Patents

Literature

98results about "Treatment with alkylation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for making high octane gasoline with reduced benzene content

InactiveUS20060194998A1Easy to handleHigh activityCatalytic crackingLiquid hydrocarbon mixtures productionBenzeneMolecular sieve

Solid phosphoric acid (SPA) olefin oligomerization process units may be converted to operation with a more environmentally favorable solid catalyst. The SPA units in which a light olefin feed is oligomerized to form gasoline boiling range hydrocarbon product, is converted unit to operation with a molecular sieve based olefin oligomerization catalyst comprising an MWW zeolite material. Besides being more environmentally favorable in use, the MWW based zeolites offer advantages in catalyst cycle life, selectivity. After loading of the catalyst, the converted unit is operated as a fixed-bed unit by passing a C2- C4 olefinic feed and a light aromatic co-feed containing benzene to a fixed bed of the MWW zeolite catalyst to effect alkylation of the benzene with the aromatic co-feed, typically at a temperature from 150 to 350° C., a pressure not greater than 7000 kpa, usually less than 4000 kPa and an olefin space velocity up to 10 WHSV.

Owner:EXXON RES & ENG CO

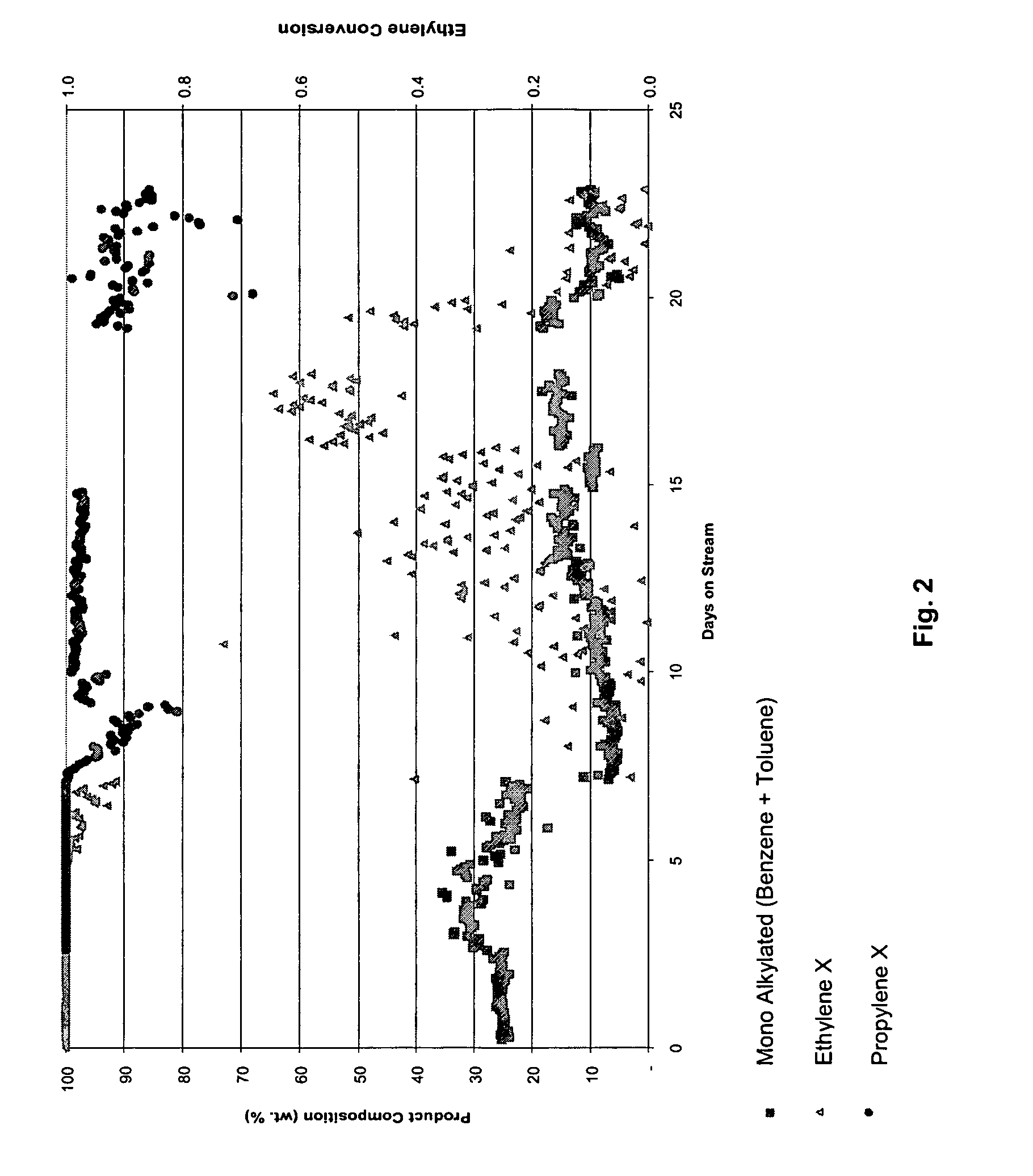

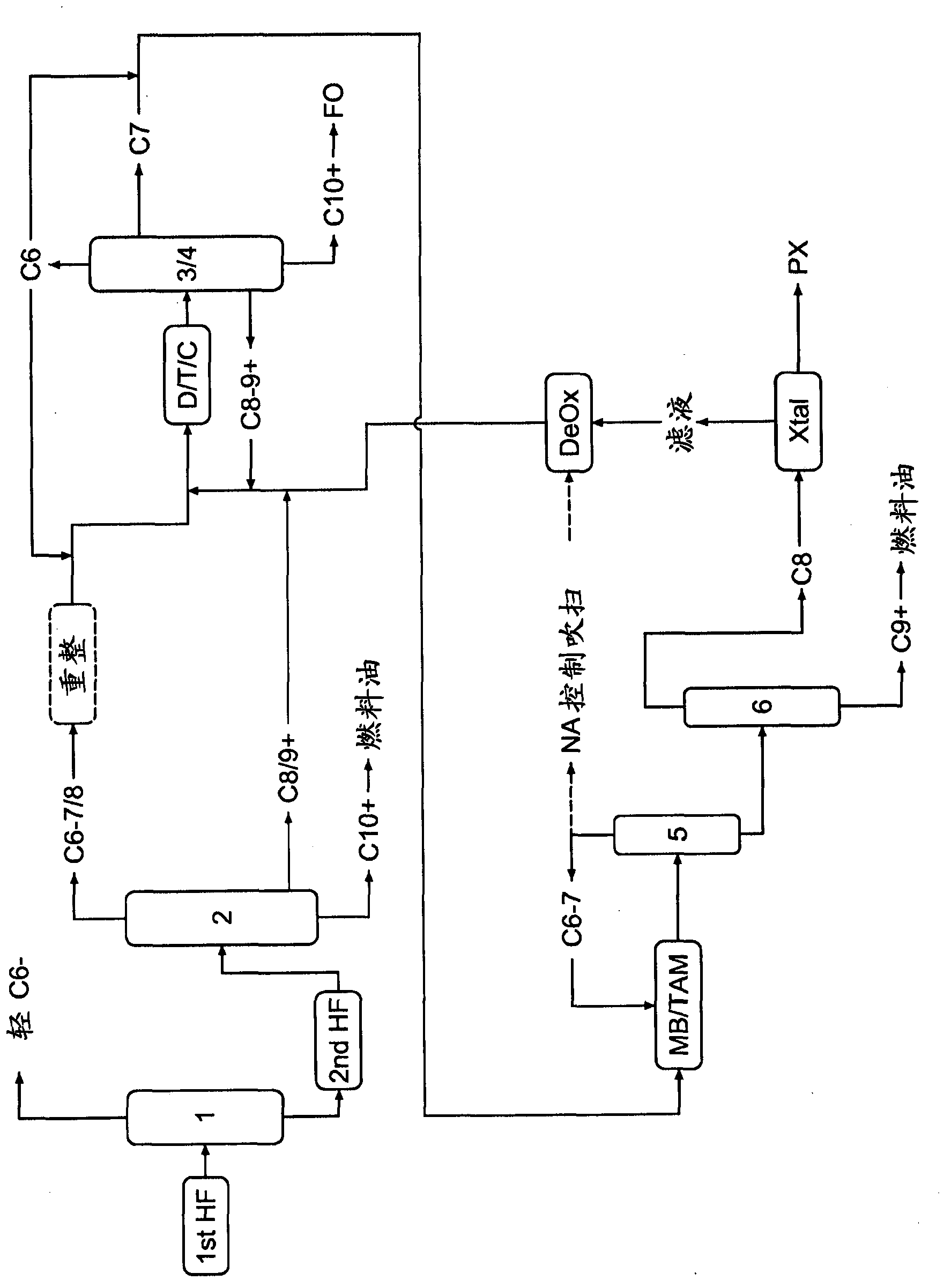

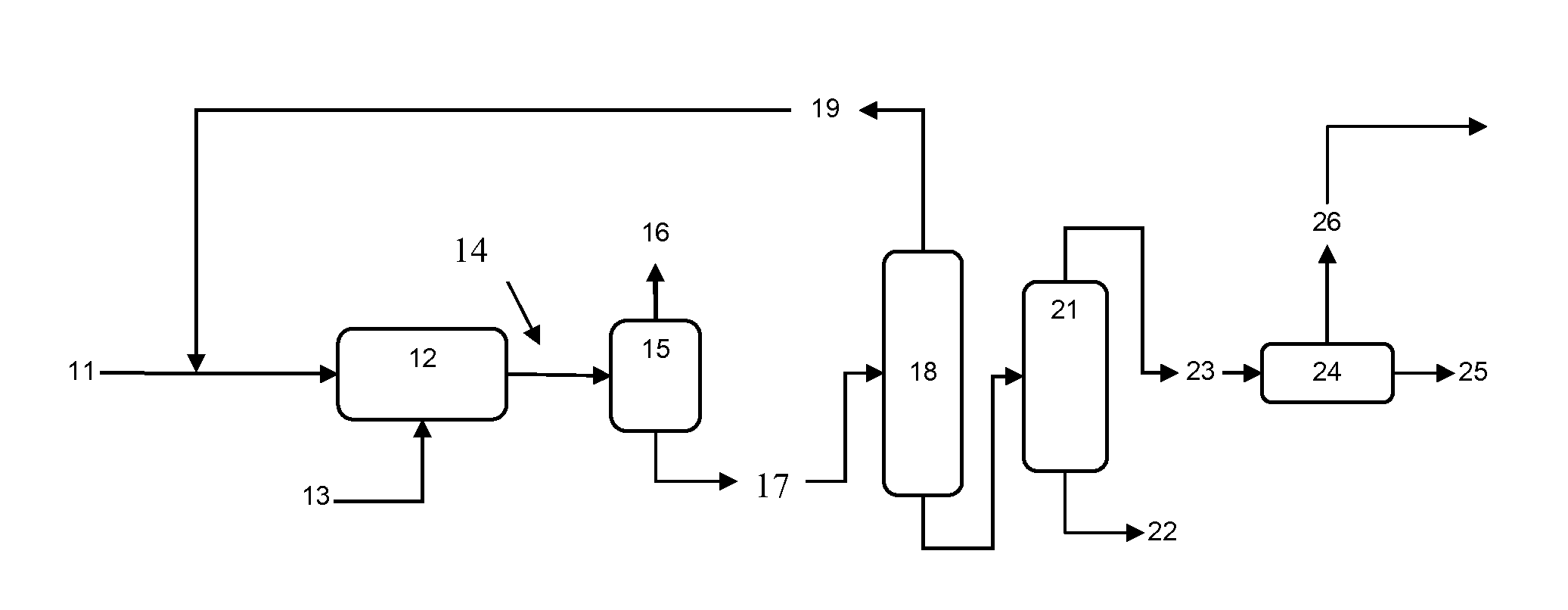

Method and apparatus for obtaining aromatics from diverse feedstock

ActiveCN103261124ATreatment with plural serial stages onlyHydrocarbons from unsaturated hydrocarbon additionBenzeneNaphtha

The process relates to the use of any naphtha-range stream containing a portion of C8+ aromatics combined with benzene, toluene, and other non-aromatics in the same boiling range to produce toluene. By feeding the A8+ containing stream to a dealkylation / transalkylation / cracking reactor to increase the concentration of toluene in the stream, a more suitable feedstock for the methylation reaction can be produced. This stream can be obtained from a variety of sources, including the pygas stream from a steam cracker, "cat naphtha" from a fluid catalytic cracker, or the heavier portion of reformate.

