Logistics tray, reverse stacking machine and stacking method

A pallet and logistics technology, which is applied to the stacking of objects, conveyor control devices, packaging, etc., can solve problems such as smashing, inability to manage pallets, easy dumping, etc., to achieve the effect of ensuring safety and preventing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

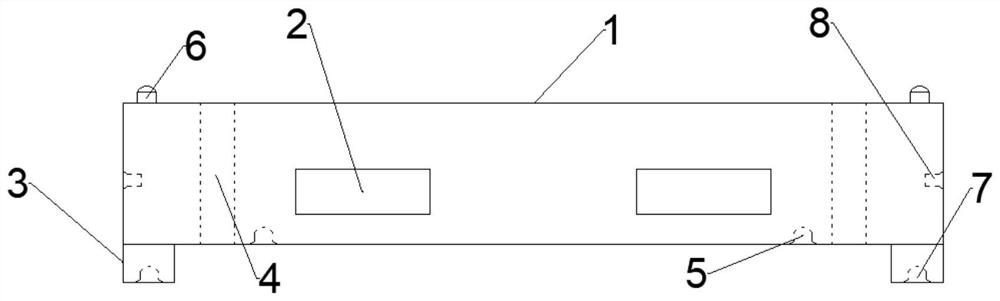

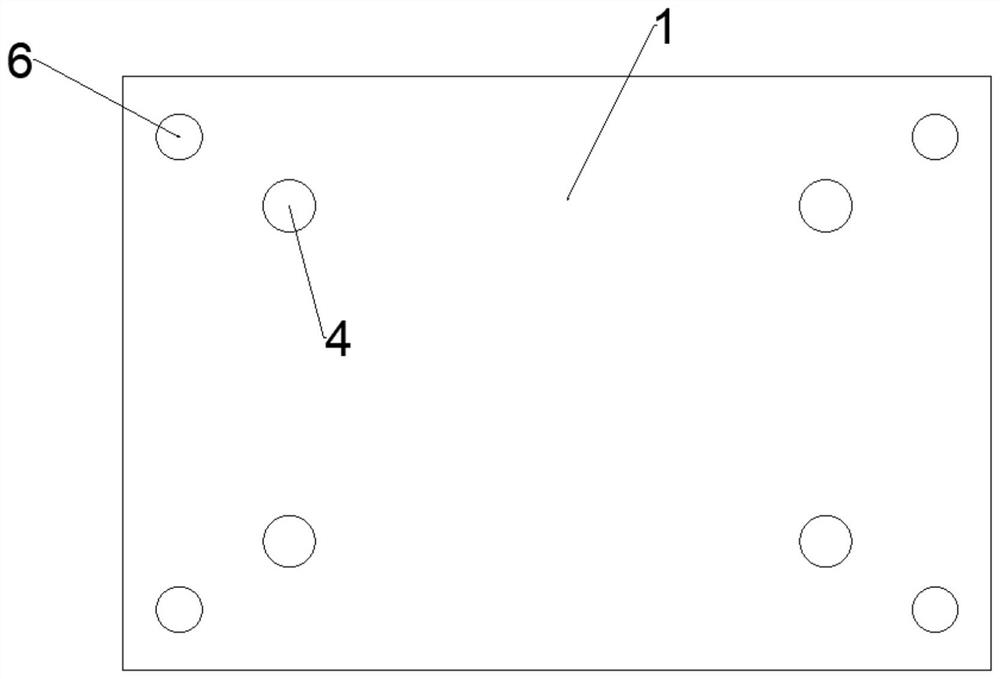

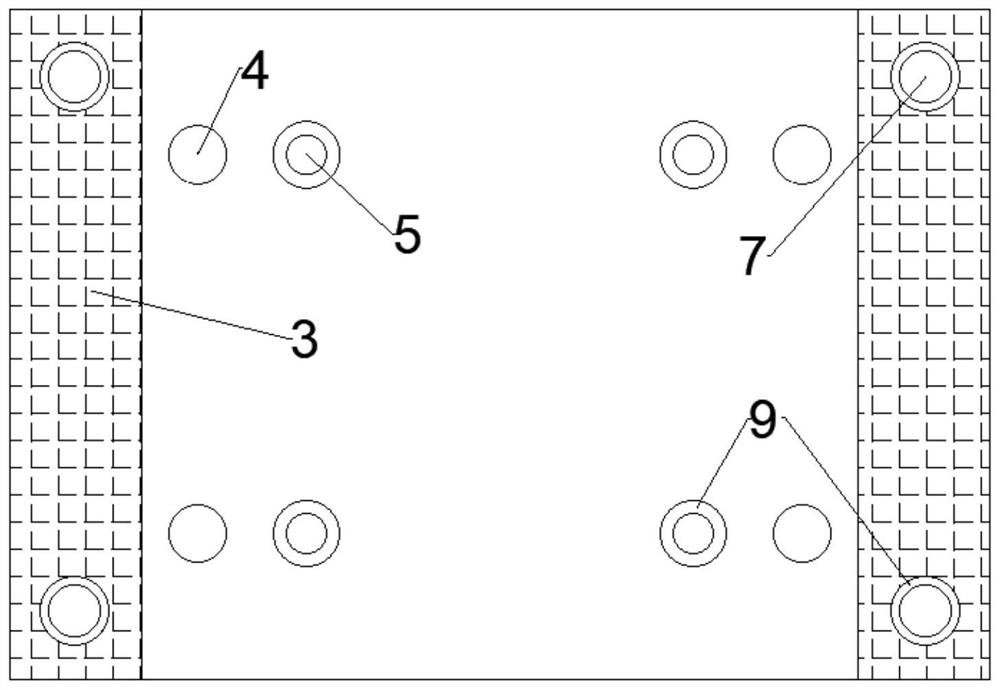

[0040] A logistics pallet, such as Figure 1-4 As shown, it includes a cube-shaped tray body 1, the edges of both sides of the lower end surface of the tray body 1 are provided with limiting blocks 3, and the front and rear parts of the bottom of the limiting block 3 are respectively provided with first positioning holes 7, On the upper surface of the tray body 1 opposite to the first positioning hole 7, a first positioning column 6 is provided, and the first positioning hole 7 is used in conjunction with the first positioning column 6, and is used for stacking up and down between the tray bodies 1 Positioning, the tray body 1 is also provided with at least two guide holes 4 that run through the upper and lower end surfaces, and second positioning holes 8 are respectively provided on both sides of the tray body 1, and the front and rear ends of the tray body 1 are also Slots 2 for inserting forklift arms are respectively provided, and the front and rear slots 2 can pass throug...

Embodiment 2

[0043] Please refer to Figure 1-8 Shown:

