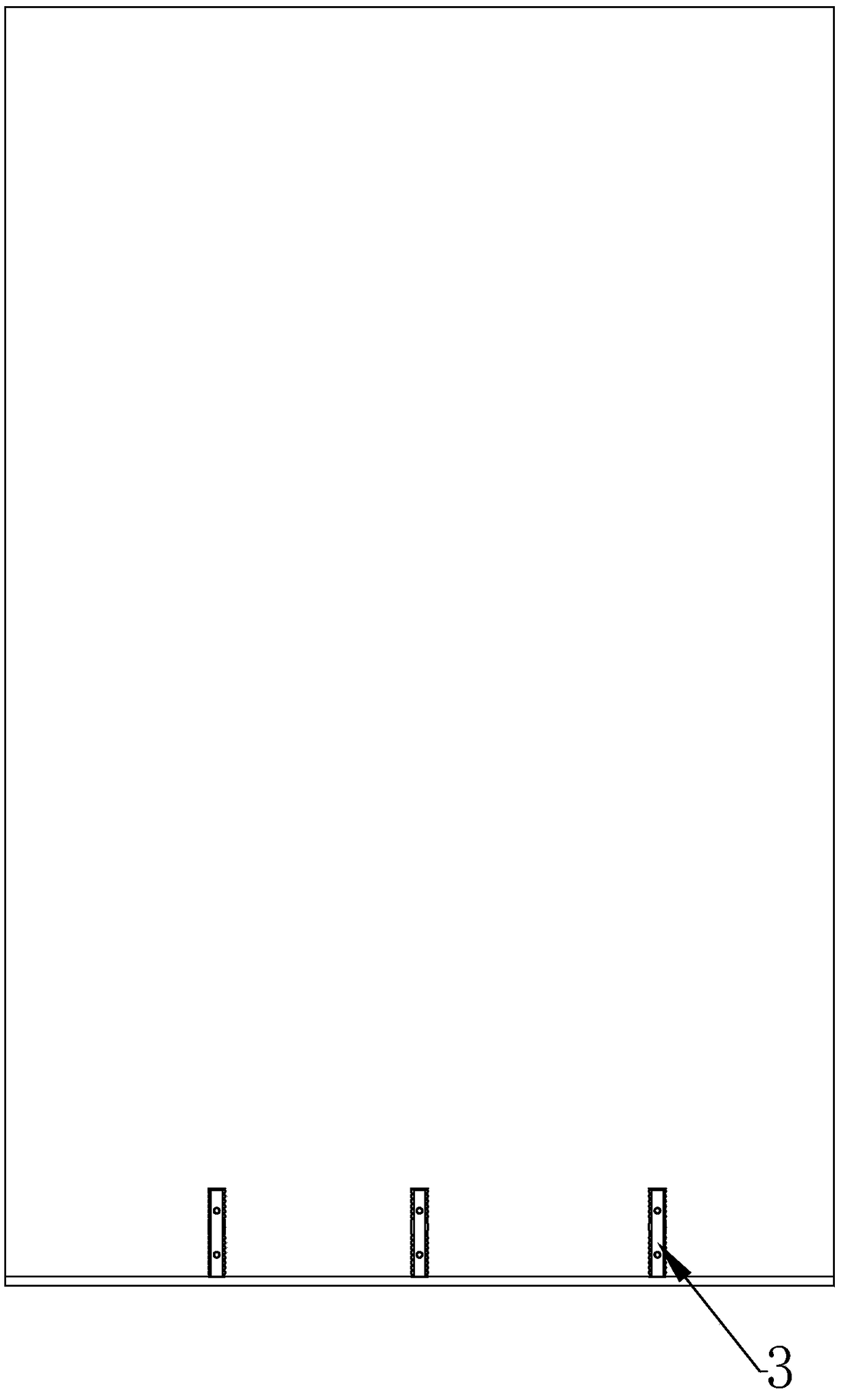

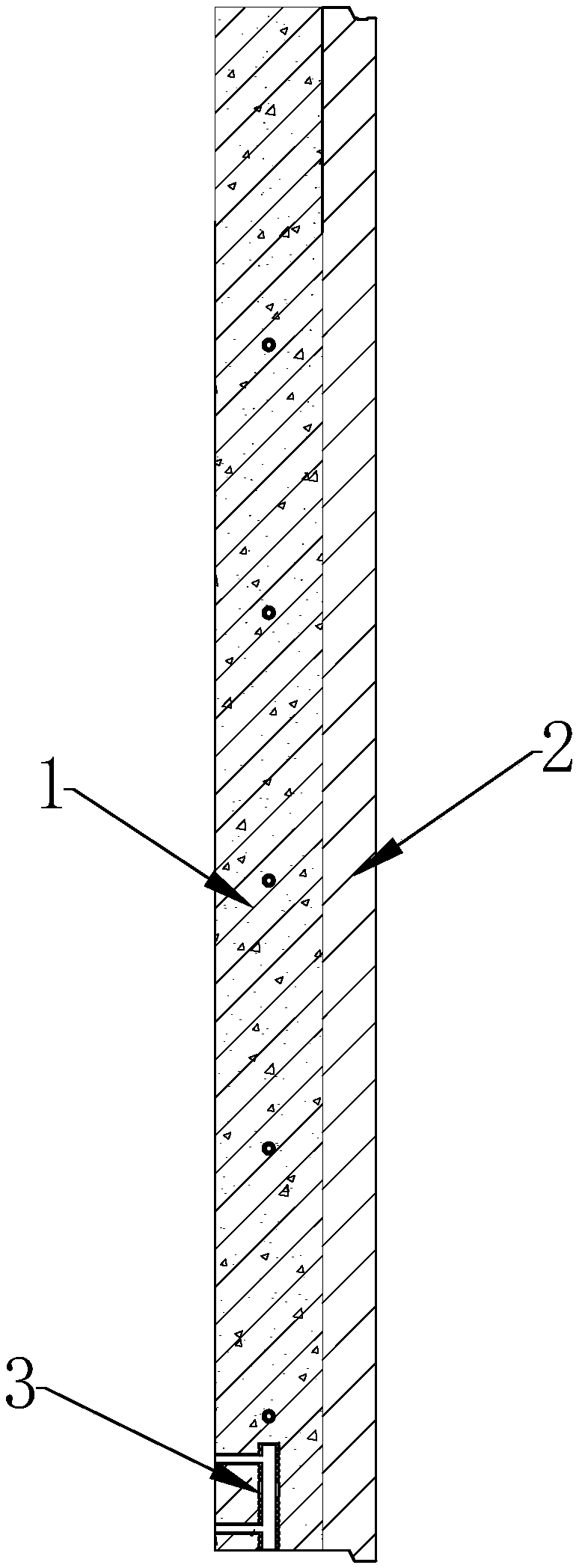

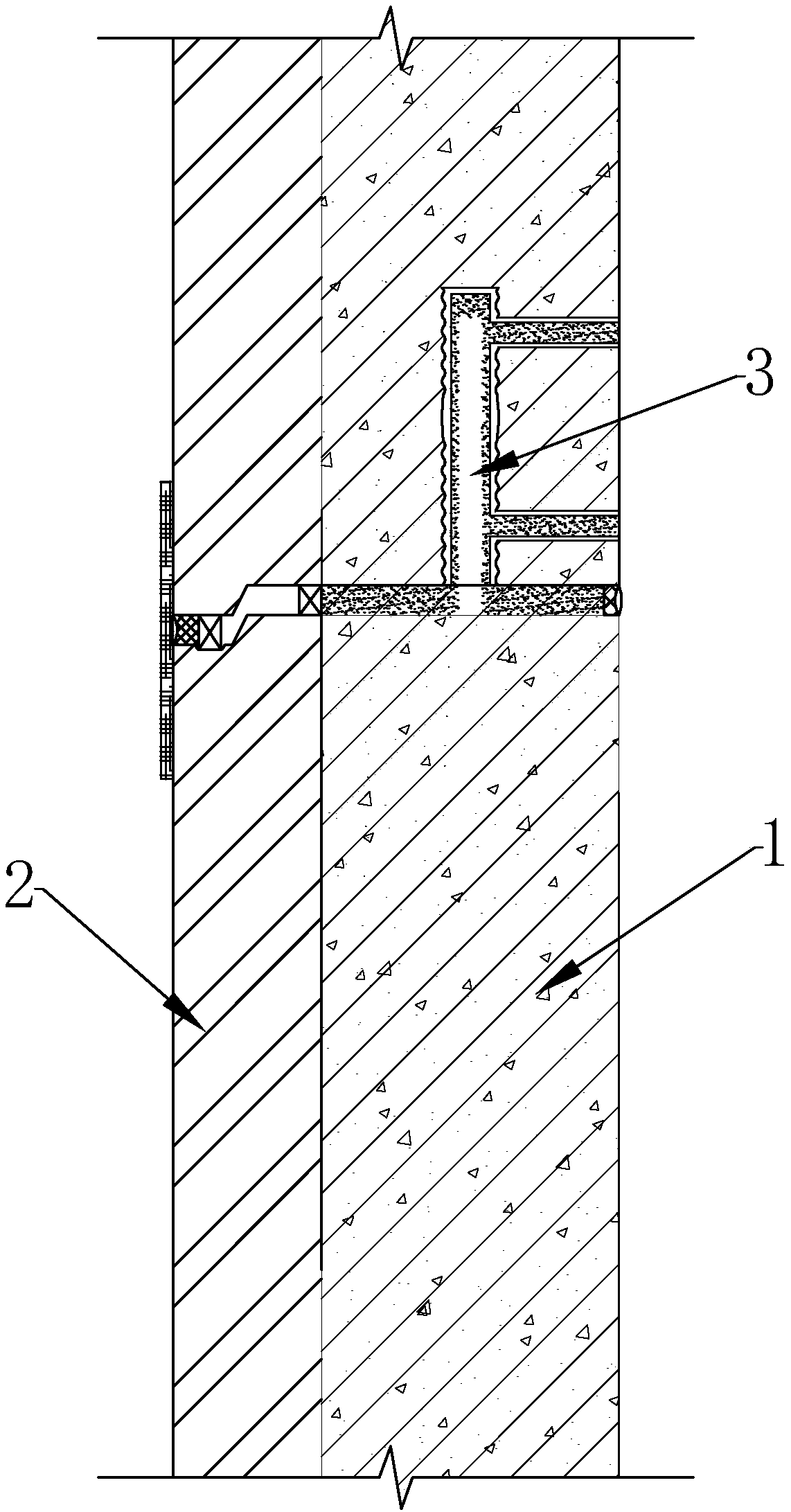

Prefabricated self-heat-preservation shearing wall

A technology of shear wall and self-insulation, which is applied in the field of construction engineering, can solve the problems of affecting the overall performance of wall panels, occupying building area, and poor insulation effect, etc., and achieves the advantages of simple structure, reduced occupation, enhanced integrity and mechanical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The glass pumice concrete layer 2 includes the following components in parts by weight: 450 parts of ordinary Portland cement with a strength grade of 42.5, 50 parts of fly ash, 2.55 parts of polycarboxylate superplasticizer, 2 parts of polypropylene short fiber, 620 parts of medium sand with a fineness modulus of 3.0-2.3, 280 parts of closed-cell glass pumice with a continuous gradation of 5-30 mm, mix the above components according to the proportion, add to the mixer and stir for 1-2 minutes, then add 165 parts of water parts, and then stirred for 3-5min.

