Patents

Literature

129 results about "Cement tile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement tiles or hydraulic tiles are handmade colourful tiles used as floor and wall tiling. They appeared in Catalonia (Spain) in the 1850s, and have been widely used in Europe and America. They represented a revolution in flooring in their day because they were much cheaper, more durable and easier to make than the previous handmade glazed ceramic tiles and were therefore more universally available for houses, and they allowed for profuse decorative patterns, their age of splendour being the end of the 19th to the middle of the 20th centuries, before they were gradually superseded by newer technology as of the 1960s, such as terrazzo, salt-glazed stoneware, etc. that didn't allow for such decorative embellishment but were cheaper.

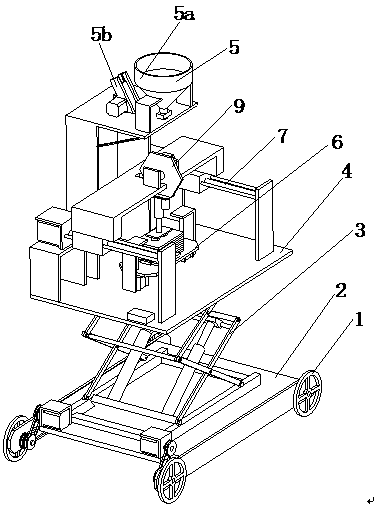

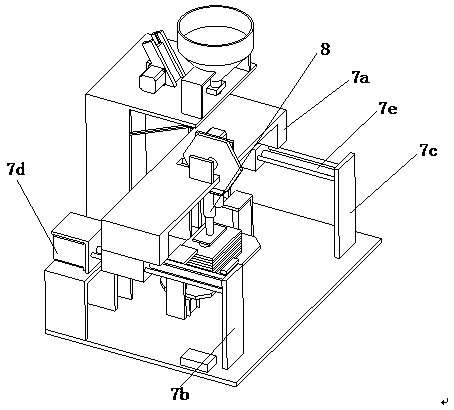

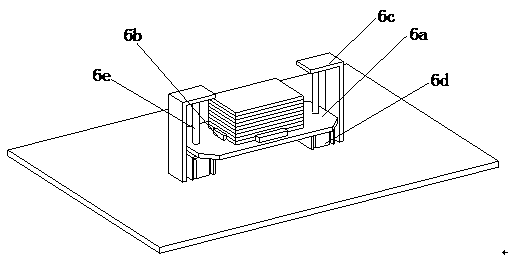

Ceramic tile sticking device for wall

The present invention relates to the technical field of construction engineering equipment, in particular to a device for tiling tiles on a wall, which includes a running assembly, a support plate arranged horizontally, an elevator, a cement plastering assembly, a tile supply assembly and a material transfer assembly. There is a fixed plate, the fixed plate and the supporting plate are rectangular parallelepiped structure, the cement plastering component, the tile supplying component and the material moving component are all located on the top of the fixing plate, and the material moving component includes a U-shaped support frame and the first feeding component, The second feeding assembly, the U-shaped support bracket is provided with a retrieving assembly and a rotating assembly, and the tile supply assembly includes a lifting plate and a lifting assembly, and the top of the lifting plate is provided with four limit plates. The invention can automatically complete the actions of taking tiles, plastering cement and laying tiles, which not only improves the efficiency of laying tiles, but also reduces manpower input, and avoids potential safety hazards caused by manual laying of tiles at high places.

Owner:刘纯久

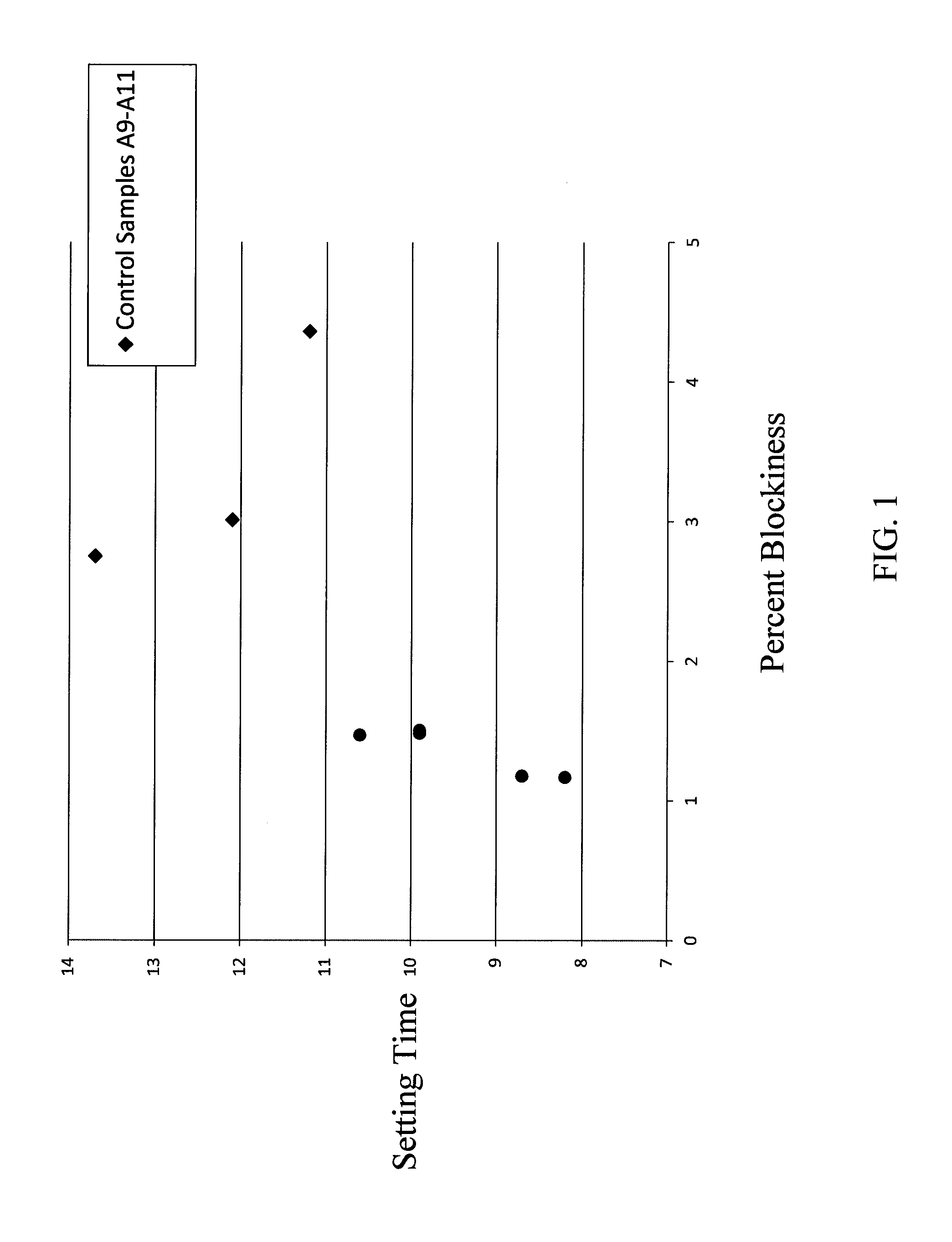

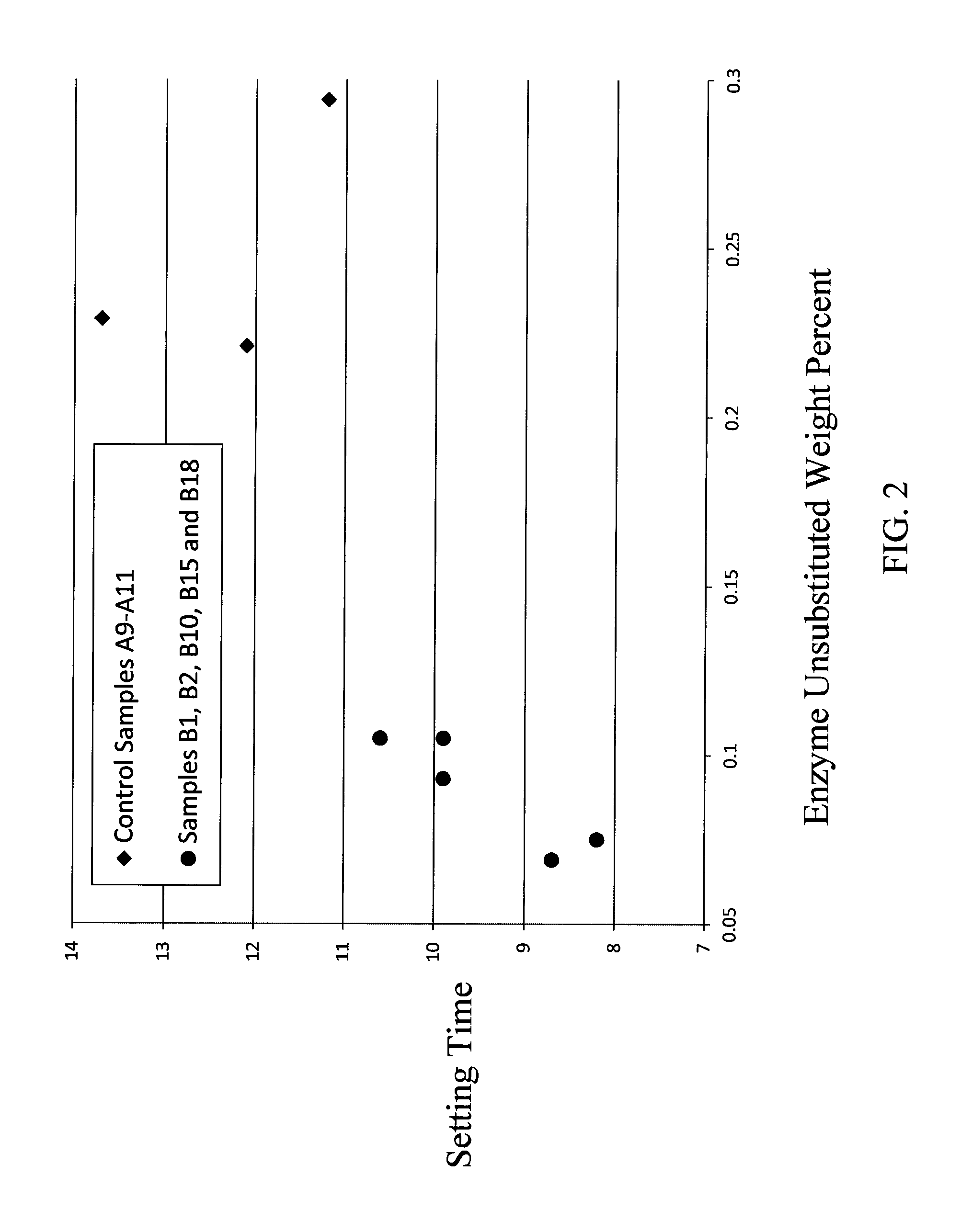

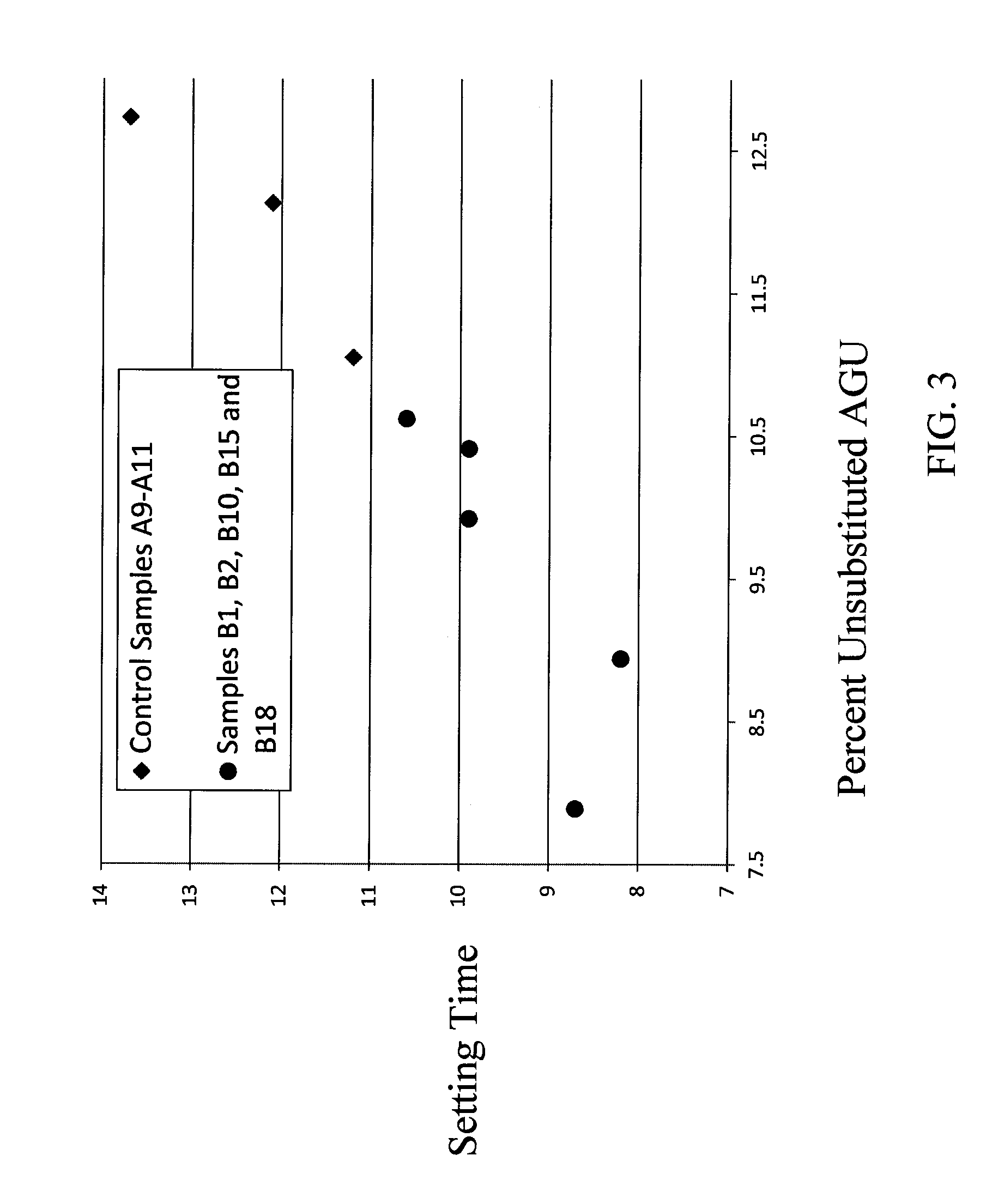

Hydraulic Composition With Prolonged Open Time

The presently disclosed and claimed inventive concept(s) relates generally to a hydraulic composition with a prolonged open time. More particularly, the composition comprises at least one cement retarder and at least one accelerator. The presently disclosed and claimed inventive concept(s) further relates to a dry mortar composition comprising the hydraulic composition having prolonged open time without deterioration of the other cement tile adhesive properties such as workability, setting time, strength development and sag resistance.

