Plant fiber concrete, preparation method and plant fiber concrete column

A plant fiber and concrete column technology, applied in the field of preparation, plant fiber concrete, plant fiber concrete column, can solve the problems of weight reduction, inconvenient construction of foamed concrete, etc., and achieve the effect of reducing self-weight, significant thermal insulation effect, and preventing thermal bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

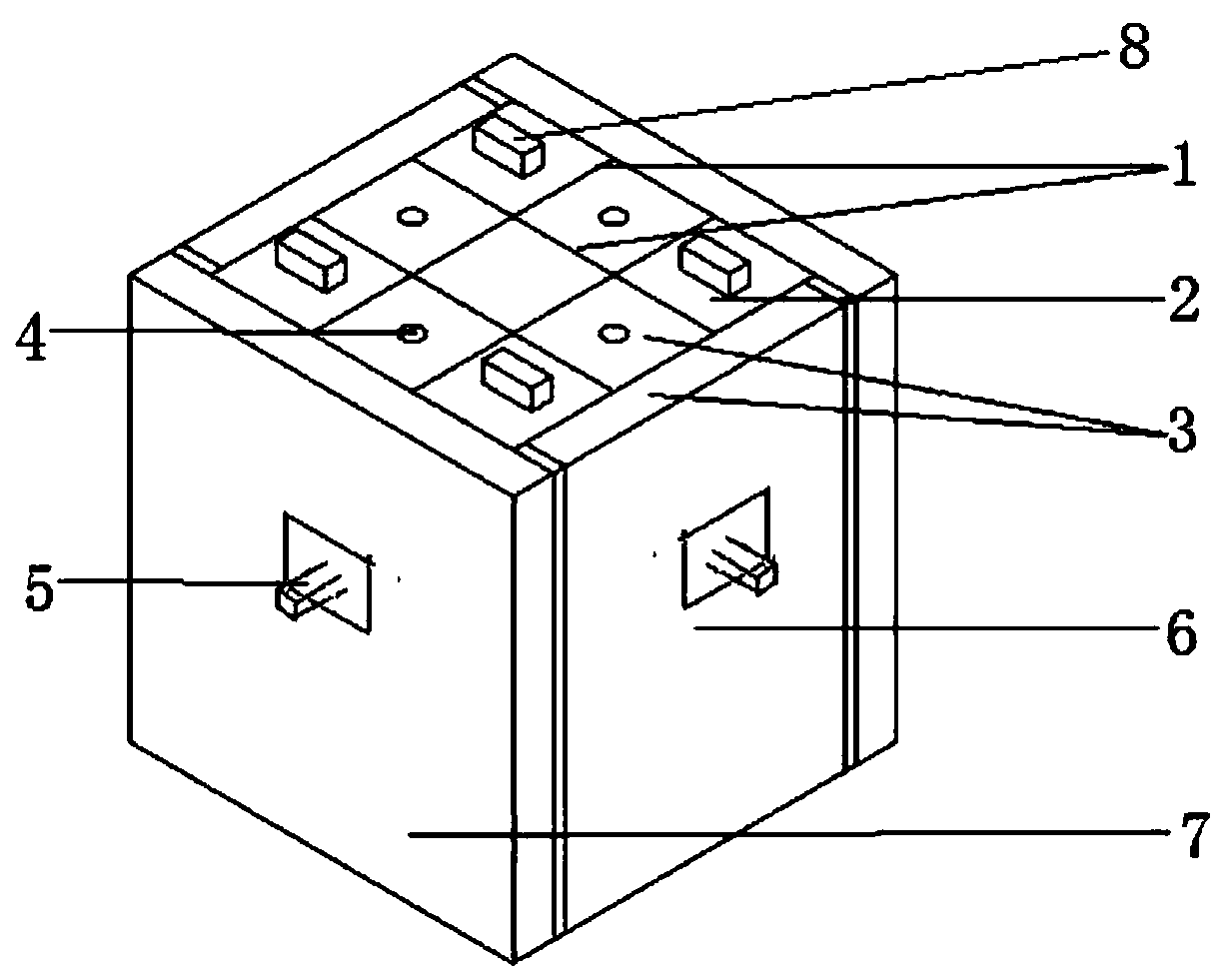

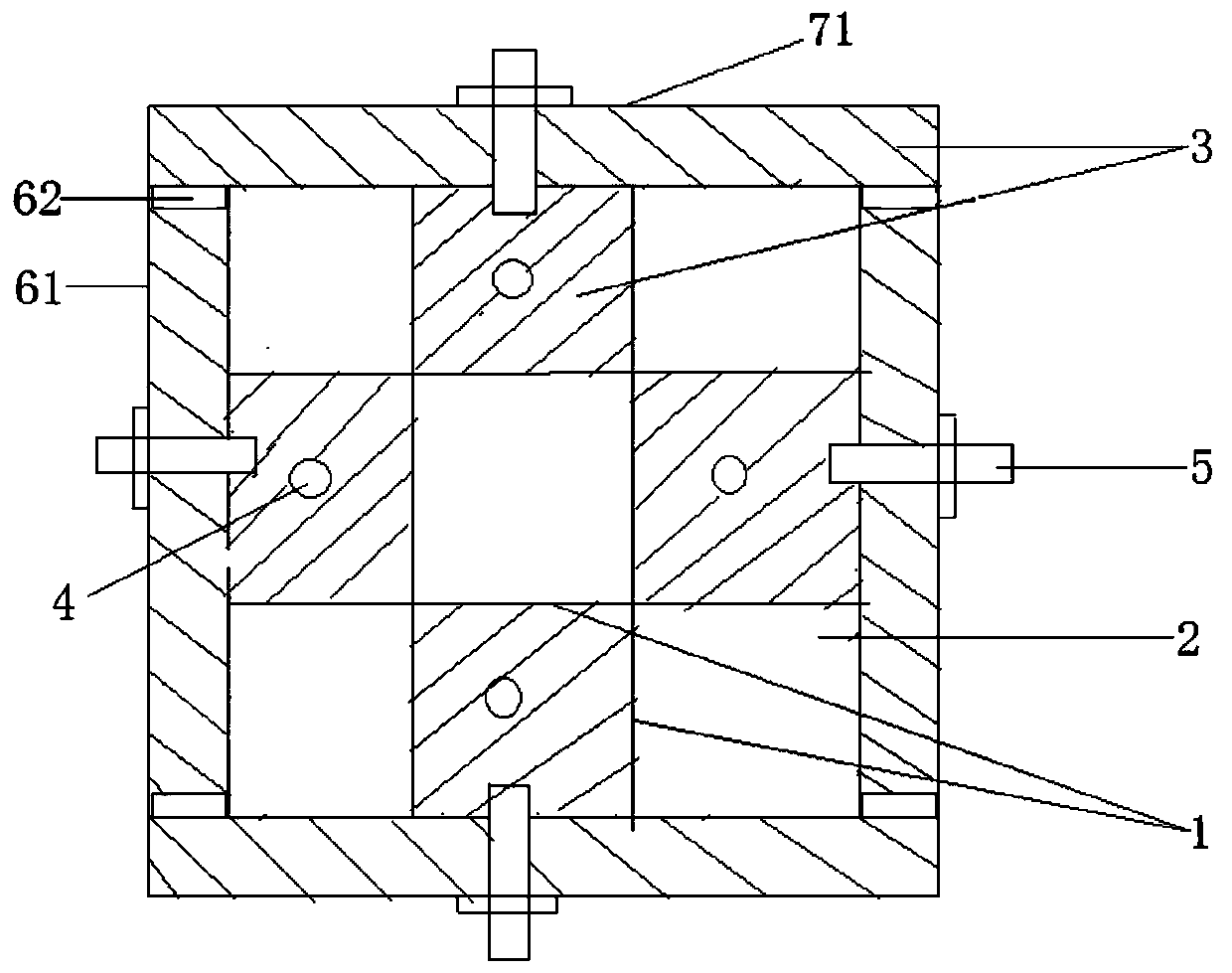

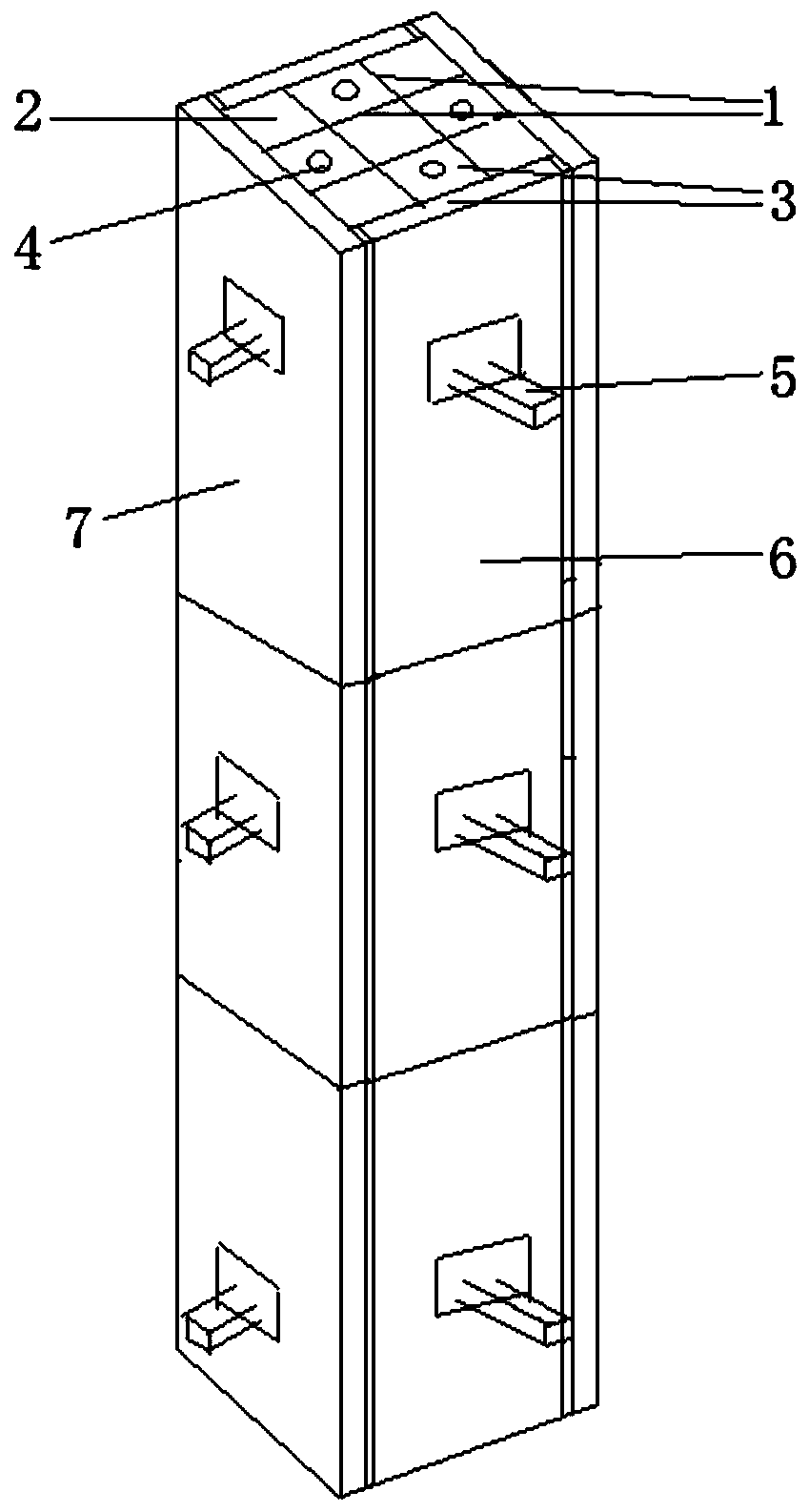

Image

Examples

preparation example Construction

[0030] A kind of plant fiber concrete preparation method of the present invention, comprises the following steps:

[0031] Step 1: Weigh according to the proportion of the following components: ordinary portland cement 210-270 parts, fly ash 80-100 parts, ash calcium powder 30-55 parts, silica fume 3-5 parts, bentonite composite cementing material 160- 180 parts, 3-6 parts of redispersible rubber powder, 0.5-1 part of hydroxypropyl methylcellulose, 0.5-1 part of reinforcing fiber, 60-100 parts of paraffin, 150-180 parts of water, 30-40 parts of expanded perlite , 50-70 parts of diatomite, 3-5 parts of lightweight aggregate and 10-15 parts of straw;

