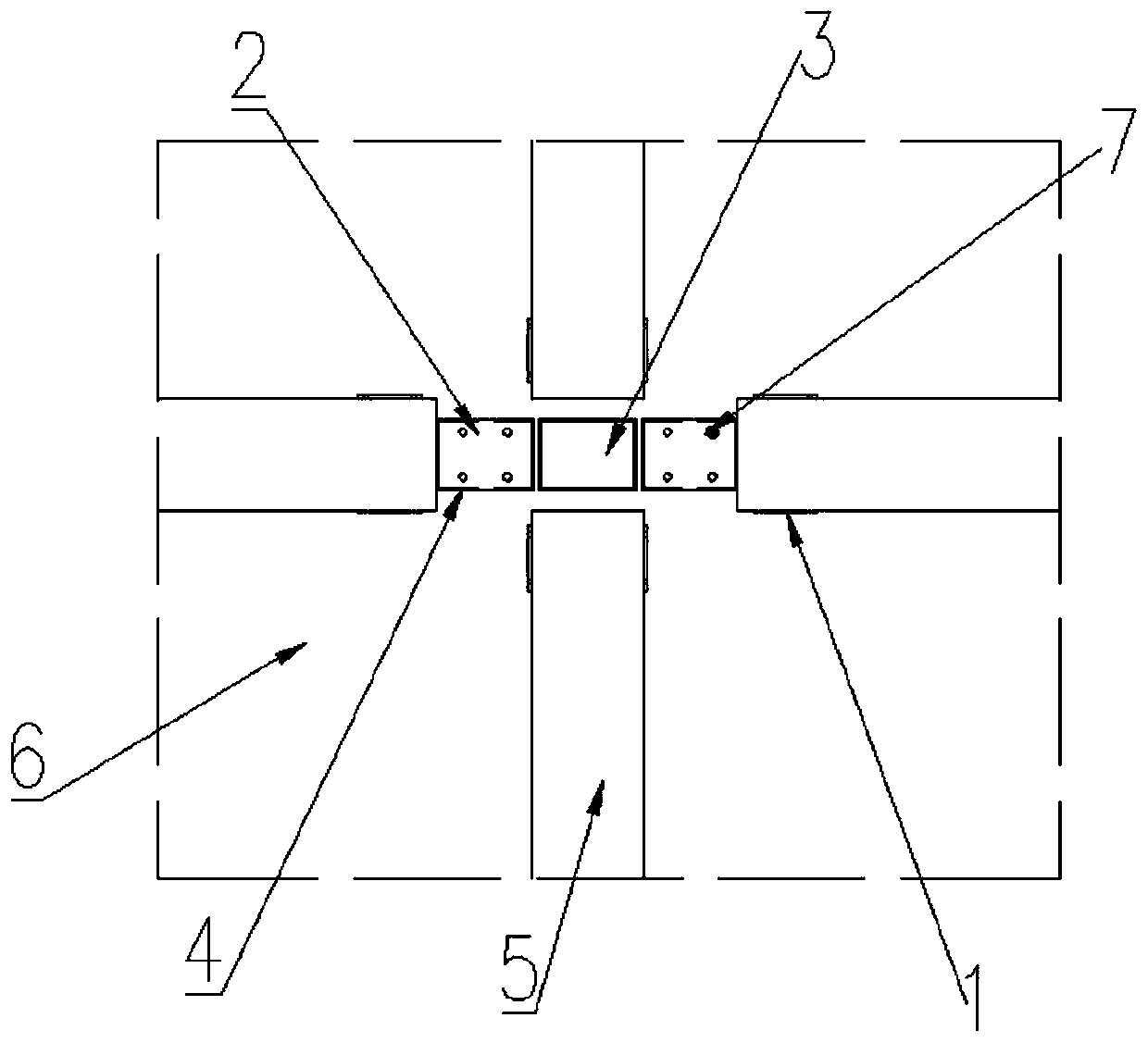

Plant fiber concrete, preparation method and plant fiber concrete column

InactiveCN110759685AHigh strengthFiber reinforcement increases strengthStrutsPillarsPlant fibreThermal bridge

According to a plant fiber concrete column, plant fiber concrete is added on the basis of an original column, the dead weight of a wall can be reduced, and the effects of heat preservation and heat insulation can be achieved. Supporting ribs are arranged in an area where the plant fiber concrete is poured and longitudinally penetrate through the whole column structure, the defect that the plant fiber concrete is low in strength is overcome, a center concrete column is welded into a nine-square frame through snowflake plates, and the bearing capacity of the concrete column is improved. And theplant fiber concrete plate is arranged outside the central concrete column, so that not only can the cold bridge phenomenon be avoided, but also the thermal bridge phenomenon can be effectively prevented, and the thermal insulation effect is more remarkable. A protrusion and a groove are formed in the top and the bottom of the center concrete column respectively so as to assemble the adjacent plant fiber concrete columns, and four concrete slabs are spliced end to end, fixed through magnets and then connected through bolts for secondary fixing. The structure is convenient to disassemble, a large amount of manpower is saved, and the disassembled concrete slabs can be reutilized.

Owner:沈阳众磊道桥有限公司

Cargo tank on orange juice cargo ship

InactiveCN110723427ATo achieve the purpose of cooling and regulating temperatureSimple structureSynthetic resin layered productsLarge containersPreservativeCargo vessel

The invention discloses a cargo tank on an orange juice cargo ship. The cargo tank comprises a tank body and a tank cover, a pipeline layer is coiled on the outer wall of the tank body, a vacuum heatinsulation layer wraps the outer portion of the pipeline layer and the upper surface of the tank cover, the pipeline layer is spirally and tightly coiled on the outer wall of the tank body through a copper pipe or aluminum pipe, one end or two ends of the copper pipe or aluminum pipe are connected with one end of a medium circulation pump, and the other end of the medium circulation pump is connected with a medium storage tank. The cargo tank on the orange juice cargo ship has the advantages of being simple in structure, rapid and convenient to machine and manufacture, low in cost, low in energy consumption, high in efficiency, long in time, capable of achieving fresh orange juice freshness retaining under the condition of being free of adding of corrosion remover and the like.

Owner:CHENGXI SHIPYARD

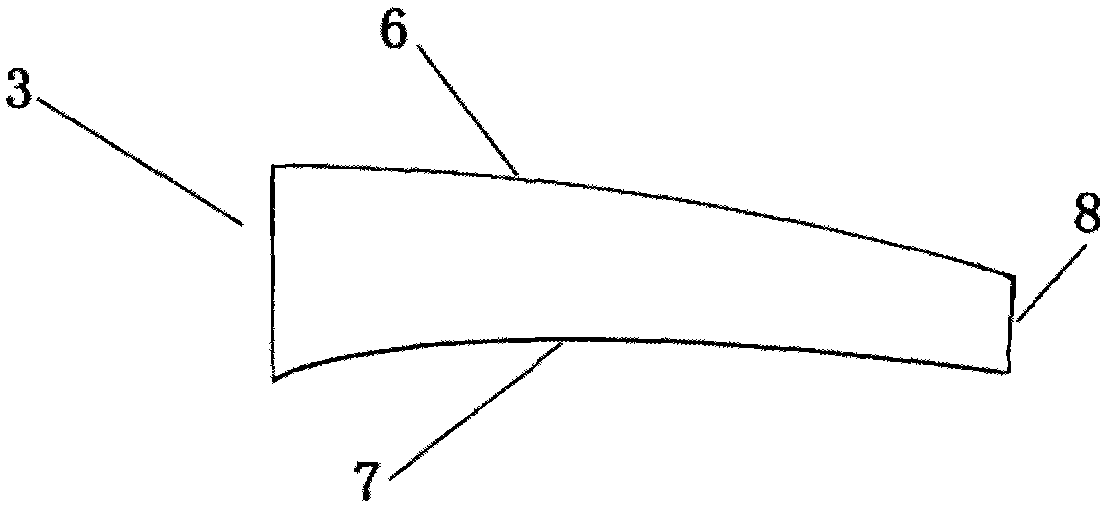

Energy-saving glass

InactiveCN103524056AAvoid elevationTo achieve thermal insulation effectDoors/windowsConvex sideEngineering

The invention belongs to the technical field of materials for buildings, and ships and vehicles, and relates to energy-saving glass. The energy-saving glass is composed of inner glass and outer glass, wherein the peripheries of the inner glass and the outer glass are sealed by sealant through edge banding glass; the inner glass is photochromic glass; a plurality of support ribs are arranged between two layers of glass in parallel; the inner and outer ends of each support rib are respectively connected and fixed together with the inner glass and the outer glass; vent holes are formed in the vertical section of each support rib; an exhaust hole is formed in the glass or the edge banding glass; each support rib is a wedge which is low in outer part and high in inner part; the upper surface is a convex surface; the lower surface is a concave surface; the convex surface and the concave surface are mirror surfaces. The energy-saving glass disclosed by the invention is formed by the inner glass and the outer glass; the convex surface and the concave surface, and the outer end face of each support rib are plated into the mirror surfaces; a ray can be scattered and reflected; sunshine is prevented from entering inside a room so as to avoid the rising of indoor temperature in summer; the inner glass adopts the photochromic glass; the color becomes dark when the sunshine irradiates; the heat can be absorbed; the energy-saving glass can play an indoor heat preservation effect in winter; an energy source also can be saved.

Owner:陈海霞

Preparation process of novel water-based nano thermal insulation material

InactiveCN112694282AIncrease heating capacityFunction increaseSolid waste managementFiberThermal insulation

The invention discloses a preparation process of a novel water-based nano thermal insulation material. The preparation method comprises the steps of firstly, preparing the following raw materials: a porous water-based nano silicon dioxide suspension, nano titanium dioxide, modified attapulgite, a wetting agent, modified fly ash, a thickening agent, modified montmorillonite, inorganic fibers, modified expanded perlite, a flame retardant, a defoaming agent, vitrified micro bubbles, an ethylene-vinyl acetate copolymer and deionized water; then preparing a mixture A; then preparing a mixture B; and finally, stirring the porous water-based nano silicon dioxide suspension, the mixture A, the mixture B, the wetting agent, the thickening agent, the defoaming agent and the flame retardant, and fully stirring and mixing to obtain the required novel water-based nano thermal insulation material. The product disclosed by the invention has excellent thermal insulation performance, and particularly, the modified attapulgite and the modified montmorillonite are added, and the thermal insulation effect can be further improved through synergistic interaction of the two components.

Owner:深圳恒固纳米科技有限公司

Insulation and anti-frostbite swelling phase change insulation board for canal subsoil in salty and cold regions

ActiveCN111719509AGood solid-liquid phase transition periodicityGood active insulation effectArtificial water canalsSoil scienceSalt solution

The invention discloses an insulation and anti-frostbite swelling phase change insulation board for canal subsoil in salty and cold regions and an insulation, seepage-proofing and anti-frostbite swelling method of the insulation and anti-frostbite swelling phase change insulation board. The insulation and anti-frostbite swelling phase change insulation board comprises a phase change insulation seepage-proofing board, non-return capillary pipes and a concrete board, wherein the phase change insulation seepage-proofing board communicates with the non-return capillary pipes, the concrete board isarranged on the phase change insulation seepage-proofing board, the phase change insulation seepage-proofing board is provided with a plurality of lattices, the four side walls of the lattices are provided with communication holes, the four edges of the phase change insulation seepage-proofing board are provided with long baffles, and prepared salt solutions are injected into the phase change insulation seepage-proofing board from a solution injection port and flow among the lattices through the communication holes, so that a phase change layer is formed. The non-return capillary pipes are inserted into one end of the soil to absorb redundant pore water in the soil to fill the phase change layer. The phase change layer can store and release heat well under the diurnal variation of temperature and solar radiation and maintain the right temperature of the soil. Local agricultural abandoned plastics are remolded as materials, the insulation and anti-frostbite swelling phase change insulation board has flexibility and seepage-proofing functions, and the poor plastic heat-conducting property has good heat insulation effects.

