Composite heat insulation concrete shear wall structure system and its construction method

A technology of thermal insulation concrete and composite thermal insulation, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of poor sound insulation performance, complex process, long construction period, etc., achieve the effect of improving thermal insulation, solving complex process, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

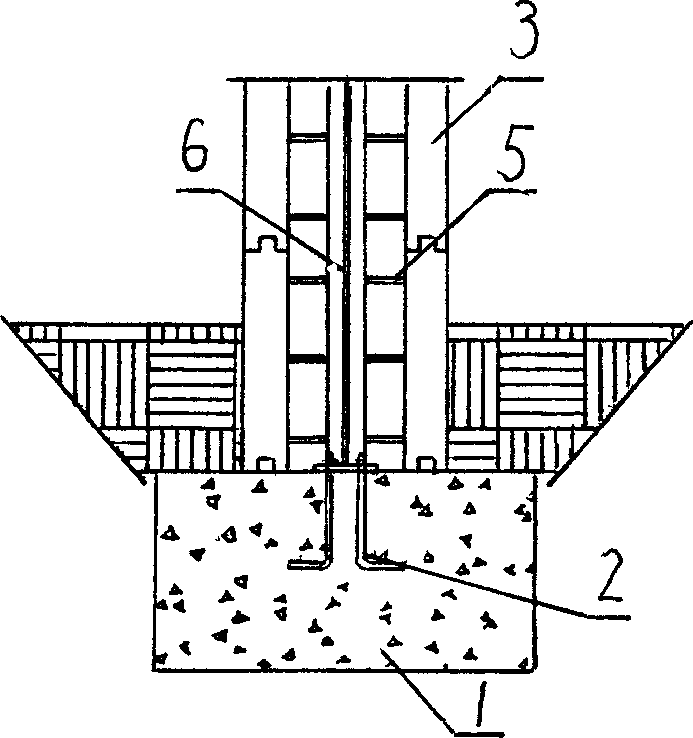

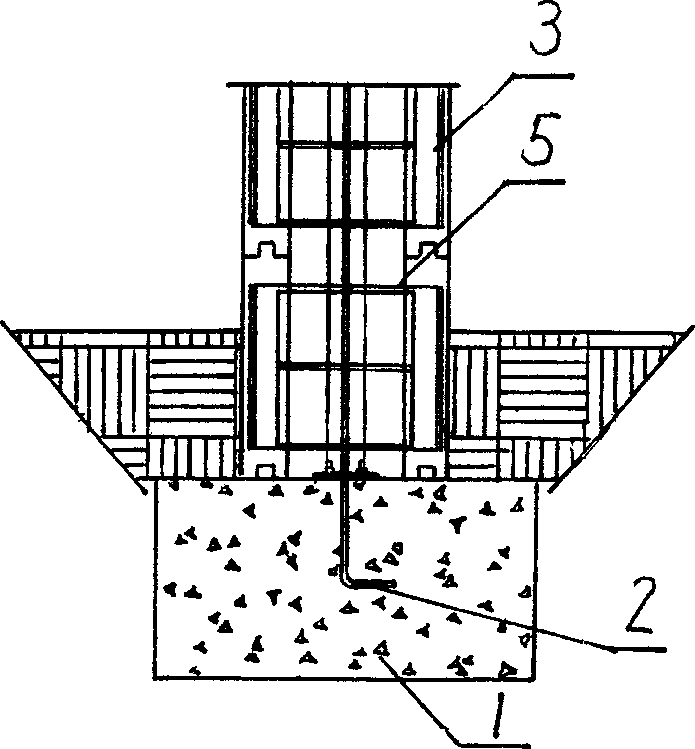

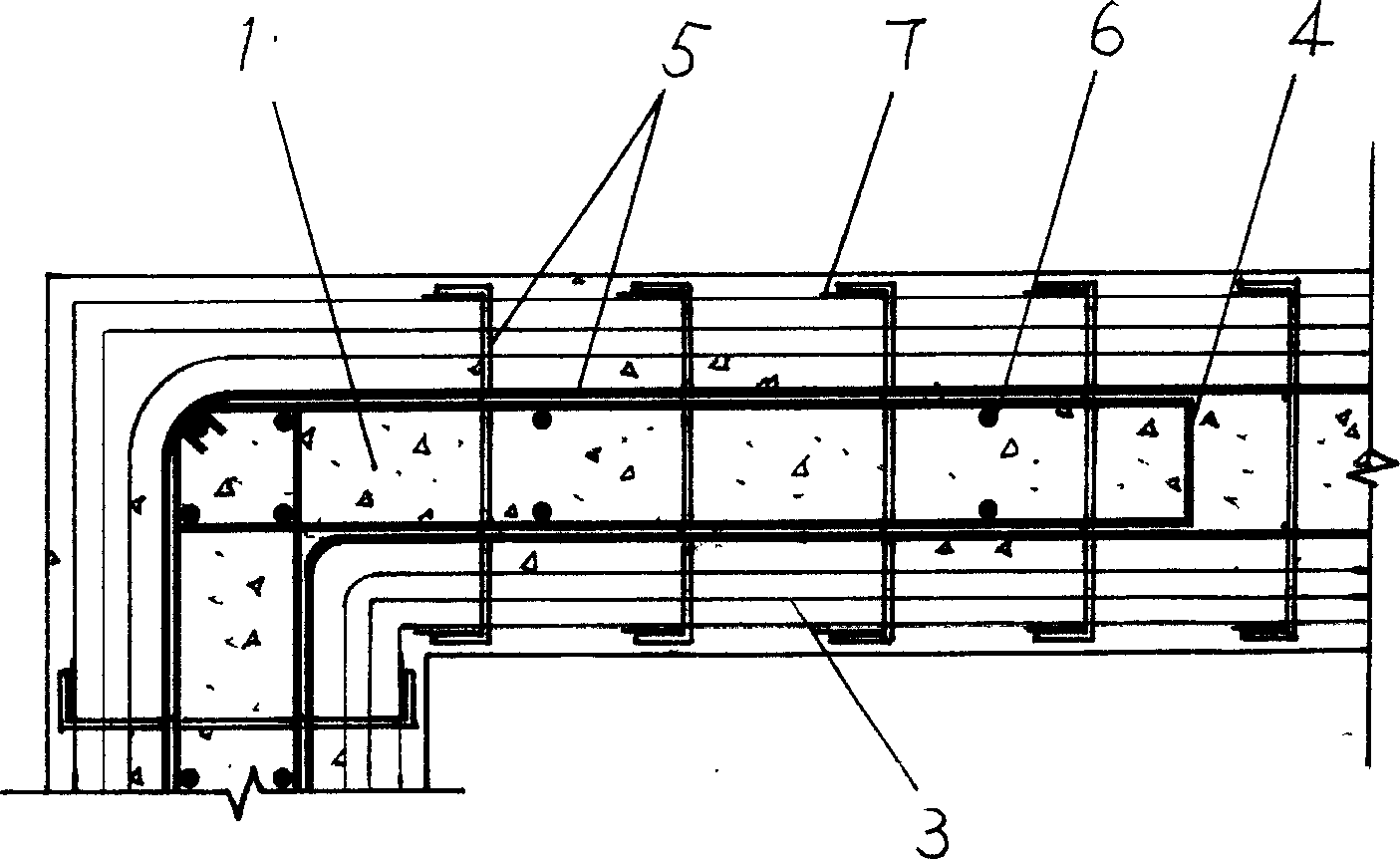

[0055] see figure 1 ,2 , 3, 5, this kind of composite thermal insulation concrete shear wall structure system, there is a steel skeleton embedded part 2 in the interior of the concrete foundation 1, and the prefabricated polystyrene thermal insulation wall formwork 3 is connected to the concrete foundation 1, and the prefabricated polystyrene insulation wall formwork 3 is connected to the prefabricated polystyrene The styrene thermal insulation wall formwork is connected with a steel skeleton, and is fixedly connected with the basic steel skeleton embedded part 2. The reinforcing bar skeleton in the prefabricated polystyrene thermal insulation wall formwork 3 has stirrups 4, transverse reinforcing bars 5, vertical reinforcing bars 6 and steel sheets 7. The prefabricated polystyrene thermal insulation wall template 3 and the cast-in-place concrete wall 10 are compositely poured into one body.

[0056] Referring to Fig. 4, the doors and windows 9 are connected with the prefabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com