[0032] Step 2: Cut the straw into straw sections with a length between 10 and 40 mm, then put them into a bucket and add NaOH crystals, add warm water to make the concentration of NaOH solution lower than 10%, soak the straw sections in NaOH solution for 20 hours and use Rinse with clean water repeatedly until neutral, and dry na...

Embodiment 1

[0038] A plant fiber concrete, comprising the following components according to the weight ratio: 210 parts of ordinary portland cement, 80 parts of fly ash, 30 parts of ash calcium powder, 3 parts of silica fume, 160 parts of bentonite composite cementing material, redispersible glue 3 parts of powder, 0.5 parts of hydroxypropyl methylcellulose, 0.5 parts of reinforcing fiber, 60 parts of paraffin, 150 parts of water, 30 parts of expanded perlite, 50 parts of diatomaceous earth, 3 parts of lightweight aggregate and 10 parts of straw.

[0039] Wherein, the redispersible rubber powder is protein. The lightweight aggregate is composed of vitrified microspheres, waste polystyrene foam particles and hollow glass microspheres. The reinforcing fibers are carbon fibers. The straw is peanut straw.

[0040]The preparation method of above-mentioned plant fiber concrete comprises the following steps:

[0041] Step 1: Weigh according to the above group distribution ratio;

[0042] Ste...

Embodiment 2

[0047] A plant fiber concrete, comprising the following components according to the weight ratio: 240 parts of ordinary portland cement, 90 parts of fly ash, 45 parts of ash calcium powder, 4 parts of silica fume, 170 parts of bentonite composite cementing material, redispersible glue 4.5 parts of powder, 1 part of hydroxypropyl methylcellulose, 1 part of reinforcing fiber, 80 parts of paraffin, 165 parts of water, 35 parts of expanded perlite, 60 parts of diatomaceous earth, 4 parts of lightweight aggregate and 12 parts of straw.

[0048] Wherein, the redispersible rubber powder is protein. The lightweight aggregate is composed of vitrified microspheres, waste polystyrene foam particles and hollow glass microspheres. The reinforcing fibers are carbon fibers. The straw is peanut straw.

[0049] The preparation method of above-mentioned plant fiber concrete is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com