Multifunctional soft wall base material production process and formula

A production process and multi-functional technology, applied in covering/lining, construction, building construction, etc., can solve unsatisfactory problems, achieve good heat insulation and sound insulation performance, improve air environment, good softness and tactile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

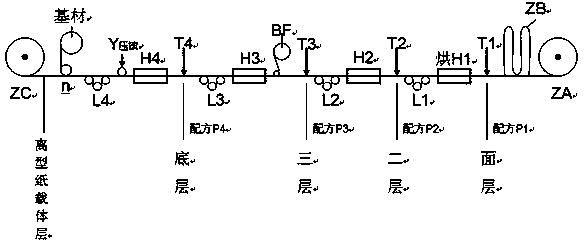

[0015] Below in conjunction with accompanying drawing, patent of the present invention is described further.

[0016] like figure 1 As shown, a "multifunctional soft wall base material" production process and formula, including production process and coating formula, is characterized in that: the coating formula includes the surface layer (T1) PU layer, the second layer (low hair foam layer) (T2), three layers (adhesive layer, low foam layer) (T3) composed of the front base fabric of the base fabric and the bottom layer of the base fabric (high foam layer) (T4); this substrate is produced in A new process based on the traditional release paper production line (see the soft wall substrate process flow chart), the carrier Z is the release paper, the entire substrate is carried on the release paper for processing, and ZA is the release paper unwinding , ZB is the release paper storage rack, the release paper is coated with T1 (formulation P1) as the surface layer, enters H1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com