Owner:NORTHWEST A & F UNIV

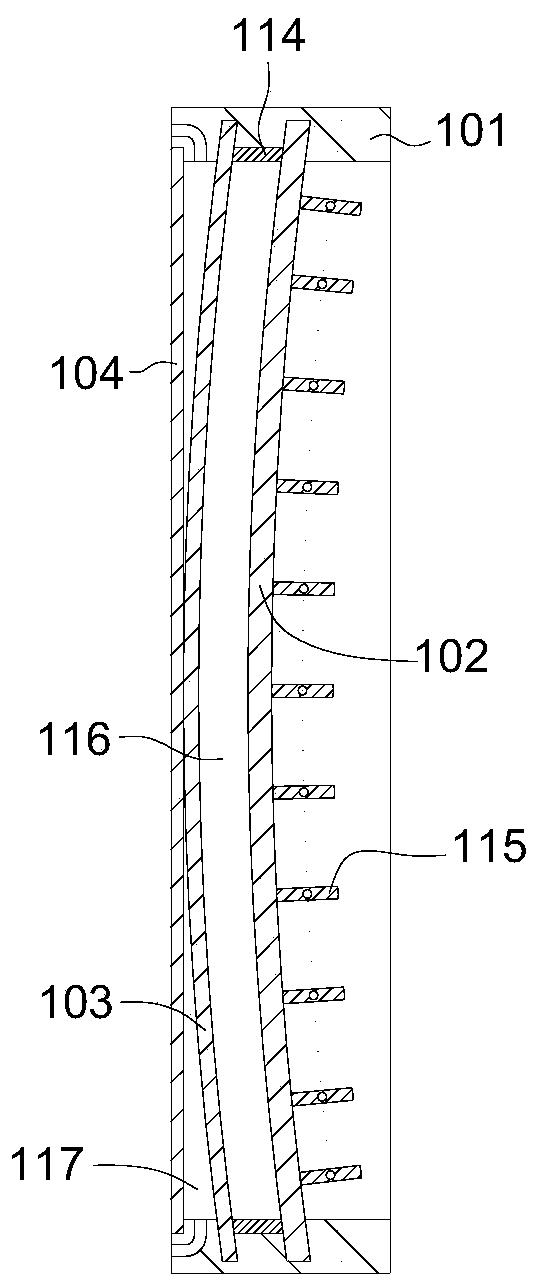

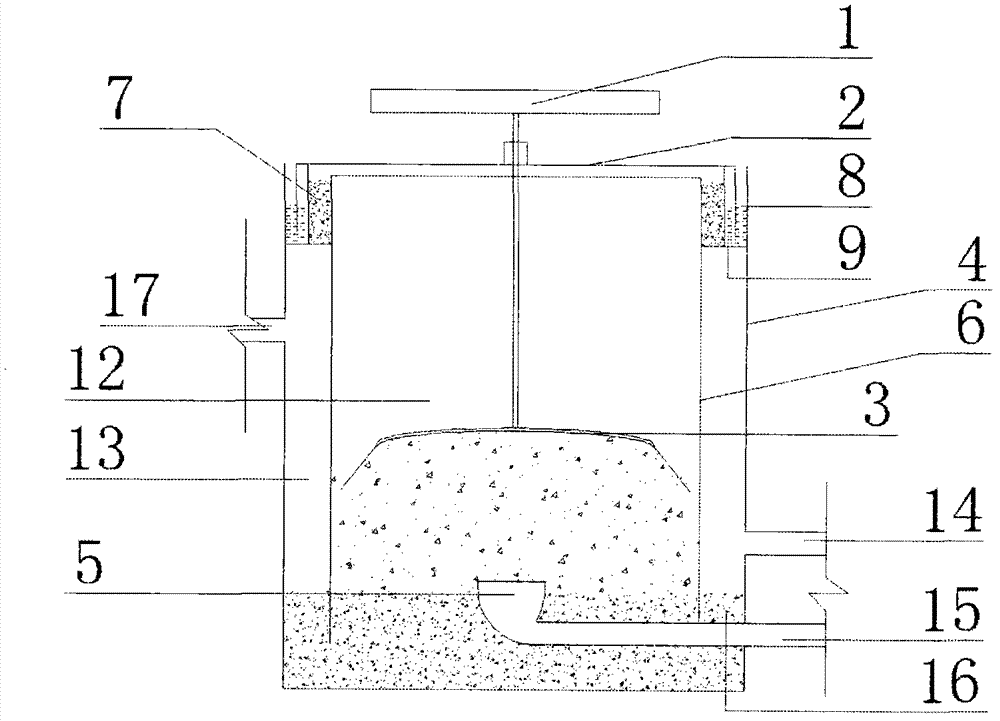

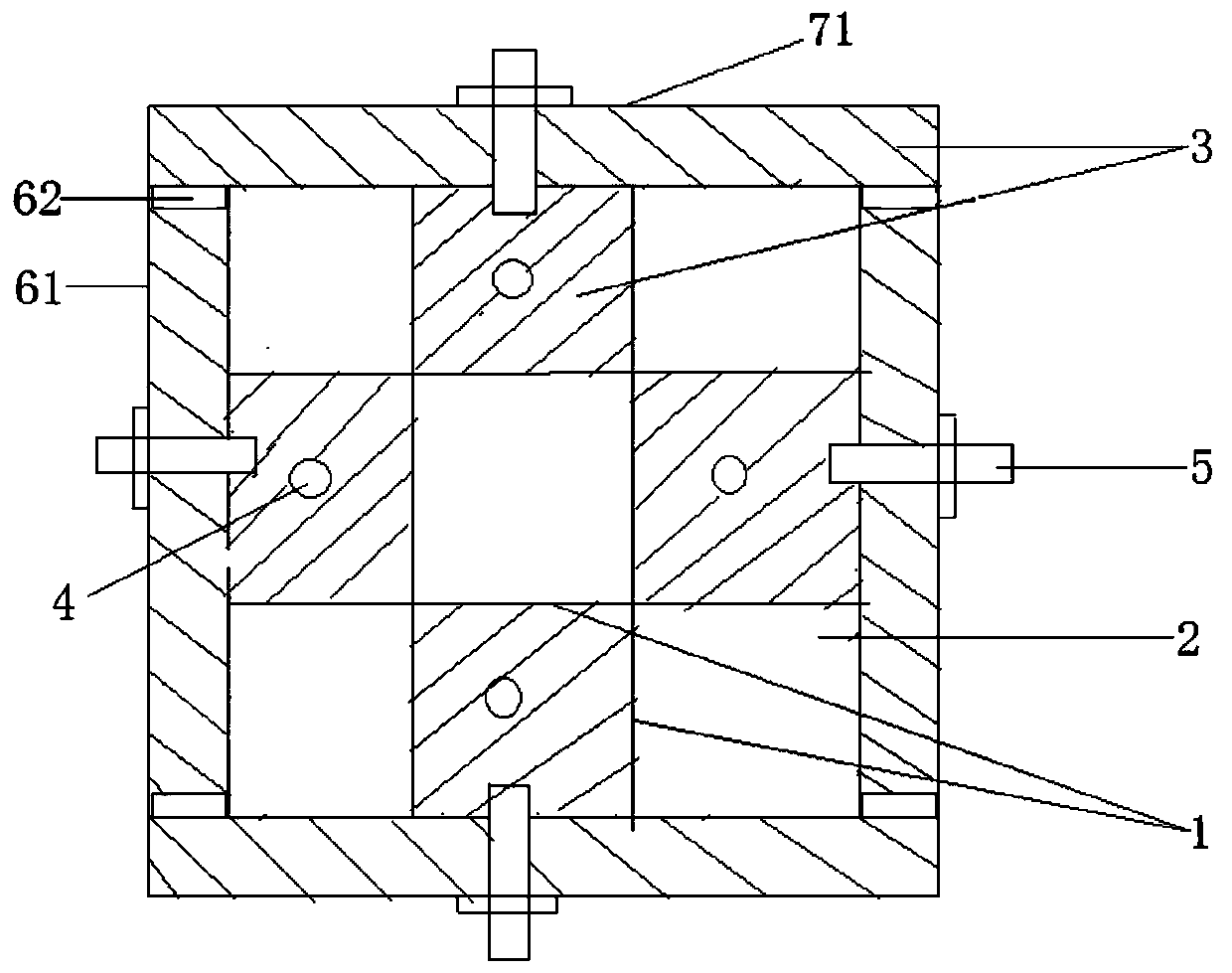

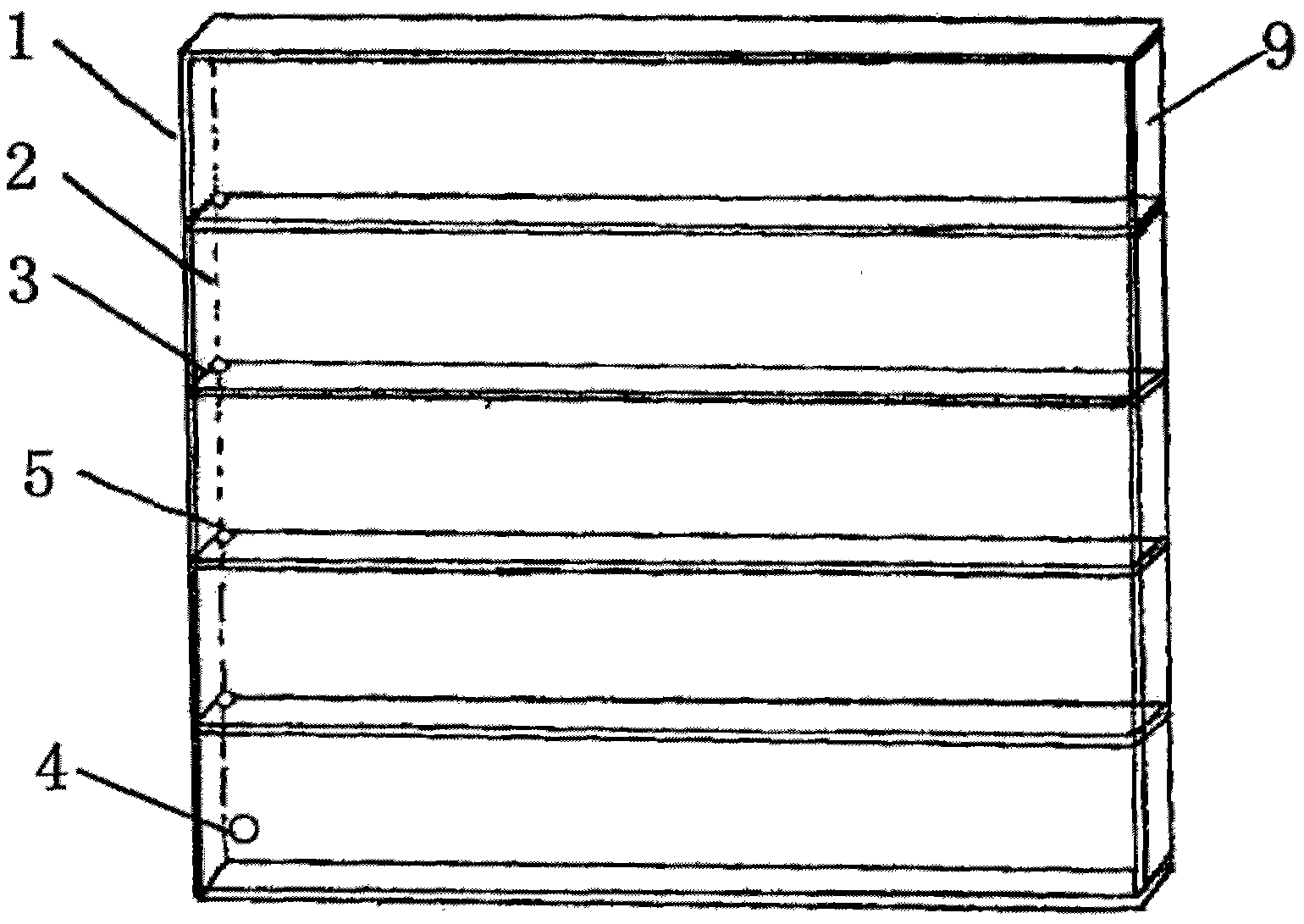

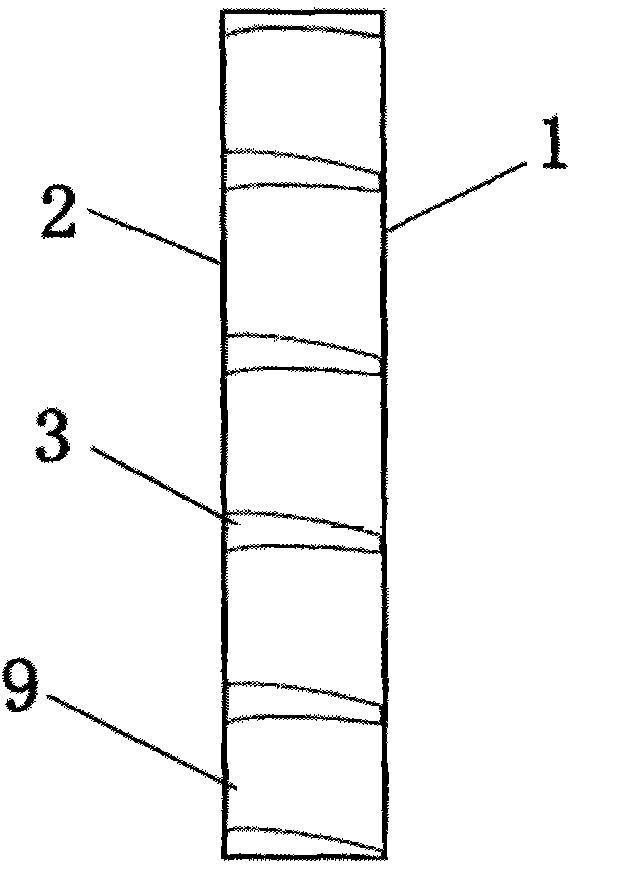

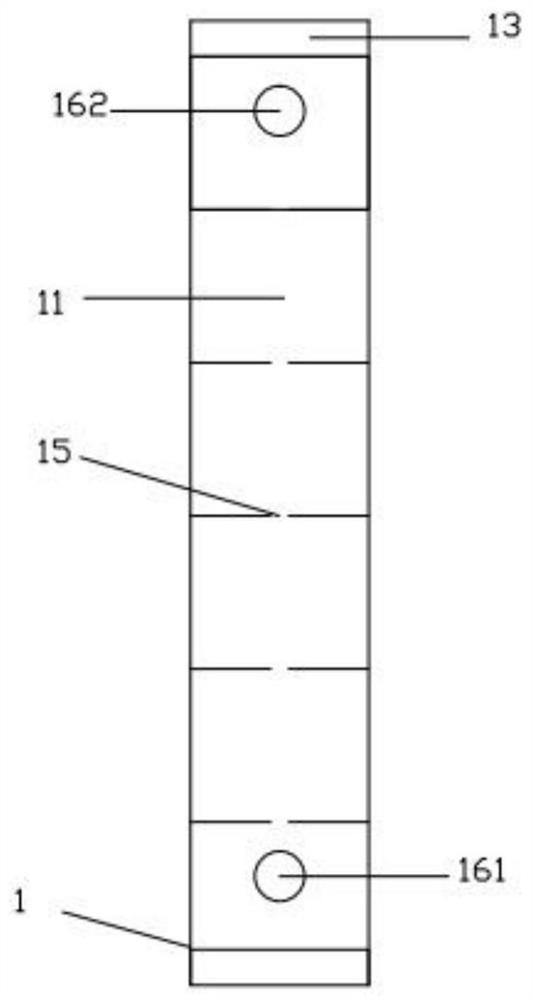

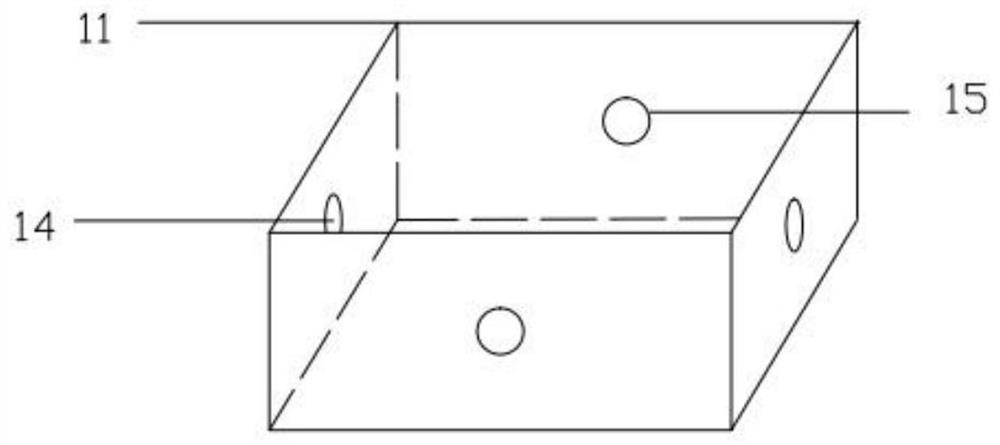

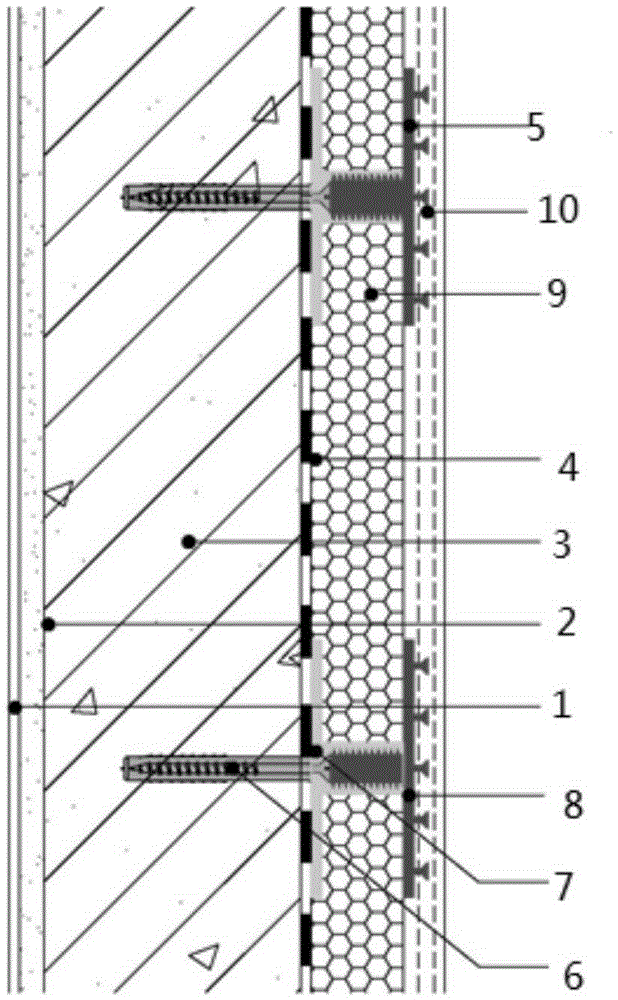

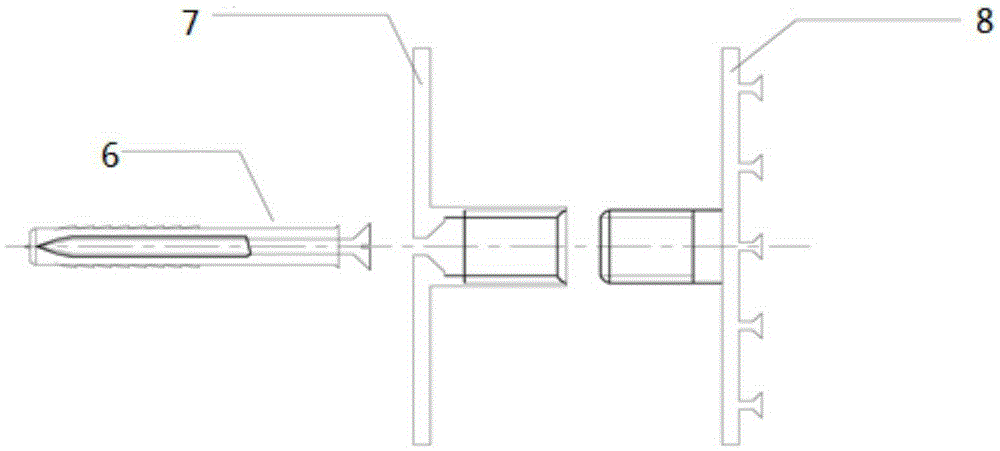

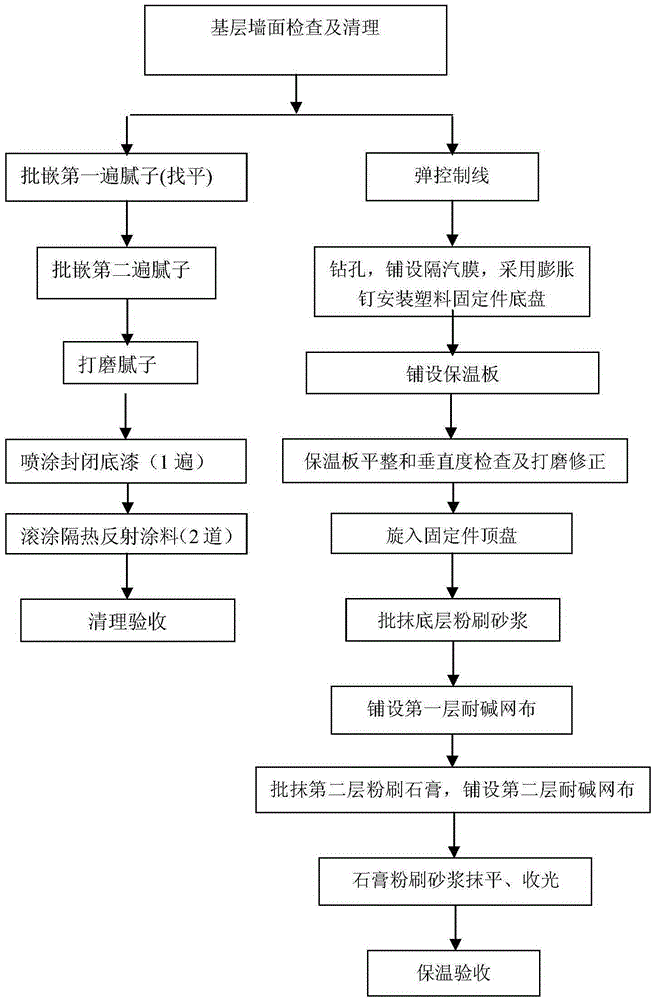

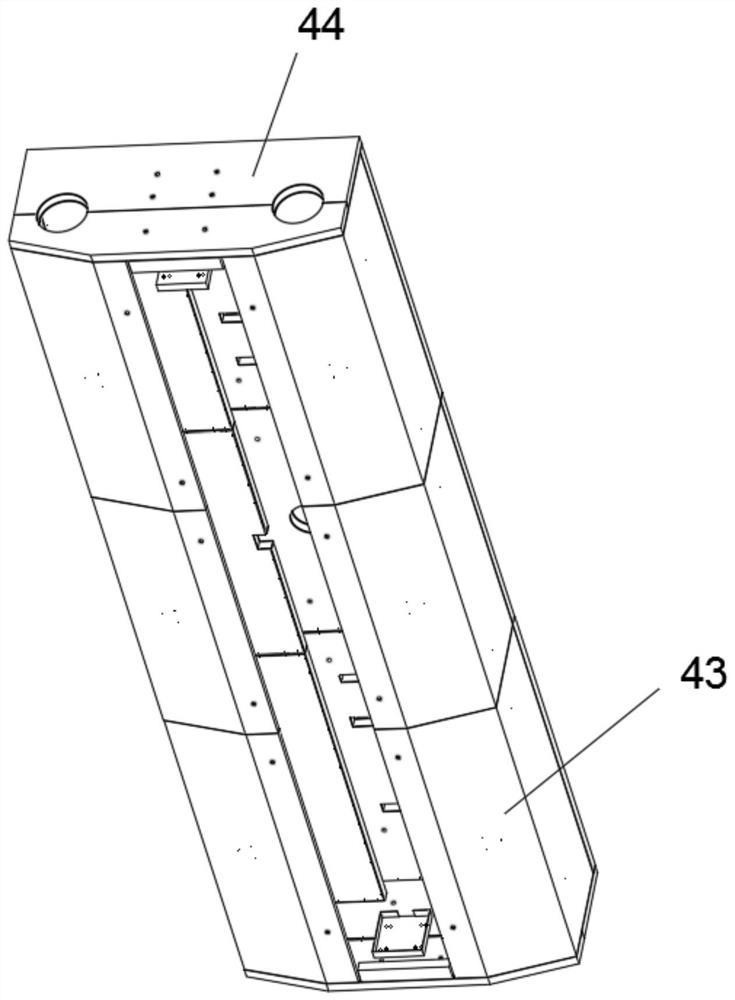

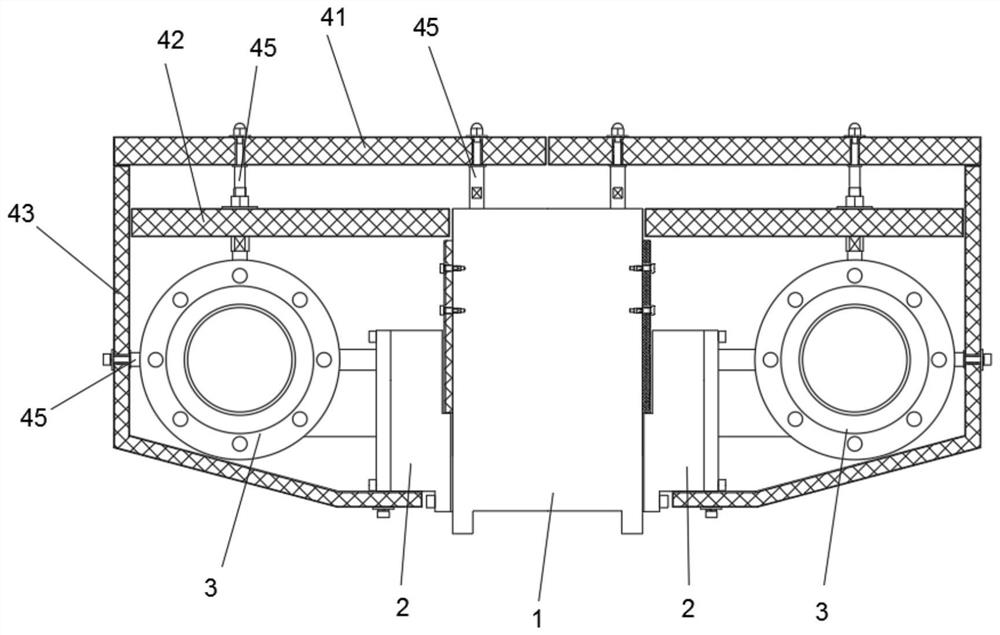

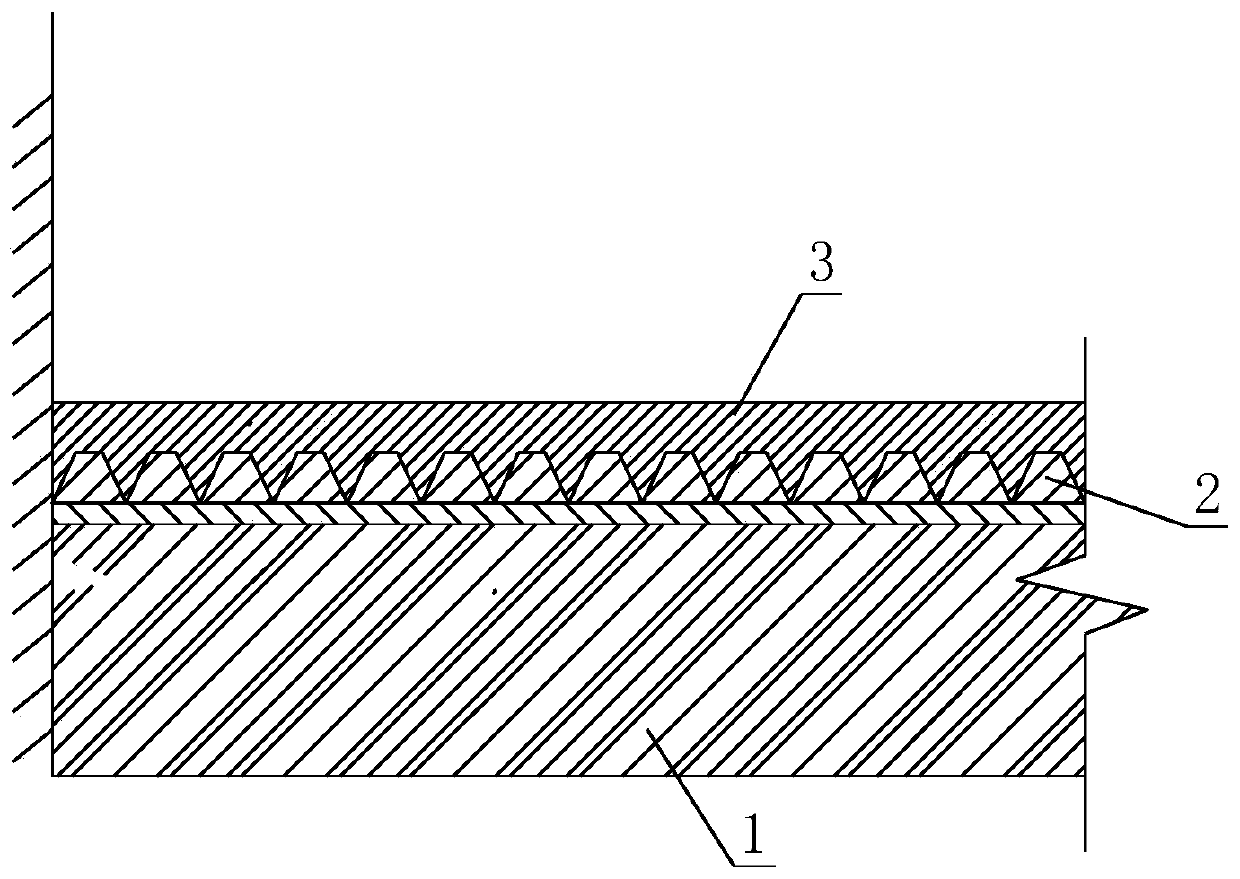

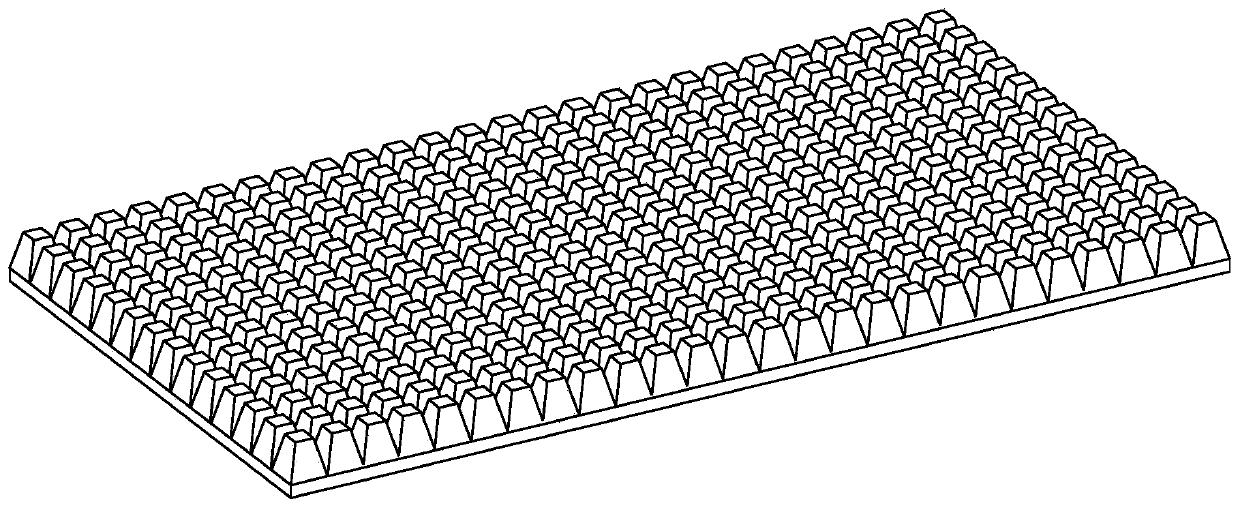

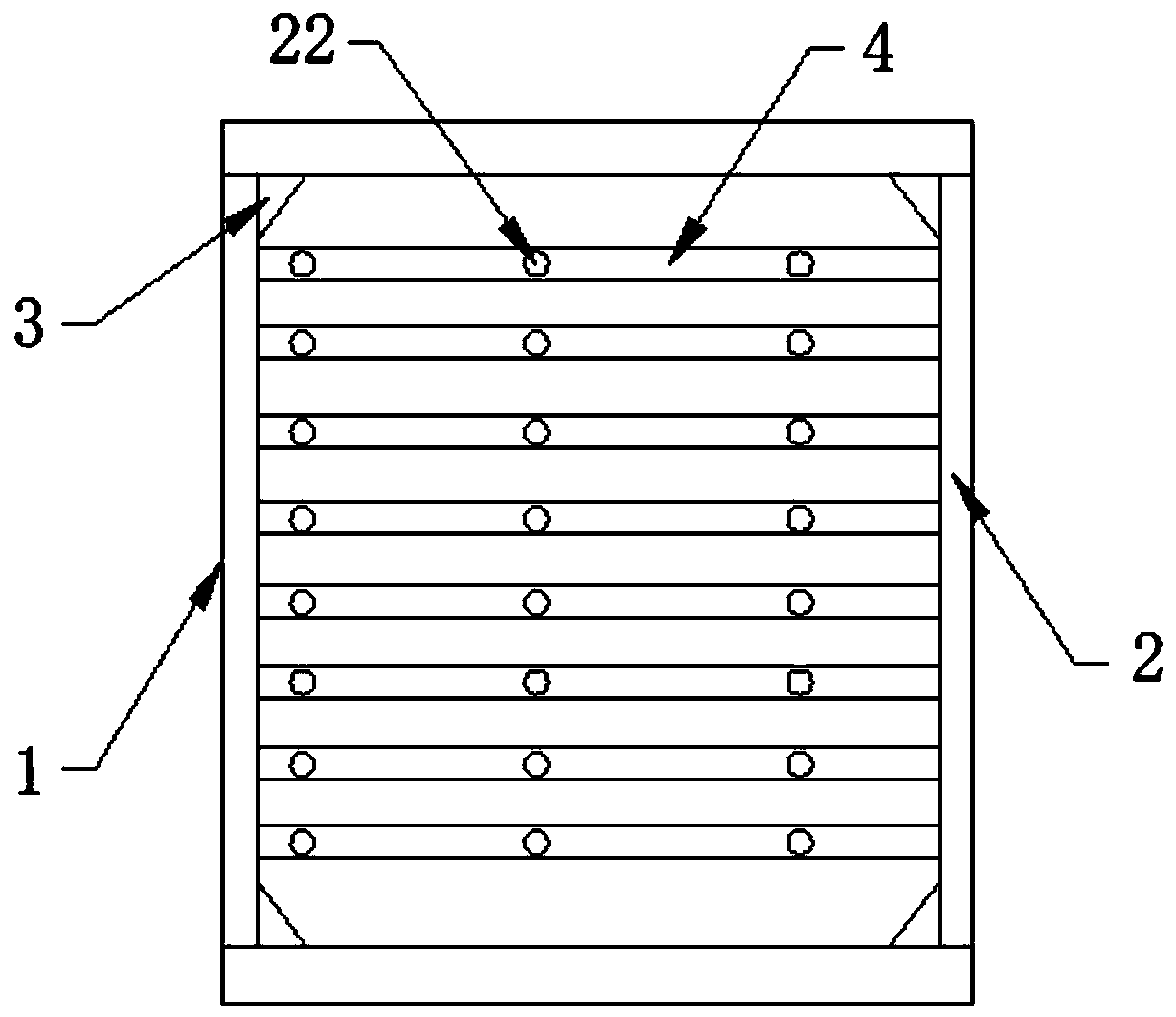

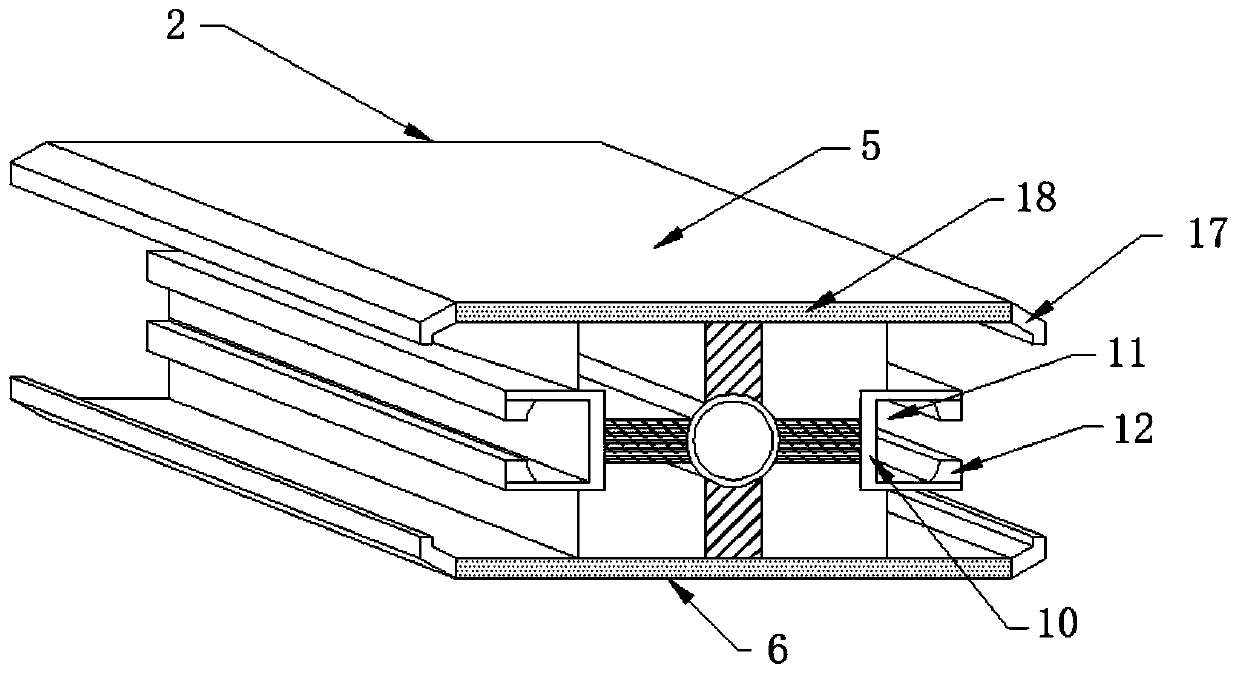

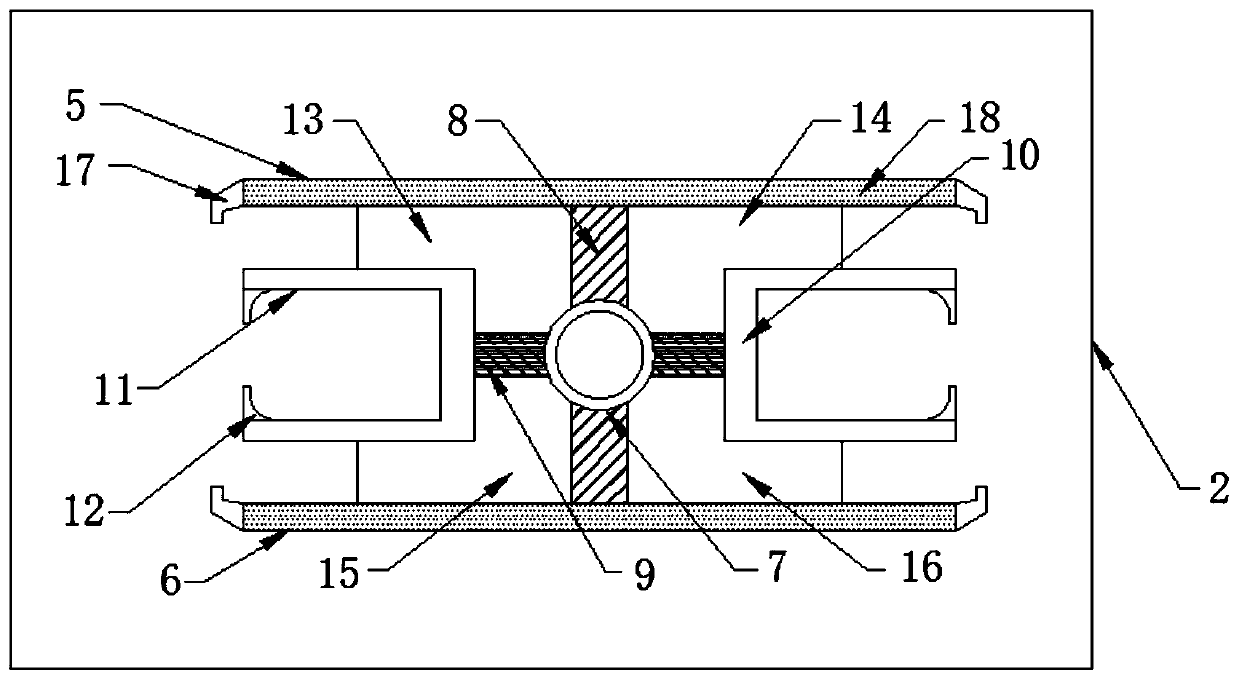

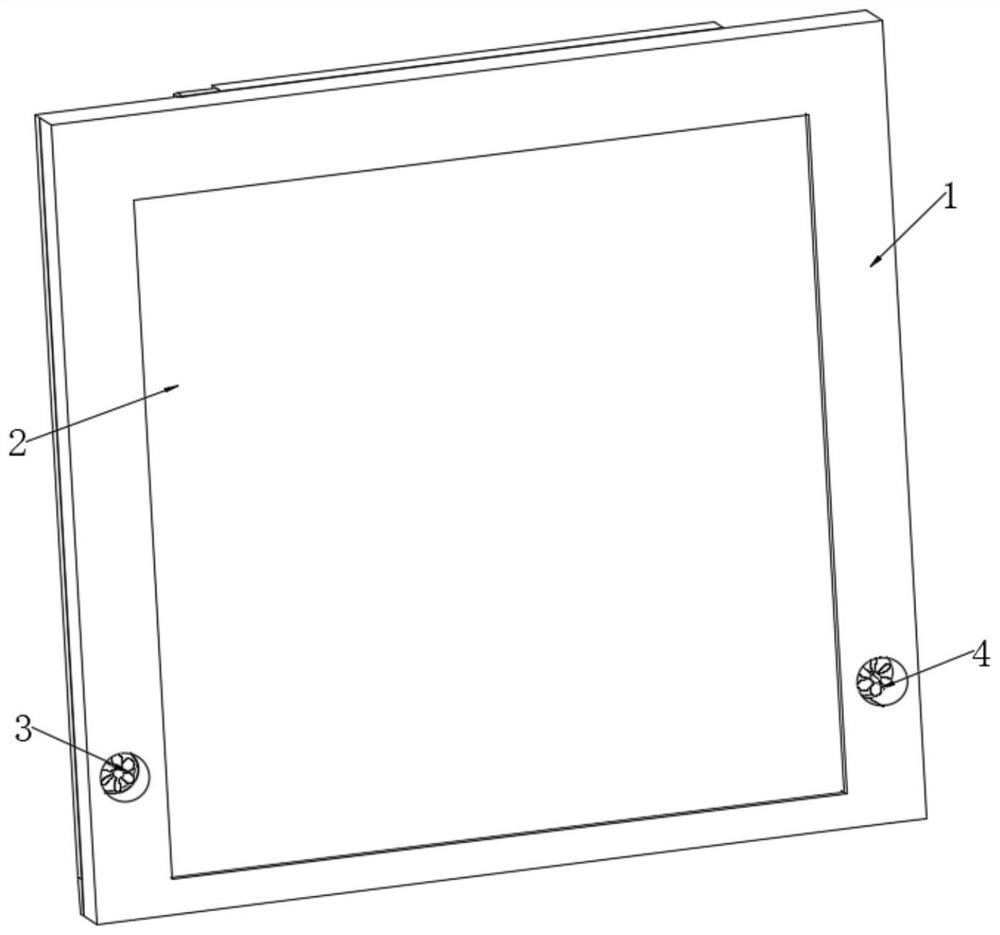

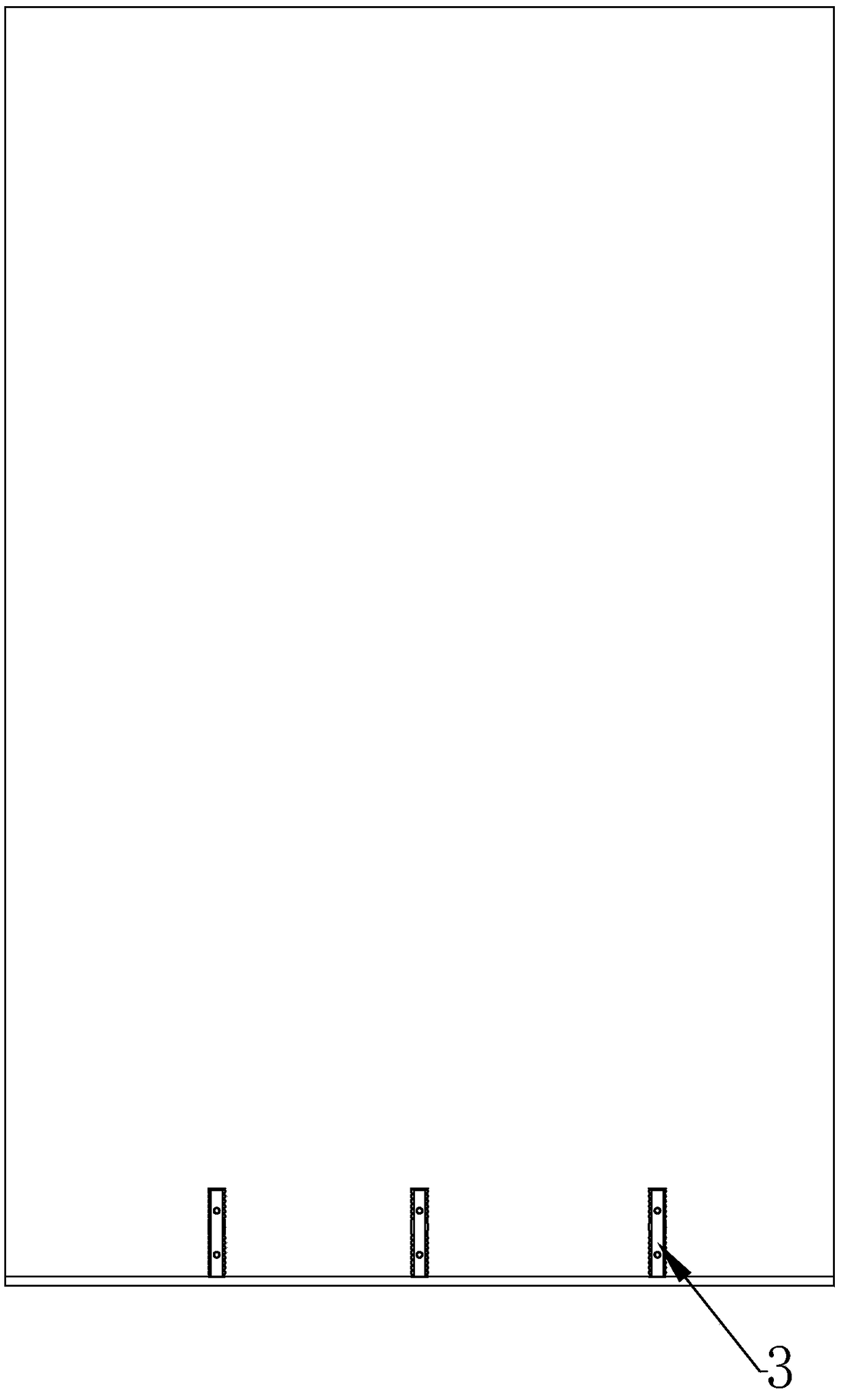

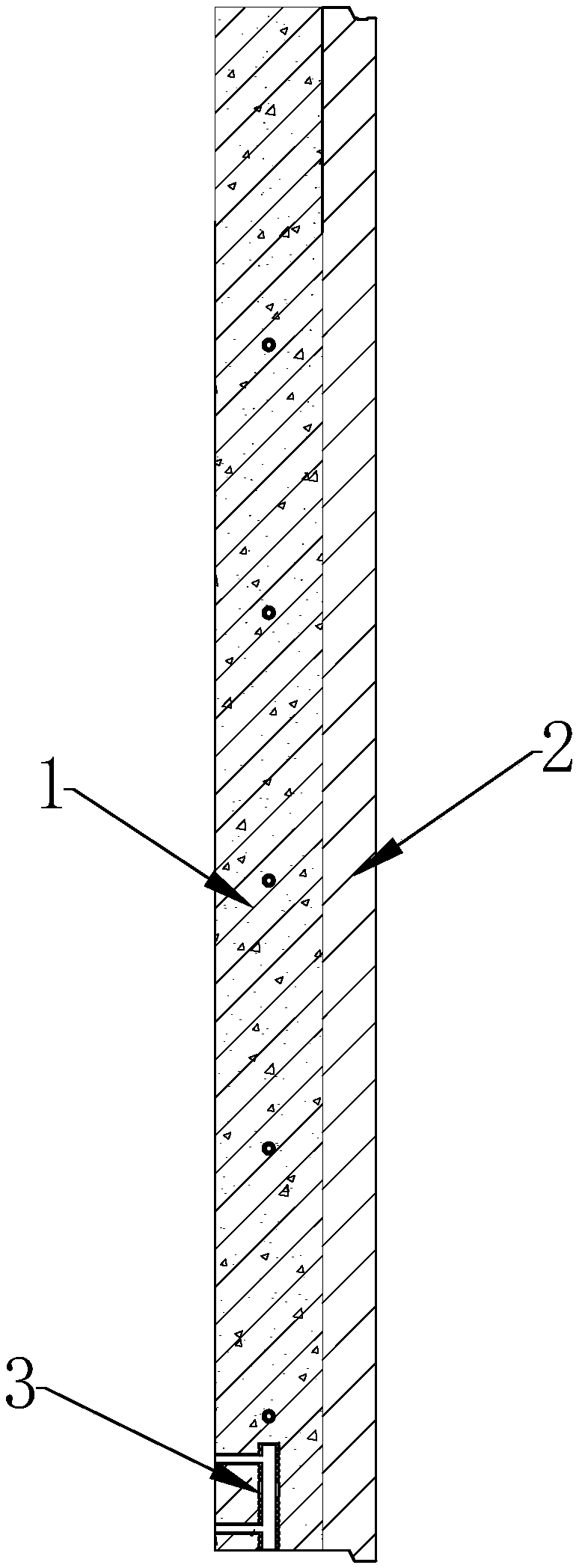

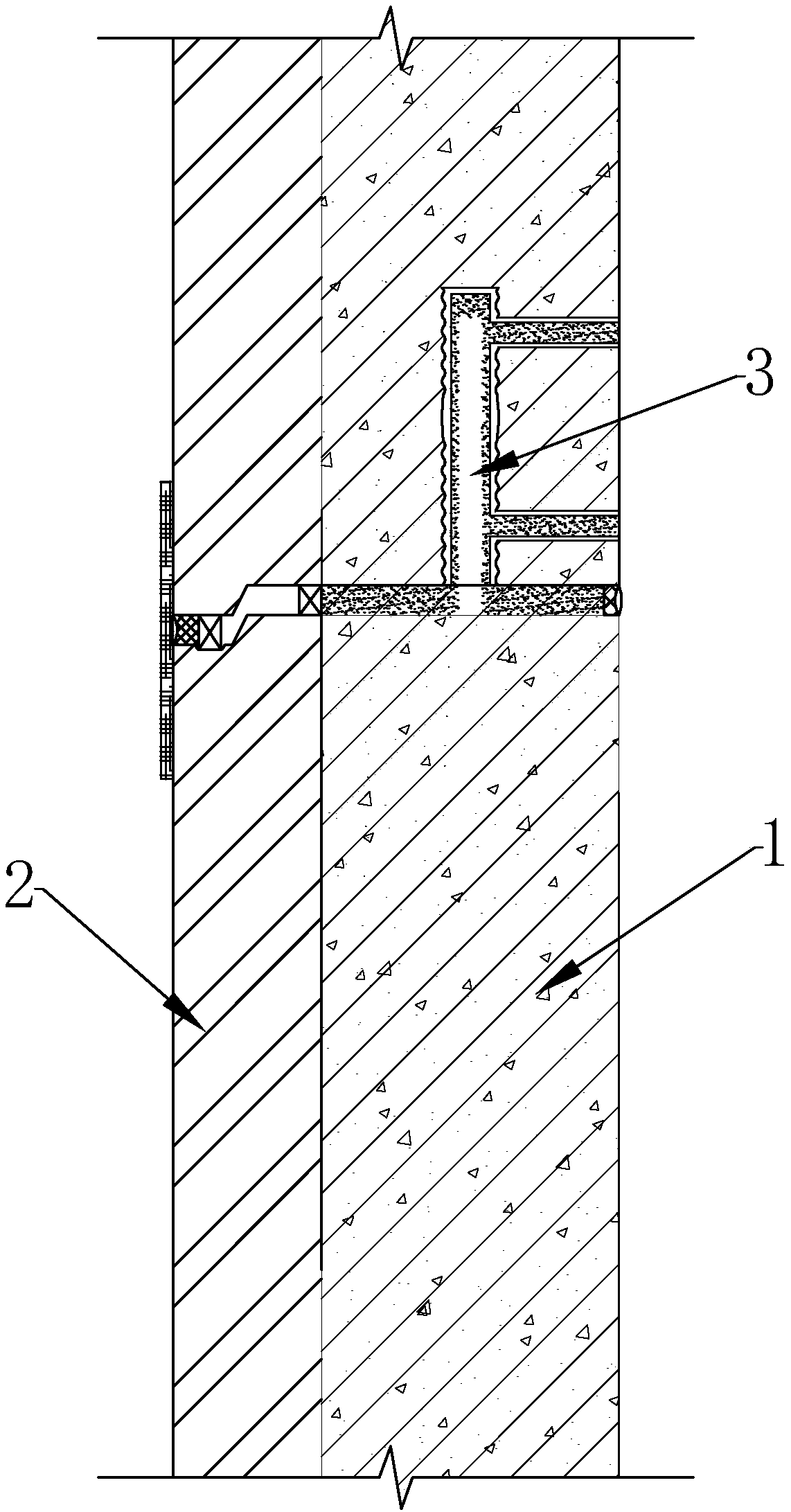

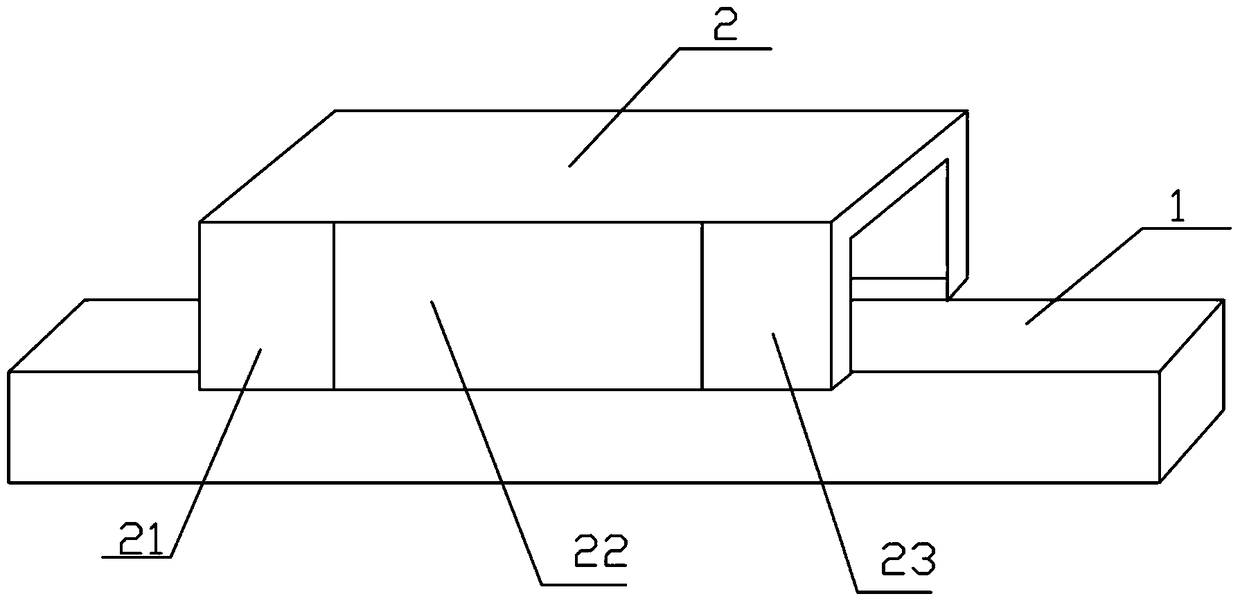