Owner:HERCULES LLC

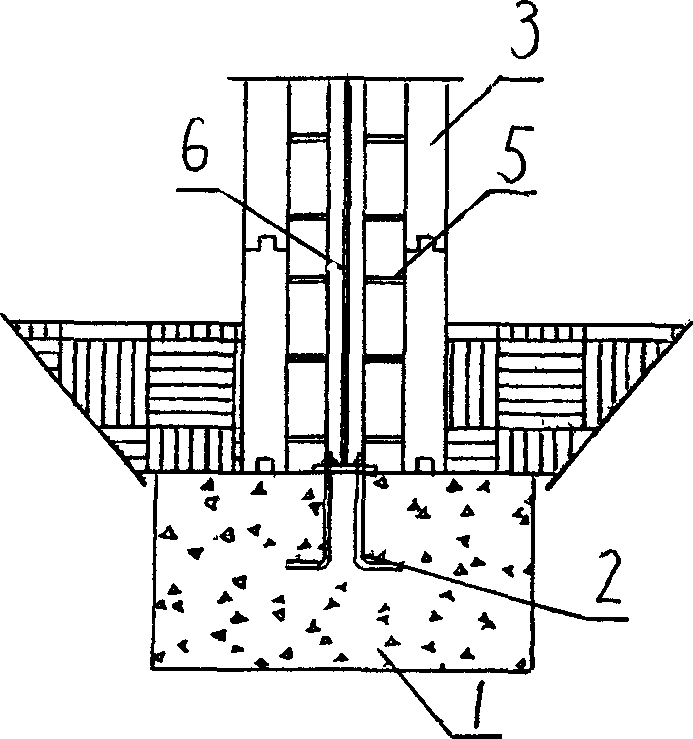

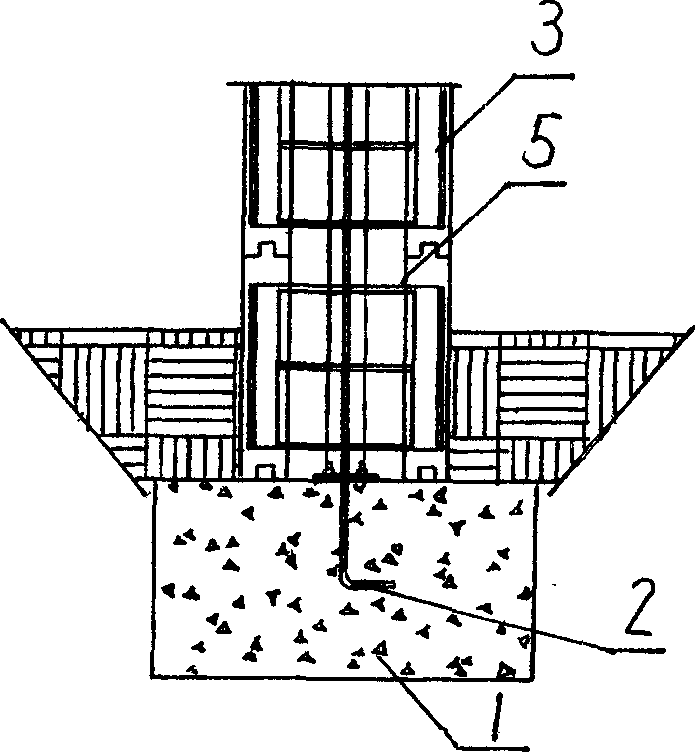

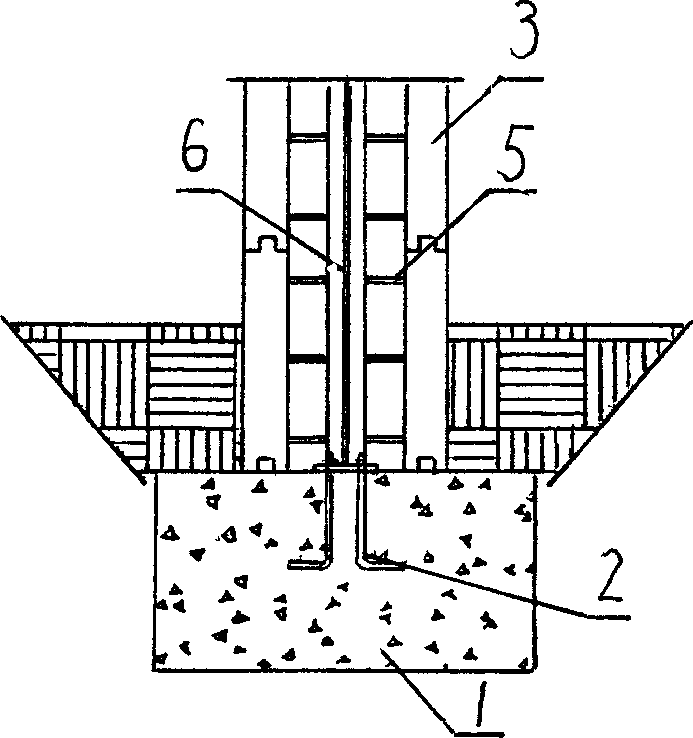

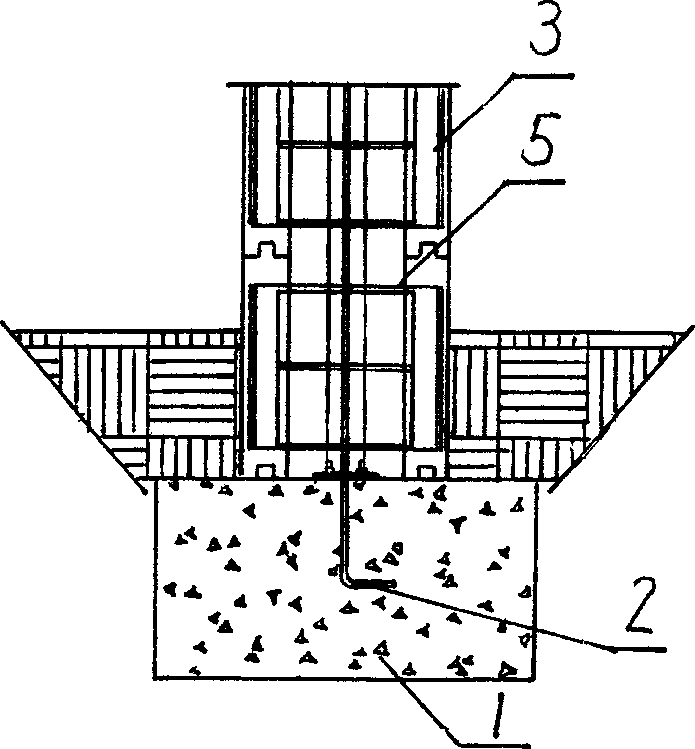

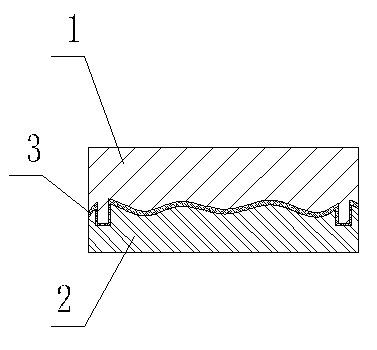

Composite heat insulation concrete shear wall and its construction method

InactiveCN1603538AImprove insulation effectImprove insulation performanceWallsHeat proofingNew energyPolystyrene

One kind of compound heat preservation heat insulation concrete shearing force is strong and the job practice, in the concrete foundation connects the prefabricated polystyrene heat preservation wall template, the prefabricated polystyrene heat preservation wall template interconnection has the steel bar skeleton, the steel bar skeleton by along the board length and along the board widely spaced establishment transverse steel, the embedment steel disk permanent connection becomes along in the board high establishment vertical steel bar and the board. Outside the prefabricated polystyrene heat preservation wall board template the side permanent connection cement tile, the prefabricated polystyrene heat preservation wall template compound constructs with the cast-in-place concrete wall is a body. The invention provides a kind of new energy conservation construction wall, reduced the construction working procedure, reduced the time limit for a project, reduced the construction cost, has solved the energy conservation construction craft complex problem. Is suitable for the multilayer and the small high-rise construction.

Owner:朱秦江

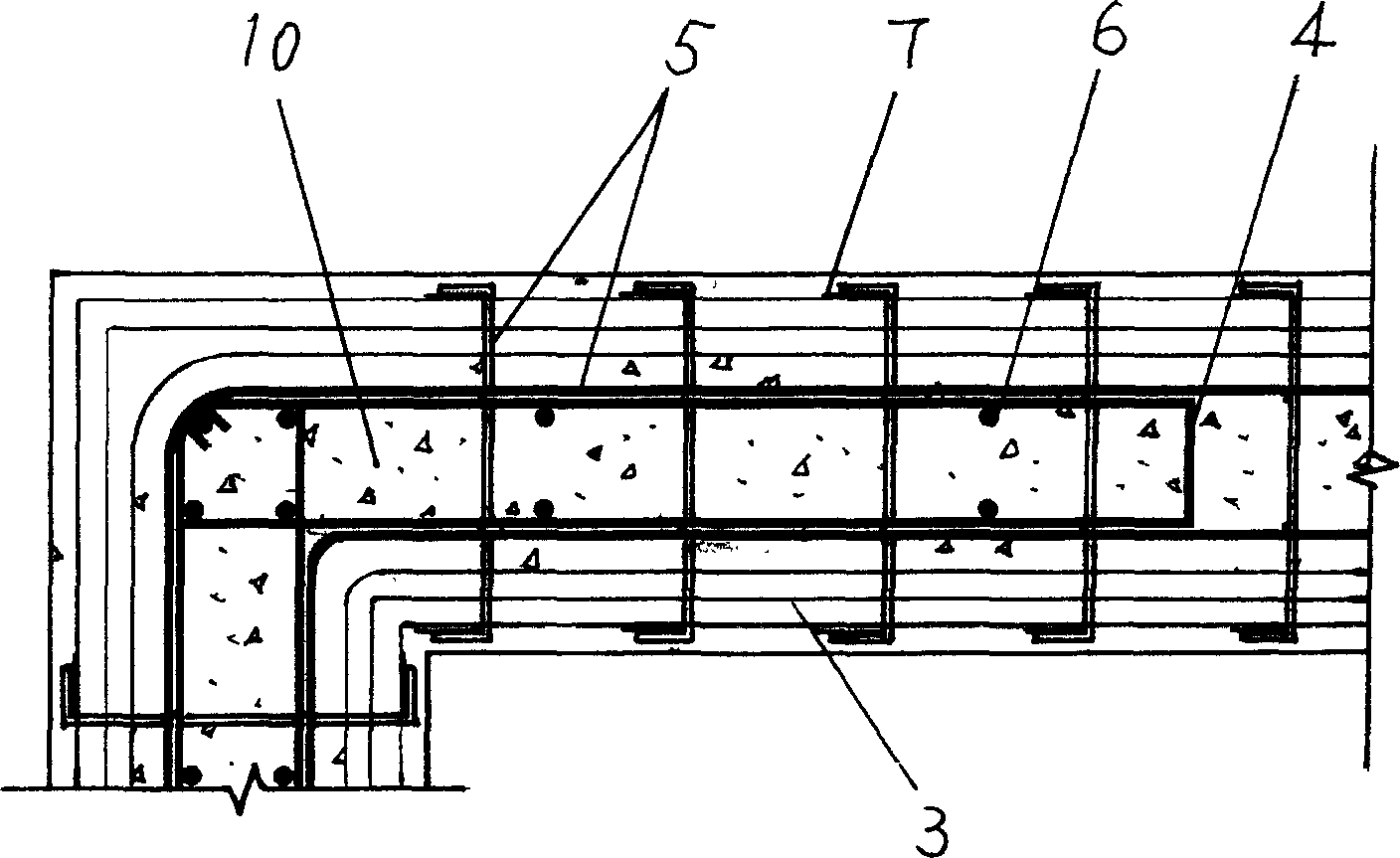

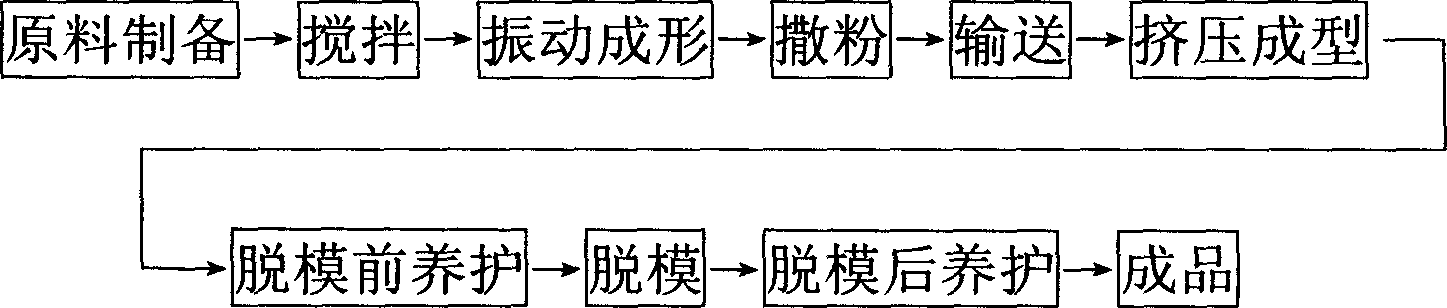

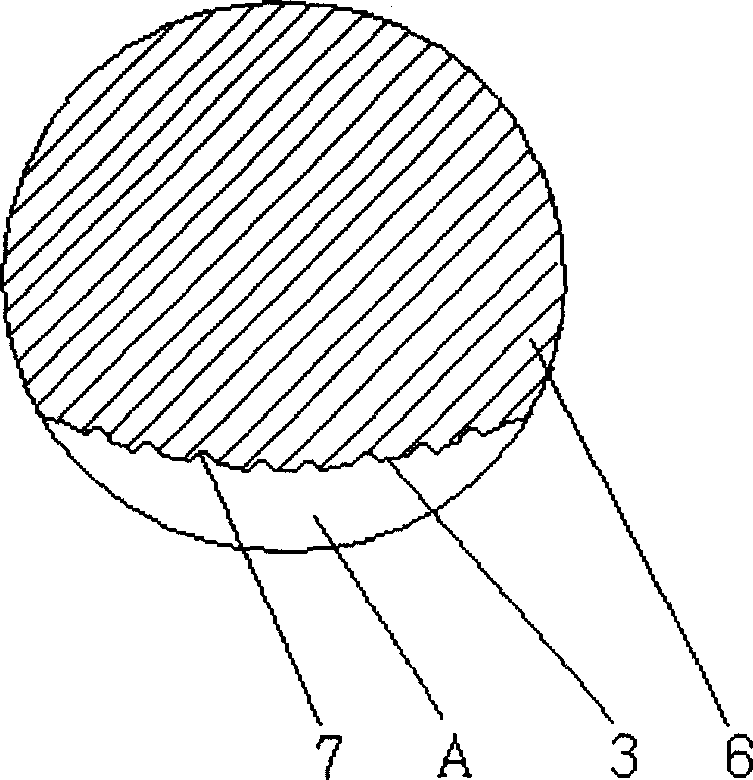

High-intensity pure-colored lithic cement tile and its production method and apparatus

InactiveCN1765813AImprove performanceHigh compressive strengthCeramic shaping apparatusHigh intensityUltimate tensile strength

The invention discloses the constituent with weight ratio of high-tension pure color lithic cement tile, and introduces in detail its process technique and key devices. This method changes prior art, and comprises mixing, vibration molding, extrusion molding, and curing before and after demolding. The product has better properties with high efficient.

Owner:荆国生

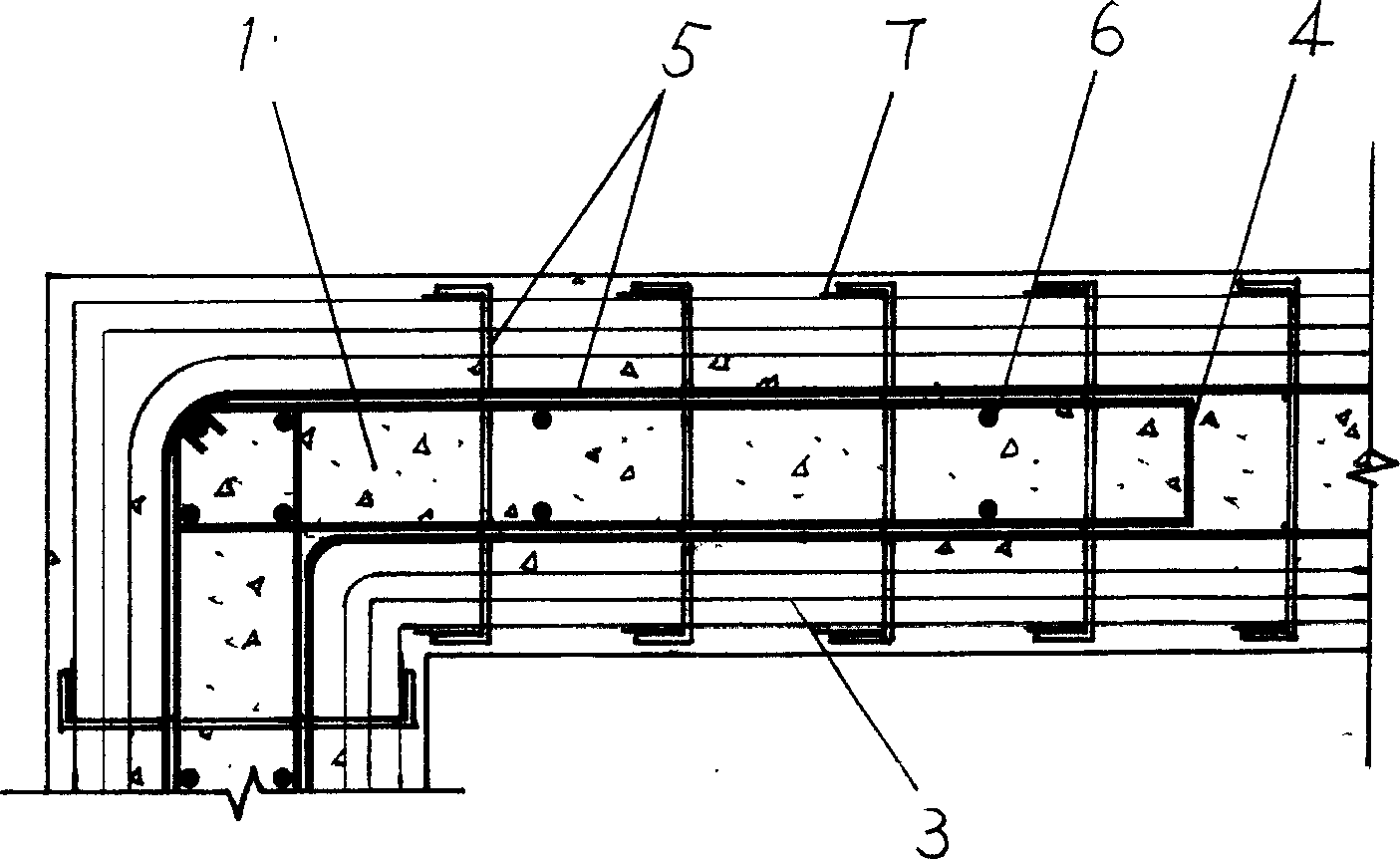

Composite heat insulation concrete shear wall structure system and its construction method

InactiveCN1603537AImprove insulation effectImprove insulation performanceWallsFloorsFloor slabNew energy

One kind of compound heat preservation heat insulation concrete shearing force wall structure system and the job practice, in the concrete foundation connect the prefabricated polystyrene heat preservation wall template, the prefabricated polystyrene heat preservation wall template interconnection has the steel bar skeleton, outside the prefabricated polystyrene heat preservation wall template the side permanent connection cement tile, the prefabricated polystyrene heat preservation wall template compound constructs with the cast-in-place concrete wall is a body; Floor by prefabricated polystyrene heat preservation trough plate and cast-in-place the steel bar layer of concrete duplicate synthesizes a body, in each prefabricated polystyrene heat preservation grooved template trough sets has the dense rib Liang steel bar, with the shearing force wall in steel bar, the polystyrene wall shell body template inside steel lumber forms the whole together the steel bar skeleton, with cast-in-place the steel bar layer of concrete constructs is a body. The invention provides a kind of new energy conservation construction system, reduced the construction working procedure, reduced the time limit for a project, reduced the construction cost, has solved the energy conservation construction craft complex problem. Is suitable for the multilayer and the small high-rise construction.

