Environment-friendly cement tile mixed with limestone powder and preparation method thereof

A limestone powder and cement tile technology, applied in the field of building materials, can solve problems such as environmental pollution, achieve the effects of protecting the environment, saving resources, and improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

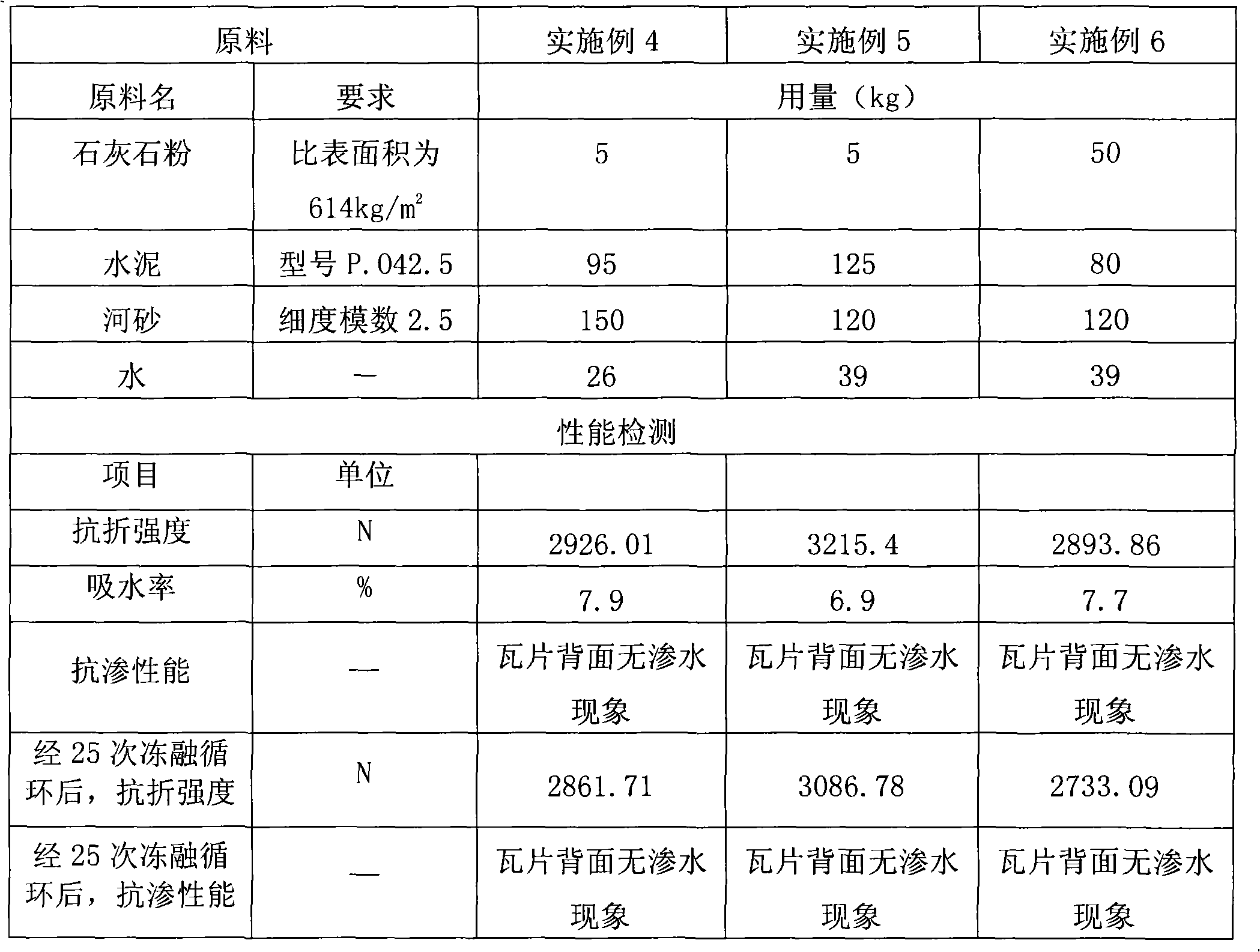

Examples

Embodiment 1

[0021] Embodiment 1, preparation and performance testing of environment-friendly cement tile mixed with limestone powder

[0022] The limestone powder cement tile is prepared by the following method, and the specific method includes the following steps:

[0023] 1) Weighing and taking materials: limestone powder (stone powder waste collected in limestone production, specific surface area is 614kg / m 2 ) 20kg, ordinary portland cement (P.042.5 model, purchased from Jidong Cement Group Co., Ltd., Hebei Province) 80kg, river sand (fineness modulus is 2.5) 150kg, water 26kg, mix the above raw materials evenly into wet material;

[0024] 2) Fill the wet material into a standard mold and press it into shape; the pressure is 10MPa, and the pressurization time is 3 seconds;

[0025] 3) Standard maintenance: After demoulding, maintain for 24 hours without water, and then soak in water for maintenance;

[0026] An environment-friendly cement tile mixed with limestone powder is obtaine...

Embodiment 2

[0032] Example 2, preparation and performance testing of environment-friendly cement tiles mixed with limestone powder

[0033] The following method is used to prepare the environment-friendly cement tile mixed with limestone powder, and the specific method includes the following steps:

[0034] 1) Weighing and taking materials: limestone powder (primary powder collected in the production of machine-made sand, the specific surface area is 621kg / m 2 ) 40kg, sulfoaluminate cement (R-SAC42.5 model, purchased from Tangshan Liujiu Cement Co., Ltd.) 60kg, river sand (fineness modulus is 3.0) 150kg, water 25kg, the above-mentioned raw materials are mixed evenly;

[0035] 2) Compression molding; pressure 20MPa, pressure hold time 2 seconds;

[0036] 3) Standard maintenance: After demoulding, maintain for 24 hours without watering, and then watering for curing.

[0037] An environment-friendly cement tile mixed with limestone powder is obtained.

[0038] The environment-friendly cem...

Embodiment 3

[0041] Embodiment 3, preparation and performance testing of environment-friendly cement tile mixed with limestone powder

[0042] The following method is used to prepare the environment-friendly cement tile mixed with limestone powder, and the specific method includes the following steps:

[0043] 1) Weighing and taking materials: limestone powder (dust collected in the production of machine-made sand, the specific surface area is 800kg / m 2 ) 30kg, ordinary Portland cement (P.O42.5 model, purchased from Hebei Province Jidong Cement Group Co., Ltd.) 50kg, river sand (fineness modulus is 2.3) 170kg, water 20kg, mix the above raw materials evenly ;

[0044] 2) Compression molding; pressure 6MPa, pressurization hold time 3 seconds;

[0045] 3) Standard maintenance: After demoulding, it is maintained for 24 hours without water, and then naturally cured;

[0046] An environment-friendly cement tile mixed with limestone powder is obtained.

[0047] The environment-friendly cement t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com