Low-temperature grain depot heat insulation system and construction method thereof

InactiveCN105298195AHigh strengthNo quality riskClimate change adaptationHeat proofingInsulation layerEngineering

The invention provides a low-temperature grain depot heat insulation system and a construction method thereof. The system comprises a bin wall outside heat insulation system, a bin wall (3) and a bin wall inside heat insulation system. The bin wall outside heat insulation system is formed by forming a plastering layer (2) on the outer side of the bin wall (3) and coating a heat reflection coating facing layer (1) on the outer side of the plastering layer (2), the bin wall inside heat insulation system is composed of a steam isolating layer (4), a fixing member (5), a heat insulation layer (9) and a plaster protection layer (10), the steam isolating layer (4) is arranged between the heat insulation layer (9) and the bin wall (3), the fixing member (5) capable of bearing pressure is adopted to fix the heat insulation layer (9) and the steam isolating layer (4) on the bin wall (3), and the plaster protection layer (10) is plastered on the outer side of the heat insulation layer (9). The invention further provides a construction method of the low-temperature grain depot heat insulation system. The low-temperature grain depot heat insulation system has heat insulation effect, has performance of resisting lateral pressure, is longer in service life and can be widely applied to wall heat insulation of a house type bin of a concrete structure or a building body structure.

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

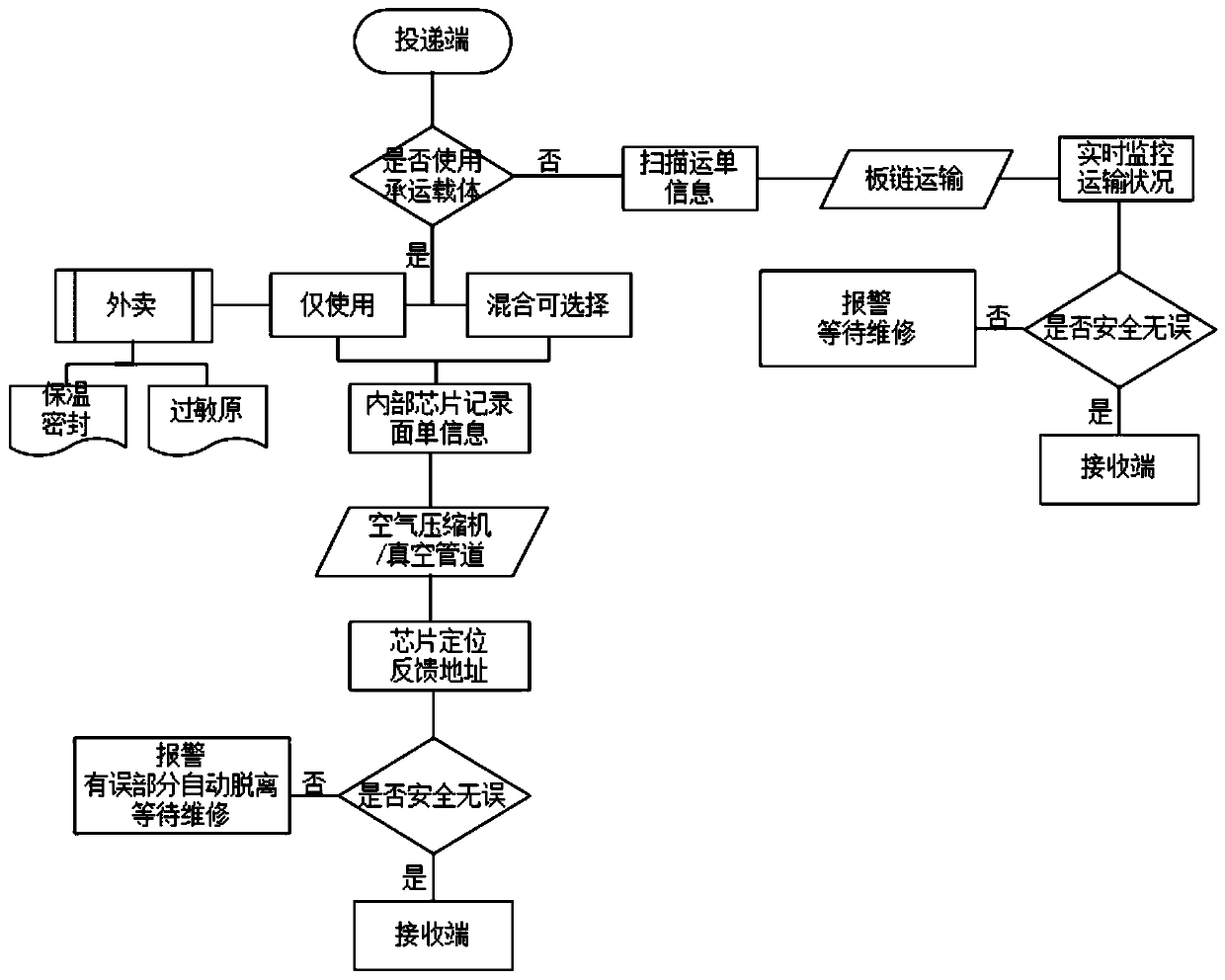

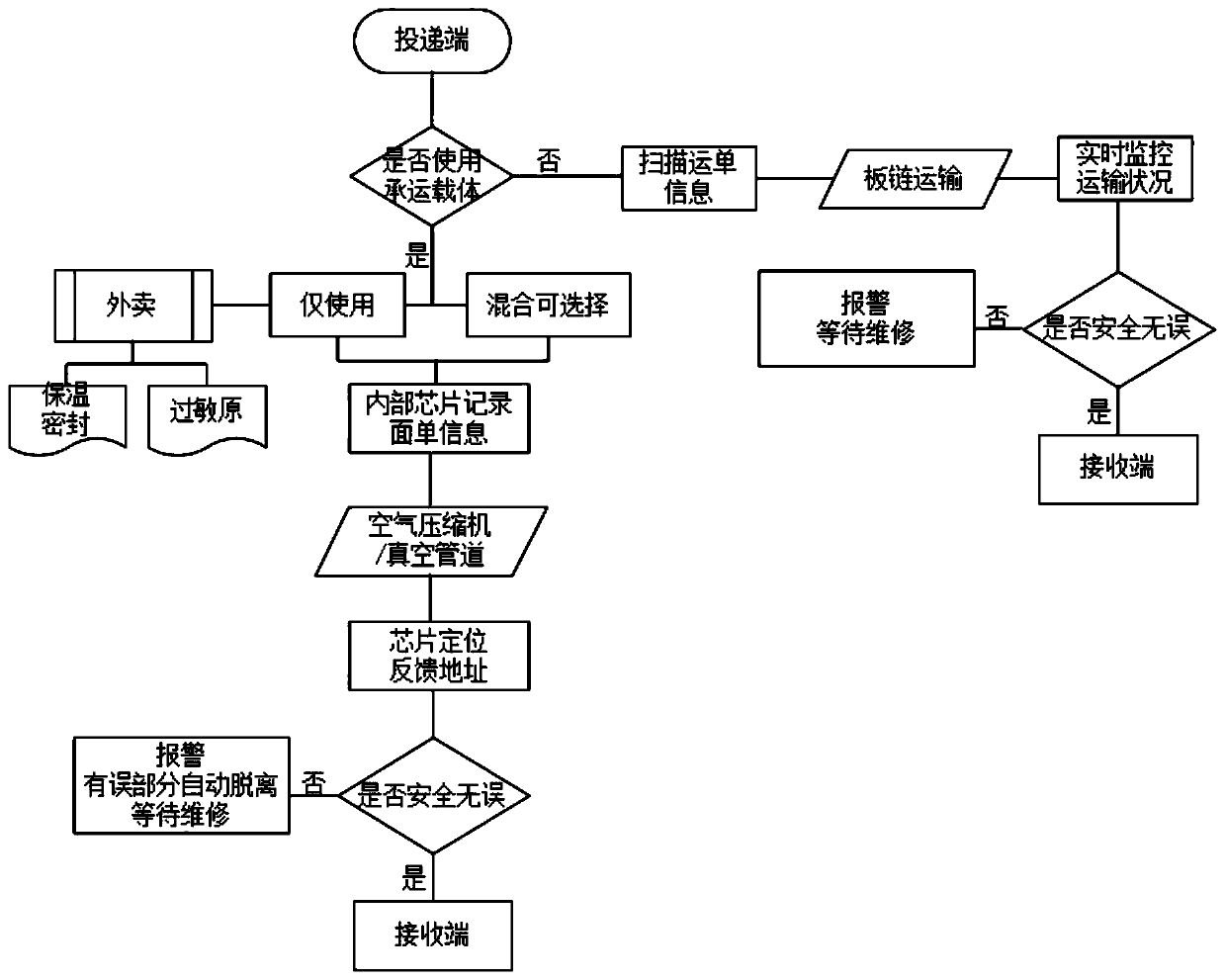

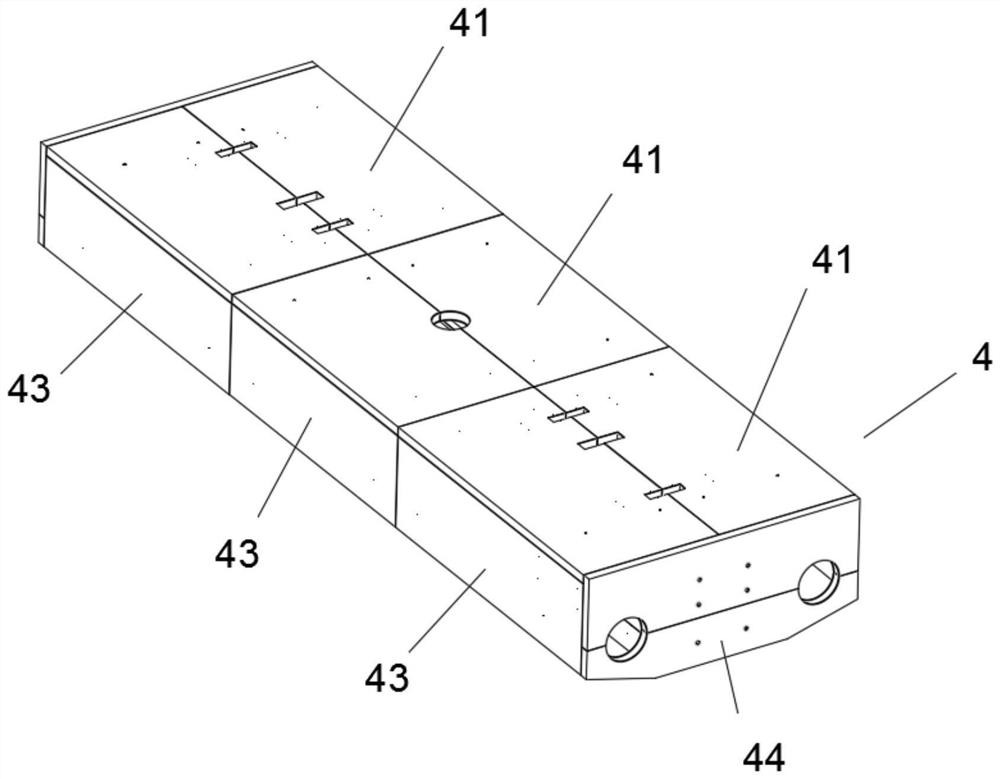

Logistics pipeline system and control method thereof