Owner:朱秦江

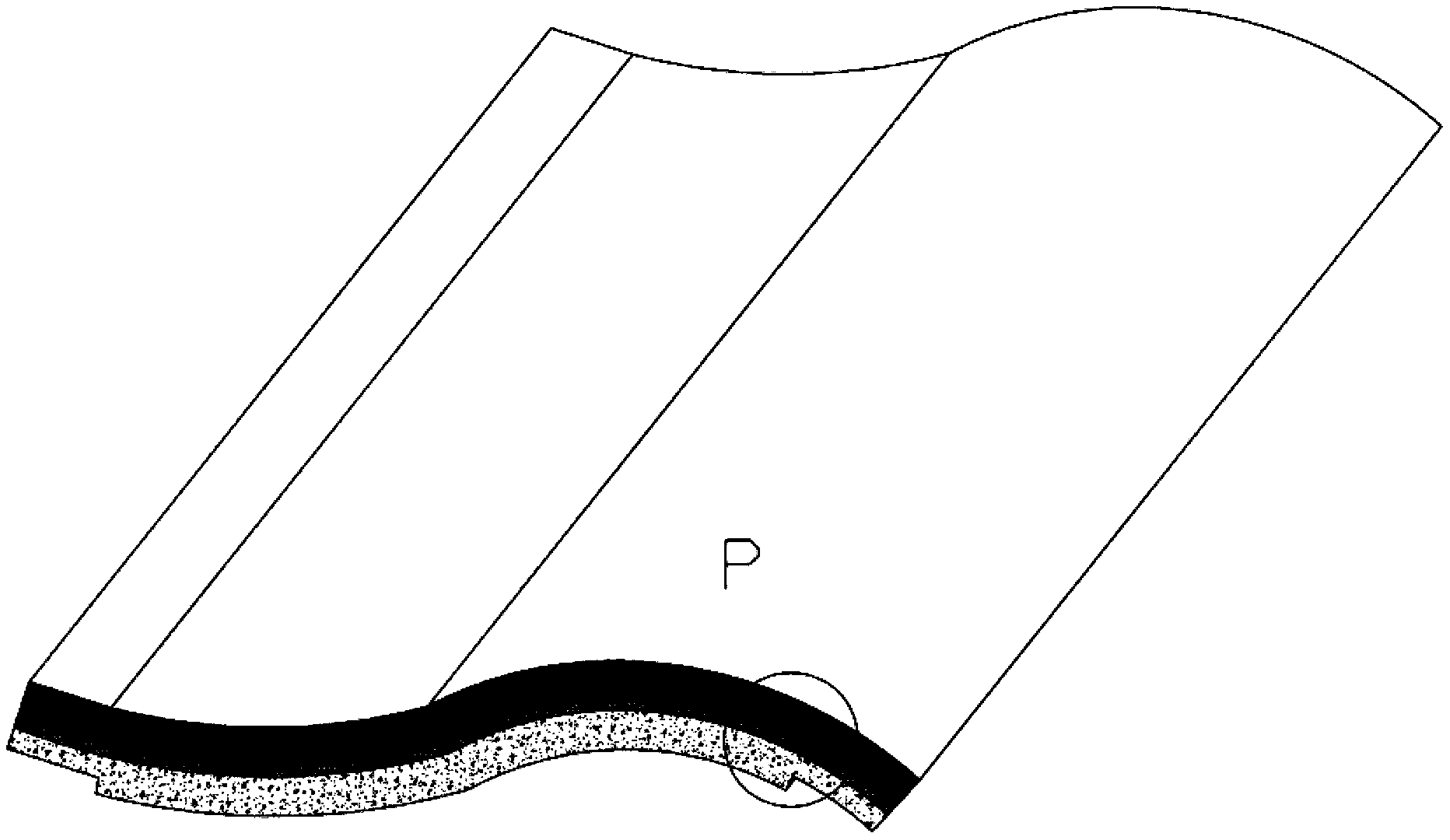

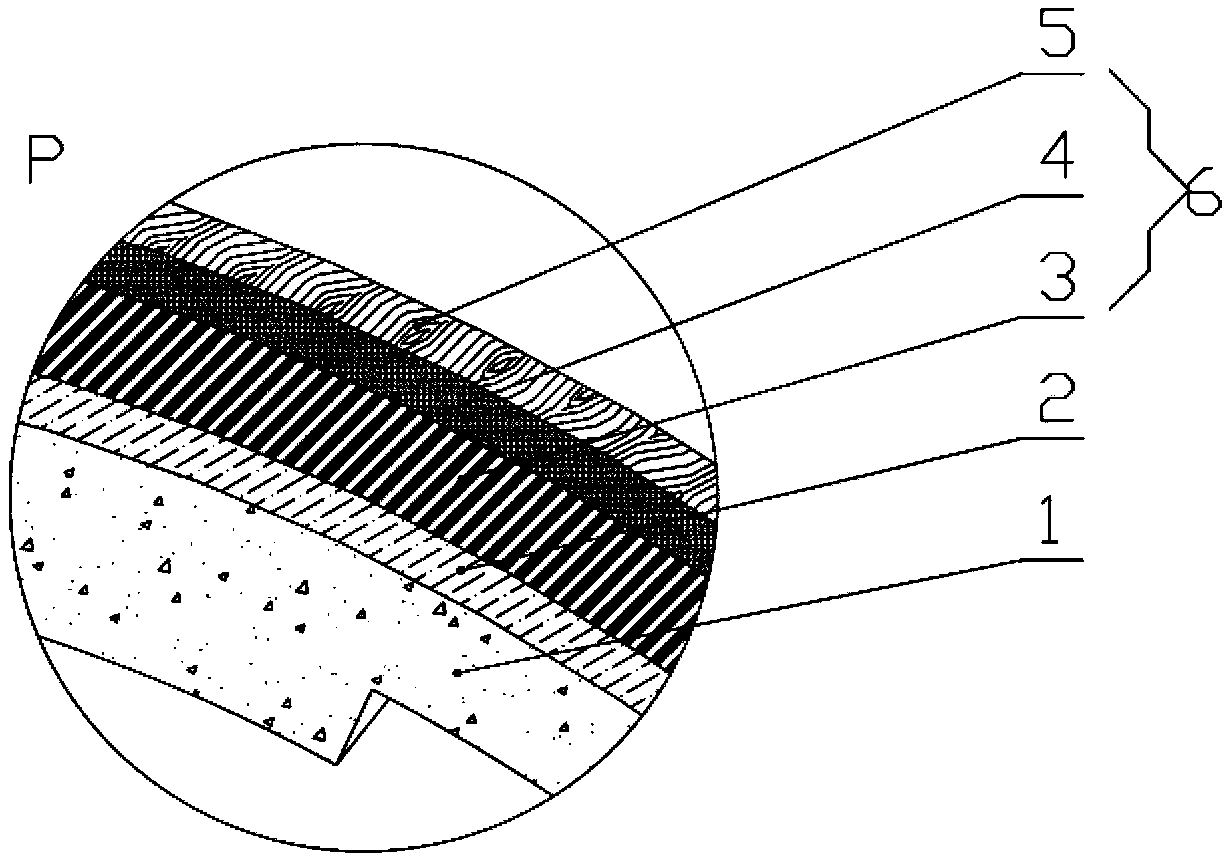

Photovoltaic tile on roof and manufacturing method thereof

ActiveCN103413847AThe function of photovoltaic power generation is soft and beautifulDoes not affect the decorative effectPhotovoltaic energy generationSemiconductor devicesRoof tileEngineering

The invention discloses a photovoltaic tile on a roof and a manufacturing method of the photovoltaic tile on the roof, wherein the photovoltaic tile on the roof integrates the functions of fire prevention, water prevention, decoration and photovoltaic power generation. The photovoltaic tile on the roof comprises a roof tile base material and a photovoltaic decorative layer, wherein the photovoltaic decorative layer and the curved surface of the roof tile base material are bonded into a whole through adhesion agents; the roof tile base material is a clay tile or a ceramic tile or a metal tile or a glass tile or a cement tile; the roof tile base material is coated with high molecular adhesion agents; the photovoltaic decorative layer sequentially comprises a flexible thin film batter assembly, a film layer and a coating layer from interior to exterior. As non-crystalline silicon and other flexible solar photovoltaic thin film batteries are bonded to the surfaces, with the waving feeling, of the ceramic tile, the clay tile, the glass tile and the like through high molecular polymer glue, photovoltaic tiles on roofs which have various complex models, can achieve the function of the photovoltaic power generation and can also keep the shape and color of the tiles on the building roofs can be produced in a factory.

Owner:嘉兴如运建筑科技有限公司

Early strength two-component polymer emulsion modified cement tile binder and using method thereof

ActiveCN105777027ASolve the strength problemSolve the long construction periodPolymer modifiedMaterials science

The invention relates to an early strength two-component polymer emulsion modified cement tile binder and a using method thereof. The tile binder comprises a liquid material and powder in a weight ratio of 1 to (3-4.5), wherein the liquid material is prepared from the following raw materials: 25-35 parts of modified butadiene-styrene copolymer emulsion, 1-4 parts of nonionic surfactant and 60.75-73.96 parts of water; and the powder is prepared from the following raw materials: 15-30 parts of 42.5-grade ordinary Portland cement, 6-20 parts of high-alumina cement, 3-5 parts of anhydrite, 35-56 parts of 40-200-mesh quartz sand and 0-10 parts of 320-mesh ground calcium carbonate. The tile binder has the beneficial effects that the early strength technology used for the two-component polymer modified cement tile binder is invented; the construction time, opening time and property of high hardening rate of the material are well balanced; the construction period is greatly reduced; the labor cost is saved; and meanwhile, performance characteristics, such as alkali efflorescence resistance and aging resistance, are improved.

Owner:JINAN WEIGAO BUILDING MATERIAL TECH CO LTD

Alkyl hydroxyalkyl cellulose ethers, methods of making, and use in cements and mortars

Disclosed are methods for the preparation of alkyl hydroxyalkyl cellulose ethers, and the use of such alkyl hydroxyalkyl cellulose ethers in the preparation and use of mortars and other cement-based systems; also disclosed is a hydraulic composition containing at least one retarder, at least one accelerator and a cellulose ether having a prolonged open time without deterioration of the other cement tile adhesive properties such as workability, setting time, strength development and sag resistance; and further disclosed are dry mortars containing encapsulated calcium chloride used in preparing mortar materials for use in construction, and the preparation and use of such mortars in cold weather environments is also disclosed.

