A palletizing conveyor belt for sludge brick production

A technology for making bricks and conveyor belts from sludge, which is applied in the production of conveyors, conveyor objects, ceramic materials, etc. It can solve the problems of inability to layer and achieve the effect of simple structure and conducive to stacking and stacking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

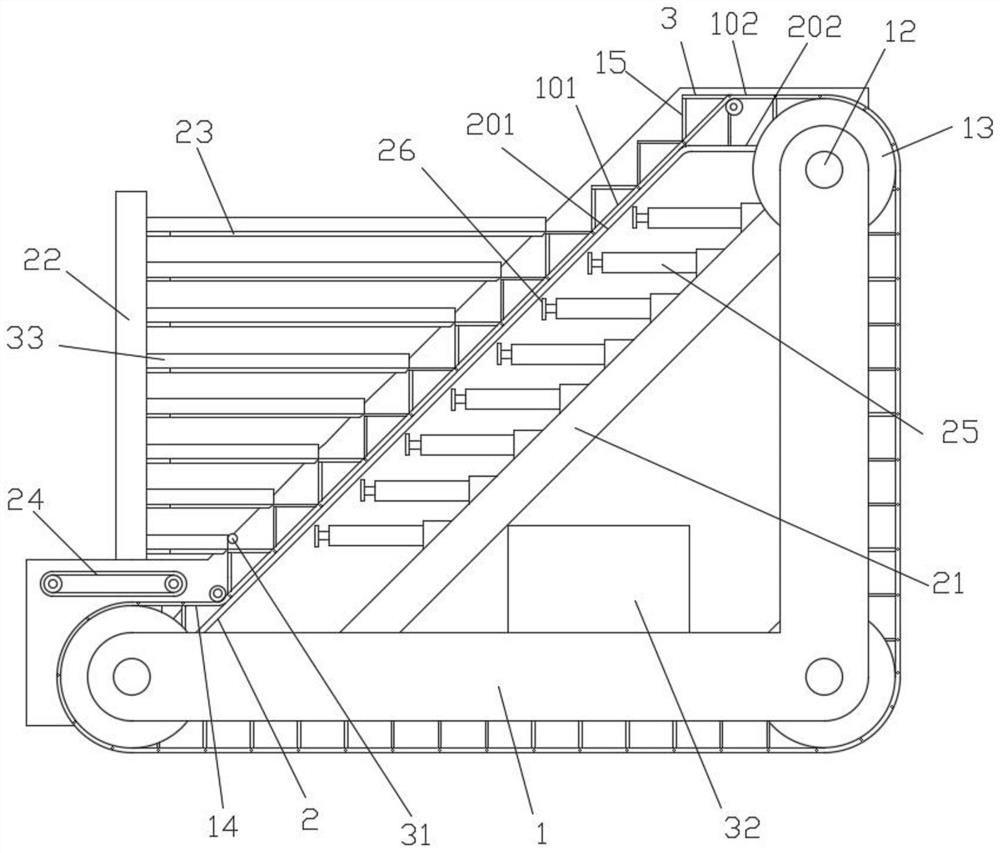

[0022] Such as figure 1 , figure 2 Shown; A kind of sludge brick production palletizing conveyor belt, comprising:

[0023] Device support 1, a plurality of drive rollers 12 are installed on the device support 1, the drive rollers 12 are driven by a drive motor, each drive roller 12 two ends are respectively equipped with a drive chain disc 13, and a drive belt chain 14 is installed on the drive chain disc 13;

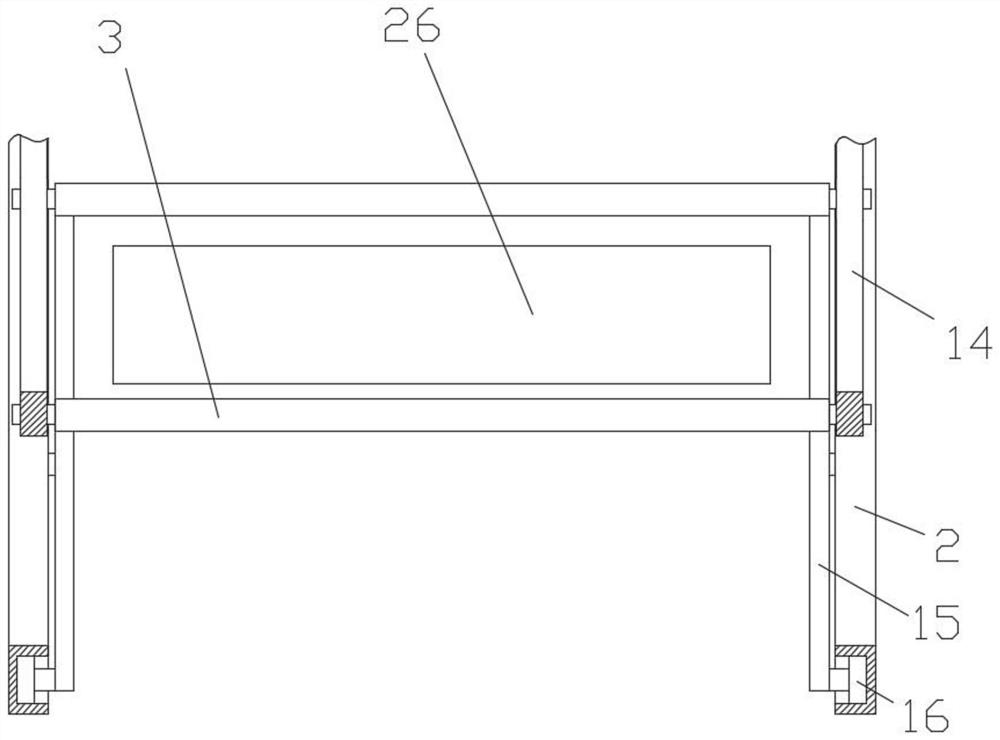

[0024] Guide slideway 2, guide slideway 2 is provided with two, is respectively fixedly installed on the device support 1 of drive roller 12 two ends, and guide slideway 2 is positioned at driving belt chain 14 inner side;

[0025] Support plate 3, support plate 3 is provided with a plurality of, equidistantly hinged on the drive belt chain 14, support plate 3 is away from drive belt chain 14 hinged side and is vertically fixedly installed with two struts 15, each strut 15 lower ends are respectively A roller 16 is installed, and the roller 16 is located inside the ...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 Shown; The horizontal distance between the tail end of the material receiving plate 23 and the chain a section 101 is equal to the width of the supporting plate 3 . It is ensured that the support plate 3 can be smoothly pushed out onto the receiving plate 23 .

[0031] An infrared sensor 31 is fixed at the end of the bottommost material receiving plate 23 on the material receiving column 22 , the infrared sensor 31 is connected to the input end of the controller 32 , and the output end of the controller 32 is respectively connected to the driving motor and the electric push rod 25 . Utilize the infrared sensor 31 to detect whether there is a brick on the support plate 3 moved to the horizontal position of the bottom receiving plate 23. When there is a brick, the infrared sensor 31 feeds back a signal to the controller 32, and the controller 32 controls the drive motor to stop working. The drive belt chain 14 stops moving, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com