[0044] A kind of reverse stacking machine, comprises workbench 10, the supporting box body 11 that is fixedly arranged on the lower end of workbench 10, is fixedly arranged on the upper surface of workbench and is opposite to support box body 11 palletizing warehouse 12, described code The bottom of the front end of the stacking bin 12 is provided with a tray input port 17, and the left and right ends of the tray input port 17 are respectively provided with a limit chute 18 extending in the stacking bin along the front and rear directions. 18 is used in conjunction with the limit block 3, and the depth of pallet insertion is limited by the block fixed at the rear end of the limit chute 18, and a through support box is provided on the workbench between the opposite surfaces of the two limit chutes 18 The opening of the body 11, the support box is provided with a controller and a lifting device, and the lower surface of the top plate ...

Embodiment 3

[0051] The difference between this embodiment and embodiment 2 only lies in:

[0052] Such as Figure 7 As shown, a warning mechanism is also provided below the top plate 26, and the warning mechanism includes a horizontal plate 27, and the guide rod can slide through the horizontal plate 27, and the upper surface of the horizontal plate 27 passes through multiple An elastic expansion part is connected with the lower surface of the top plate 26, and the elastic expansion part includes a first sleeve 28 fixedly arranged on the lower surface of the top plate 26, a second sleeve 29 arranged on the upper surface of the horizontal plate 27, and the first sleeve 29 fixed on the upper surface of the horizontal plate 27. The lower end of the second casing 29 is fixedly connected to the upper surface of the horizontal plate 27, the second casing 29 is slidably sleeved in the first casing, and the top of the second casing is connected to the lower surface of the top plate in the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com