Reaction, separation, washing, evaporation and drying integrated device and method

A reaction device and reaction technology are applied in the direction of improving process efficiency, which can solve the problems of poor leaching, filtering and washing effect, large amount of reaction liquid phase, and increasing washing times, etc., so as to reduce the content of chemicals and valuable components, reduce the operation Simple and convenient, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

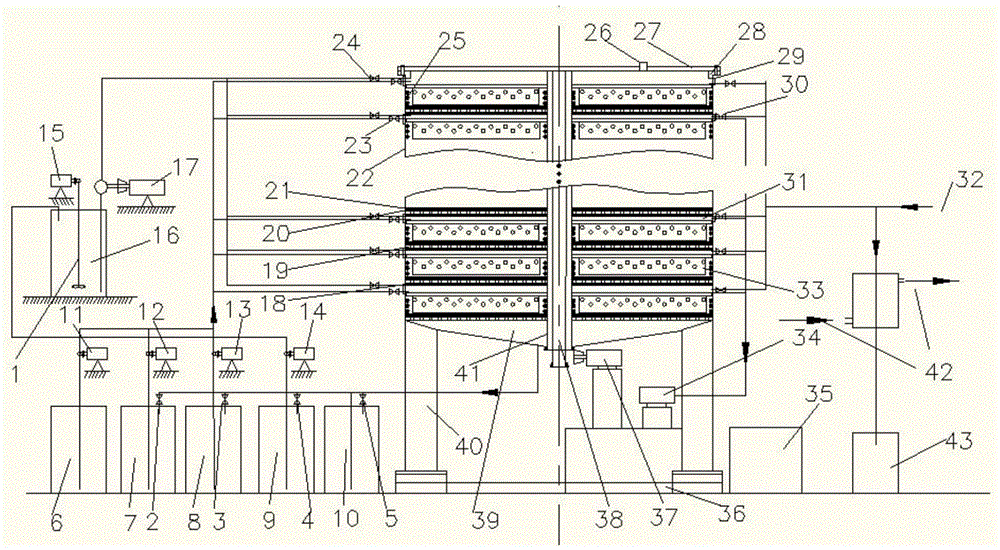

Method used

Image

Examples

Embodiment 1

[0054] High pressure and high temperature leaching, impurity removal, separation and washing of clay vanadium ore

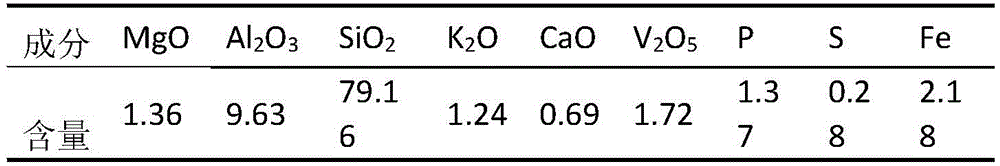

[0055] The test raw material was taken from a clay vanadium mine in Hubei, and its chemical composition is shown in the following table:

[0056]

[0057] It can be seen from the table that the main chemical composition of the clay is SiO 2 and Al 2 o 3 , where V 2 o 5 The calculated grade is 1.72%.