The invention discloses a logistics pipeline system and a control method thereof. Through pipeline series-parallel connection and both-way conveying, objects arrive at a piece taking port from a delivery port or reverse logistics storage is achieved. In the logistics pipeline system and the control method thereof, selection of different series-parallel connection manners can be decided according to the actual environment and other factors, and high compatibility and optimizing performance are achieved. Multiple flow directions of a pipeline in a conveying unit can be adopted, and larger spacecan be achieved for interaction compatibility of the pipeline, the delivery port and the piece taking port through the multi-flow-direction design. Meanwhile, due to selection diversity of the flow directions in the pipeline, higher operability and variability can be brought.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Heat generation transparent glass powder paint

InactiveCN108329779AImprove mechanical propertiesEvenly distributedPowdery paintsThermal isolationAcrylic resin

The invention relates to powder paint, and discloses heat generation transparent glass powder paint. The heat generation transparent glass powder paint is prepared from the following ingredients in parts by weight: 30 to 40 parts of acrylic resin, 15 to 25 parts of far infrared ceramic powder, 1 to 2 parts of leveling agents and 5 to 8 parts of light stabilizers. The powder paint is powder with the nanometer particle diameter, which is favorable for spray coating. The raw material distribution is uniform; white spots due to powder agglomeration cannot easily occur; the coating layer mechanicalperformance is facilitated; the coating layer transparency is high; the powder paint is suitable for being applied to the glass surface; the light energy is used to be converted into infrared radiation heat energy; the heat insulation and thermal isolation effects are achieved.