Owner:EXXONMOBIL CHEM PAT INC

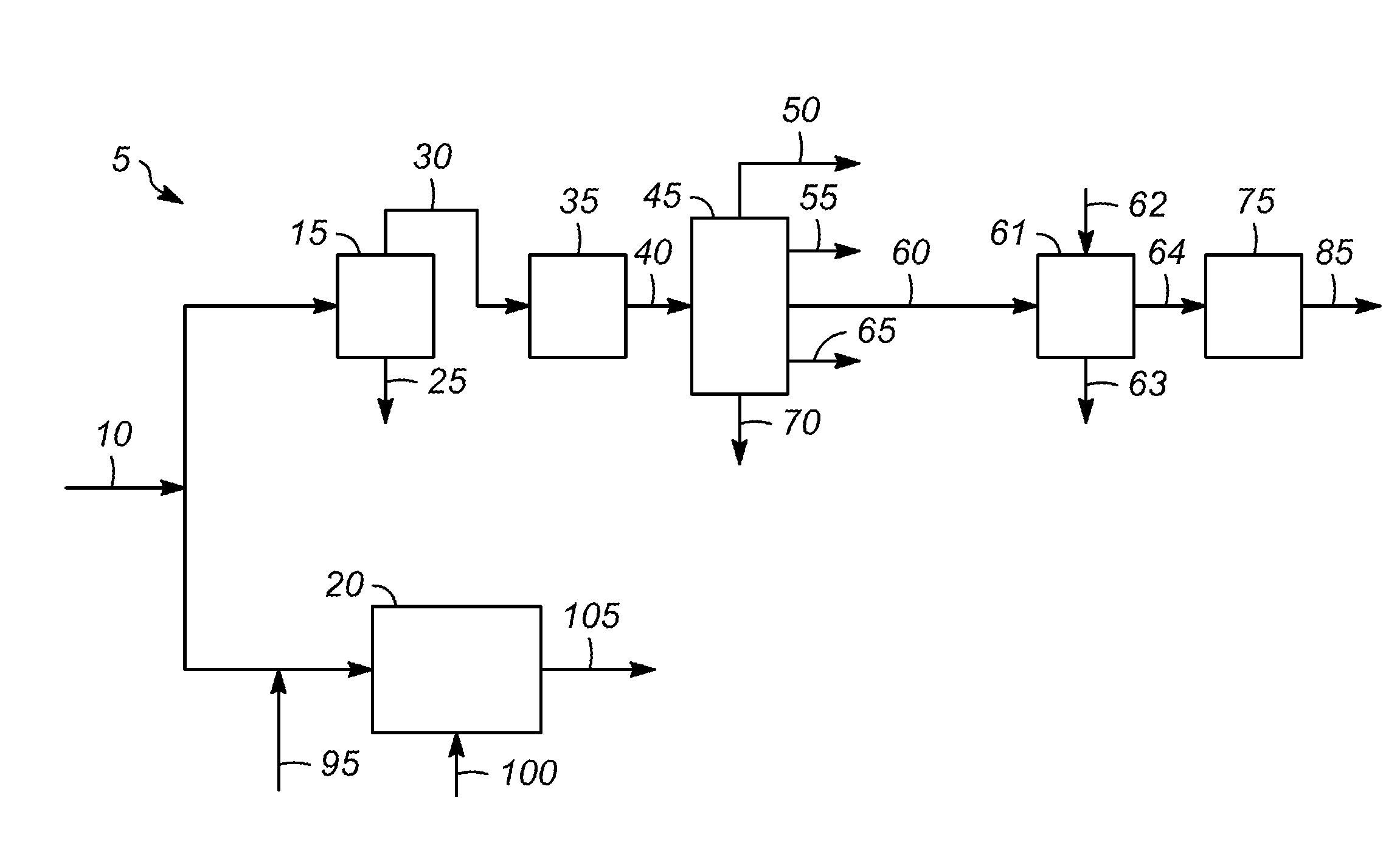

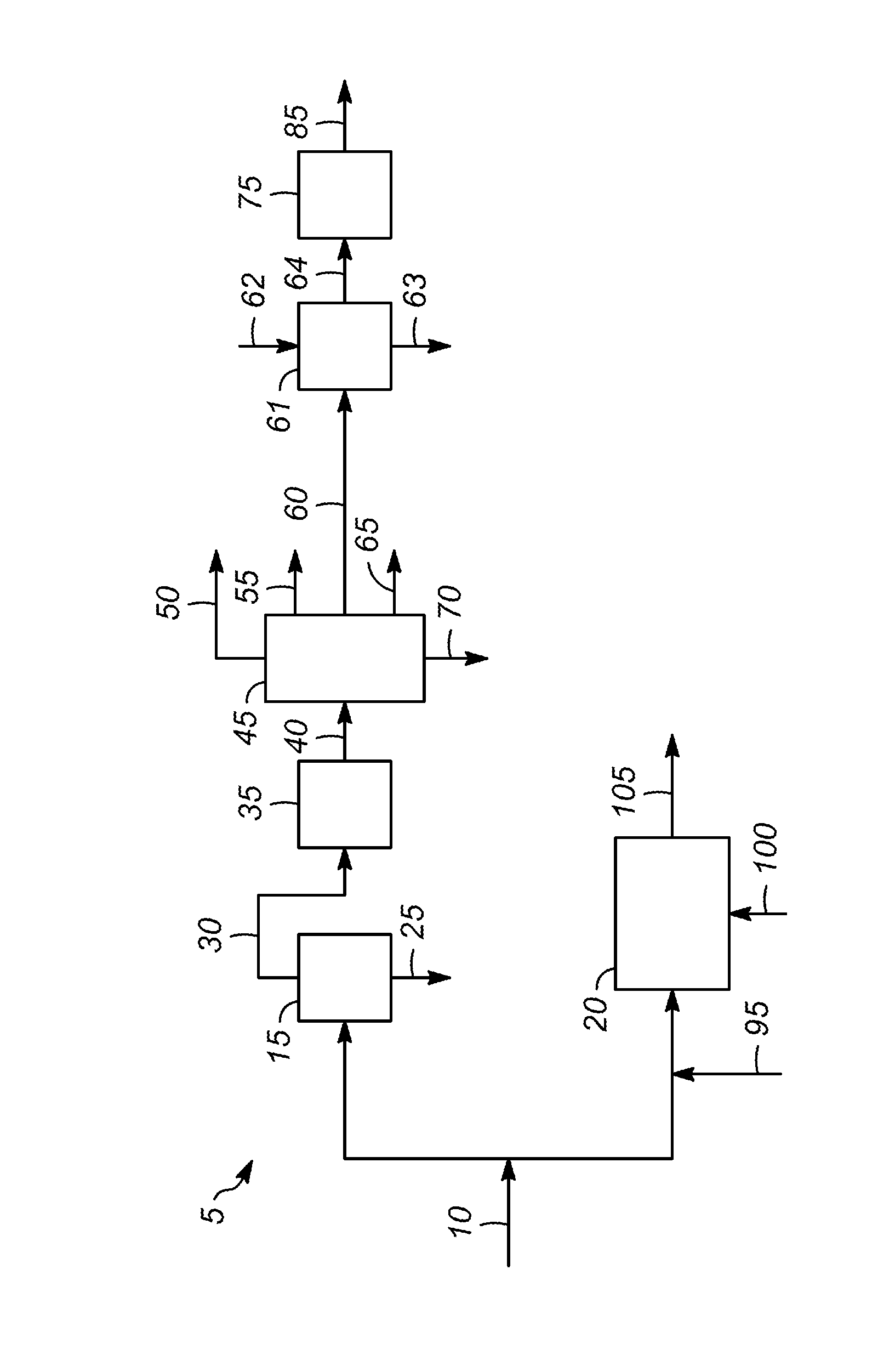

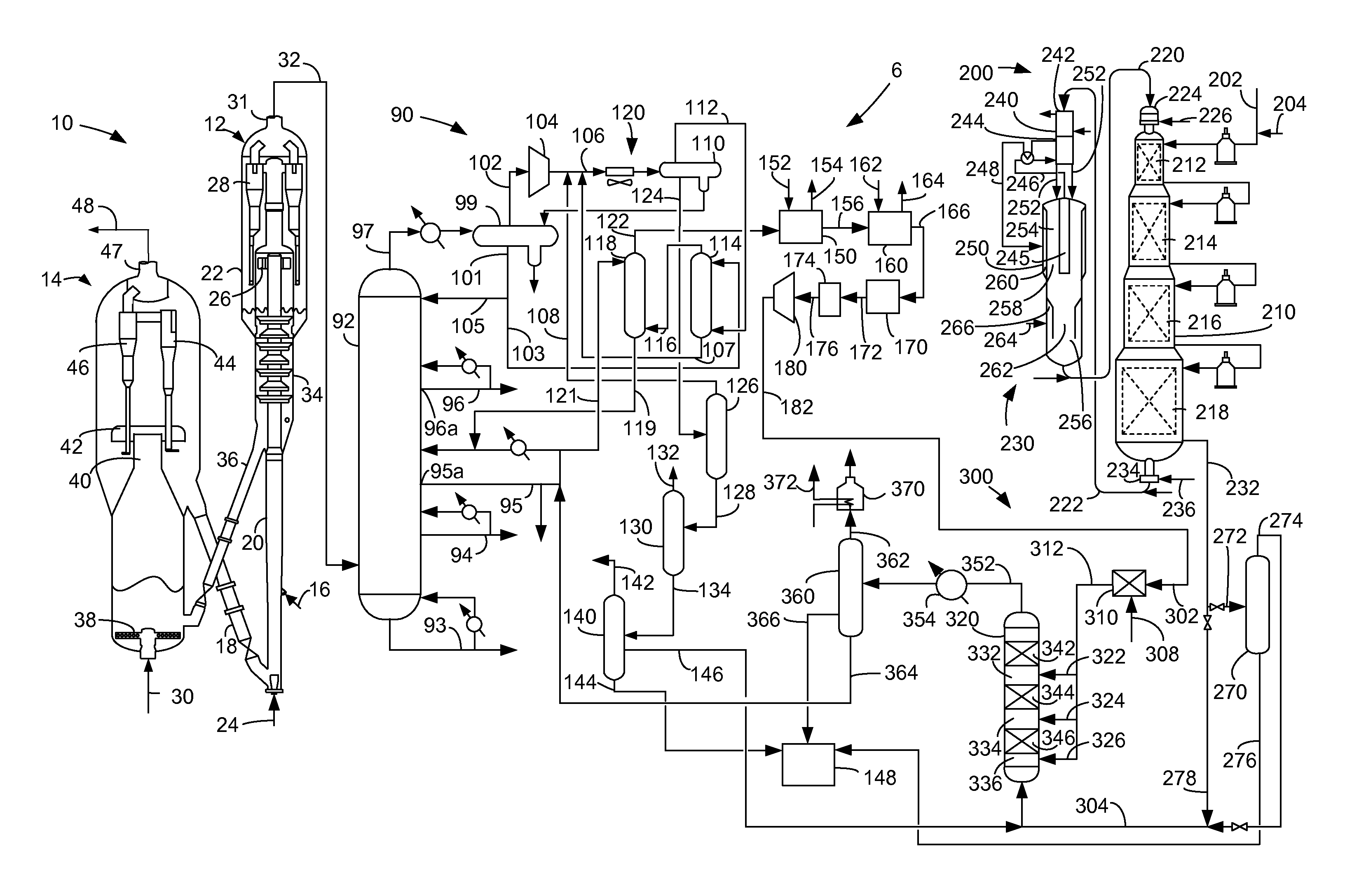

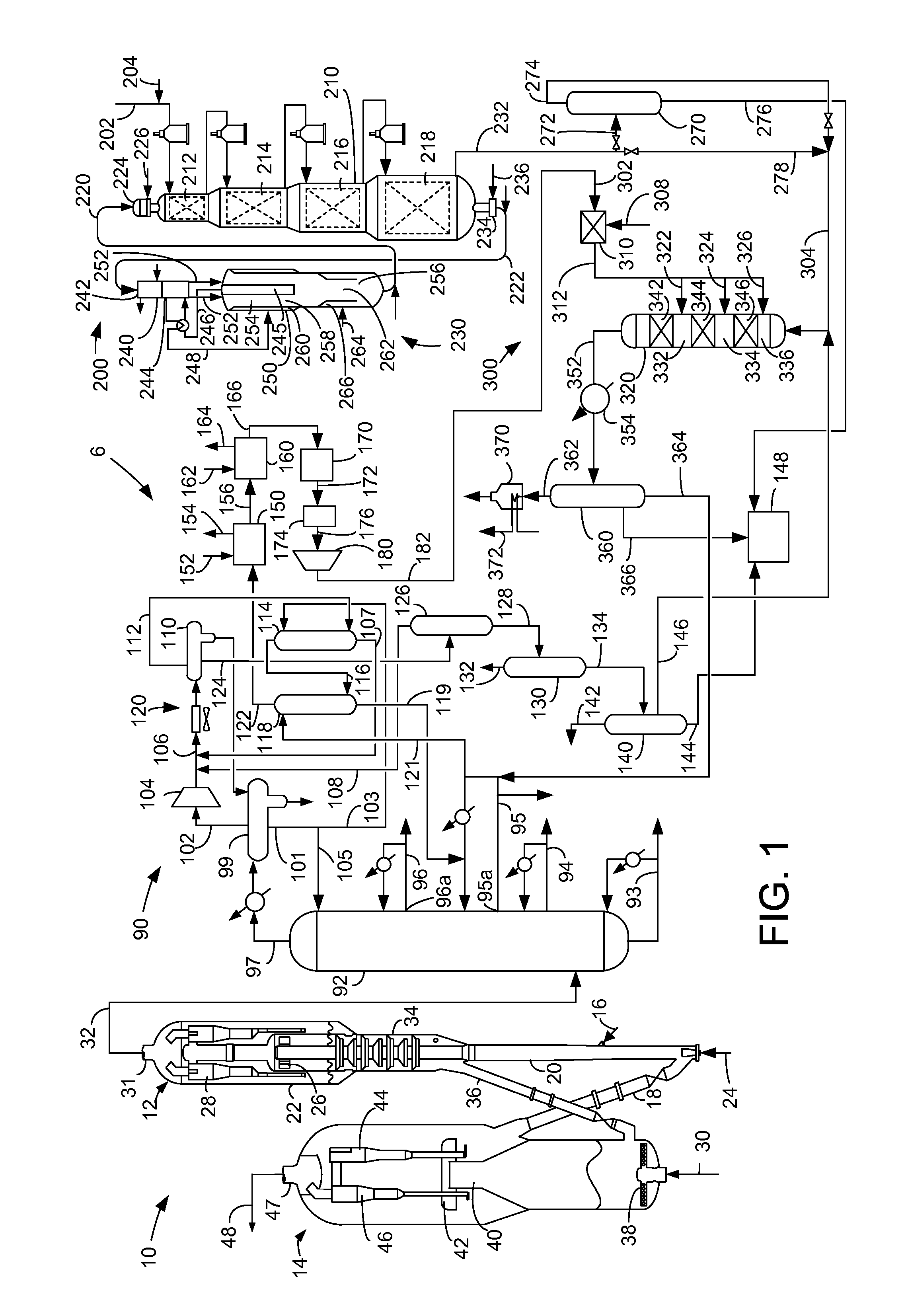

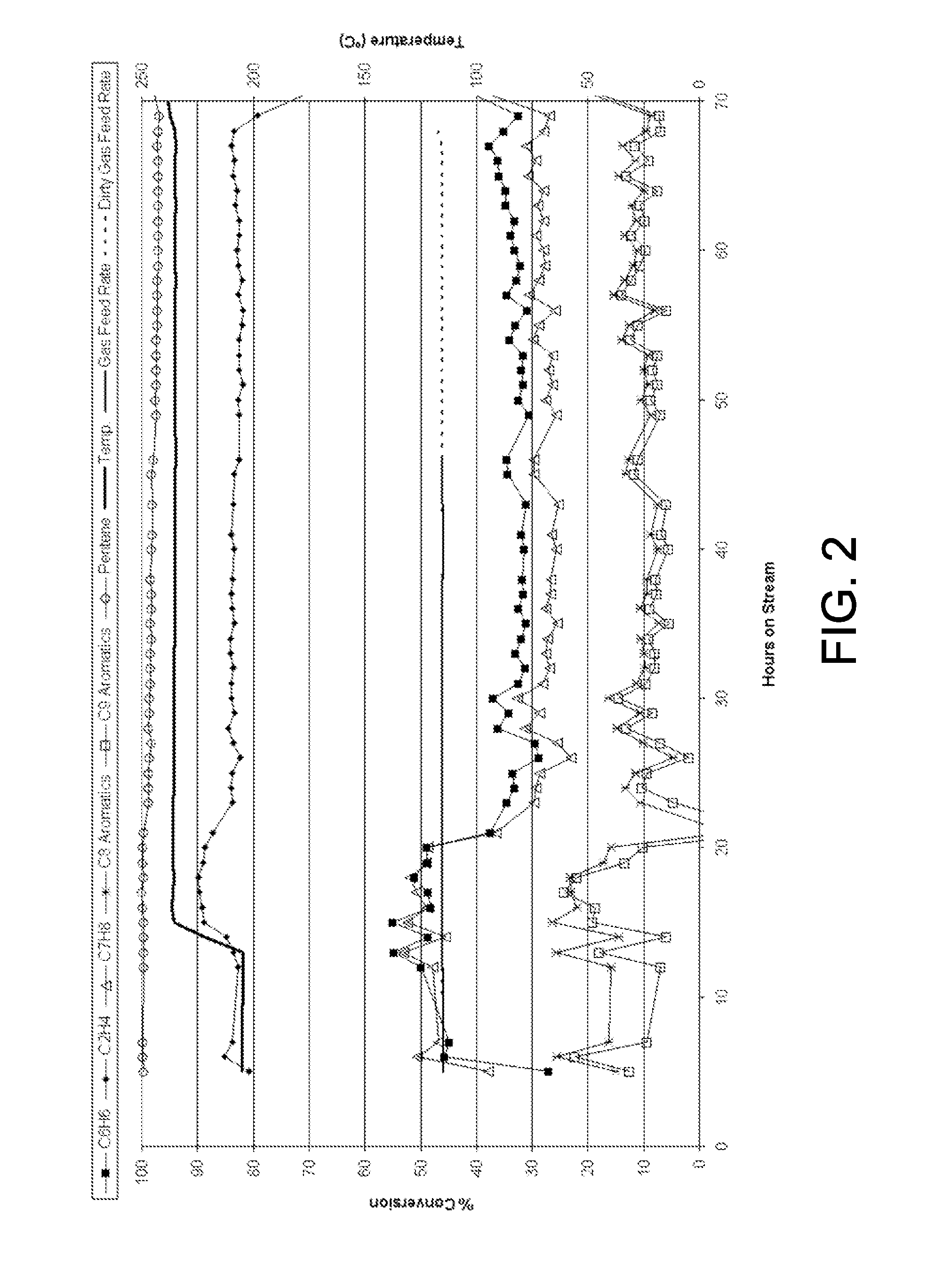

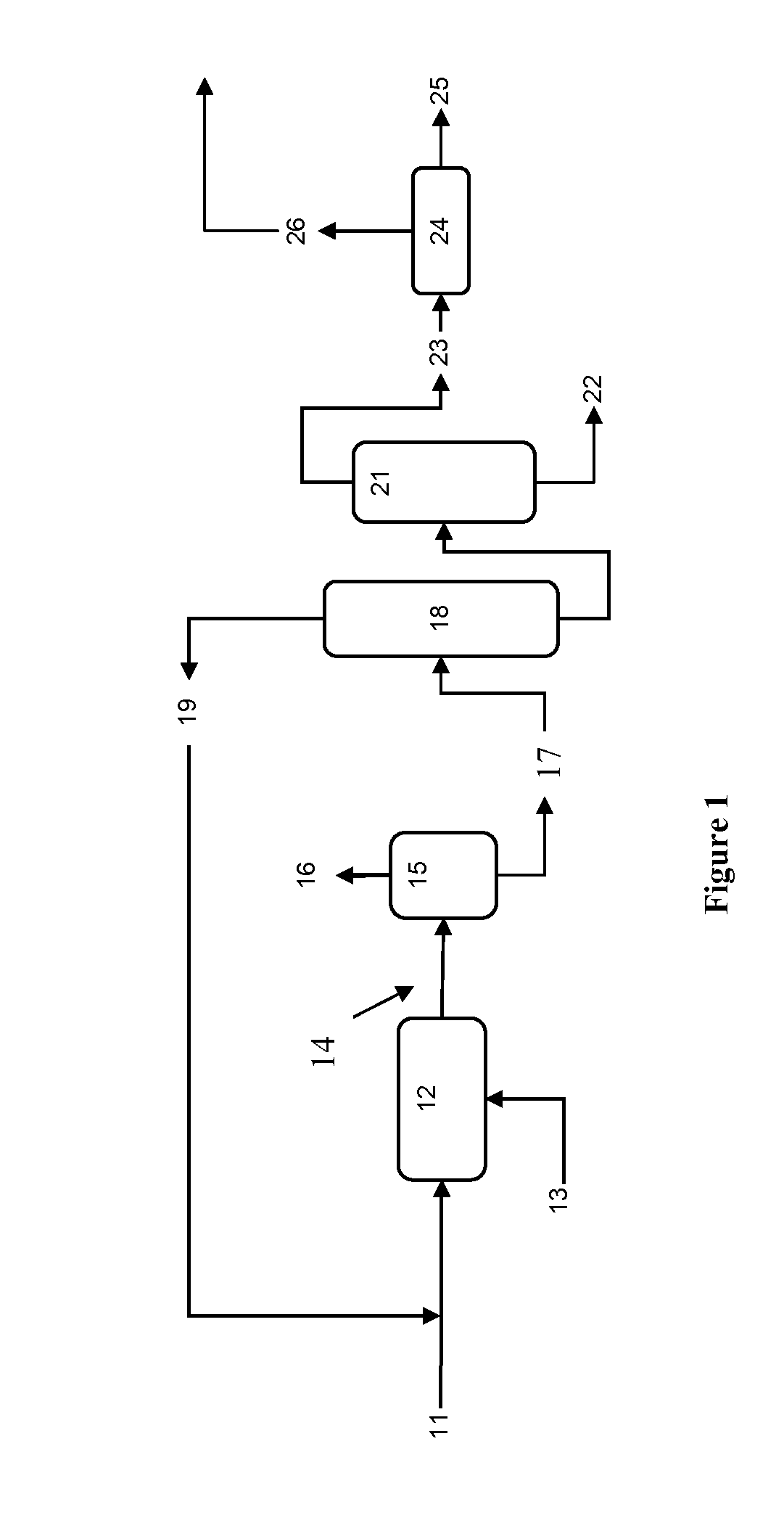

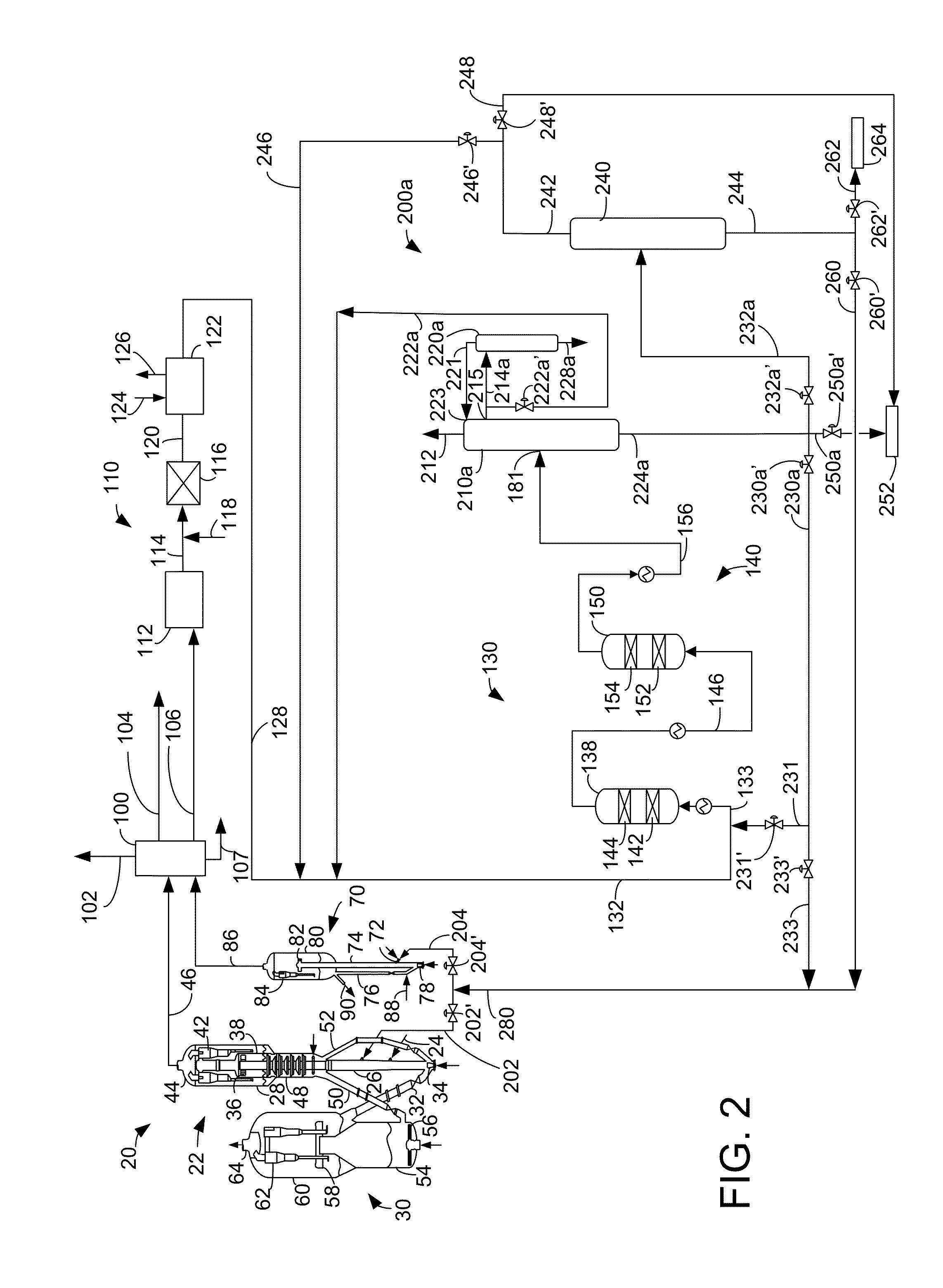

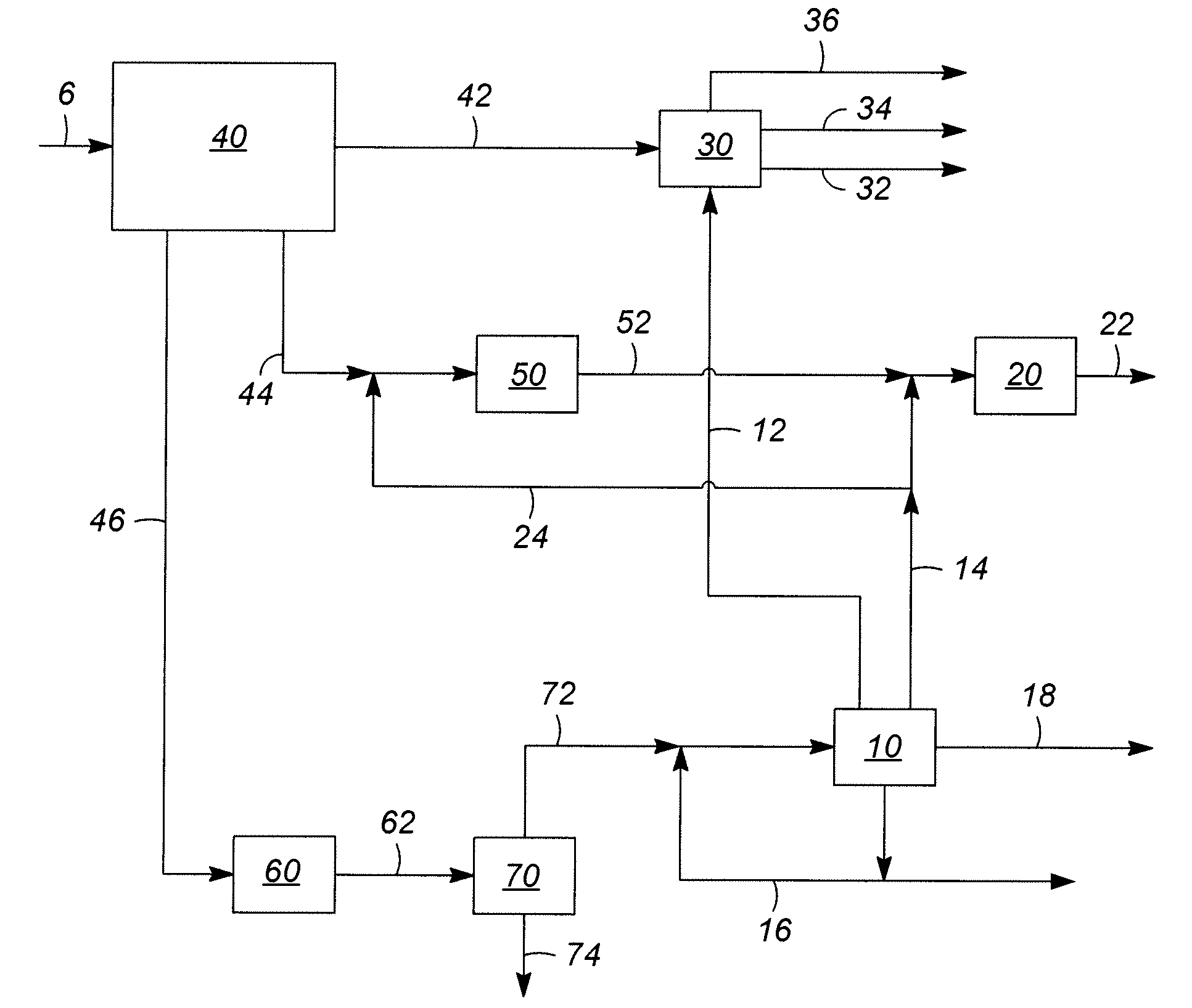

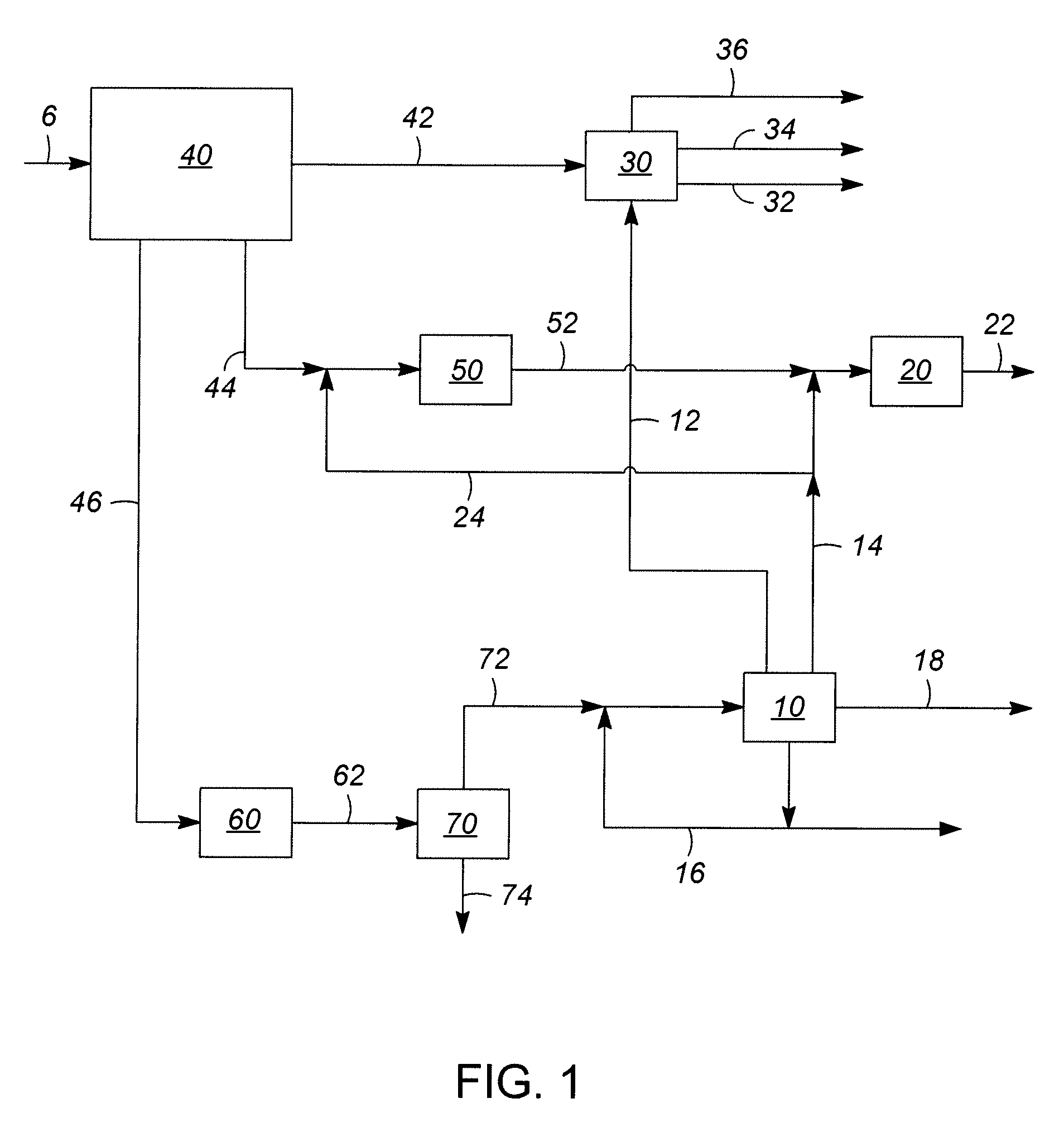

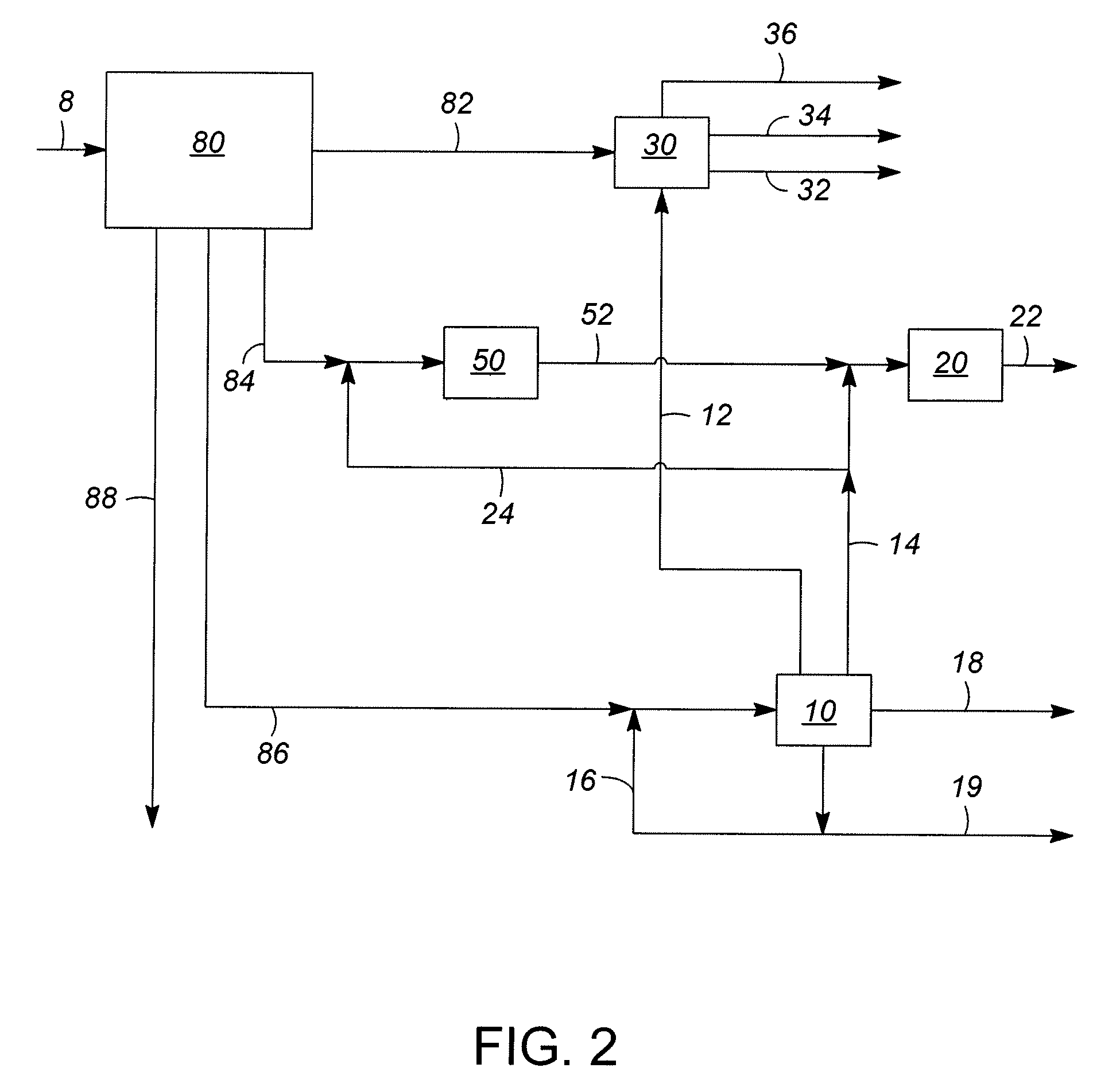

Integration of Cyclic Dehydrogenation Process with FCC for Dehydrogenation of Refinery Paraffins

ActiveUS20120071701A1Increase productionIncreased paraffinic contentCatalytic crackingCatalystsAlkaneParaffin wax

A process for increasing light olefin yields from the fluidized catalytic cracking process. The process combines small units to treat the paraffinic components in the product streams from the fluidized cracking process. The paraffins are dehydrogenated and light olefins are separated. Heavier olefins are passed to an olefin cracking unit for increasing the yields of ethylene and propylene.

Owner:UOP LLC

Reduction of organic halide contamination in hydrocarbon products

ActiveUS8105481B2Reducing organic halide concentrationCatalystsHydrocarbon preparation catalystsMolecular sieveHalogen

A method for reducing halide concentration in a hydrocarbon product having an organic halide content from 50 to 4000 ppm which is made by a hydrocarbon conversion process using an ionic liquid catalyst comprising a halogen-containing acidic ionic liquid comprising contacting at least a portion of the hydrocarbon product with at least one molecular sieve having pore size from 4 to 16 Angstrom under organic halide absorption conditions to reduce the halogen concentration in the hydrocarbon product to less than 40 ppm is disclosed.