Owner:HERCULES LLC

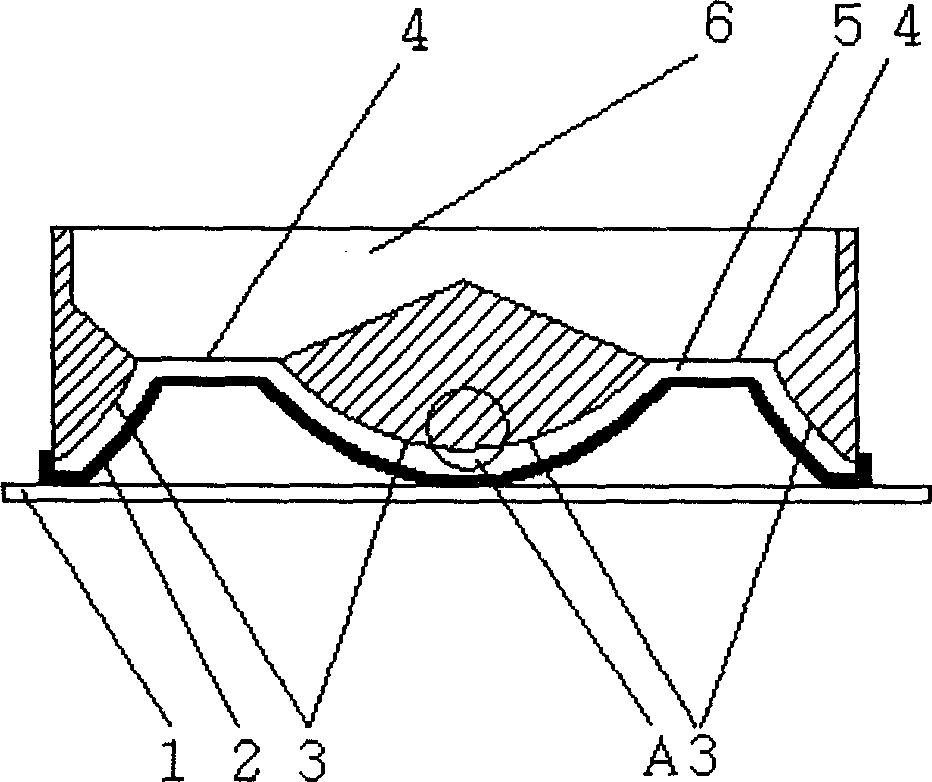

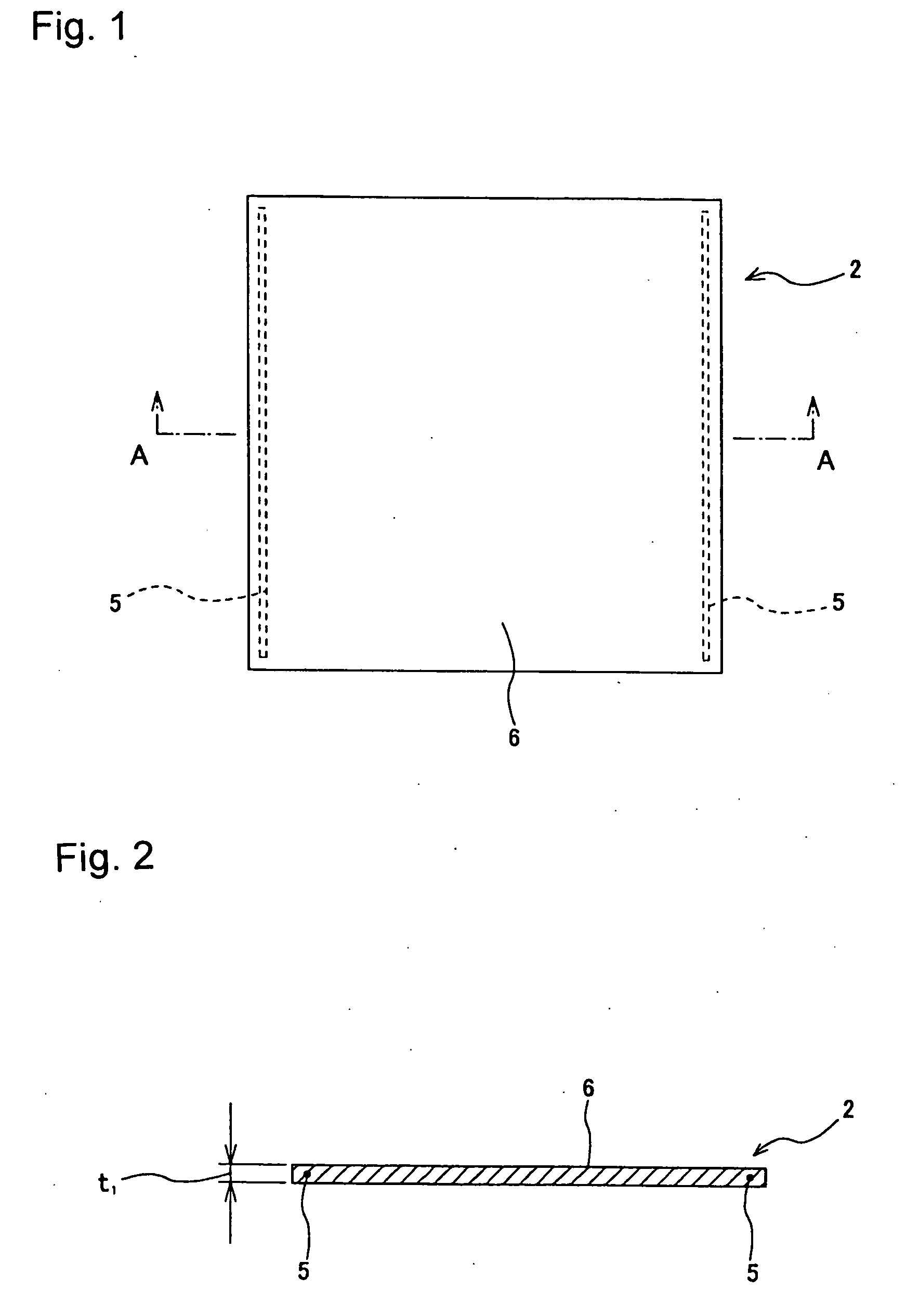

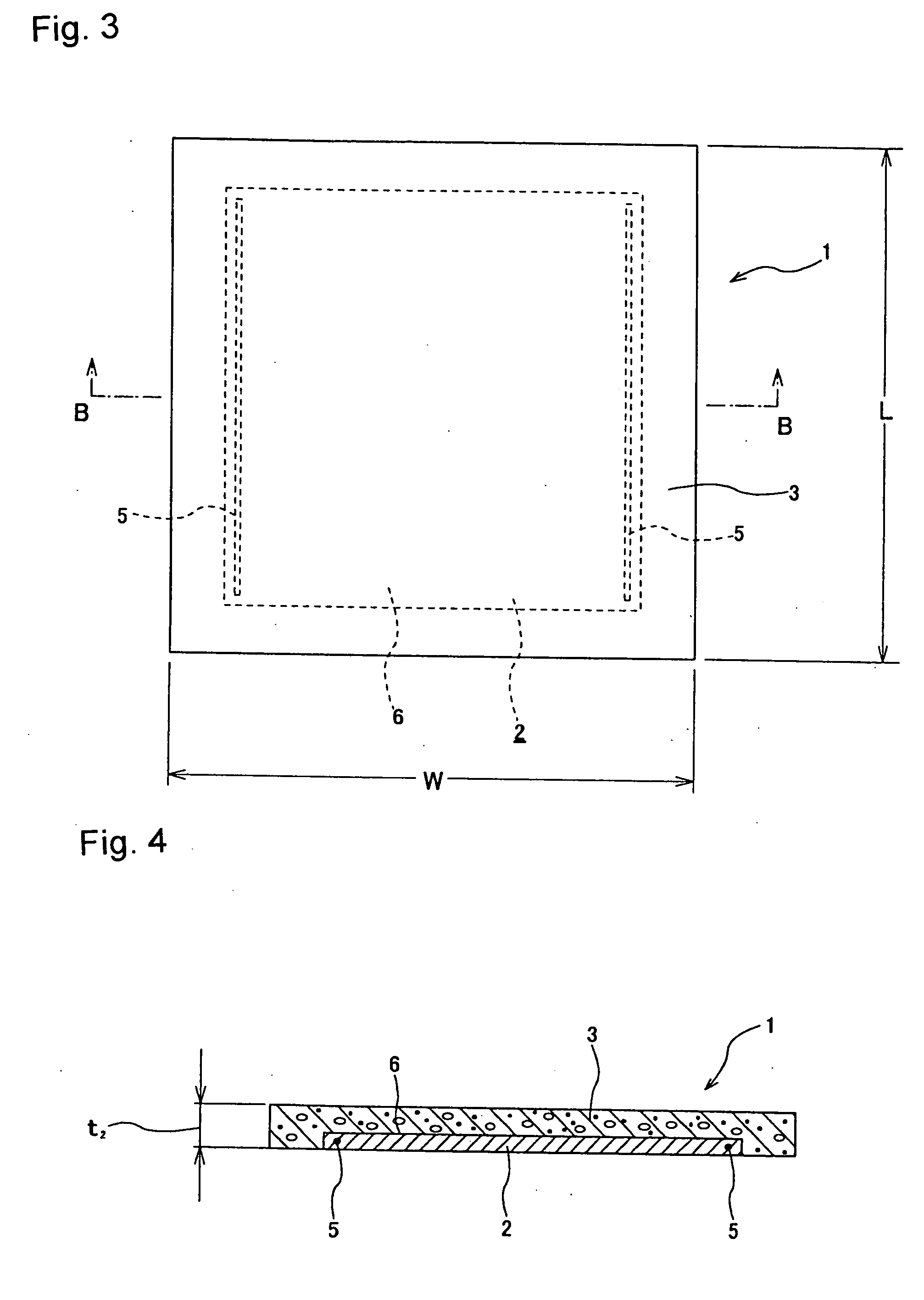

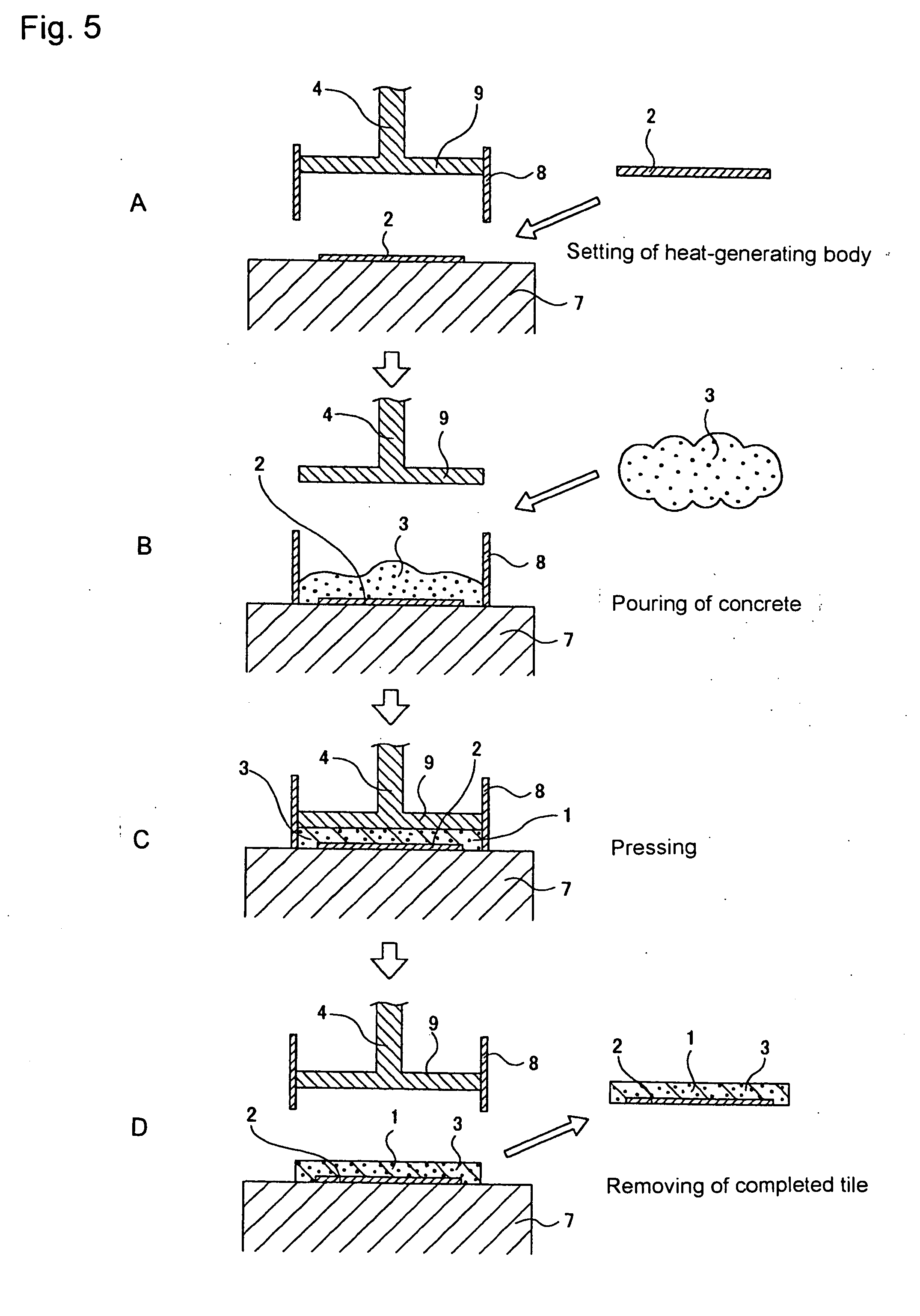

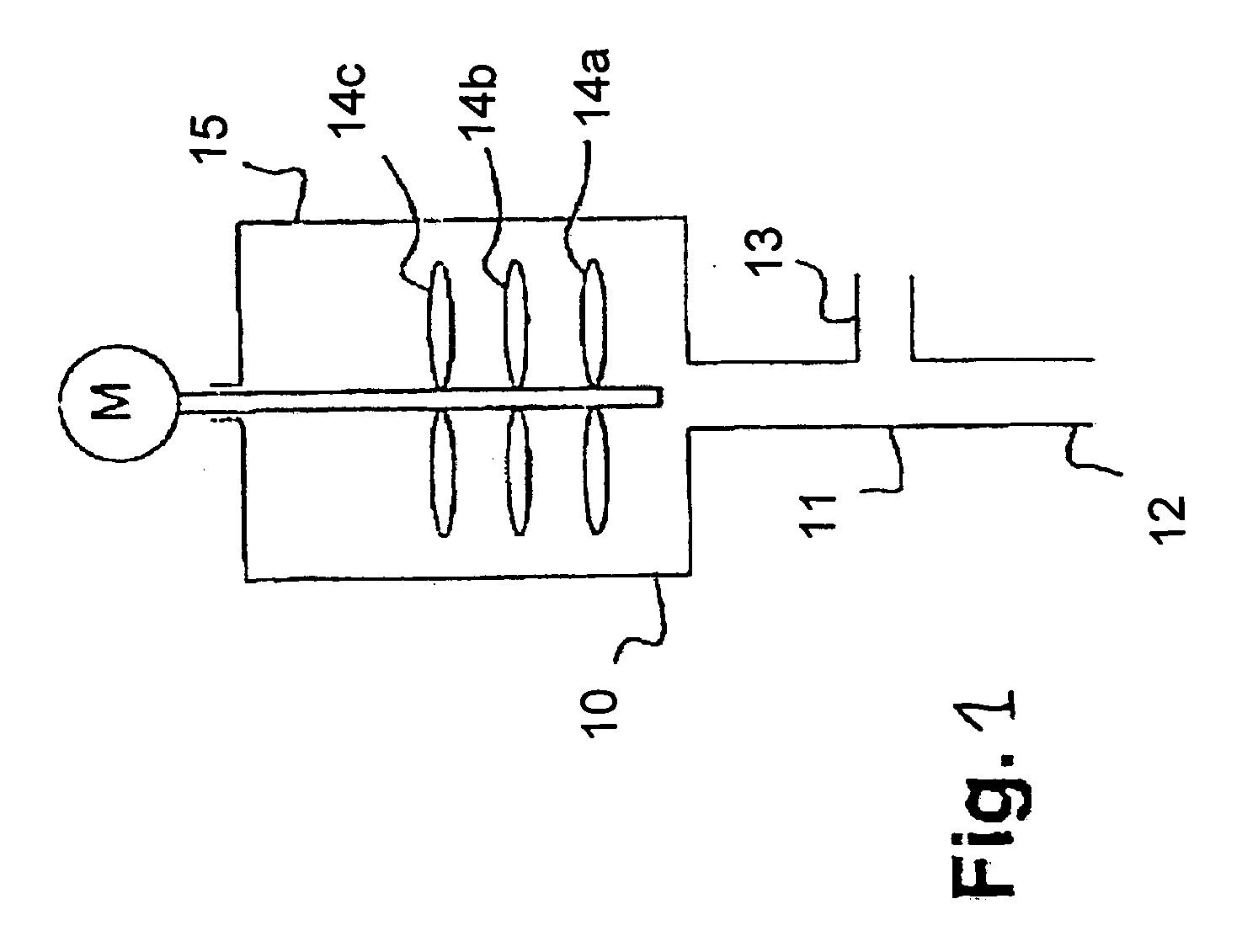

Heat-generating cement body, heat-generating cement tile and manufacturing method thereof

InactiveUS20070186824A1Increase distribution densityIncrease contactMouldsPaving detailsSnow removalBrick

A sidewalk tile with snow-removal function is stably obtained that is capable of being heated to a desired temperature, while at the same time sufficiently maintaining strength. A heat-generating concrete body is obtained by mixing particle-form (granular) or powder-form carbon material with un-hardened concrete at a specified ratio, and then pressing it with a high-pressure press at a pressure of approximately 980 kN to remove moisture and to form it into a tile shape. A pair of electrodes are embedded in end sections on both ends in the width direction of the heat-generating concrete body. The outer surfaces of the heat-generating concrete body are covered with an insulation-coating layer. One side and the circumference of the heat-generating concrete body are covered with un-hardened concrete and formed into a single tile shape by pressing with a high-pressure press to obtain a sidewalk tile with the snow-removal function.

