Insulation and anti-frostbite swelling phase change insulation board for canal subsoil in salty and cold regions

A technology of anti-frost heave and canal foundation soil, which is applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of easy water seepage failure, poor effect, complex structure, etc. The effect of poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

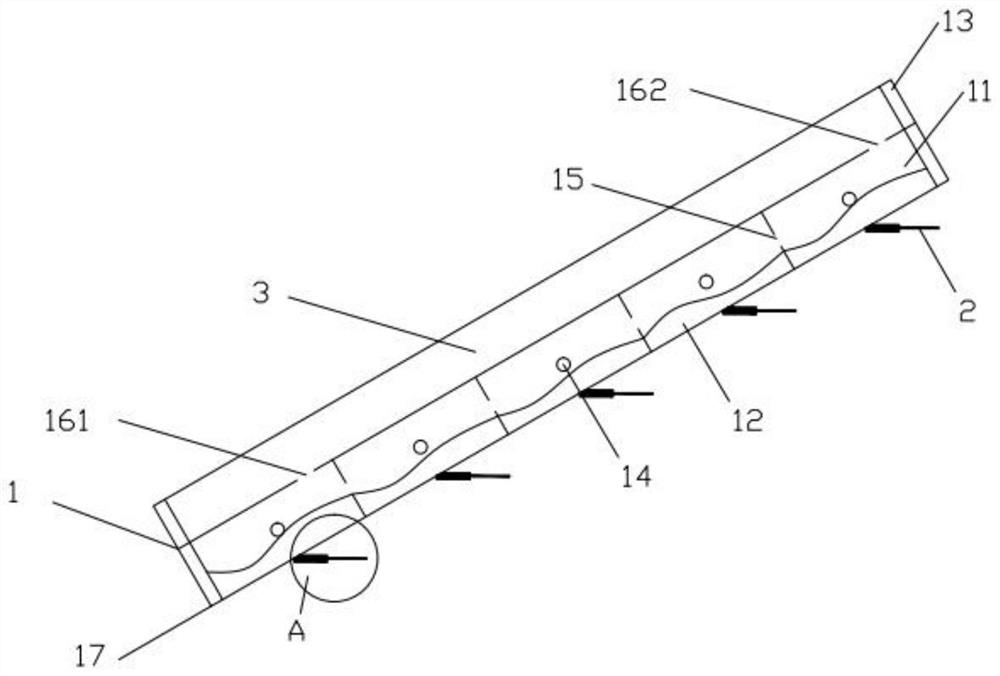

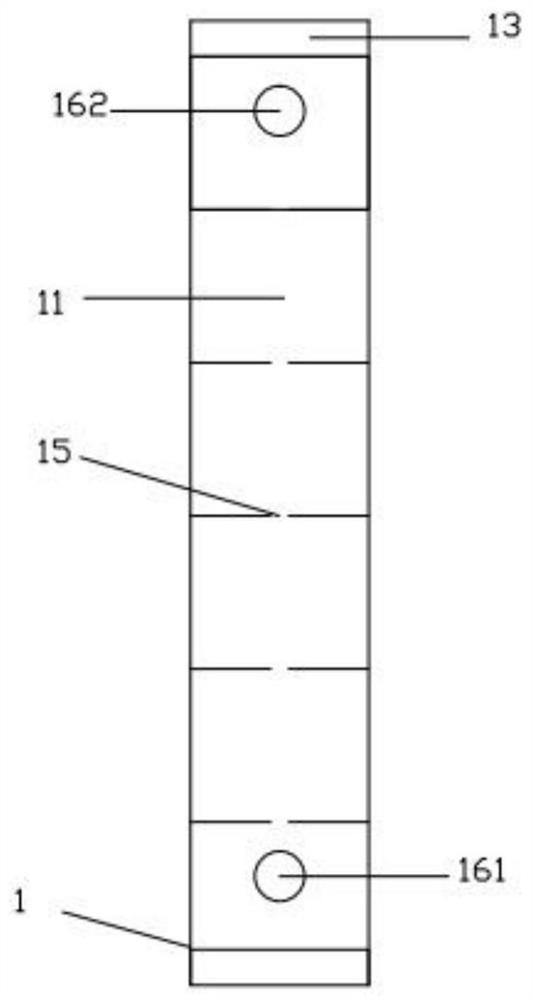

[0067] Taking the Urumqi area as an example, a phase-change thermal insulation board for heat preservation and anti-frost heaving of canal foundation soil in salty and cold areas includes a phase-change thermal insulation and anti-seepage board 1, a backstop capillary 2 and a concrete board 3, and the phase-change thermal insulation and anti-seepage board 1 The height is 200mm, the concrete slab 3 is arranged on the phase-change thermal insulation and anti-seepage board 1, the backstop capillary 2 adopts injection molding process, and is integrally connected with the bottom of the phase-change thermal insulation and anti-seepage board 1, and the The phase-change thermal insulation and anti-seepage board 1 is connected to the circular arc section 21 adopting the arc structure of the transition section.

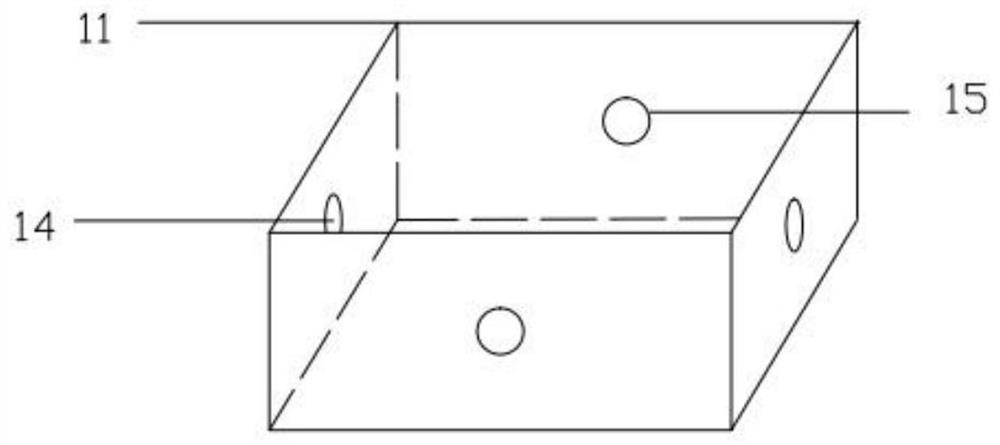

[0068] The phase change thermal insulation and anti-seepage board 1 includes a plurality of lattices 11, a phase change layer 12, a long baffle 13, a liquid injection port 161, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com