Owner:CHEVROU USA INC

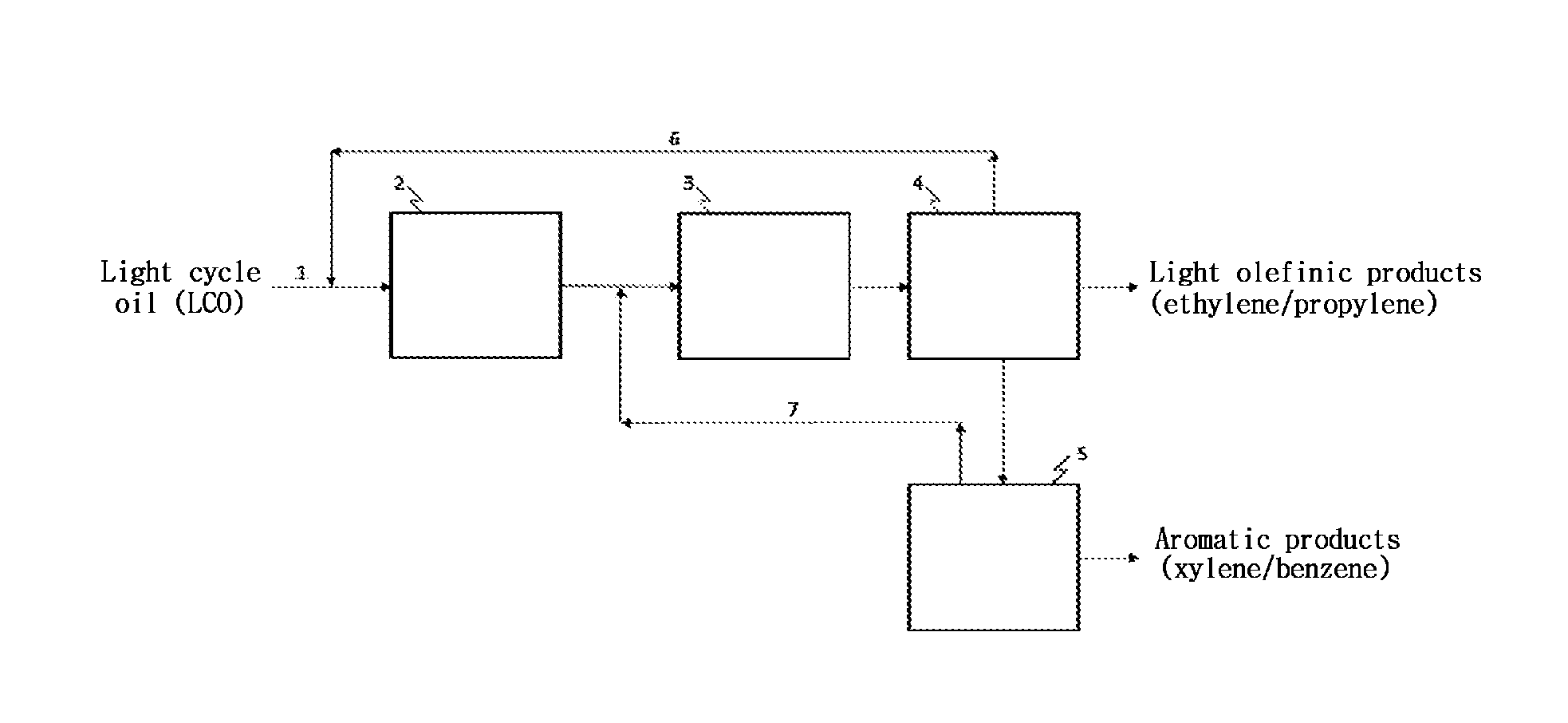

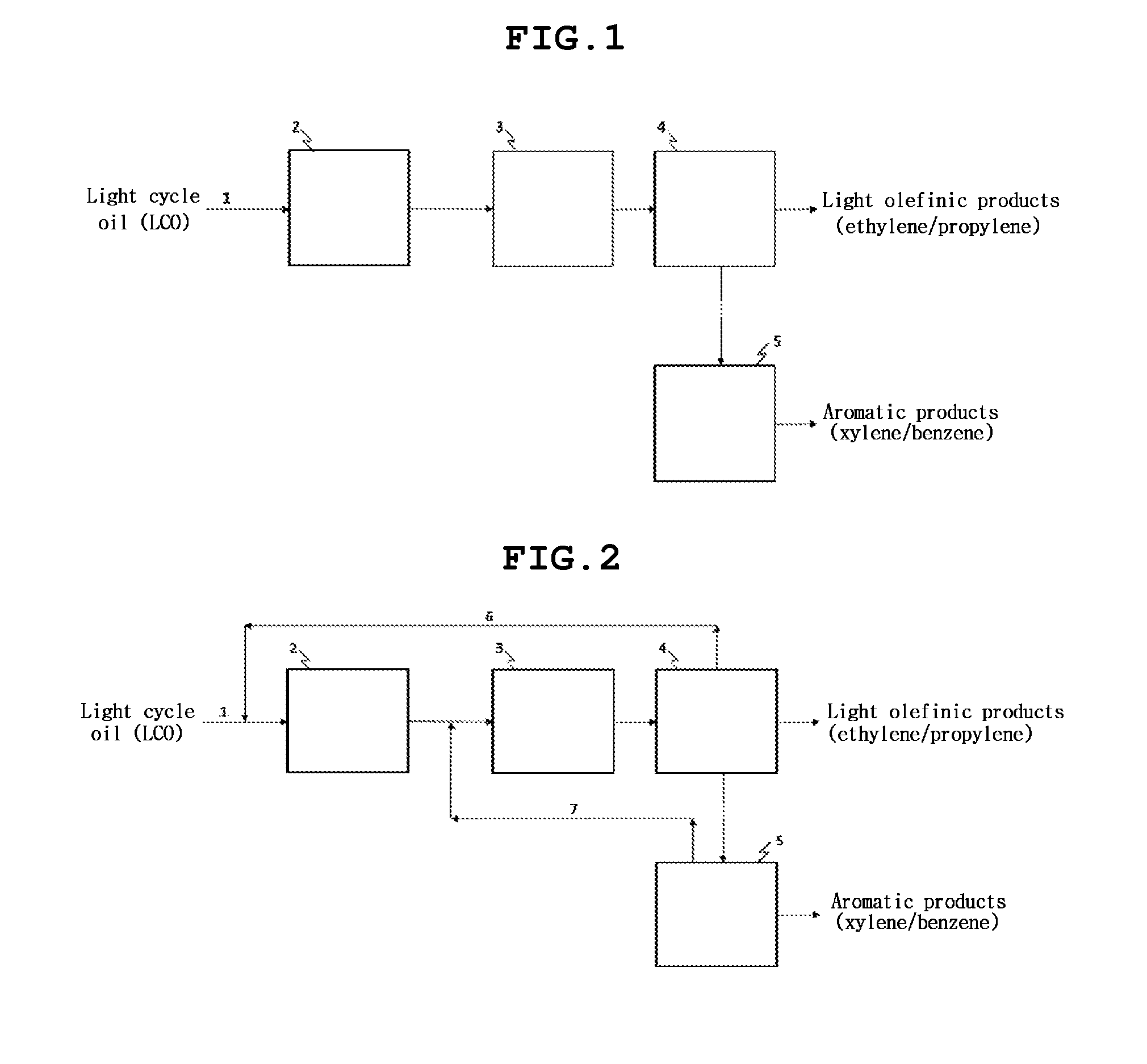