[0040] The preparation method of the above-mentioned glass pumice concrete layer 2, according to the following components by weight, 450 parts of cement, 50 parts of fly ash, 2.55 parts of water reducing agent, 2 parts of fiber, 620 parts of medium sand, and 280 parts of glass pumice , 165 parts of water, mixed and stirred, added to the mold, and the mold was removed after natural drying. The dry density of the gl...

Embodiment 2

[0042] The glass pumice concrete layer 2 includes the following components in parts by weight: 450 parts of ordinary Portland cement with a strength grade of 42.5, 50 parts of fly ash, 2.65 parts of polycarboxylate superplasticizer, 2 parts of polypropylene short fiber, 680 parts of medium sand with a fineness modulus of 3.0-2.3, 296 parts of closed-cell glass pumice with a continuous gradation of 5-30mm, mix the above components according to the proportion, add to the mixer and stir for 1-2min, then add 165 parts of water parts, and then stirred for 3-5min.

[0043] The preparation method of the above-mentioned glass pumice concrete layer 2, according to the following components by weight, 450 parts of cement, 50 parts of fly ash, 2.65 parts of water reducing agent, 2 parts of fiber, 680 parts of medium sand, and 296 parts of glass pumice , 165 parts of water, mixed and stirred, added to the mold, and the mold was removed after natural drying. The dry density of the glass pu...

Embodiment 3

[0045] The glass pumice concrete layer 2 includes the following components in parts by weight: 500 parts of ordinary Portland cement with a strength grade of 42.5, 50 parts of fly ash, 2.75 parts of polycarboxylate superplasticizer, 2 parts of polypropylene short fiber, 730 parts of medium sand with a fineness modulus of 3.0-2.3, 300 parts of closed-cell glass pumice with a continuous gradation of 5-30 mm, mix the above components according to the proportion, add them to the mixer and stir for 1-2 minutes, then add 165 parts of water parts, and then stirred for 3-5min.

[0046] The preparation method of the above-mentioned glass pumice concrete layer 2, according to the following components by weight, 500 parts of cement, 50 parts of fly ash, 2.75 parts of water reducing agent, 2 parts of fiber, 730 parts of medium sand, and 300 parts of glass pumice , 165 parts of water, mixed and stirred, added to the mold, and the mold was removed after natural drying. The dry density of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com