Alkylation product separation method, alkylation reaction separation method and alkylation reaction separation device

A technology for an alkylation reaction and a separation method, which is applied in the field of the separation method and separation device of the alkylation reaction products of low-carbon olefins and alkanes, can solve problems such as inability to effectively recover and utilize, and achieves remarkable energy saving effect, easy control, and reduction of steam. The effect of the total amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 illustrates the effect of the separation method of the alkylation reaction product provided by the present invention.

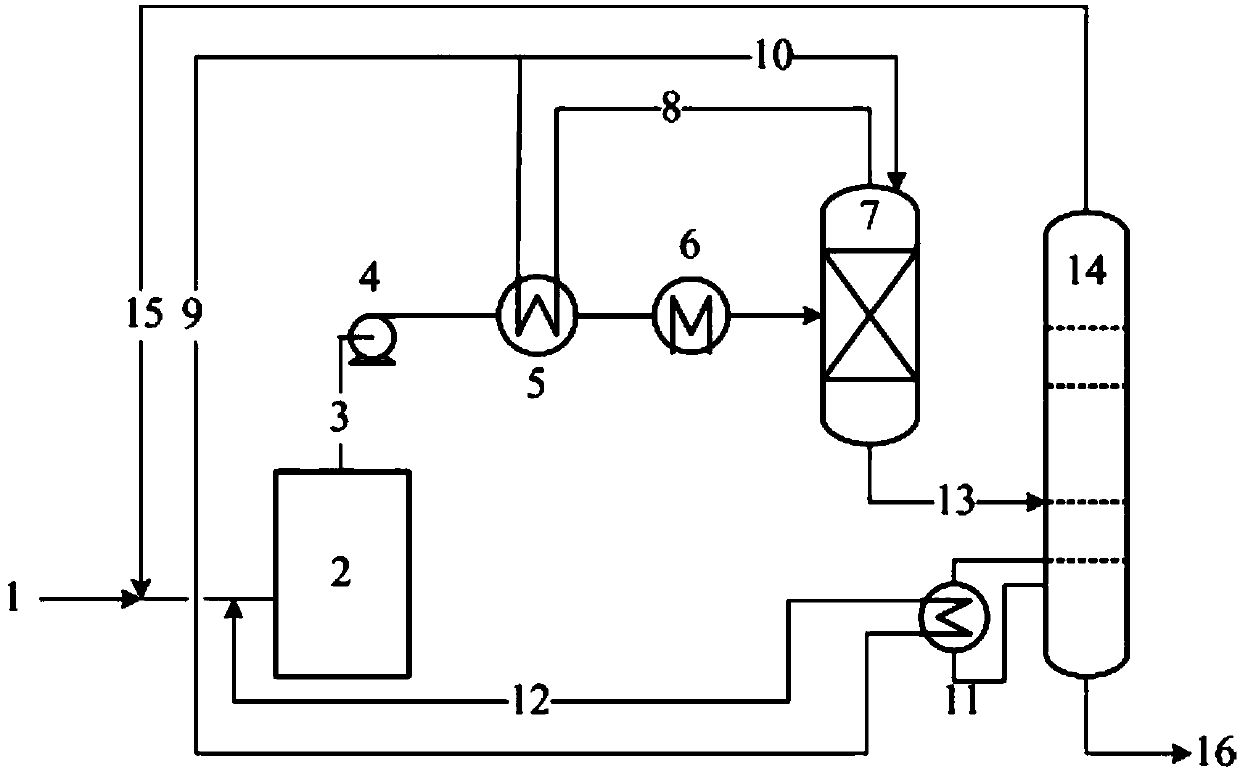

[0050] Attached figure 1 In the reaction separation process shown, the alkylation reaction unit is the same as that of Comparative Example 1, and the alkylation reaction product obtained by the alkylation reactor is the same as that of Comparative Example 1.

[0051] Using the alkylation product separation system and method described in the present invention, the specific operating conditions are as follows: the outlet pressure of the booster pump is 3.6MPa, the outlet temperature of the cold flow heat exchanger is 76°C, the outlet temperature of the external heater is 160°C, and the vapor phase fraction 0.6, the operating pressure of the high-pressure flash tower is 3.5MPa, the vapor phase temperature at the top of the tower is 148°C, the reflux ratio is 0.6, and the liquid phase temperature at the bottom of the tower is 157°C. The vapor ph...

Embodiment 2

[0059] Example 2 illustrates the effect of the separation method for the alkylation reaction product provided by the present invention.