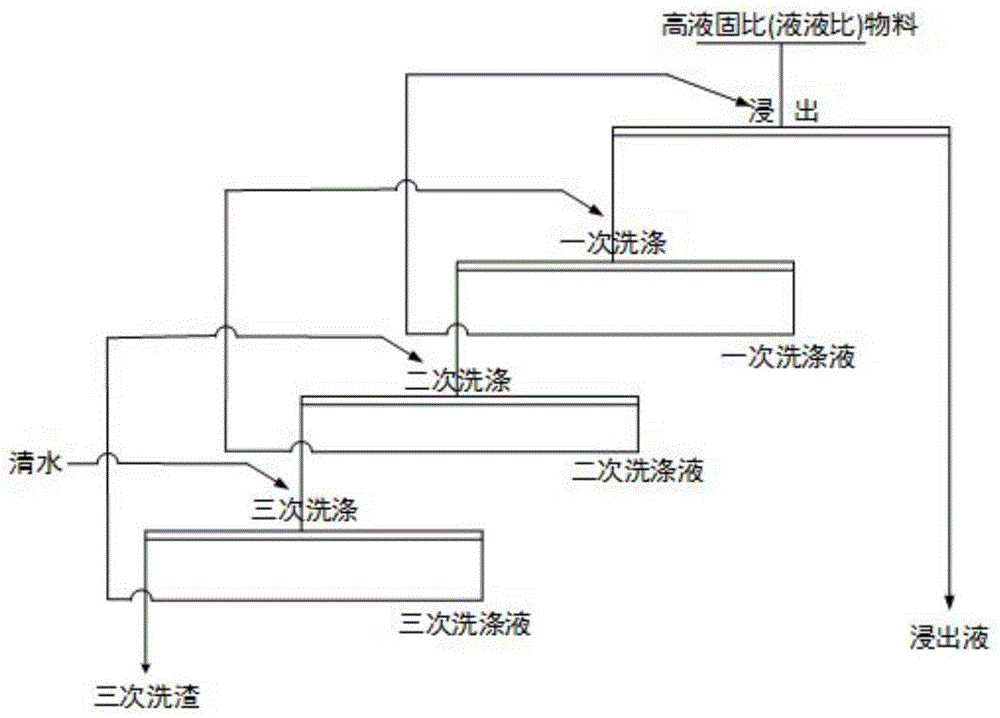

[0058] Crush the ore until the particle size is less than 3mm, accounting for 100%, add leaching aid MnO 2 , the amount is 3% to account for the mass fraction of clay vanadium ore, adding sulfuric acid with a mass fraction of 20% is made into a slurry with a solid-to-liquid ratio of 1:1.5, and the slurry is driven into the reaction compartment with a pump, and the stirring speed of the stirring scraper is The temperature is 150r / min, and the tail gas is introduced to pressurize the reaction pressure to 0.3MPa. The material in the reaction compartment is hea...

experiment example 2

[0061] Acid leaching vanadium solution precipitation vanadium

[0062] The vanadium solution in this example is the leaching solution obtained by leaching in Example 1, the pH of the solution is adjusted to be 2.4, and the tetravalent vanadium ions are extracted with P204 organic phase, and then the sulfuric acid solution of 1.5mol / L is used as a stripping agent to remove Impurities in the acid leaching vanadium solution obtain a relatively pure vanadium-containing solution, and the solution composition is as shown in the table below:

[0063]

[0064] Adjust the pH of the solution to be 5, the vanadium-containing solution and 250g / L of NH 4 Add equal volumes of Cl into the reaction compartment. At this time, the ammonium addition coefficient is K=5, the stirring speed of the stirring scraper is 150r / min, and the liquid phase in the reaction compartment is heated by a heating device. At 30°C, the reaction pressure React at 0.3MPa for 1 hour to produce precipitated sodium a...

Embodiment 3

[0067] Straw Hydrolysis Sugar

[0068] The straw in this example is taken from a farmland in Xiaogan, Hubei, China. After natural air-drying, it is crushed to below 20 meshes. Its main components are hemicellulose, cellulose, lignin, and reducing sugar, and its moisture content is 6.23%.

[0069] Take straw samples under 20 mesh and mix them with sulfuric acid with a mass fraction of 5% to make a material with a solid-to-liquid ratio of 1:2. Use a pump to pump the mixture into the reaction compartment, and the stirring speed of the stirring scraper is 150r / min, feed tail gas and pressurize to the reaction pressure of 0.3MPa, soak in water at 125°C, react for 2 hours, filter to obtain the leachate, and wash the reaction slag three times with the washing method adopted in the present invention, and discharge Leach residue.

[0070] The hydrolyzed reducing sugar yield was 57.30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com