Vacuum honeycomb ceramic body

A honeycomb ceramic body and a technology of honeycomb ceramics, applied in the field of honeycomb ceramic materials, can solve the problems of reducing the thermal insulation performance of the honeycomb ceramic body, reducing the thermal insulation performance of the honeycomb ceramic body, shortening the service life of the honeycomb ceramic body, etc., and achieving cost saving and light weight. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

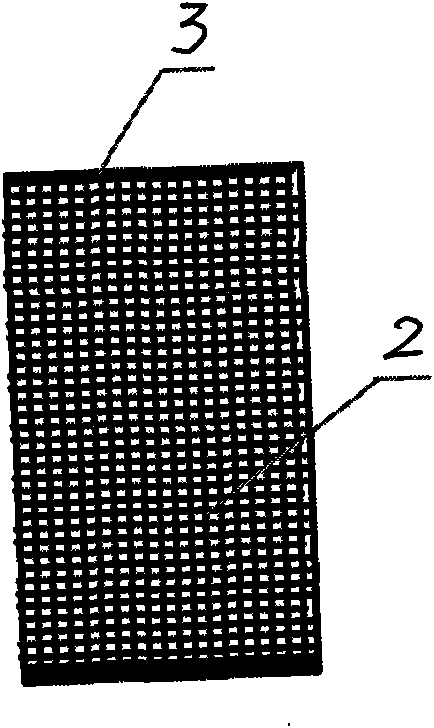

[0019] Example 1, the vacuum honeycomb ceramic body is in the shape of a cuboid and is manufactured according to the following steps:

[0020] (1) adding bauxite, kaolin, talc, feldspar and organic cellulose in a ball mill in proportion to ball milling for 3 hours to form a powder,

[0021] (2) Add the powder into the kneader and add an appropriate amount of water and tung oil to knead to form mud,

[0022] (3) Put the mud material into staleness for 24 hours and use a mud trainer to train the mud to form a mud section,

[0023] (4) Put the mud section into the mold of the press, and press to form a 150×150×300mmmm honeycomb ceramic wet body,

[0024] (5) Put the wet billet into the drying room, and dry it at a temperature of 60-120°C to form a semi-dry billet.

[0025] (6) Put the semi-dry green body into the kiln and fire it into a cordierite honeycomb ceramic body at a temperature of 1350°C.

[0026] (7) Put the honeycomb ceramic body into a vacuum box with a vacuum degr...

Embodiment 2

[0028] Embodiment 2, the vacuum honeycomb ceramic body is in the shape of a cube, and is manufactured according to the following method steps:

[0029] (1) Add bauxite, clay, alumina powder, quartz powder, feldspar and organic cellulose in proportion to ball milling in a ball mill for 3.5 hours to form a powder,

[0030] (2) Add the powder into the kneader and add an appropriate amount of water and engine oil to knead to form a mud,

[0031] (3) Put the mud material into staleness for 24 hours and use a mud trainer to train the mud to form a mud section,

[0032] (4) Put the mud section into the mold of the press, and press to form a 150×150×300mm honeycomb porcelain wet billet.

[0033] (5) Put the wet billet into the drying room, and dry it at a temperature of 60-120°C to form a semi-dry billet.

[0034] (6) Put the semi-dry green body into the kiln, and fire it at a temperature of 1250°C to make a mullite honeycomb ceramic body,

[0035] (7) Place the honeycomb ceramic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com