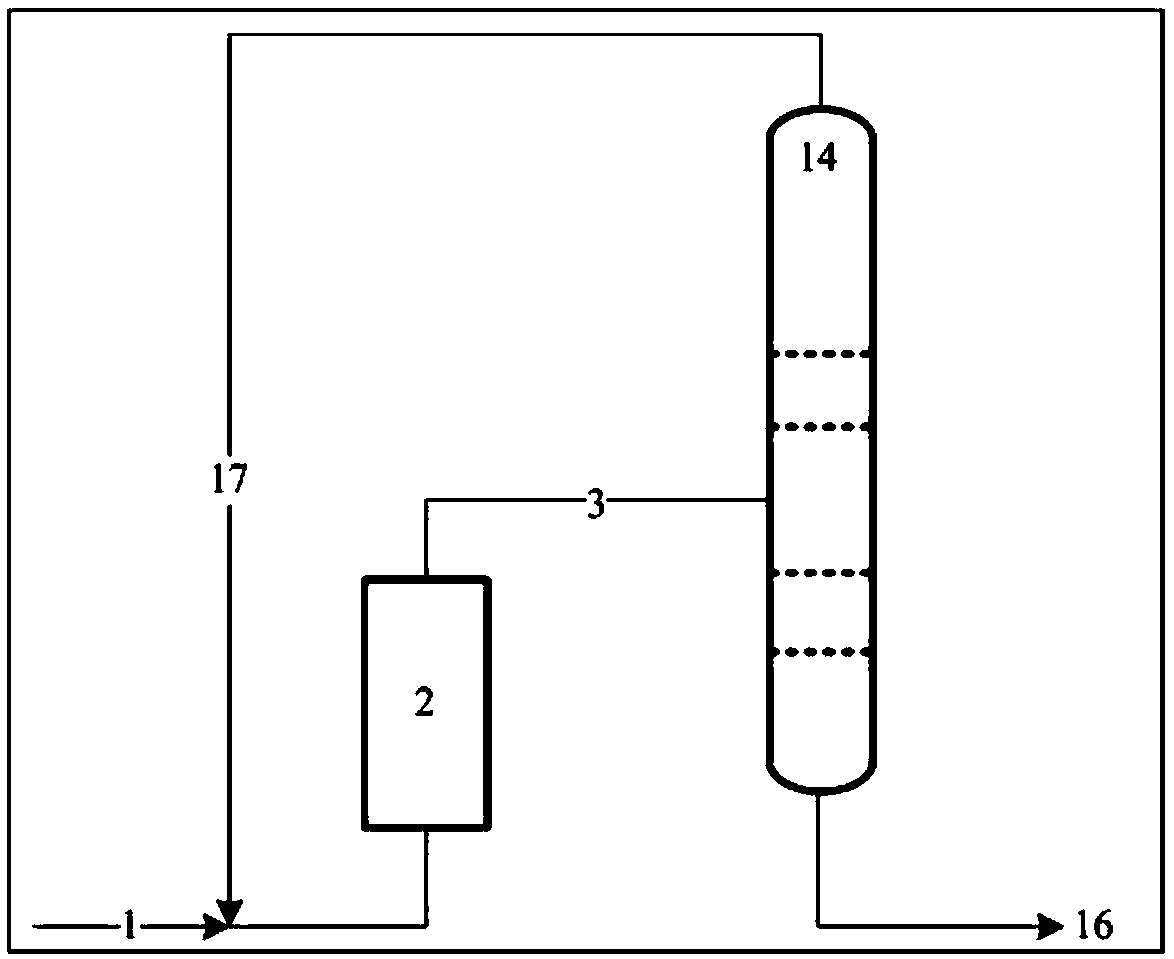

[0060] Attached figure 2 In the reaction separation process shown, the alkylation reaction unit is the same as that of Comparative Example 2, the reactor outlet pressure is 3.0 MPa, and the high-pressure flash pressure is 2.9 MPa, so there is no need to install a booster pump in the middle. The outlet temperature of the first heat exchanger of the cold stream is 115°C, the outlet temperature of the second heat exchanger is 135°C, the vapor phase fraction is 0.9, the vapor phase temperature at the top of the high pressure flash tower is 128°C, the reflux ratio is 0.5, and the bottom liquid The phase temperature is 133°C. The vapor phase at the top of the flash tower exchanges heat with the material at the outlet of the reactor, and the temperature drops to 120°C and condenses into a full liquid phase, and then exchanges heat with the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com