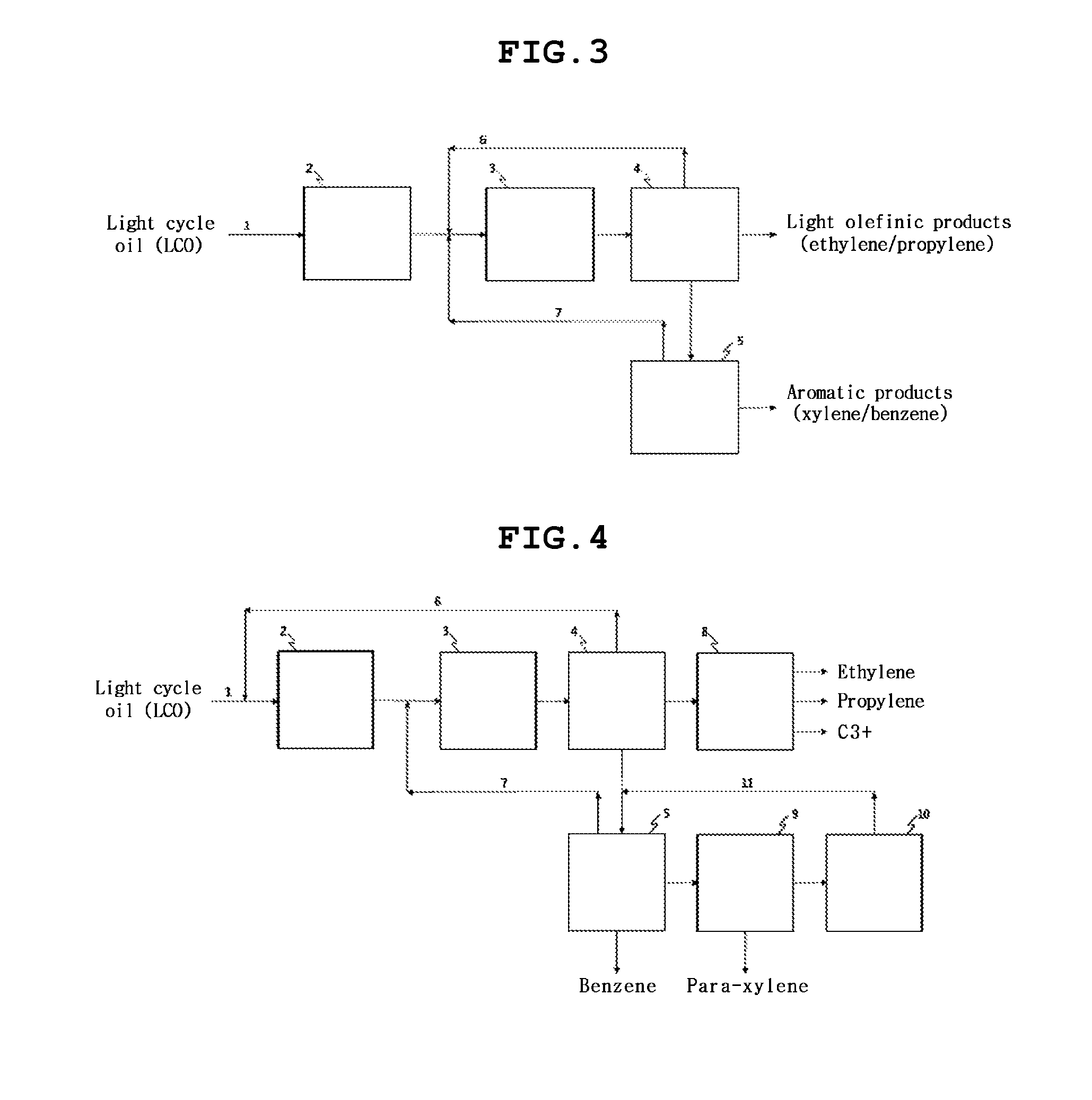

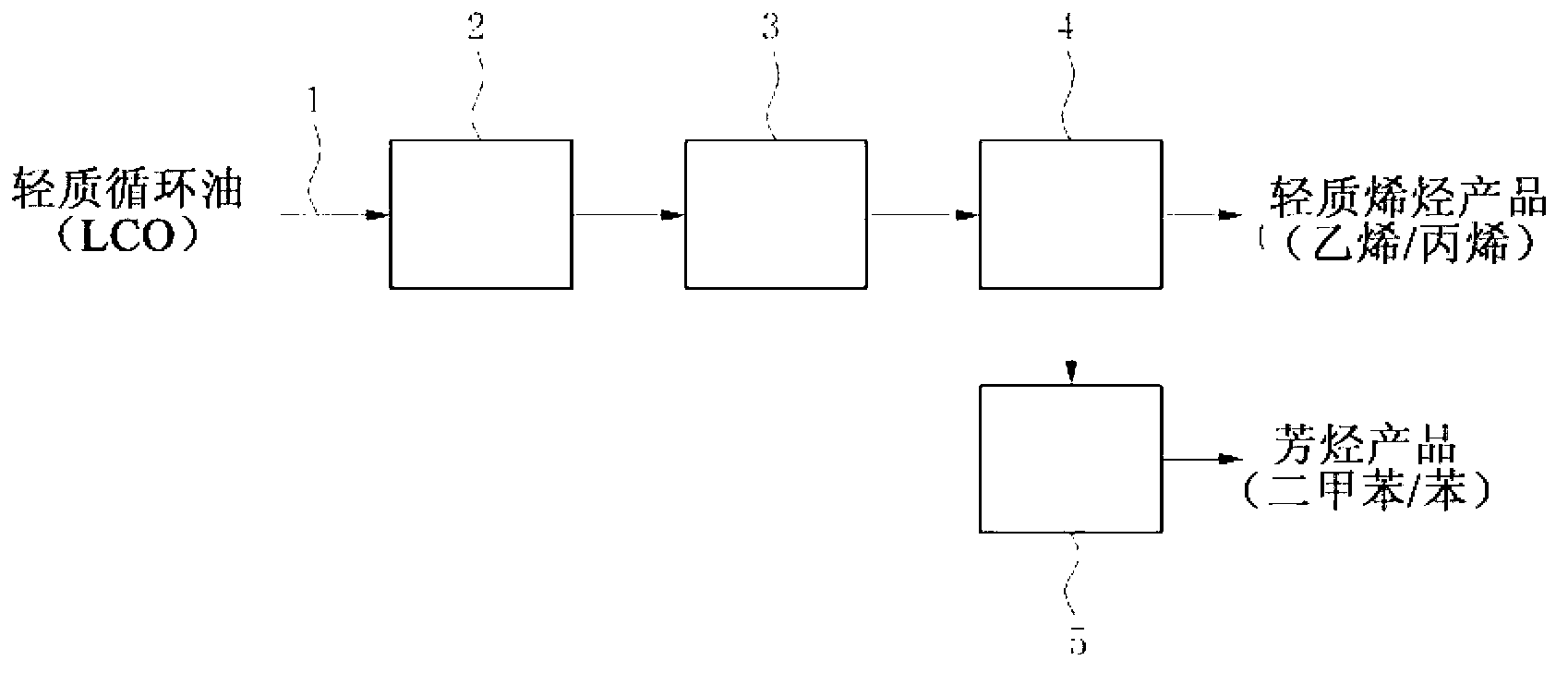