Owner:TAKAHASHI HITOMI +2

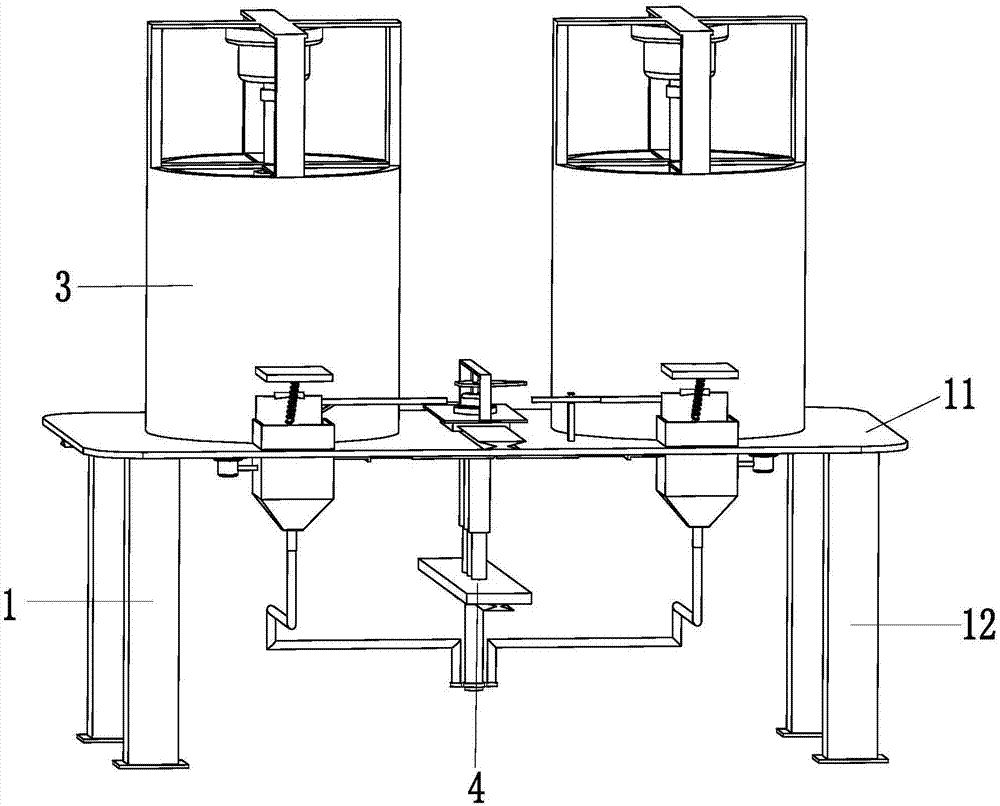

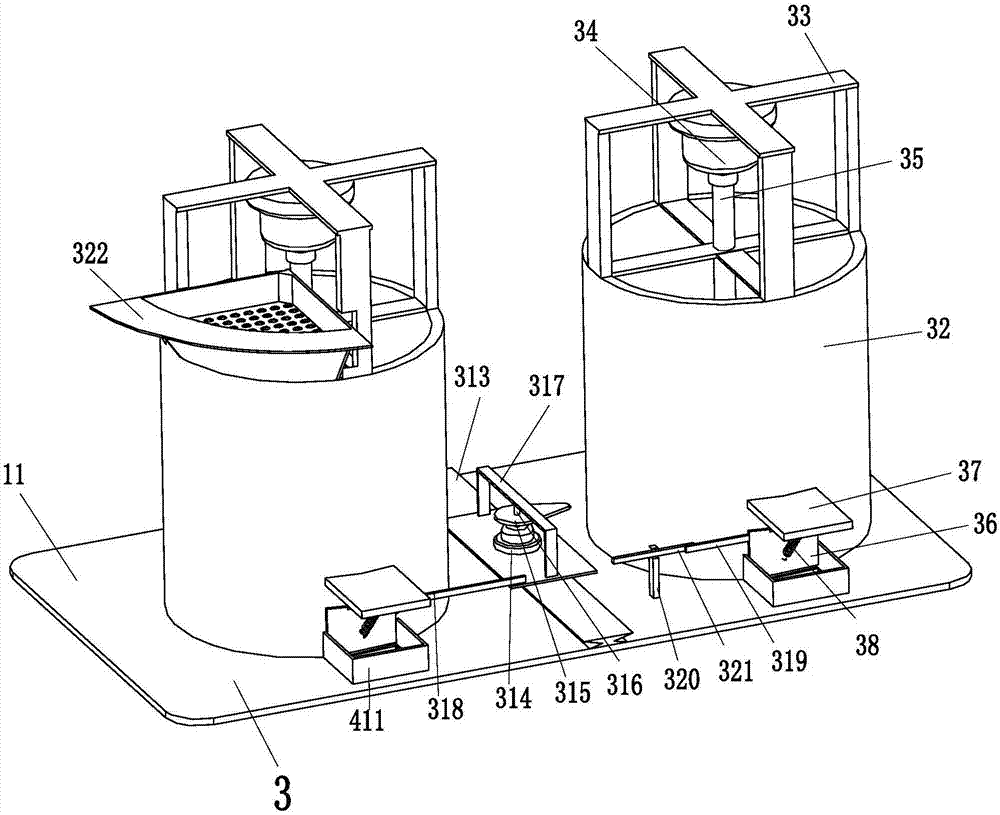

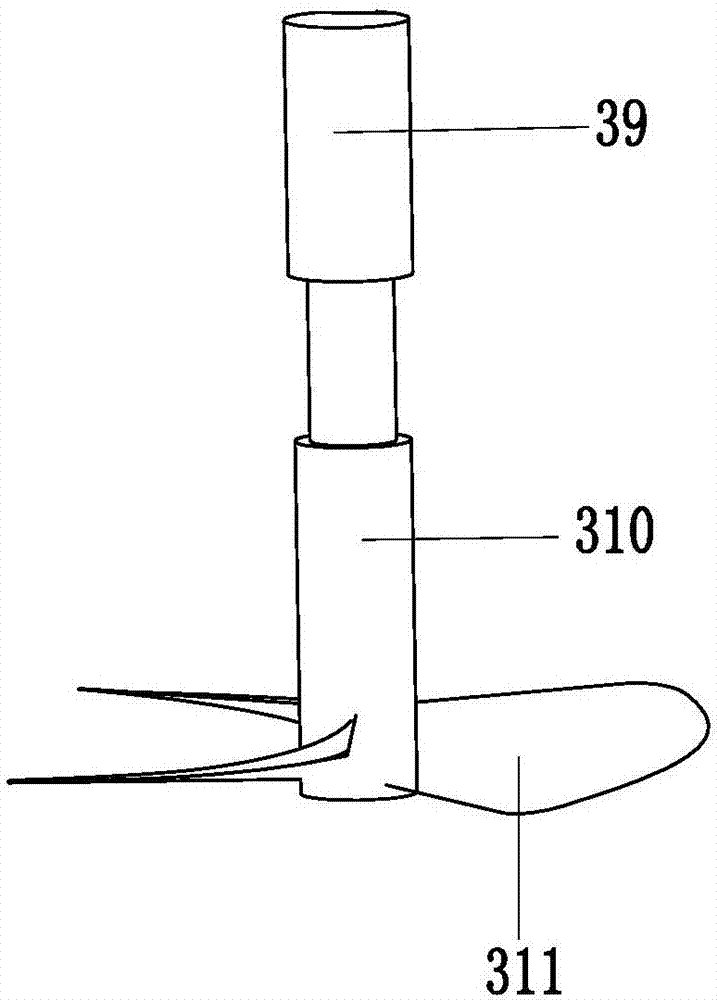

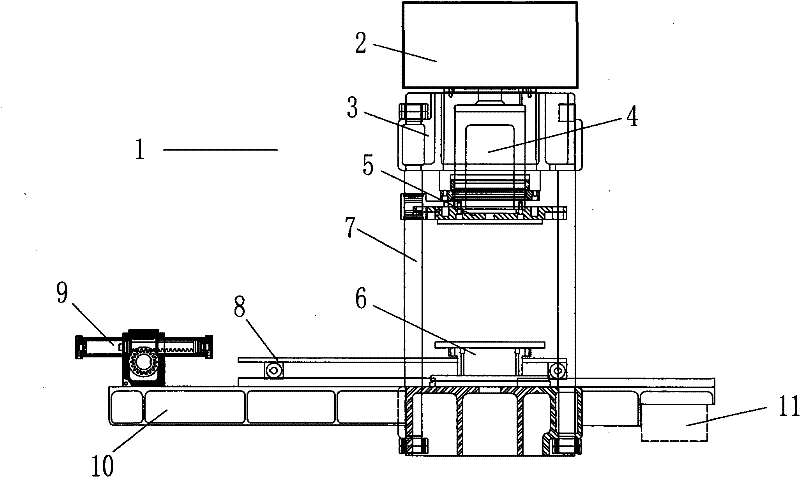

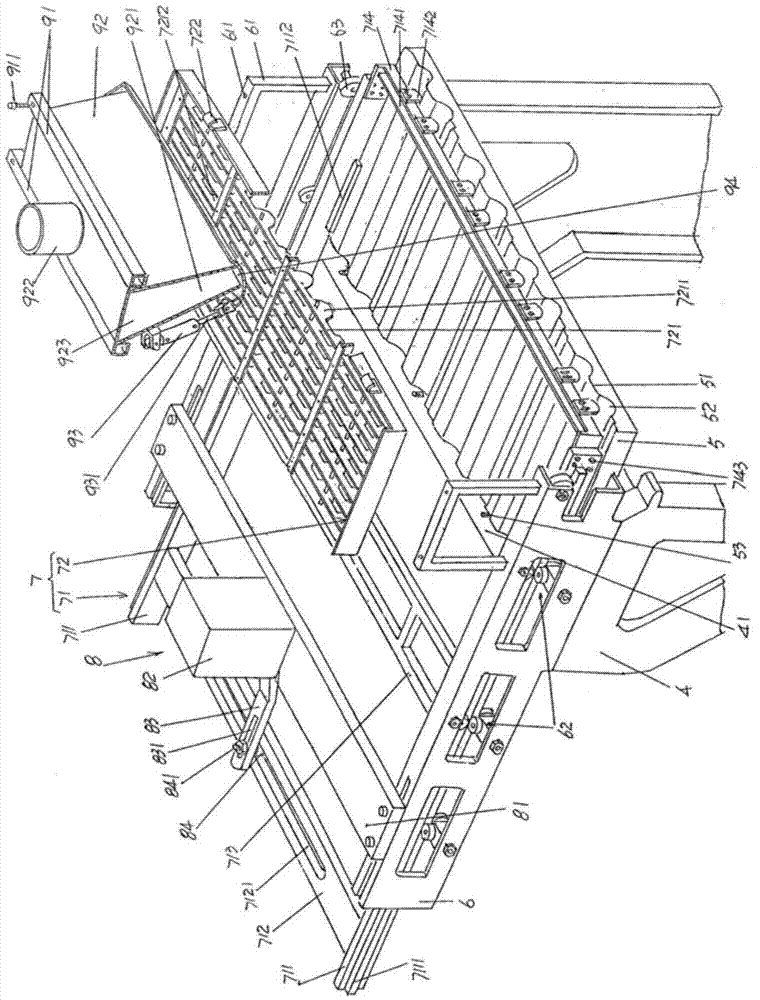

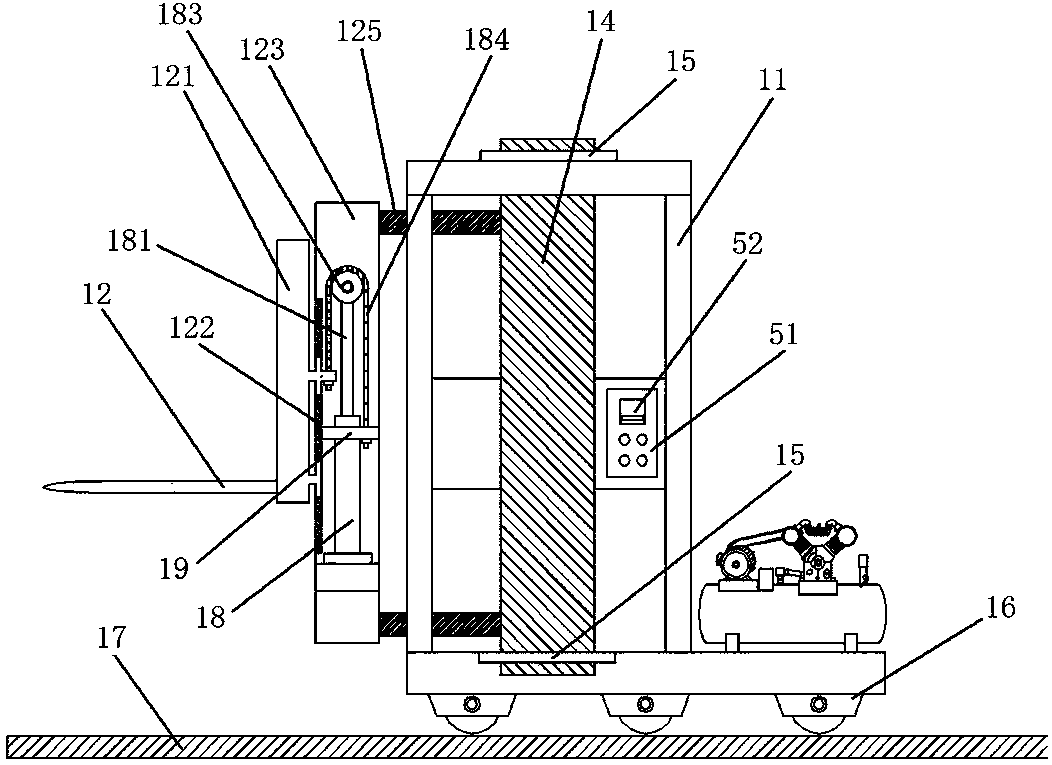

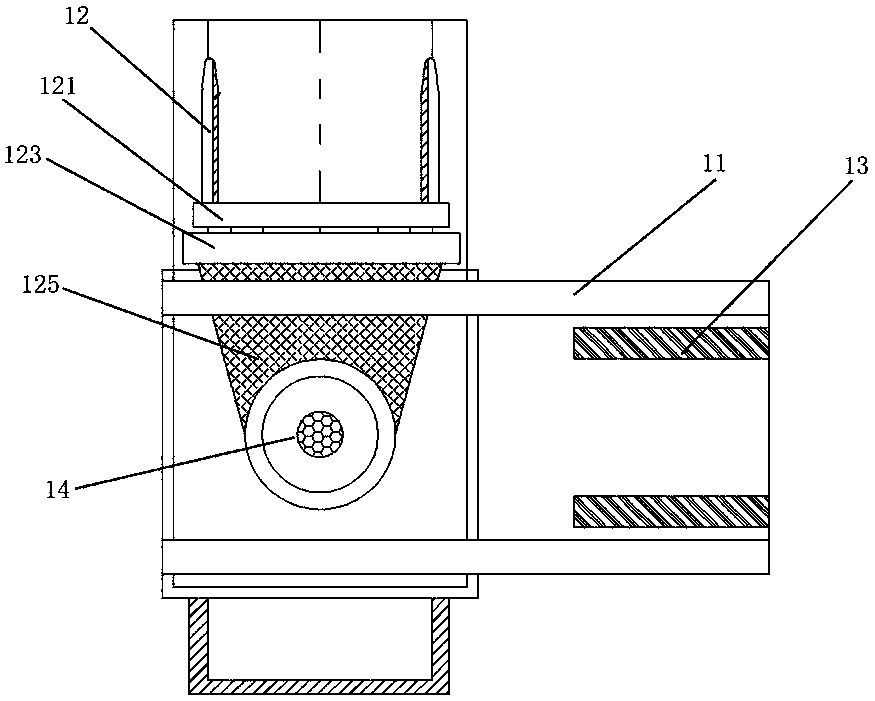

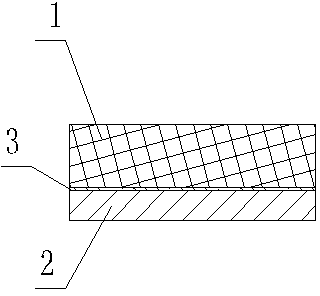

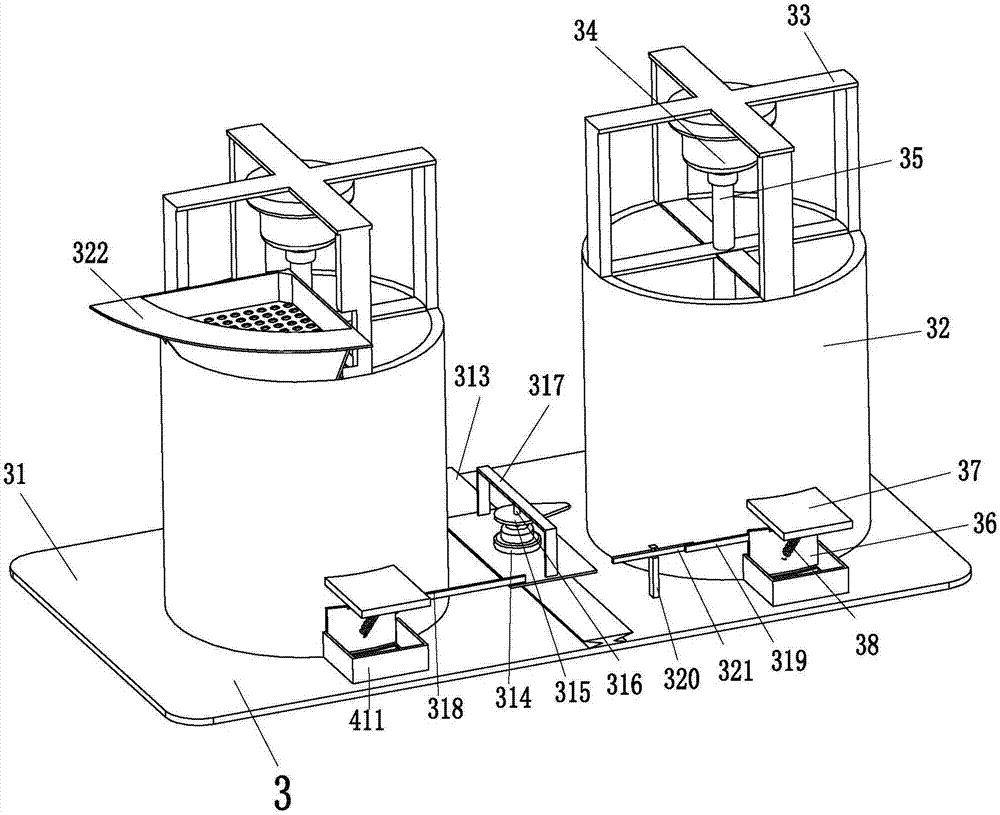

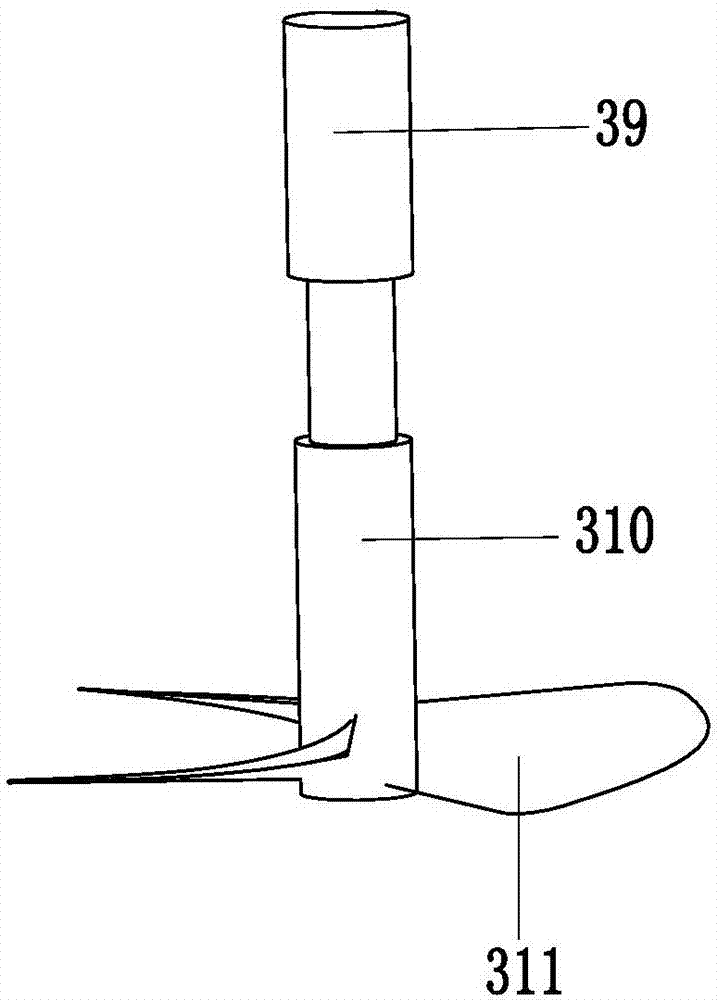

Automatic control material discharging equipment for cement tiles of building decoration materials

InactiveCN107297824AStir wellUniform automatic feedingDischarging apparatusFeeding arrangmentsAutomatic controlCement tile

The invention relates to an automatic control blanking equipment for cement tiles, a building decoration material, which includes a support device, a stirring device and an automatic blanking device. The support device includes a support plate and four support columns, the support plate is a cuboid structure, four The support column is symmetrically installed on the bottom of the support plate; the stirring device is installed on the end surface of the support plate, and the automatic unloading device is installed on the support plate. The invention can solve the existing problems of low work efficiency, high labor intensity, manual stirring of the tile base material, and manual placement of the tile base material into the mold when the cement tiles are processed and unloaded manually; The function of uniform mixing and automatic feeding of the tile base material has the advantages of high work efficiency, low labor intensity, mechanized uniform mixing of the tile base material, and mechanized automatic pressing of the tile base material into the mold.

Owner:俞樑兵

Production method of color cement tile

The invention discloses a production method of a color cement tile. The production method is characterized by comprising the following steps: preparing raw materials including sand, cement, flocculent cotton fibers and pigments; mixing and proportioning: mixing and evenly stirring the sand, the cement and the flocculent cotton fibers in a stirring container, wherein the contents of the sand, the cement and the flocculent cotton fibers account for 60%, 30% and 10% respectively, and the content of the pigments just enables the cement to show a desired color; adding water containing a coagulator to the mixture in a spraying manner during the stirring process, wherein the content of the water just enables the mixture to be pasty; preliminary forming: adding the pasty mixture to forming equipment to obtain a cement tile billet in an extrusion forming manner; and air drying: drying the cement tile billet in a ventilation environment, applying a layer of non-woven fabrics on the surface of the cement tile billet, spraying water to maintain the wetting of the surface of the cement tile billet and carrying out air drying after the consolidation forming is finished. With application of the method provided by the invention, the color cement tile with uniform color and fastness can be manufactured. In addition, the method has the advantages of short production period and simplicity and easiness in operation.

