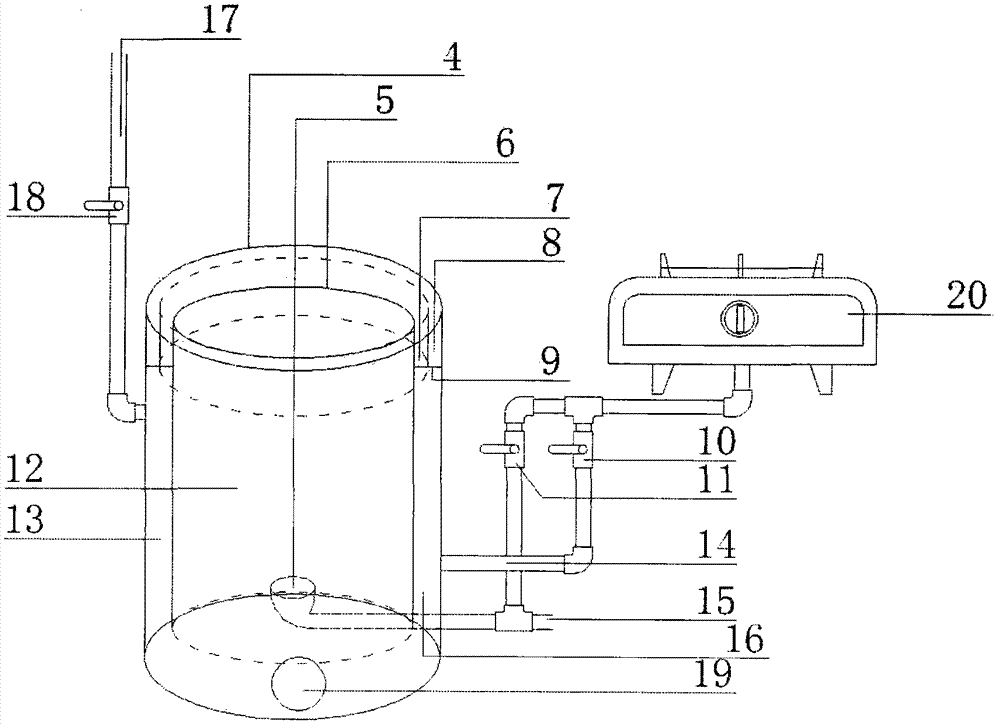

Straw gasification furnace

A technology of gasification furnace and straw, which is applied in the direction of household stove/stove, manufacture of combustible gas, gaseous heating fuel, etc. It can solve the problems of high cost, pipeline blockage, and failure to achieve the effect, and achieve the goal of increasing production and reducing carbon black The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

