aluminum alloy door

An aluminum alloy and profile technology, applied in the direction of windows/doors, window/door frames, buildings, etc., can solve the problems of reduced structural stability of door frames, inconvenient long-term use of profile doors, general thermal insulation of profile doors, etc. Service life, enhanced thermal insulation effect, excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

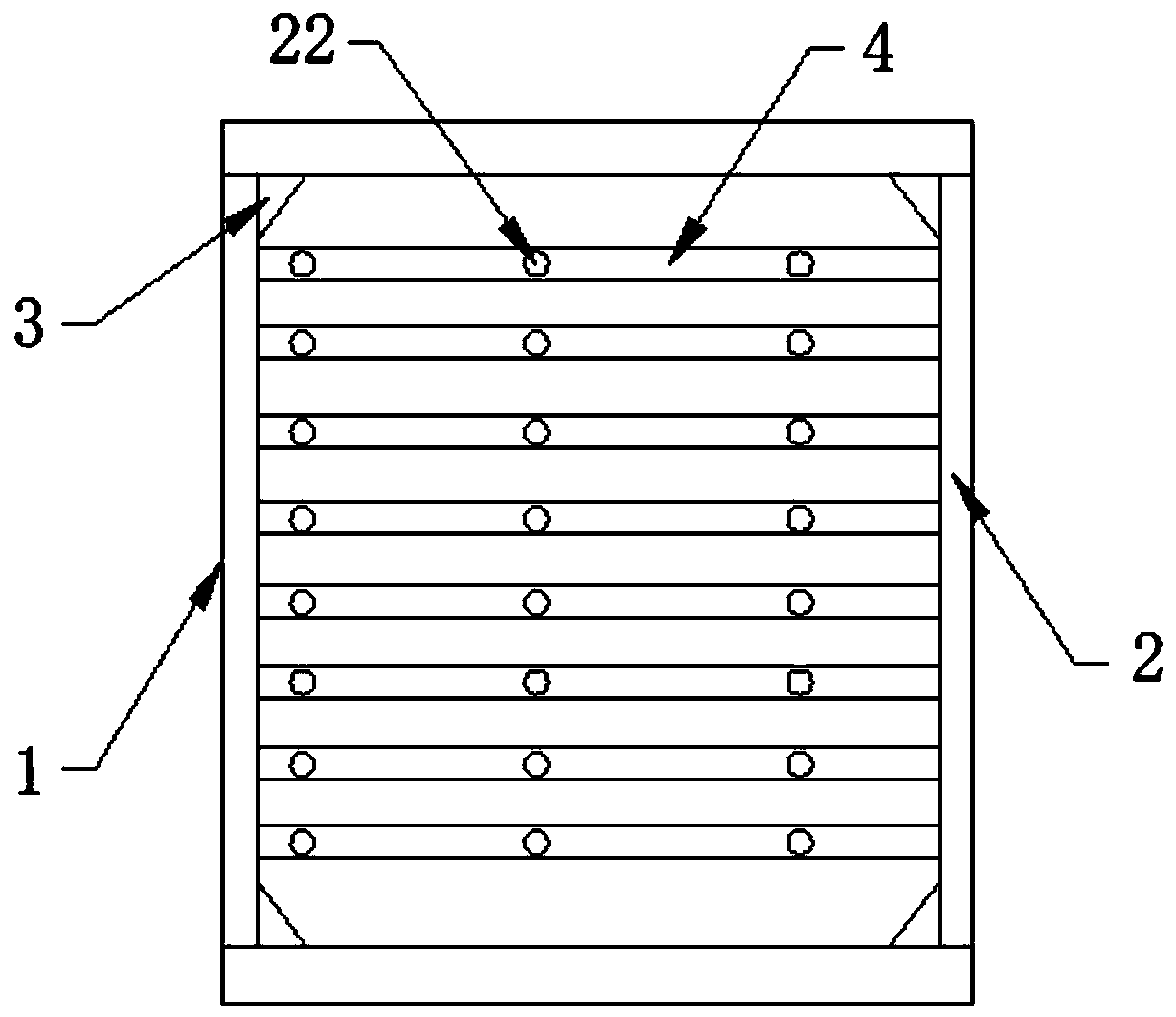

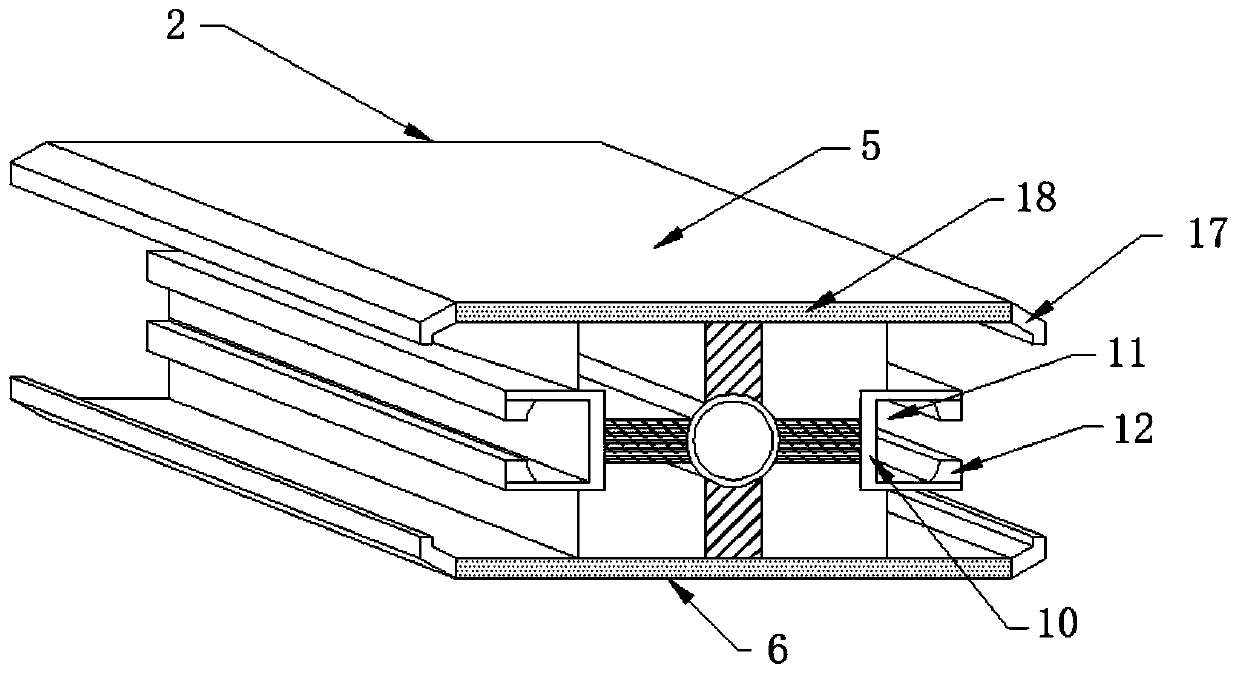

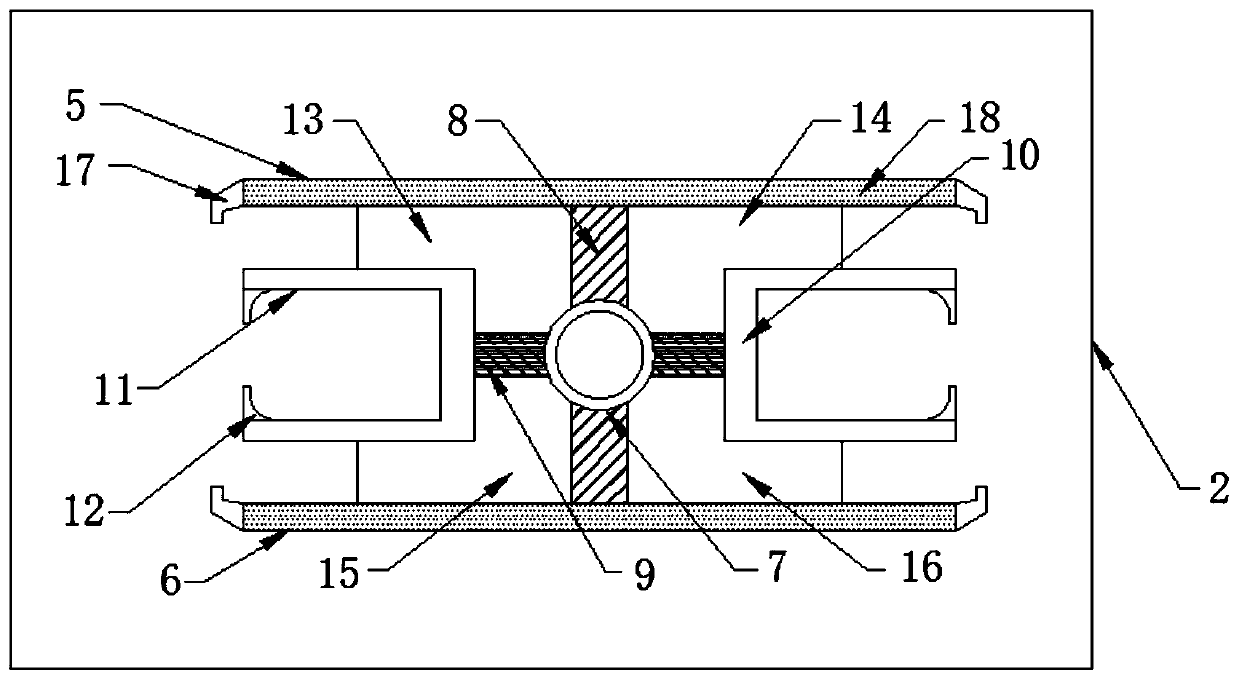

[0022] Such as Figure 1-5 As shown, the present invention provides an aluminum alloy profile door, including a frame 1, the frame 1 is composed of four profile frames 2, the ends of the profile frames 2 are connected with profile corner connectors 3, and the profile frames 2 pass through the profile corner connectors 3 are spliced into a frame 1. Several beam plates 4 are installed inside the frame 1. The profile frame 2 includes a top plate 5, a bottom plate 6 and a central column 7. The bottom of the top plate 5 is equipped with a central column 7, and the bottom of the central column 7 is installed with a The bottom plate 6, the top plate 5, the bottom plate 6 and the central column 7 are provided with a vertically downward first reinforcing rib 8, and both sides of the central column 7 are also equipped with a second reinforcing rib 8 that is horizontal and perpendicular to the first reinforcing rib 8. Rib 9, one end of the second rib 9 is equipped with a fixed buckle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com