Owner:王新颖

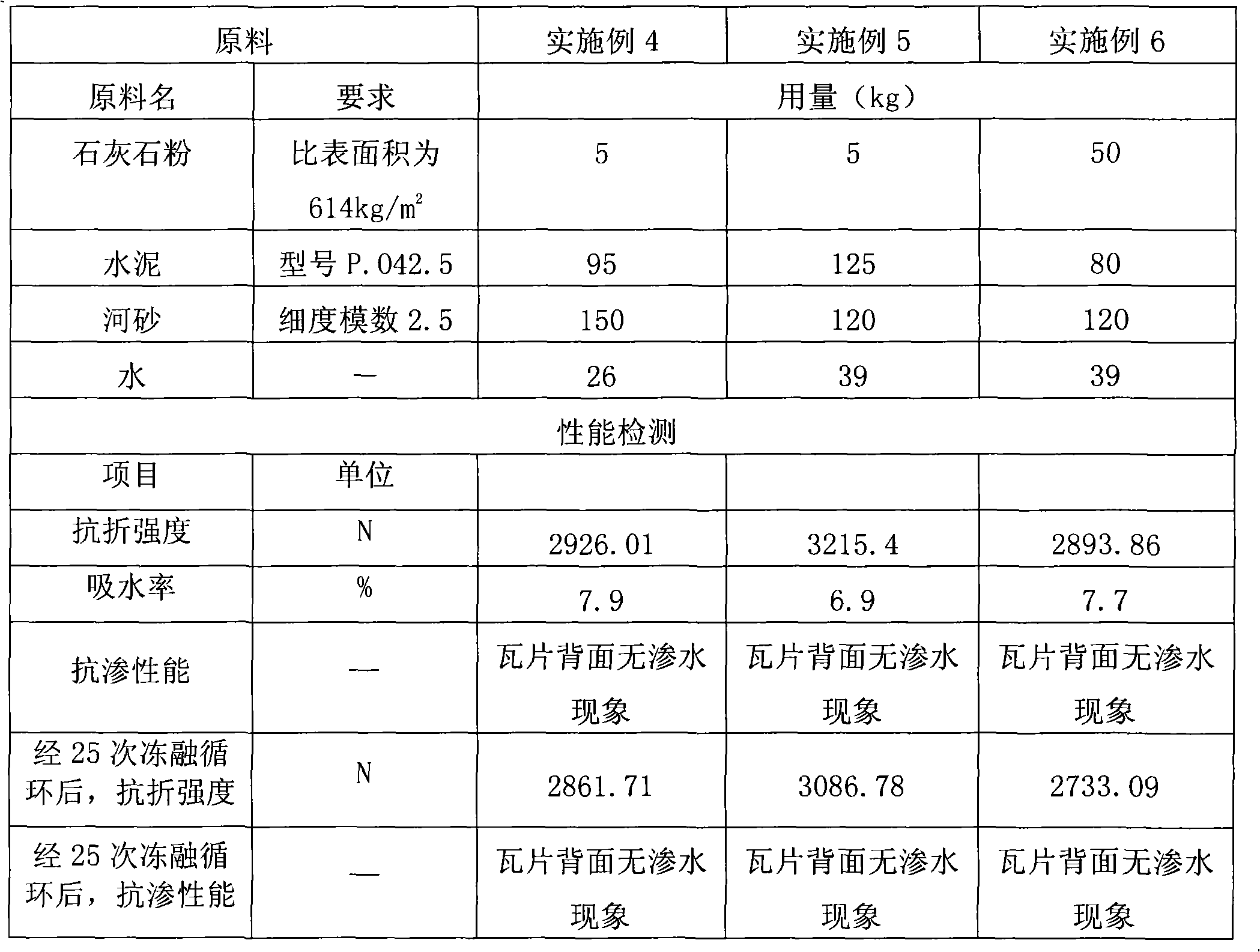

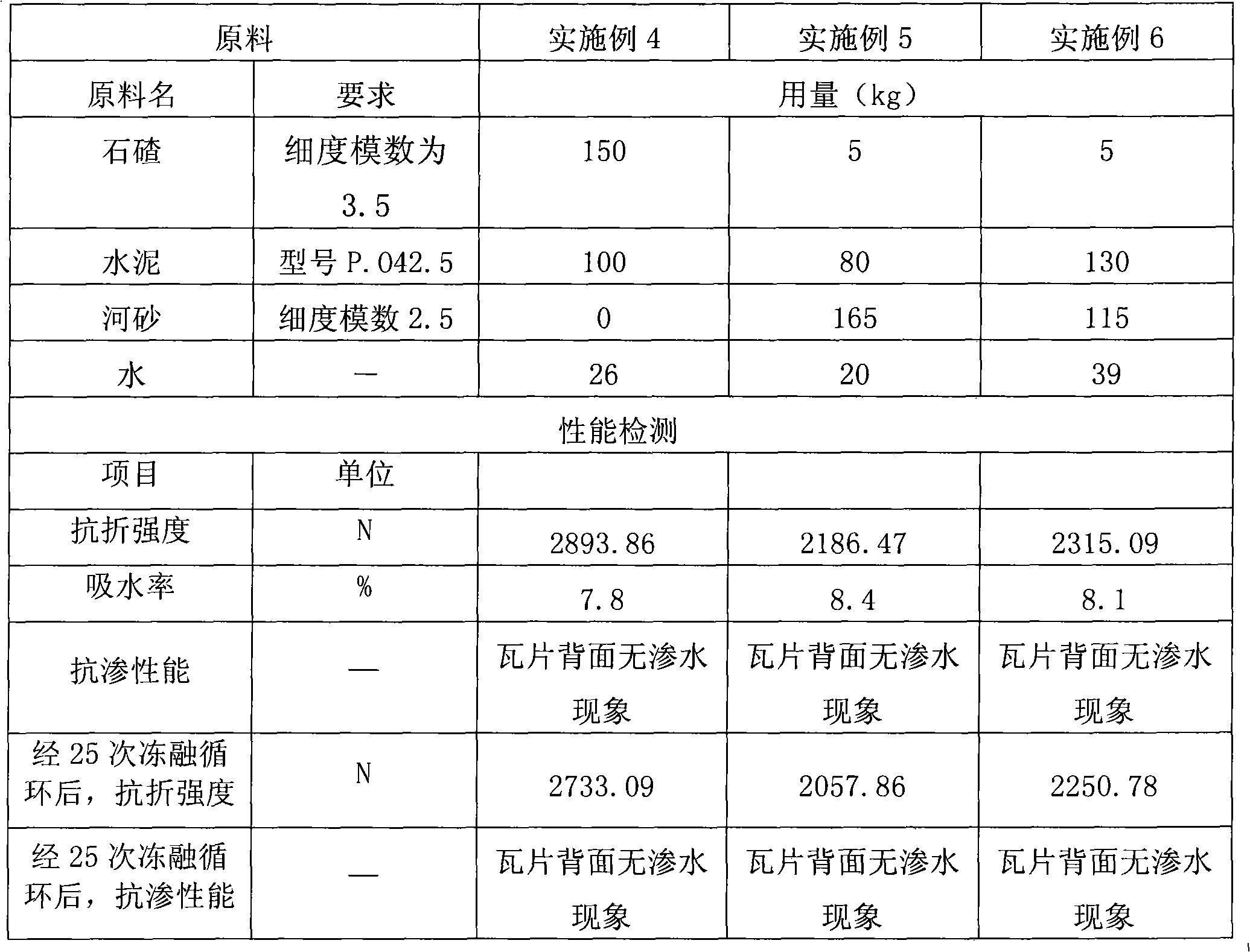

Environment-friendly cement tile mixed with limestone powder and preparation method thereof

ActiveCN101666139AReduce dosageImprove flexural strengthRoof covering using tiles/slatesMixing operation control apparatusBreaking strengthMaterials science

The invention discloses environment-friendly cement tile mixed with limestone powder and a preparation method thereof. The environmental-friendly cement tile is prepared by adding limestone powder into the raw materials of the common cement tiles, and the raw materials comprise 5 to 50 parts of limestone powder, 50 to 125 parts of cement, 120 to 170 parts of sand and 20 to 39 parts of water. Through experiments, by adding the limestone powder to the cement tiles, the breaking strength of the cement tiles is improved, and a great amount of waste limestone powder and machine-made sand powder areconsumed, thereby the waste is utilized, the resources are saved, and the environment is protected. The environmental-protection cement has a great function in the building field and wide market prospect.

Owner:CHINA BUILDING MATERIALS ACAD

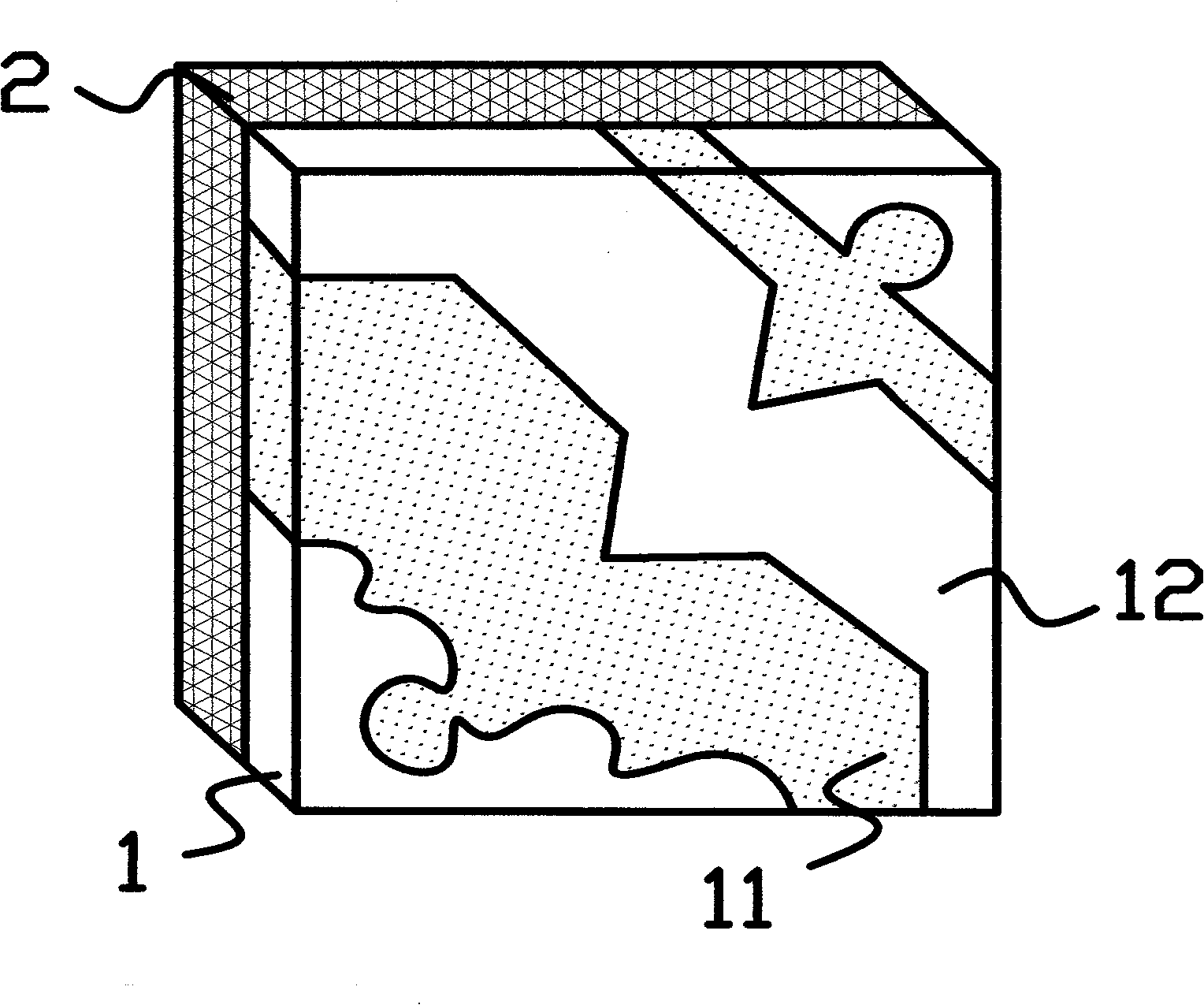

Floor tile

The invention discloses a floor tile which comprises a cement tile layer and a plastic layer. The plastic layer is bonded on the cement tile layer. The contact face of the plastic layer in contact with the cement tile layer is uneven. The plastic layer is added on a traditional cement tile, and the face of the plastic layer fixed with the cement tile layer is uneven, so that the figurability of the plastic tile is improved, and the plastic bonding performance is also improved.

Owner:WUXI CITY UNITE PETRO CHEM EQUIP

Colour cement tile coating, and its preparing process

InactiveCN1891769AEmphasis on glass transition temperatureGood weather resistanceMulticolor effect coatingsTemperature controlVitrification

The invention relates to color cement roof paint and its preparation technology. Its material constituents and weight percentages are as follows: acrylic resin 20-45%, pigment or dye 0.5-15%, auxiliary 0.1-3%, and solvent 45-78%. Its preparation technology adopts resin and paint manufacturing steps. Compared with the current technique, it emphasizes glass temperature control more to make the product have better weathering and water resistances. Thus it can be used in outdoor cement product, especially for the protection and decoration of the cement roof tile surface.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

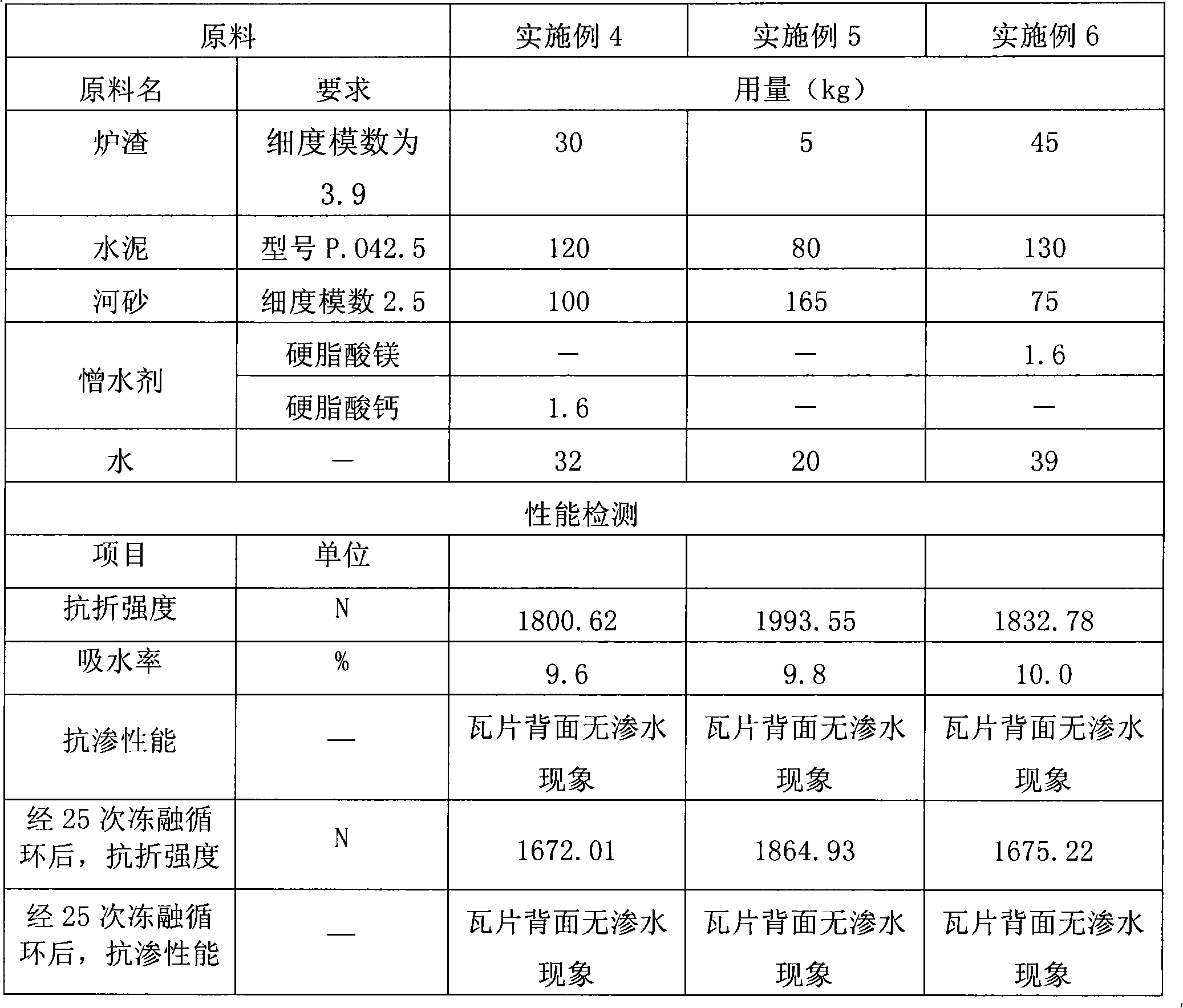

Environmental-friendly cement tile mixed with slag and preparation method thereof

ActiveCN101624855AReduce dosageSave resourcesRoof covering using tiles/slatesSolid waste managementBreaking strengthSlag

The invention discloses an environmental-friendly cement tile mixed with slag and a preparation method thereof. The environmental-friendly cement tile is prepared by adding slag on the basis of a common cement tile raw material and comprises the following raw materials: 5-60 parts of slag, 80-130 parts of cement, 75-165 parts of sand, 0-1.6 parts of water repellent and 20-39 parts of water. Tests prove that the slag added into the cement tile leads the breaking strength of the cement tile to meet the standard requirement and can consume waste residues generated after a plurality of lump coal or pea coal is burnt; and the invention utilizes the waste, saves resources and protects the environment. The invention plays an important role in the field of construction and has wide market prospect.