Owner:ZHEJIANG HUACAI NEW MATERIAL CO LTD

A logistics pipeline system and its control method

ActiveCN109809197BBig spaceEasy to operateConveyorsStorage devicesLogistics managementProcess engineering

The invention discloses a logistics pipeline system and a control method thereof. Through pipeline series-parallel connection and both-way conveying, objects arrive at a piece taking port from a delivery port or reverse logistics storage is achieved. In the logistics pipeline system and the control method thereof, selection of different series-parallel connection manners can be decided according to the actual environment and other factors, and high compatibility and optimizing performance are achieved. Multiple flow directions of a pipeline in a conveying unit can be adopted, and larger spacecan be achieved for interaction compatibility of the pipeline, the delivery port and the piece taking port through the multi-flow-direction design. Meanwhile, due to selection diversity of the flow directions in the pipeline, higher operability and variability can be brought.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Protective cover for heat insulation and heat preservation of extrusion die head

PendingCN114059179ATo achieve thermal insulation effectSpinnerette packsEngineeringHeat conservation

According to the technical scheme, a protective cover for heat insulation and heat preservation of an extrusion die head comprises the die head, a hot air box is connected to the two sides of the die head, hot air pipes are connected to the outer sides of the hot air box, a heat preservation cover is arranged in the outer side of the hot air box, the hot air pipes and the die head, the heat preservation cover comprises a top plate, a middle plate, left and right side plates and front and back side plates; the lower portions of the left and right side plates extend inwards to the bottom face of the hot air box, the left and right side plates cover the side faces and the bottom face of the hot air pipes and the hot air box, the middle plate covers the top faces of the hot air pipes and the hot air box, the top plate is located over the middle plate and covers the die head and the middle plate, and the front and back side plates cover the front side faces and the rear side faces of the hot air box, the hot air pipes and the die head. The protective with the independent heat preservation and insulation structure is arranged outside the die head, so that the heat preservation and insulation effect on the extrusion die head is achieved.

Owner:ZHEJIANG JINGCHENG MOLD MASCH CO LTD

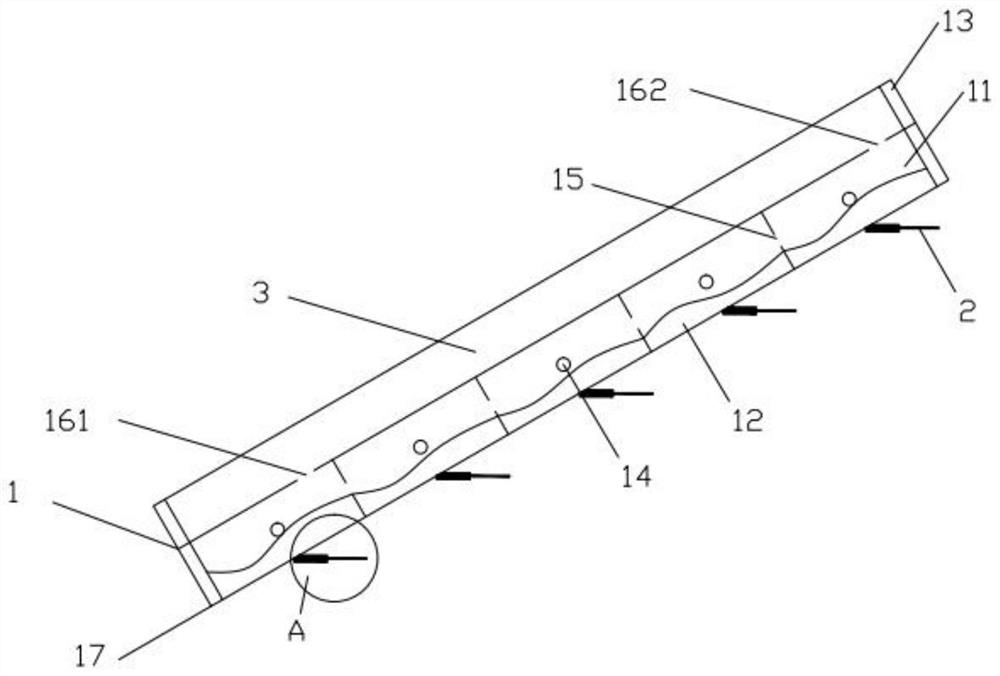

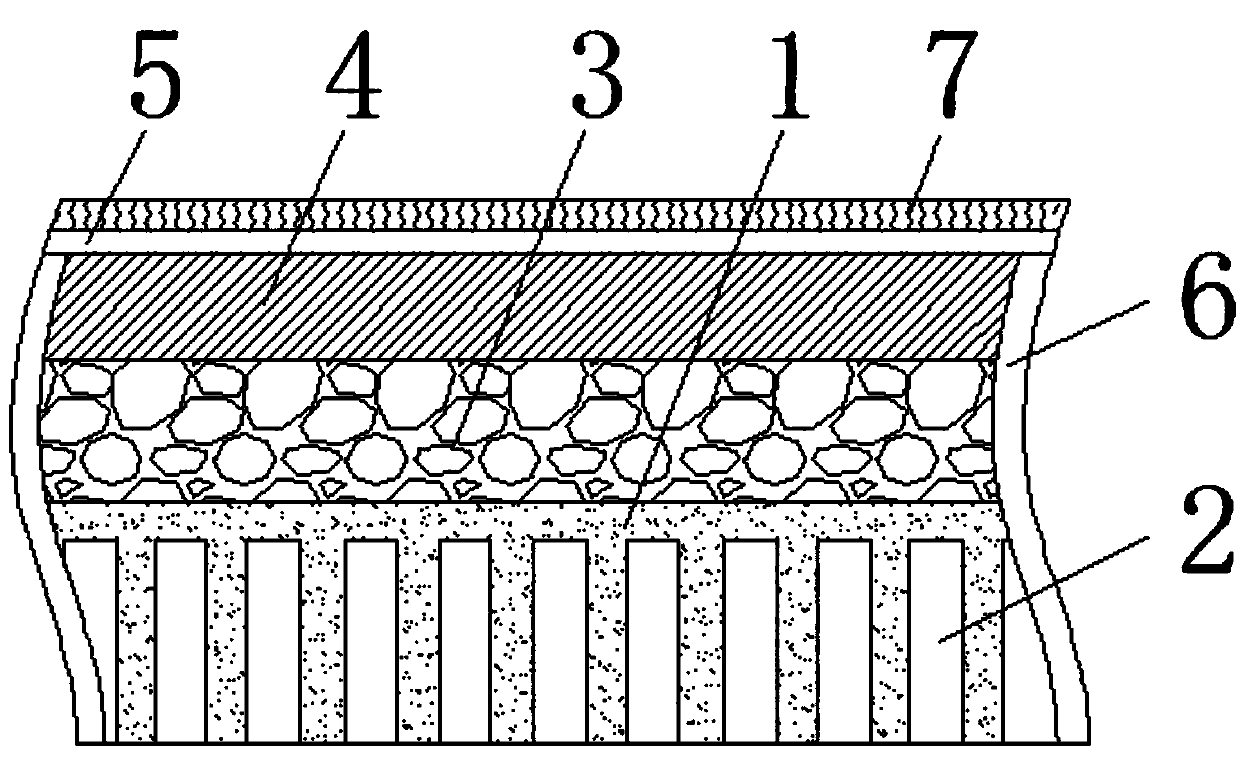

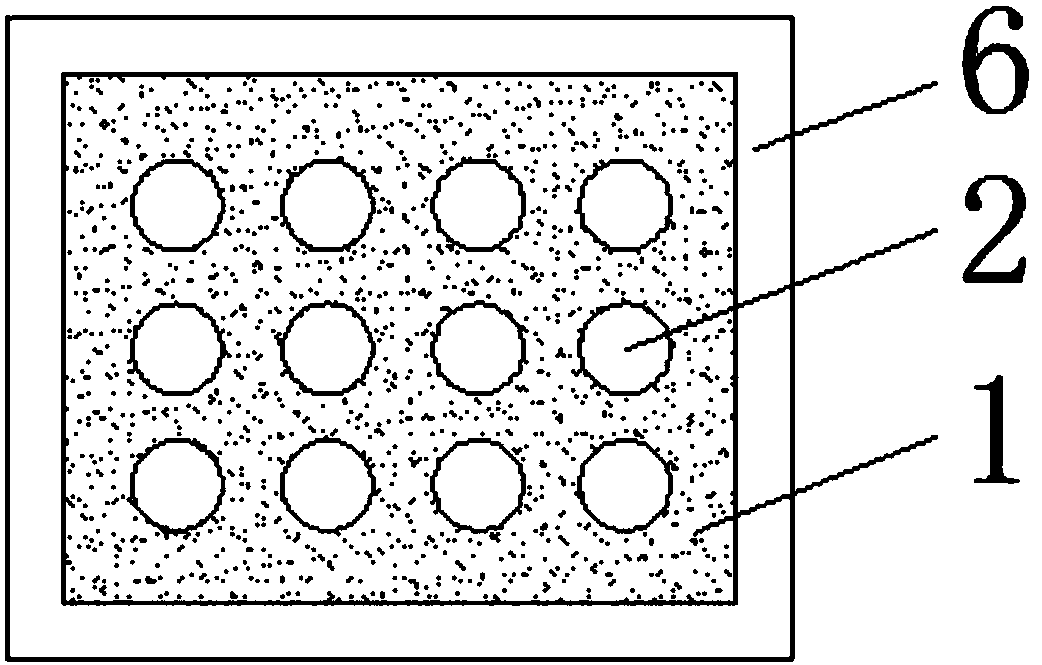

Inclined cylinder sound insulation and heat preservation floor slab

PendingCN111519808AStop crackingAvoid crackingFloorsHeat proofingReinforced concreteInsulation layer

The invention relates to the technical field of constructional engineering, in particular to an inclined cylinder sound insulation and heat preservation floor slab. According to the specific technicalscheme, the inclined column sound insulation and heat preservation floor comprises a reinforced concrete layer, a heat insulation and sound insulation layer and a gravel concrete layer are sequentially arranged above the reinforced concrete layer, and the heat insulation and sound insulation layer is formed by arranging a plurality of inclined columns with the upper faces and the lower faces being parallel and the side faces being inclined. According to the inclined cylinder sound insulation and heat preservation floor slab, the situation that the floor slab is easy to crack and break due touneven load when the commonly used floating floor slab is used is avoided, and the sound insulation and heat preservation effects are achieved at the same time.

