High-intensity pure-colored lithic cement tile and its production method and apparatus

A production method and high-strength technology, used in ceramic molding machines, manufacturing tools, etc., can solve problems such as limiting production efficiency, breakage, and improvement, and achieve uniform color, high compressive strength, and high flexural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

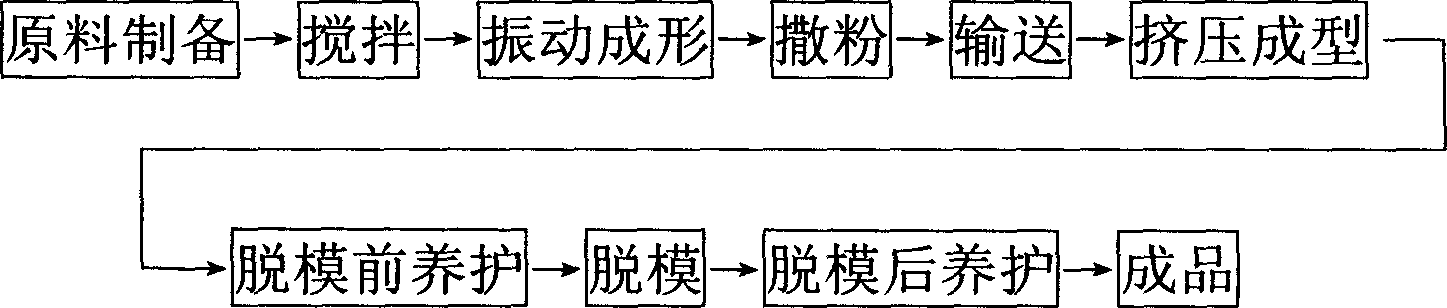

[0028] One, the embodiment of the present invention production process step process

[0029] (1) Raw material preparation

[0030] The raw material components are as follows by weight: 100 parts of high-quality cement, 50 parts of ordinary cement, 475 parts of graded sand (of which 180 parts of coarse-grained sand, 135 parts of medium-grained sand, and 160 parts of fine-grained sand), 9 parts of pigment, high-efficiency 1.5 parts of water reducer, 4 parts of polymer, and 48 parts of water are used to prepare mortar concrete raw materials;

[0031] Among the above ingredients, the selection of various ingredients is very important.

[0032] ① Cement: Cement is one of the important raw materials to achieve high strength of high color tile products. According to the design requirement that the strength of mortar concrete should be greater than M35, high-quality cement should choose PII52.5R early-strength Portland cement, but because PII52.5R cement has a finer particle size, g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com