Owner:CHINA BUILDING MATERIALS ACAD

Process For Manufacturing Sound Absorbing Cement Tile

A continuous process for manufacturing a sound absorbing tile made from a slurry including, quick setting cement, water, fibers and foaming agent, the process including the steps of (i) mixing cementitious material, water, foaming agent but without incorporation of prefabricated foam with fibers into a slurry; subsequently; (ii) injecting and distributing air into the slurry of step (i) to form a cellular slurry; subsequently; (iii) forming tiles or precursor products of tiles from the cellular slurry; and finally; (iv) allowing the cellular slurry to set into the desired tile or a precursor thereof.

Owner:ETEX BUILDING PERFORMANCE INT SAS

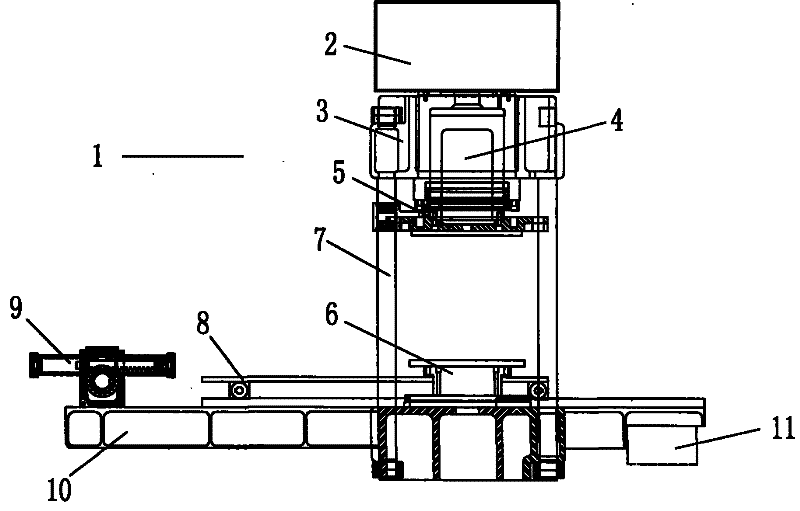

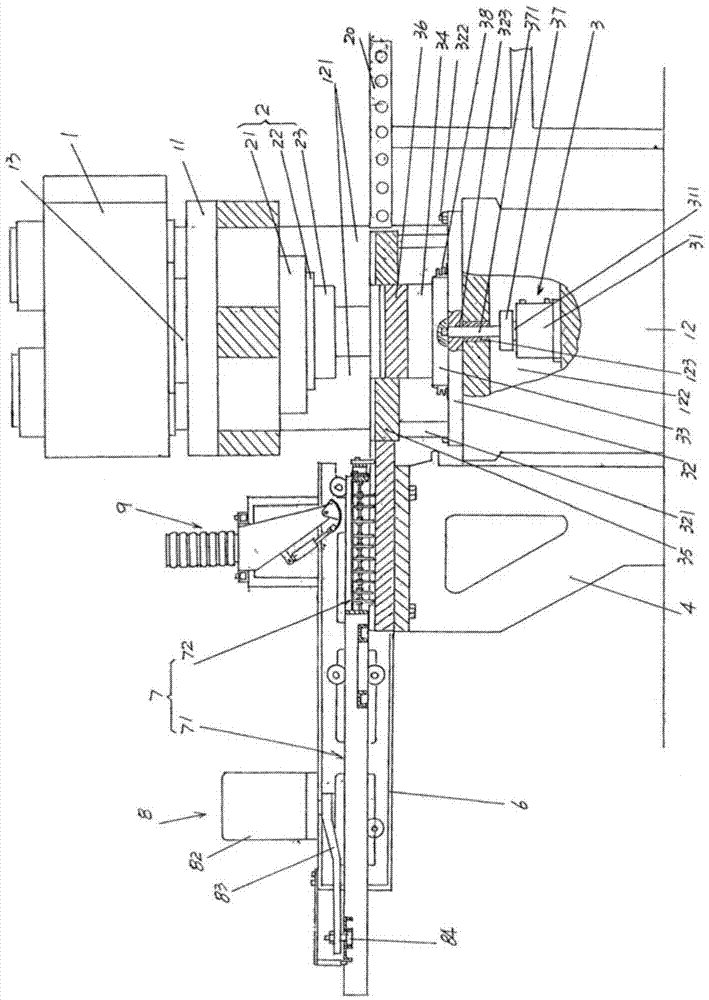

A cement tile filter press molding machine

InactiveCN102275206AReduce energy consumptionFast molding speedAuxillary shaping apparatusHigh densityMolding machine

A cement tile filter press forming machine, which is composed of a main engine and a hydraulic system. The main engine includes an oil tank, an upper mold platform, a lower mold platform and a machine base. A swing oil cylinder and a slide table are also arranged on the base. The swing oil cylinder can make The sliding table moves left and right. The cement tile filter press molding machine disclosed by the present invention has low energy consumption, and adopts mortar concrete to be formed by filter press molding. The product structure is perfect, there are many varieties, high density, high strength, and accurate size, which can meet the needs of various buildings. It is a fine product among concrete products.

Owner:常熟通江机械有限公司

Carboxyl group containing acrylic RDP and dry mix cement formulations containing them

The present invention provides water redispersible polymer powder (RDP) compositions that perform well even when redispersibility is fair comprising carboxyl group containing multi-stage acrylic copolymers having an alkali-soluble resin outer stage and one or more inner stage acrylic (co)polymer having a glass transition temperature (Tg) of from −40 to 50° C., one or more nucleating agent having a boiling point of 150° C. to 500° C., and a water solubility of 3.5% or less, preferably, an alkyl isobutyrate and a branched alkyl isobutyrate, and one or more colloidal stabilizer. Also provided are dry mix cement tile adhesive compositions comprising the water redispersible polymer powder an ordinary Portland cement, an alumina rich cement with an alumina content of from 30 wt. % to 85 wt. %, and calcium sulfate. The invention enables a broad range of the claimed acrylic polymers in useful RDPs.

Owner:DOW GLOBAL TECH LLC +1

Environmental-friendly cement tile mixed with ballast and preparation method thereof

ActiveCN101624856AReduce dosageImprove flexural strengthRoof covering using tiles/slatesSolid waste managementCement tileMaterials science

The invention discloses an environmental-friendly cement tile mixed with ballast and a preparation method thereof. The environmental-friendly cement tile is prepared by adding ballast on the basis of a common cement tile raw material and comprises the following raw materials: 5-150 parts of ballast, 80-130 parts of cement, 0-165 parts of sand and 20-39 parts of water. Tests prove that the ballast added into the cement tile not only improves the breaking strength of the cement tile, but also can consume fine chips and stone chips generated in the process of mechanically processing broken stone in a plurality of waste quarries; and the invention utilizes the waste, saves resources and protects the environment. The invention plays an important role in the field of construction and has wide market prospect.

Owner:CHINA BUILDING MATERIALS ACAD

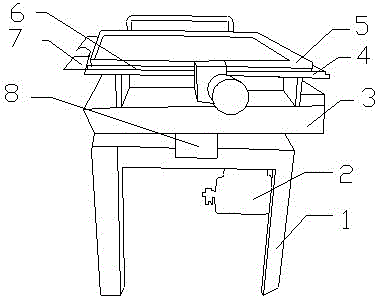

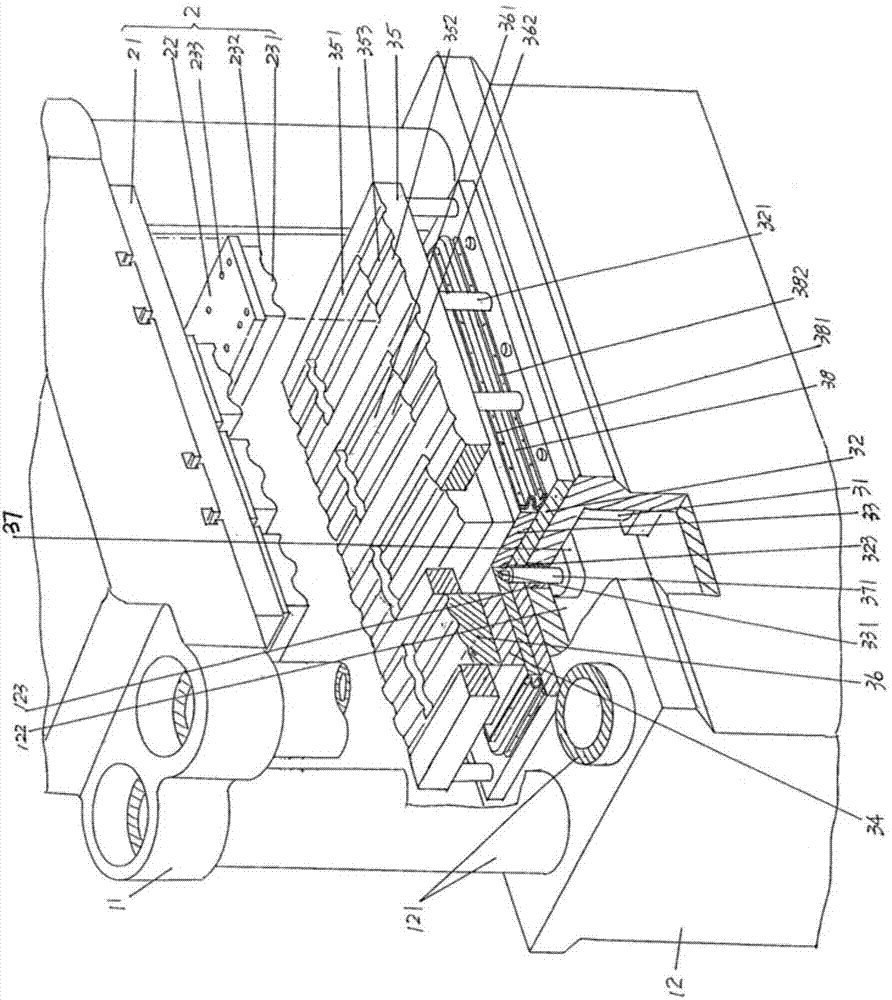

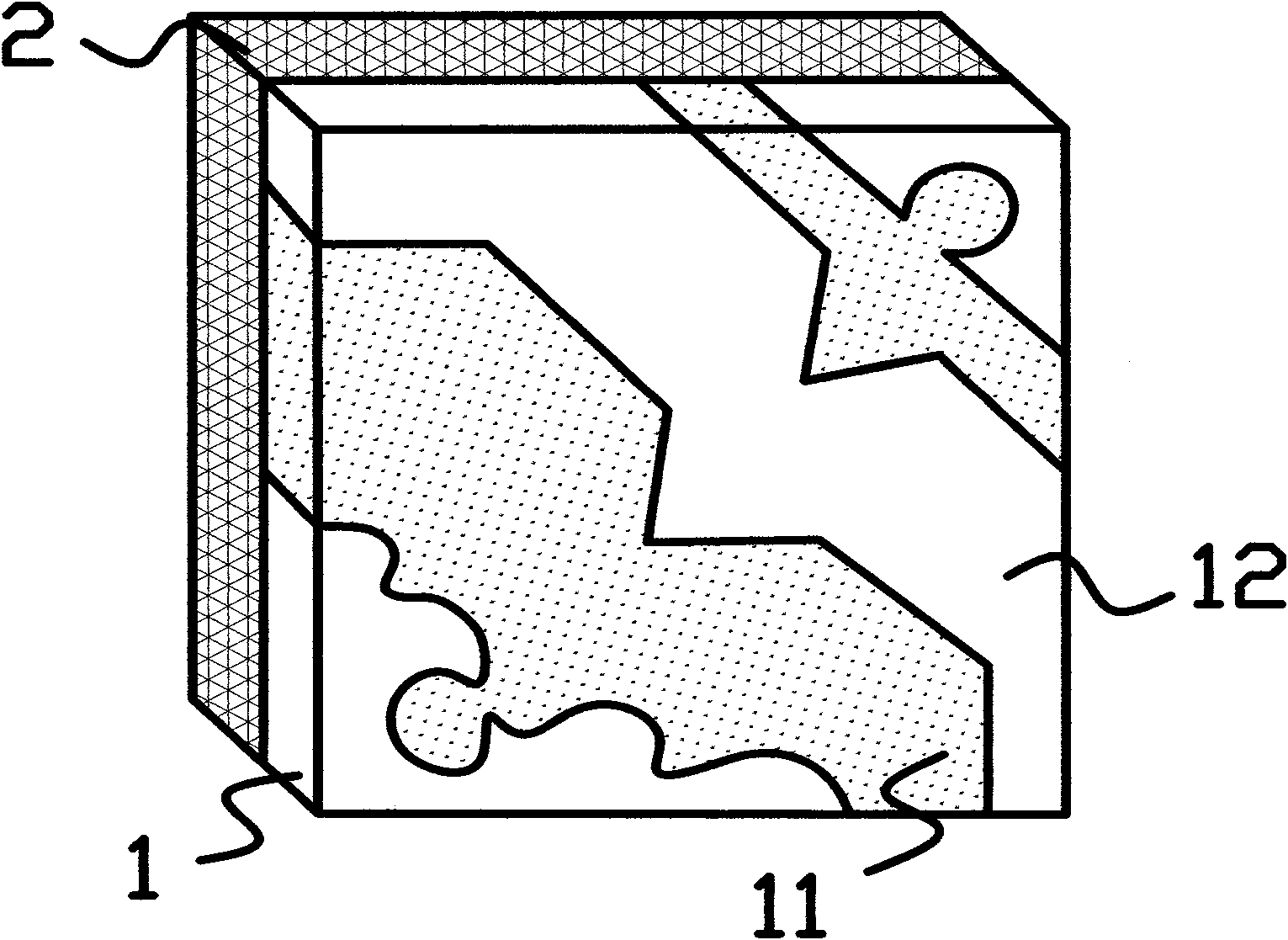

Cement tile and method and equipment for manufacturing same

InactiveCN103334546AHigh strengthLow costRoof covering using tiles/slatesSilicic acidElectric machinery

The invention discloses a cement tile, which is characterized by comprising the following components in parts by weight: 50 parts of common silicic acid cement, 150 parts of coarse sand, 1 part of dye and water in balancing amount. The dye comprises any one or combination of ferric oxide dyes and ultramarine mineral dyes, and the common silicic acid cement is common cement in serial number of P. 032.5 or P. 042.5. Equipment for manufacturing the cement tile comprises a machine base, an electric motor, an electric motor switch, a vibration groove plate, a material vibration module, a material clamping frame, a deformation plate and a deformation tile module, and is characterized in that the deformation tile module is formed by deforming a steel plate in thickness of 0.88 mm; the electric motor is a single-phase electric motor with power of 0.75 kW-1.1 kW; the size of the deformation tile module is equal to that of the material clamping frame. A method for manfufactruing the cement tile is characterized by comprising the steps of slurry preparation, vibration, formation and maintenance, the steps are simple and less. The cement tile provided by the invention is high in density and low in water absorption, can save material for building construction, and is simple in manufacturing process and production equipment.

Owner:杨朝阳

Cementitious tile adhesives and method of applying the same to a tile substrate

ActiveUS20120318434A1Superior water immersion shear strength shear strengthIncreased shear strengthLiquid surface applicatorsCovering/liningsCellulosePolymer science

Cement tile adhesives and methods for using them, the adhesives comprising a dry mix of a water-redispersible polymer powder made from a low carboxylation, large particle size water-soluble film-forming vinyl aromatic-diene copolymer latex and a reduced amount of cellulose ether exhibit superior water immersion shear strength and freeze / thaw shear strength.