Owner:重庆立库科技有限公司

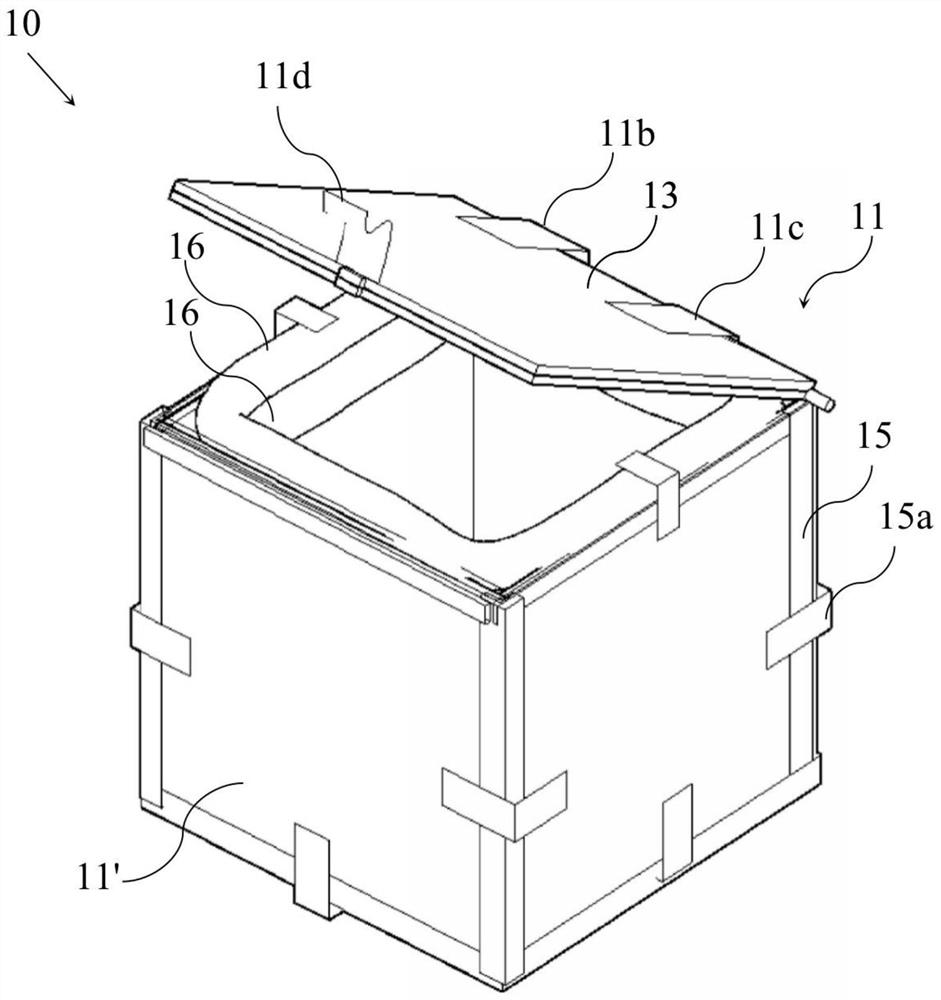

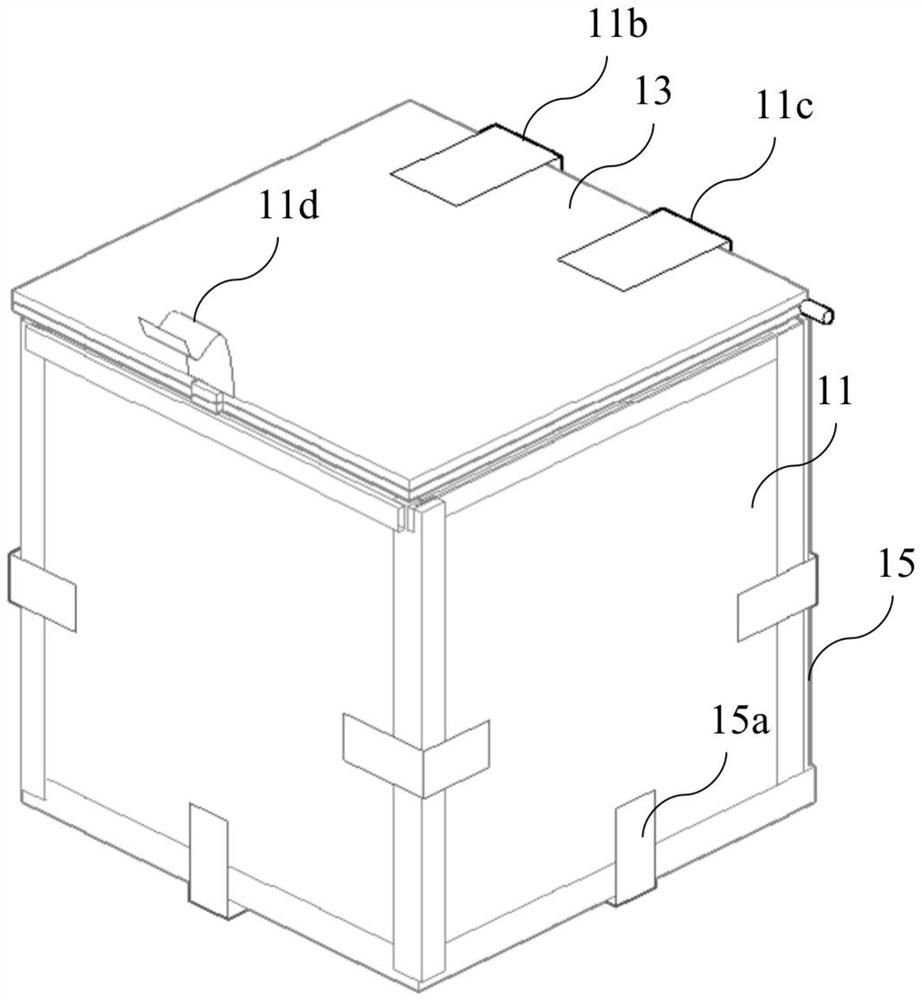

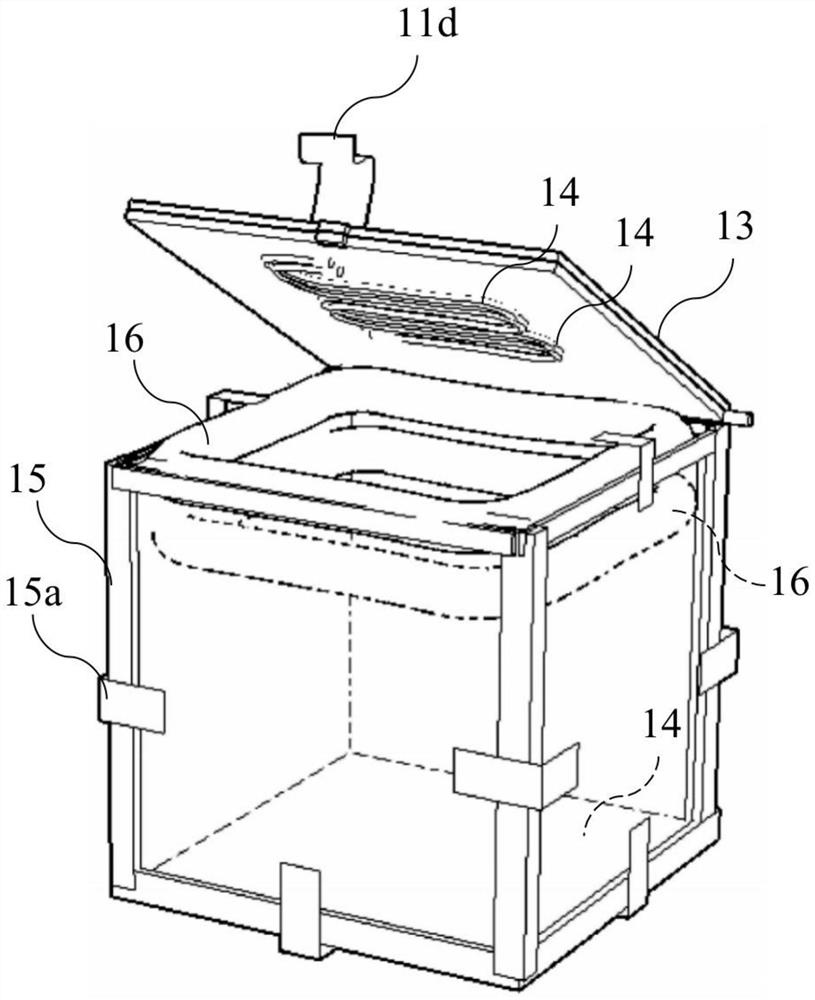

Incubator with life-saving function

ActiveCN112623155BIncrease application rateEffective insulationDomestic cooling apparatusLighting and heating apparatusInsulation layerThermal insulation

The invention provides an incubator with life-saving function, comprising: a box body, an upper opening, a bottom and a side part folded from an uninflated whole safety air cushion; a plate blower, which is flat and matches the opening of the box body , which is detachably installed on the opening of the box, as a box cover; the fixed frame, matched with the box, fixes and maintains the shape of the box; the sealing layer, formed by the life buoy in the uninflated state, detachably surrounds the box The inner side of the opening is arranged; the air pipe, the input port matches the outlet of the plate blower, the output port matches the inflation port of the safety air cushion and the inflation port of the life buoy, and is detachably arranged on the lower side of the plate blower; and heat insulation The insulation layer is arranged on the inner side of the box body. The incubator provided by the invention can be used for daily heat preservation and storage, and can greatly increase the probability of saving people's lives and reduce property losses when emergency events occur (such as falling from a height and drowning), and has good social and economic benefits .

Owner:WUHAN UNIV

aluminum alloy door

ActiveCN107489354BThermal insulationTo achieve thermal insulation effectWindow/door framesWing framesMaterials scienceCorrosion

Owner:YANGZHONG YANGZILV PROCESSING CO LTD

Water-based transparent heat-insulating coating for energy-saving doors and windows and preparation method thereof

The invention discloses a water-based transparent heat-insulating paint used for energy-saving doors and windows. The paint comprises the following components by weight: 50 to 60% of an aqueous base latex, 20 to 30% of aqueous nanometer heat-insulating slurry, 0.5 to 1% of a defoaming agents, 1 to 5% of a thickening agent, 0.5 to 1% of a film forming auxiliary agent and 0.5 to 1% of a leveling agent, with the balance being deionized water, wherein the aqueous base latex is an aqueous acrylic resin emulsion with solid content of 30 to 60 wt% or an aqueous polyurethane resin emulsion with solid content of 30 to 60 wt%, and the aqueous nanometer heat-insulating slurry contains the two functional particles consisting of fluorine-doped tin oxide and aluminum-doped zinc oxide. The invention further discloses a preparation method for the paint. The paint prepared in the invention can be coated on the surface of door and window glass to form a transparent film; and the film can absorb the vast majority of ultraviolet light and obstruct more than 60% of infrared light and has average transmittance of more than 70% in a visible light area.

Owner:ZHEJIANG UNIV

Novel self-adaptive intelligent auxiliary energy-saving window

ActiveCN114704180AReduce heat exchangeReduce angleMechanical apparatusDoor/window protective devicesMicrocontrollerLine sensor

The invention relates to the technical field of energy-saving windows, in particular to a novel self-adaptive intelligent auxiliary energy-saving window which comprises a window frame, double-layer hollow glass is arranged on the window frame, a temperature and humidity sensor for sensing external temperature and humidity is arranged on the window frame, and a single chip microcomputer for receiving digital signals is arranged on the window frame. The window frame is provided with a left fan used for sucking air and a right fan used for exhausting air, the window frame is provided with a light sensor used for sensing the external illumination intensity, the window frame is provided with a heater and a refrigerator, and the window frame is provided with a sunshade assembly; a polycrystalline silicon solar panel for collecting solar energy is arranged on the sunshade assembly, a knocking mechanism for removing dust is arranged on the sunshade assembly, and the novel self-adaptive intelligent auxiliary energy-saving window can achieve intelligent adjustment of the indoor air temperature.

Owner:CHONGQING UNIV

Prefabricated self-heat-preservation shearing wall

The invention discloses a prefabricated self-heat-preservation shearing wall which comprises a common concrete layer and a glass pumice concrete layer, wherein double-layer bidirectional reinforcing steel bars are arranged in the common concrete layer; single-layer bidirectional reinforcing steel bars are arranged in the glass pumice concrete layer; the double-layer bidirectional reinforcing steelbars and the single-layer bidirectional reinforcing steel bars are fixed through U-shaped ribs and tying bars to form a reinforcement cage; the glass pumice concrete layer comprises the following components in parts by weight: 400-650 parts of cement, 20-60 parts of coal ash, 120-200 parts of water, 1.5-3.5 parts of a water reduction agent, 0.8-3.2 parts of a fiber, 620-800 parts of medium sand of which the fineness modulus is 3.0-2.3, and 250-320 parts of continuously graded glass pumice of 5-30mm. The shearing wall is good in heat preservation effect, small in thickness, good in durabilityand free of cold bridge phenomenon.

Owner:NINGBO PRECA CONSTR TECH CO LTD

A kind of food packaging container and preparation method thereof

ActiveCN105691846BNot easy to producePlay a thermal insulation effectCoverings/external coatingsEngineeringVolumetric Mass Density

The invention relates to a food packaging container and a manufacturing method thereof. A foamed layer is arranged on the outer surface of the side wall of the food packaging container and comprises a supporting layer and a fuzz layer. The supporting layer is integrally connected with the outer side wall of the food packaging container, the fuzz layer is integrally connected to the supporting layer, and the density of the fuzz layer is smaller than that of the supporting layer. The foamed layer is arranged on the outer surface of the side wall of the food packaging container, and therefore the effect of heat insulation can be achieved.

Owner:刘军

Novel cement brick

The invention relates to the technical field of building materials, and discloses a novel cement brick. The novel cement brick comprises a fiber-reinforced-cement structure layer, hollow holes are formed inside the fiber-reinforced-cement structure layer, a flexible anti-fracture-face layer is fixedly connected to the upper surface of the fiber-reinforced-cement structure layer, a hot-galvanized welded wire mesh is fixedly connected to the upper surface of the flexible anti-fracture- face layer, a plastering layer is fixedly connected to the upper surface of the hot-galvanized welded wire mesh, a decorating depicting layer is fixedly connected to the upper surface of the plastering layer, and waterproof layers are fixedly connected to the two sides of the fiber-reinforced-cement structurelayer, the flexible anti-fracture- face layer and the hot-galvanized welded wire mesh. According to the novel cement brick, by arranging hollow holes, materials can be reduced, the production is reduced, and meanwhile a heat preservation and insulation effect can be achieved; as the multiple hollow holes are formed, the bearing capacity of a cement tile is dispersed, and therefore the problem thatas bearing is over large, the cement tile is fractured is solved.

Owner:天津凌盛水泥制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com