Ceramic tile sticking device for wall

A technology for tiling tiles and walls, applied in construction, building construction, etc., can solve problems such as worker mistakes, time-consuming and labor-intensive efficiency, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

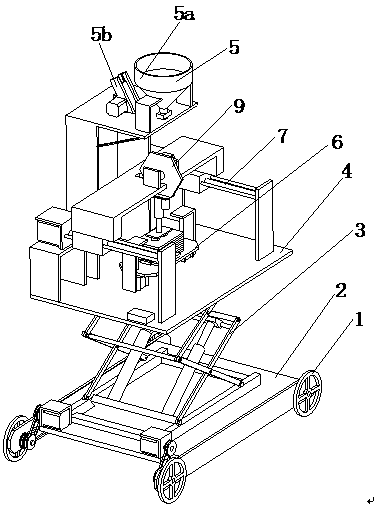

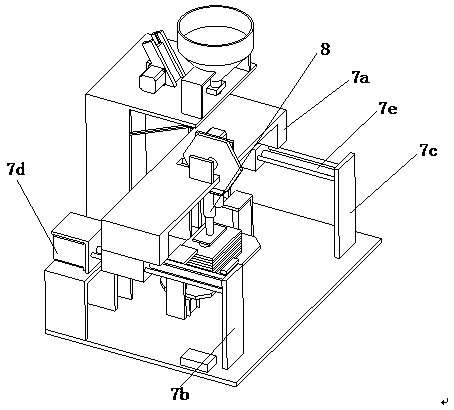

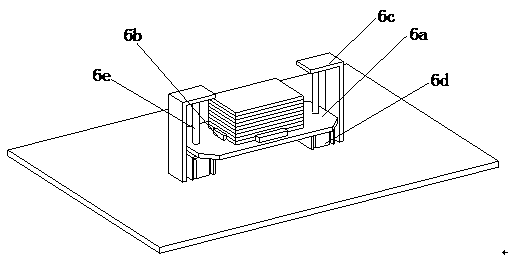

[0027] refer to Figure 1 to Figure 9The device for laying tiles on the wall includes a running assembly 1, a support plate 2 arranged horizontally, an elevator 3, a cement plastering assembly 5, a tile supply assembly 6 and a material transfer assembly 7, and the elevator 3 is located on the support The top of the board 2, the travel assembly 1 is located at the bottom of the supporting board 2, and the top of the elevator 3 is also provided with a fixed board 4 arranged horizontally, the fixed board 4 and the supporting board 2 are cuboid structures, and the wiper The cement component 5, the tile supply component 6 and the material shifting component 7 are all located on the top of the fixed plate 4, and the material moving component 7 includes a U-shaped support bracket 7a located above the fixed plate 4 and a U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com