Owner:DOW GLOBAL TECH LLC

Preparation method of glazed ceramic tile and molding device used in the method

ActiveCN103538141BReduce weightImprove viewing effectRoof covering using tiles/slatesFeeding arrangmentsWeather resistanceGlaze

Owner:常熟大象建陶有限公司

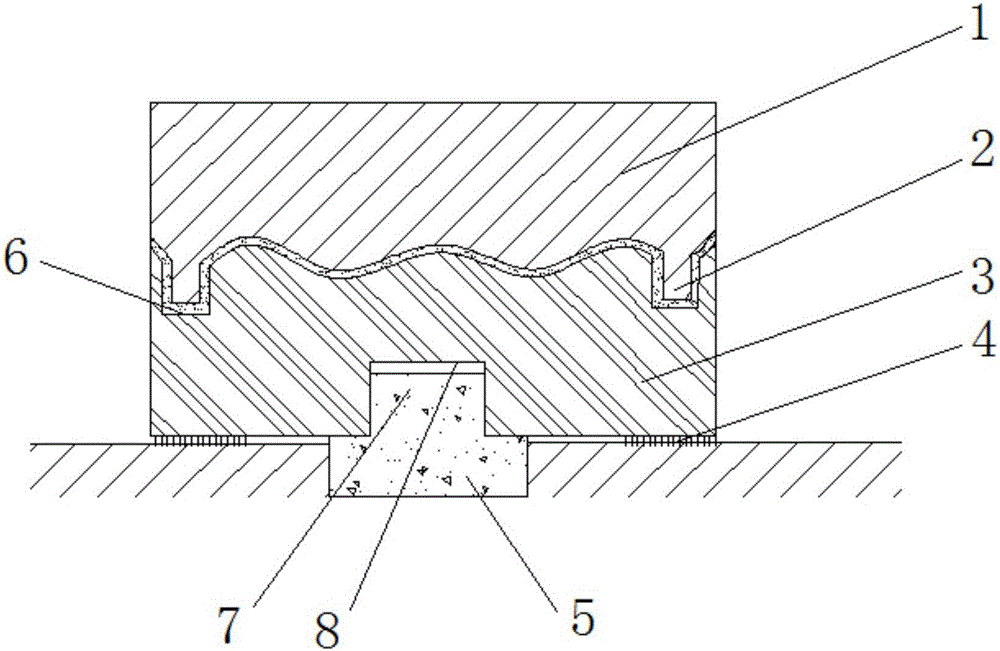

Antiskid floor tile

The invention relates to an antiskid floor tile which comprises a base body fixed on the ground, a cement tile layer and a plastic layer, wherein the cement tile layer sleeves the base body; the plastic layer is adhered to the cement tile layer; a bulge is arranged on the upper end face of the base body; and a groove matched with and connected with the boss in a clamping manner is formed in the lower end face of the cement tile layer. Preferably, a contact surface between the plastic layer and the cement tile layer is an uneven curved surface; since the uneven contact surface is adopted between the plastic layer and the cement tile layer, a bonding surface is increased, bonding strength is improved, the antiskid floor tile is convenient to pave since the antiskid floor tile can be paved by adopting a conventional cement brick paving manner and the effects of the antiskid floor tile are the same as that of a plastic floor tile. Since the cement tile layer sleeving the base body and the plastic layer are adopted, replacement is convenient and rapid, settability of the floor tile can be improved, further bonding performance of plastic is improved and an antiskid effect is good.

Owner:腾志理

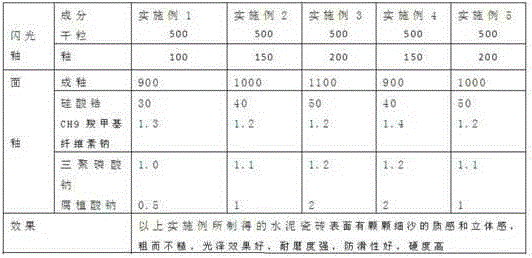

Cement tile

The present invention provides a cement tile. The cement tile is characterized in that the cement tile is obtained according to the following method. The method comprises the following steps: covering a cement body with overglaze, then spraying dry granular glaze by using a glaze spraying cabinet, firing and processing to obtain the cement tile, wherein the dry granular glaze comprises 500 parts of dry granular and 100-200 parts of glaze by weight. Compared with the prior art, the cement tile provided by the present invention has the advantages that the surface has the texture and stereoscopic feeling of fine sands, and is rough but not coarse, excellent in luminous effect, high in wear resistance, high in slip resistance and high in hardness.

Owner:广东博华陶瓷有限公司

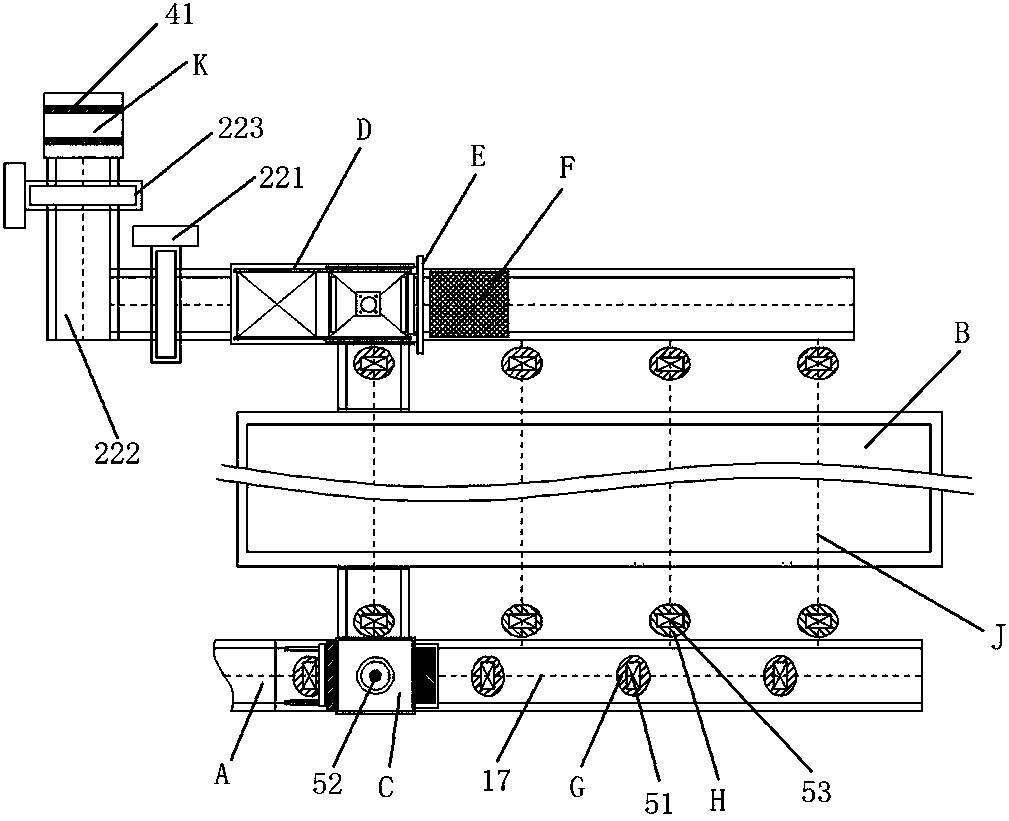

Cement green brick curing and stacking production line

PendingCN107914334APalletizingRealize one machine multi-point continuous change direction conveyingCeramic shaping plantsProduction lineBrick

The invention belongs to the technical field of baking-free brick production equipment, and particularly relates to a cement green brick curing and stacking production line. According to the main technical scheme of the cement green brick curing and stacking production line, the cement green brick curing and stacking production line comprises a turning conveying device arranged between a green brick conveying belt and a curing shed inlet, a cement brick stacking device arranged at a curing shed outlet, and a green brick tray overturning device; the turning conveying device is mainly composed of a rack with a power rotation shaft, a lifting fork driven by the power rotation shaft, and a bearing arm arranged at the other end of the rack; the cement brick stacking device comprises a frame with the bottom provided with a cement brick initial platform and a stacking platform, and the upper portion of the frame is provided with a guide rail for the transverse movement of a vertical telescopic mechanical arm; the green brick tray overturning device mainly comprises a frame body and a horizontal overturning platform which is arranged at the upper portion of the frame body and can fix a tray. The cement green brick curing and stacking production line has the beneficial effects of being reasonable in structure layout, compact in link linkage and high in production efficiency.

Owner:张青云

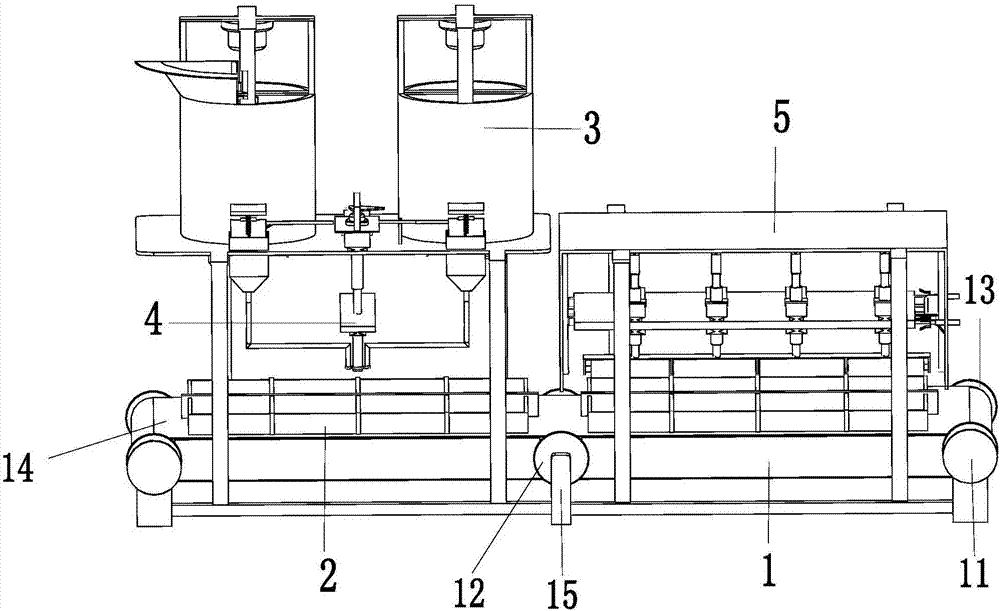

Manual cement tile

InactiveCN102213030AHigh strengthTo achieve personalized special decorative art effectFlooringSurface layerPortland cement

The invention provides a manual cement tile and relates to the technical field of building decoration materials. The manual cement tile comprises a surface layer mixed material and a bottom layer mixed material and is characterized in that: the surface layer mixed material is prepared by uniformly stirring 20 to 35 percent of natural river sand, 55 to 75 percent of colored cement, 5 to 10 percent of water and 0.1 to 0.8 percent of water-soluble antalkaline; and the bottom layer mixed material is prepared by uniformly stirring 50 to 70 percent of yellow sand, 20 to 40 percent of portland cement, 4 to 8 percent of water and 0.3 to 0.12 percent of water-soluble antalkaline. The manual cement tile is prepared by the following steps of: uniformly placing the bottom layer mixed material and the surface layer mixed material into a mould sequentially; performing mechanical extrusion forming; and demoulding, convalescing, stacking and curing. The invention has the advantages that: the manual tile is prepared by integrally extruding the surface layer mixed material and the bottom layer mixed material with different decorative patterns by a simple mechanical extrusion method, is durable in use and has a good decorative effect.

Owner:柯海艇

High-molecular, transparent and colorful self-adhesive coiled material and production process thereof

InactiveCN105924885AHigh transparencyAging resistantLaminationLamination apparatusEpoxyAsphalt shingle

The invention discloses a high-molecular, transparent and colorful self-adhesive coiled material and a production process thereof. The self-adhesive coiled material comprises the following raw materials in parts by weight: 15-30 parts of butyl-reclaimed rubber, 1-8 parts of EVA, 1-8 parts of epoxy, 1-8 parts of SBS-1401 and 45-60 parts of C5 hydrogenated petroleum resin. The raw materials, after being weighed according to the parts by weight, are evenly stirred in a container; the self-adhesive coiled material is obtained after the primary and secondary hot melt vertical compression. The self-adhesive coiled material has the advantages of high transparency, thermal insulation, ageing resistance and high adhesion, can effectively reduce roof temperature and production cost, and is conducive to environment protection; the self-adhesive coiled material can withstand the temperature as high as 110 DEG C; the bonding strength is larger than 1.5 N / mm; and the self-adhesive coiled material remains flexible at the temperature below minus 20 DEG C, and has excellent practicability and high temperature resistance. The self-adhesive coiled material has the appearance effect of asphalt shingle, concrete tile, terracotta and metal tile, and is compatible with different outer wall colors and styles, highly three dimensional, and rich in style and color.

Owner:GUIZHOU SHENGYUAN WATERPROOF MATERIAL

Floor tile

The invention discloses a floor tile which comprises a cement tile layer and a plastic layer. The plastic layer covers the cement tile layer. The cement tile layer and the plastic layer are fixedly connected. The plastic layer is added on a traditional cement tile and seeps into the cement tile, the figurability of the plastic tile is improved, and the plastic bonding performance is also improved.

Owner:WUXI CITY UNITE PETRO CHEM EQUIP

Automatic unloading and rolling former for building decorative material designed cement brick

InactiveCN107322756AEasy to take outImprove work efficiencyDischarging arrangementDischarging apparatusBrickMaterial Design

The invention relates to an automatic blanking and rolling forming machine for building decoration materials, cement tiles, which includes a conveying support device, a formwork device, a stirring device, an automatic unloading device and a vibrating rolling device. The formwork device is placed on the conveying support On the device, the stirring device is installed on the left side of the conveying support device, the automatic unloading device is installed on the stirring device, and the vibrating rolling device is installed on the conveying support device. The invention solves the problems of low work efficiency in the existing manual processing of cement tiles, the need to manually stir and cut the tile base material, manually vibrate and roll the tile base material, and take out the cement tiles from the mold after processing. It is very difficult and other problems; it can realize the functions of controlling the automatic blanking of the tile base material and automatically vibrating and rolling the tiles when processing the tiles. It has high work efficiency, mechanized stirring and cutting of the tile base material, and mechanized vibration of the cement tiles. It has the advantages of rolling and cement tiles, which are easy to take out from the mold after processing.

Owner:俞樑兵

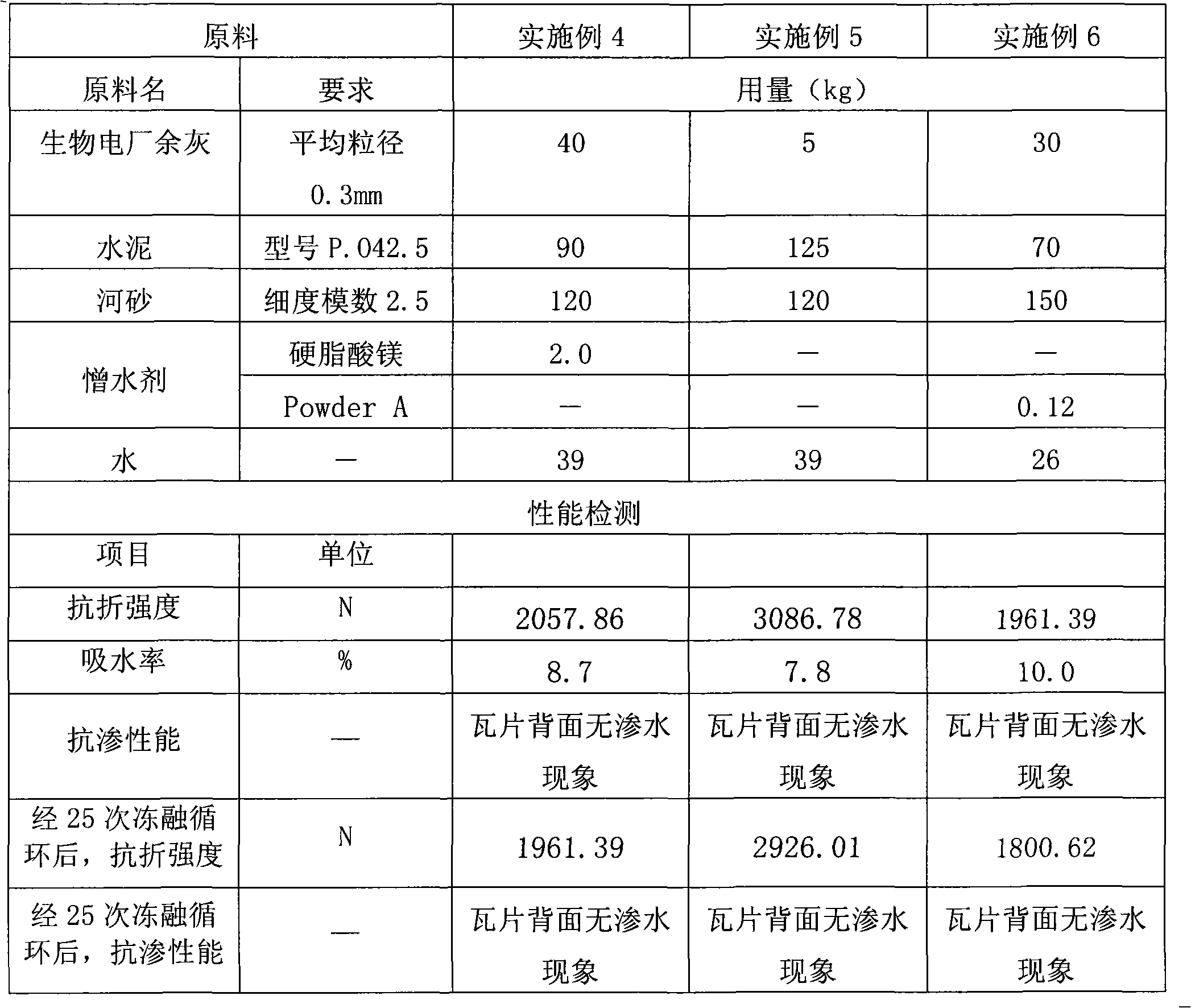

Environmental-friendly cement tile mixed with biological power plant residual dust and preparation method thereof

ActiveCN101624857AReduce dosageSave resourcesRoof covering using tiles/slatesSolid waste managementCement tileWater repellent

The invention discloses an environmental-friendly cement tile mixed with biological power plant residual dust and a preparation method thereof. The environmental-friendly cement tile is prepared by adding biological power plant residual dust on the basis of a common cement tile raw material and comprises the following raw materials: 5-40 parts of biological power plant residual dust, 50-125 parts of cement, 120-170 parts of sand, 0-2.0 parts of water repellent and 20-39 parts of water. Tests prove that the residual dust added into the cement tile leads the breaking strength of the cement tile to meet the standard requirement and can consume dust removal residues of a plurality of waste heat power plants; and the invention utilizes the waste, saves resources and protects the environment. The invention plays an important role in the field of construction and has wide market prospect.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com