A graphene anion heating inner warm quilt

A negative ion and graphene technology, applied in the field of inner warm quilts, can solve problems such as the influence of hollow cotton fibers on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Method for preparing null cotton in graphene negative ions, including:

[0036](1) Crushing the hollow cotton to obtain the hollow cotton particles, spare;

[0037](2) The hollow wool particles are added to the silane coupling agent aqueous solution, and the addition amount of the silane coupling agent is 0.1% of the weight of the hollow cotton particles, and the ultrasonic dispersion is 15 min to form a dispersion liquid;

[0038](3) Mix the oxidized graphene and far infrared ceramic powder in a mass ratio of 4: 1 to ion water, ultrasonic dispersion 15 min is made into a dispersion liquid, stand, filtrate, to obtain a far-infrared ceramic powder inserted oxide graphene precipitate; The diameter of the oxide in graphene powder is 100 to 200 nm, and the thickness of the layer is 1.0 to 1.5 nm; the amount of the oxide oxide and the far-infrared ceramic powder is 0.3% by weight of the hollow cotton particles according to the hollow cotton particles; the far infrared Titanium oxide is cont...

Embodiment 2

[0045]Method for preparing null cotton in graphene negative ions, including:

[0046](1) Crushing the hollow cotton to obtain the hollow cotton particles, spare;

[0047](2) The hollow wool particles are added to the silane coupling agent aqueous solution, and the addition amount of the silane coupling agent is 0.5% by weight of the hollow cotton particles, and the ultrasonic dispersion is 20 min to form a dispersion.

[0048](3) Mix the oxidized graphene and far infrared ceramic powder in a mass ratio of 6: 1 to ion water, ultrasonic dispersion of 20 min to prepare a dispersion, stand, filtered to obtain a far-infrared ceramic powder inserted oxide in graphene precipitate; The diameter of the oxide in graphite powder is 100 to 200 nm, the thickness of the sheet is 1.0 to 1.5 nm; the amount of the oxide oxide and far-infrared ceramic powder is added to 1% by weight of the hollow cotton particles described in step 2;

[0049]The far-infrared ceramic powder contains nano-oxide, which has catalyti...

Embodiment 3

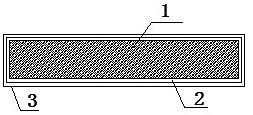

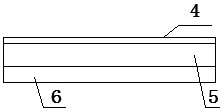

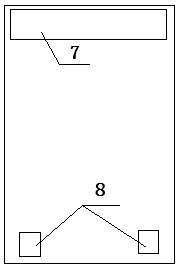

[0055]A graphene negative ion is warm, including a sleeve and placed in a sleeve, such asfigure 1 As shown, the core includes: a graphene anion hollow cotton filler 1, a nano silver antibacterial cloth layer 2 wrapped in a graphene anion, a radiation radiation layer 3 wrapped outside the nano-silver antibacterial cloth layer 3. Nano-silver antibacterial layers can function to antibacterial sterilization, while the radiation protection layers can function as radiation protection, and the health care is better.

[0056]The graphene negative ion hollow cotton was prepared in the formula 1 or 2, the obtained graphene negative centrift cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com