Cement green brick curing and stacking production line

A production line and cement brick technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of unsatisfactory market promotion and application, low integration of water conveying chain, high price, etc., to facilitate packaging and transportation. , The effect of good intelligence and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

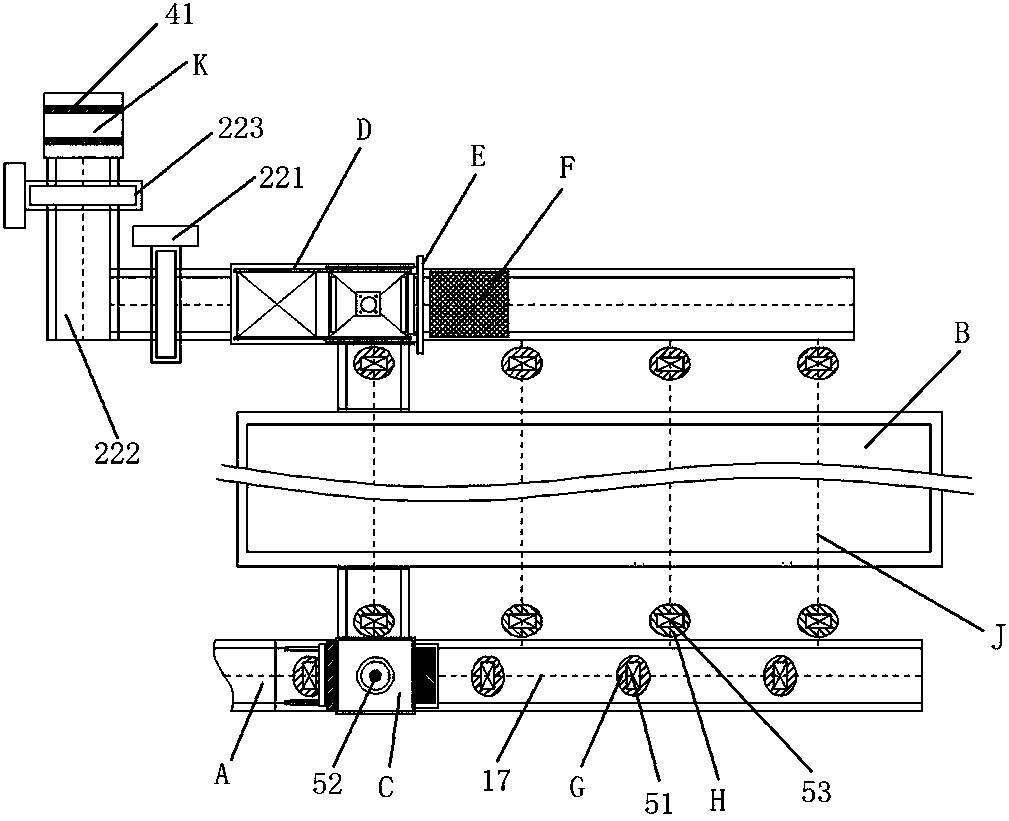

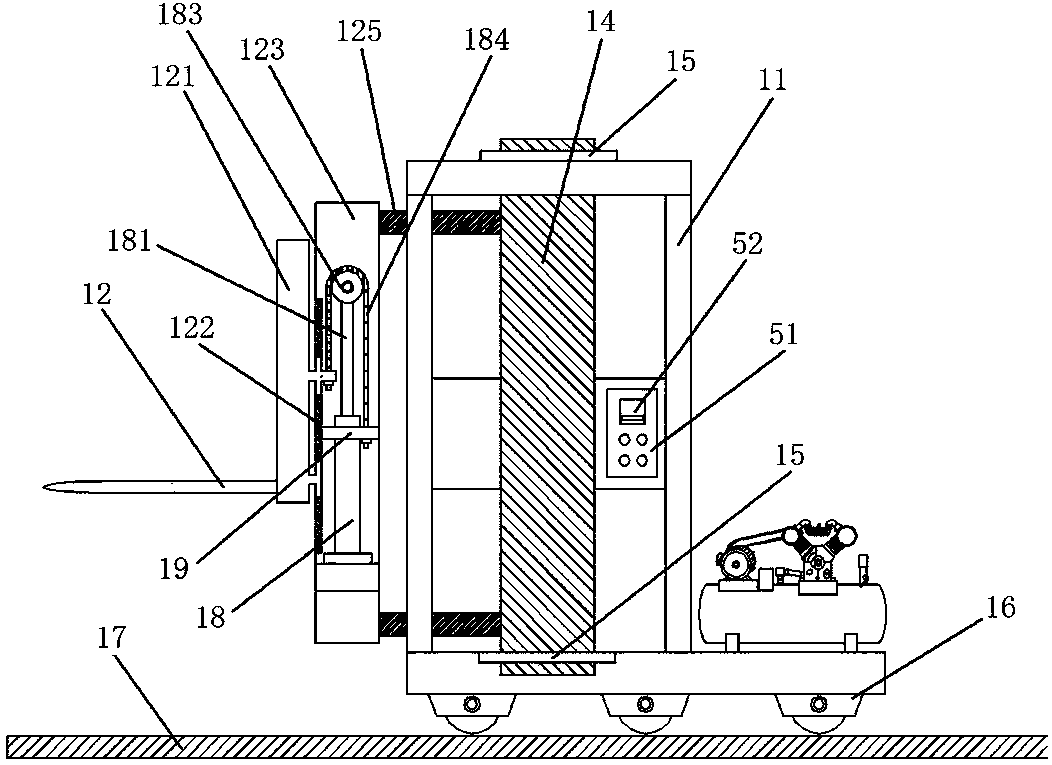

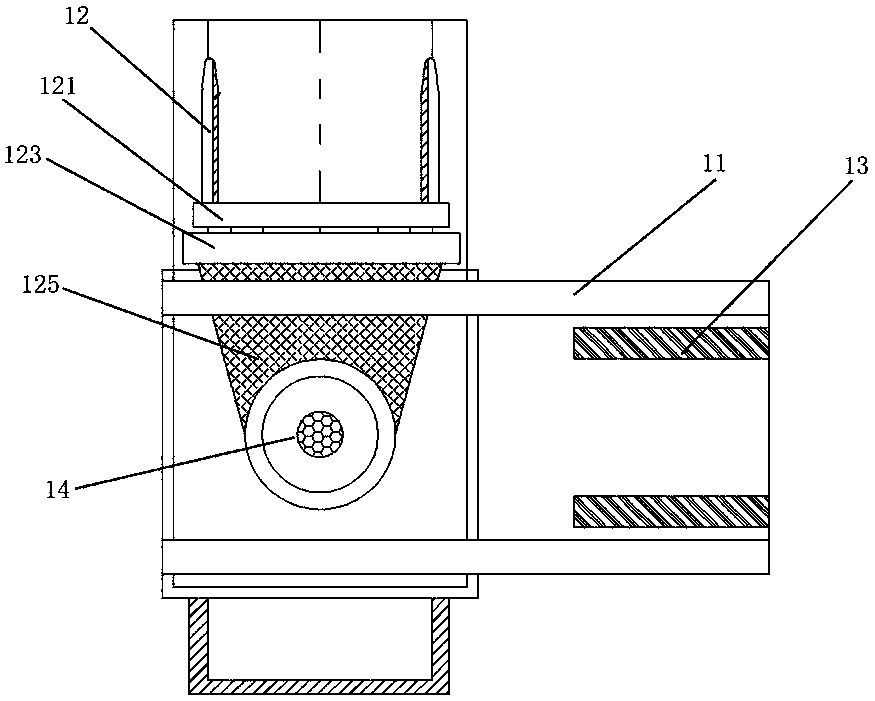

[0032] The structure and working principle of a cement brick adobe curing and stacking production line provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] Such as Figures 1 to 9 Shown is a structural schematic diagram of a cement brick adobe curing and stacking production line provided by the present invention. The structure constituting the production line includes a reversing conveying device C arranged between the adobe conveyor belt A and the entrance of the curing shed B, a cement brick palletizing device D and an adobe tray turning device E arranged at the exit of the curing shed B, wherein,

[0034] The direction-changing transmission device C is mainly composed of a frame 11, a rotatable lifting fork 12 arranged at one end of the frame 11, and a receiving arm 13 arranged at the other end of the frame 11, wherein the lifting fork 12 is arranged on the The power shaft 14 inside the frame 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com