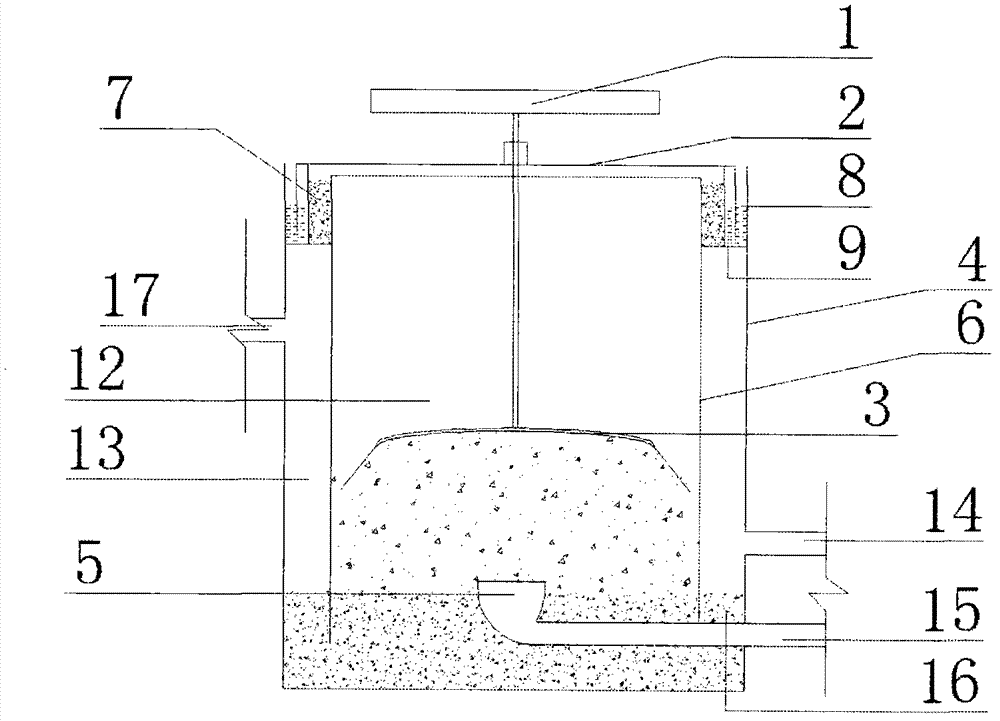

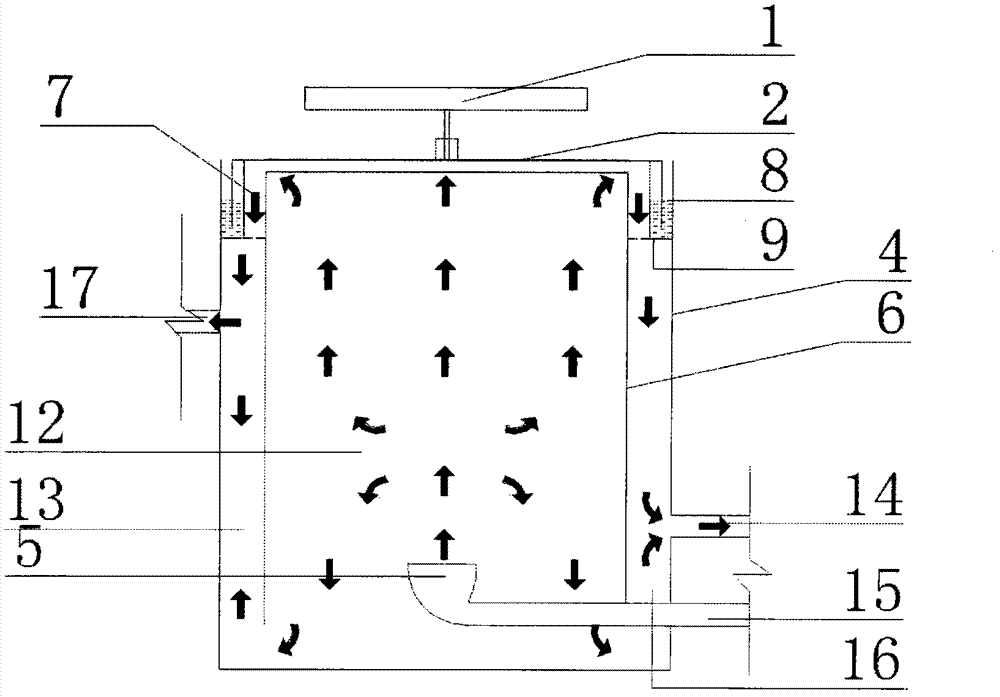

[0028] Furnace inner bladder 6 is arranged inside the outer furnace bladder 4, forming fuel chamber 12 and circulation chamber 13 like this. The fuel is placed in the fuel chamber 12 and ignited. A partition 9 is arranged above the circulation chamber 13. The partition is divided into a filter groove 7 and a sealing groove 8. Water is added to the sealing groove 8 to cover the furnace cover 2, thus reaching the furnace body. sealing effect. A burner 5 is arranged at the lower part of the fuel chamber 12, and the burner 5 blows air into the fuel chamber 12 through an air inlet 15 to make gas. The gas enters the circulation chamber 13 after filtering through the upper filter tank 7 and the lower filter tank 16, and the circulation chamber 13 is provided with two gas outlets up and down, which are output pipe 14 and exhaust port 17 respectively. The gas enters the output pipe 14 and the exhaust port 17 through the circulation chamber 13, the exhaust port 17 is provided with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com