Cement tile and method and equipment for manufacturing same

A technology of cement tile and Portland cement, which is applied in building construction, roofing using tile/slate tile, roofing, etc., can solve the problems of complex production process, complicated equipment and high cost of cement tile, so as to reduce the cost of housing and reduce production costs. Simple equipment, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The production process steps of the embodiment of the present invention:

[0014] (1) pulping

[0015] Mix 50 parts by weight of ordinary Portland cement, 150 parts of coarse sand, 1 part of pigment, and an appropriate amount of water, and stir the above materials into a slurry.

[0016] (2) Vibration

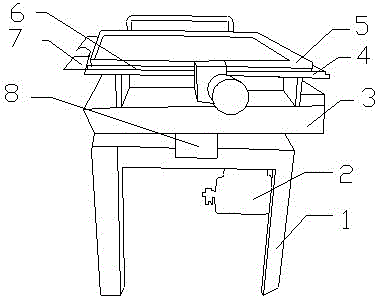

[0017] Connect the motor (2) to the socket (8), connect the power supply, snap the vibrating material mold (4) into the vibrating plate groove (3) and lock it tightly, open the clamping material frame (5), insert the deformation plate (6), and deform Lay the diaphragm (7) on the plate (6), and close the card material frame (5). Add the material required for one tile into the card material frame (5), turn on the power, the slurry vibrates in the frame, when the air bubbles in the slurry are removed and the slurry is evenly spread on the diaphragm of the deformed plate, disconnect the The power supply and the slurry vibration process are completed.

[0018] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com