Cement tile

A cement and ceramic tile technology, applied in the ceramic tile field, can solve the problems of poor product texture and low grade, and achieve the effects of strong wear resistance, high hardness and good slip resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Now in conjunction with embodiment the present invention is described in further detail:

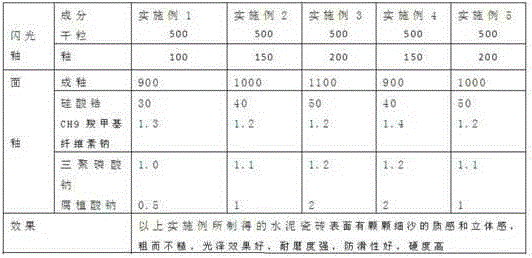

[0013] this invention cement tile It is achieved through the following methods: including applying the top glaze on the cement body, spraying the dry granular glaze through the glaze spray cabinet after the top glaze is applied, and then firing and post-processing. The dry granular glaze includes 500 parts by weight of dry granular , the glaze of 100-200 parts by weight.

[0014] After spraying the special dry granule glaze, further spray the fixing agent to fix the dry granule and prolong the drying time of the special dry granule glaze. The fixing agent includes polyvinyl alcohol and water, and the weight ratio of the two is 1:2.5-3.5. Spray a layer of firm and dense film with a water jet glazing cabinet, and the spraying weight is calculated as 4±1 / 300×600 pallets.

[0015] The particle size of the dry particles is between 120 and 250 mesh.

[0016] The amount of dry granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com