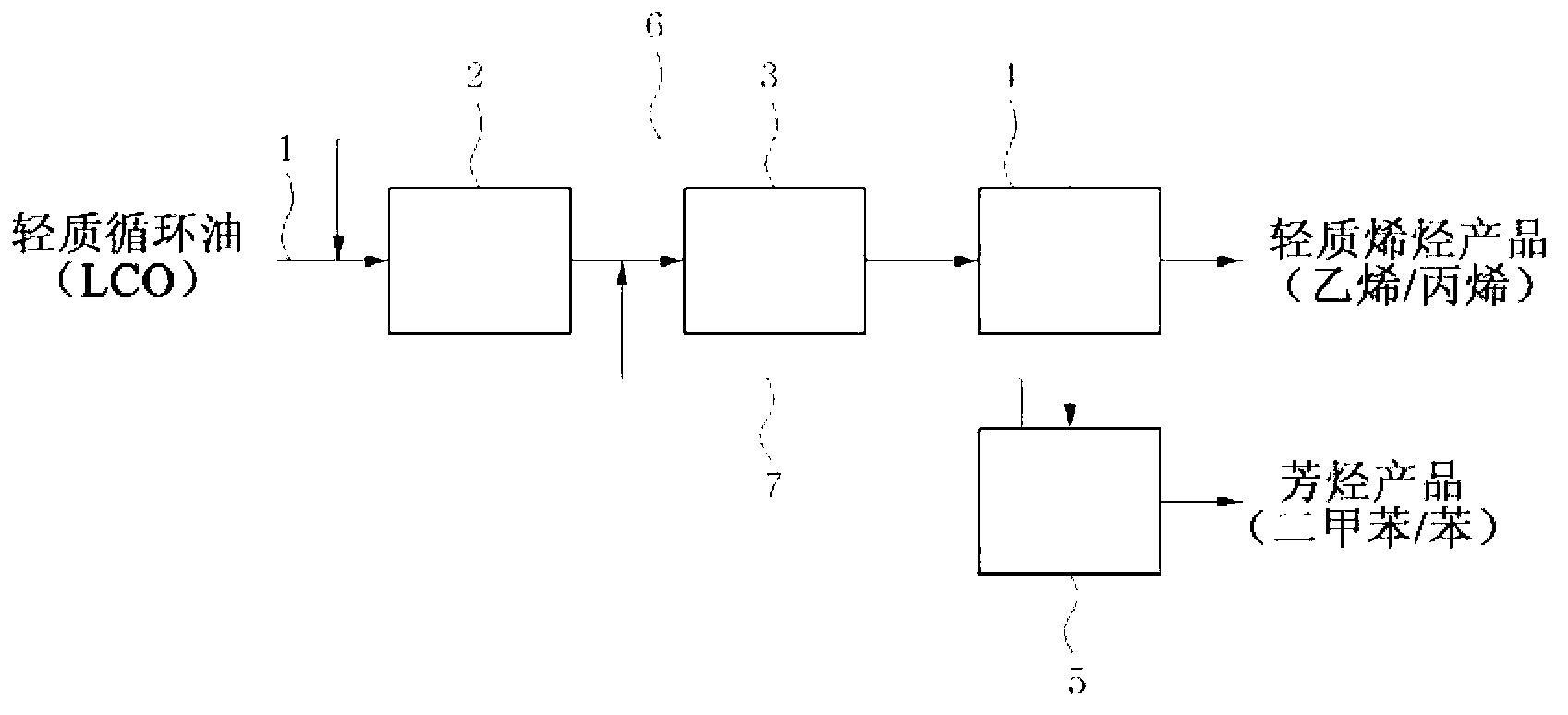

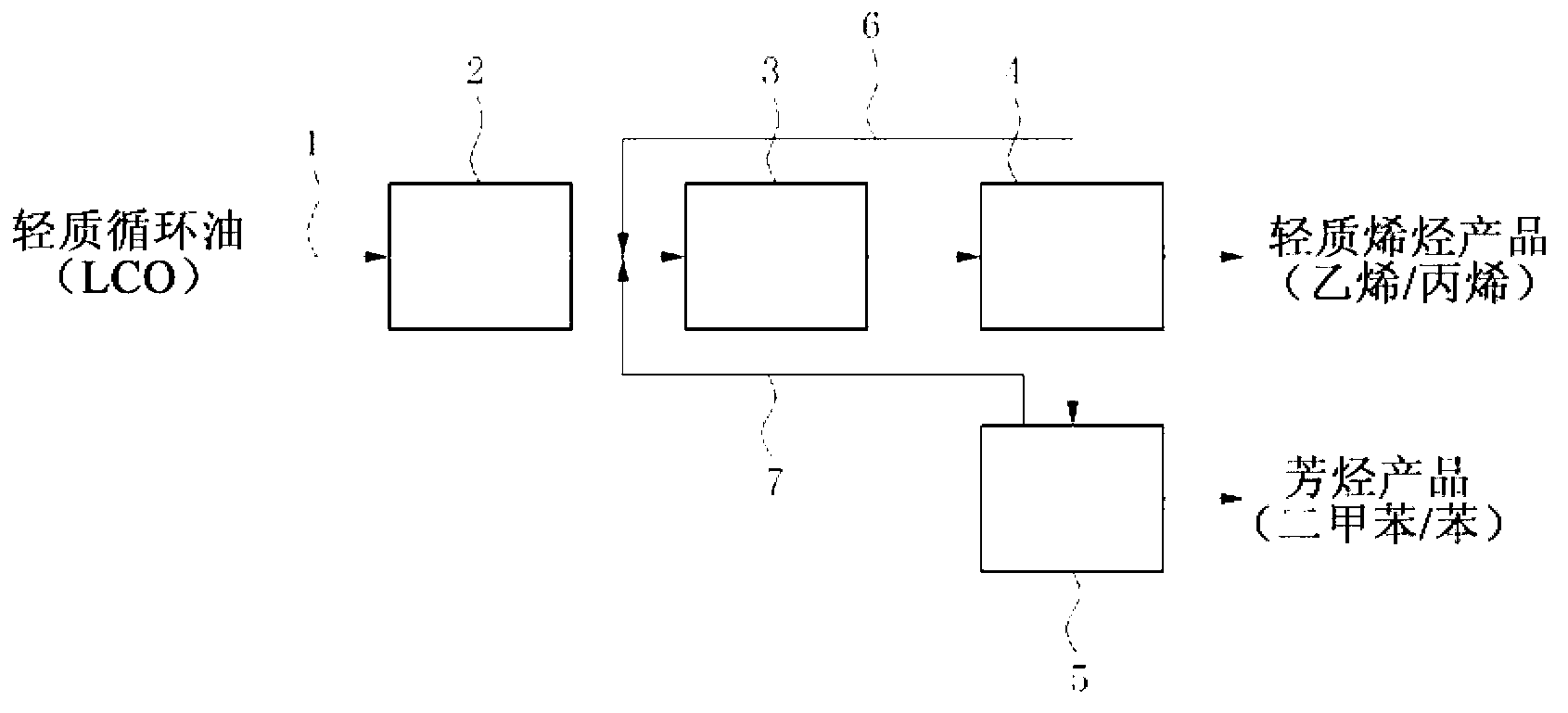

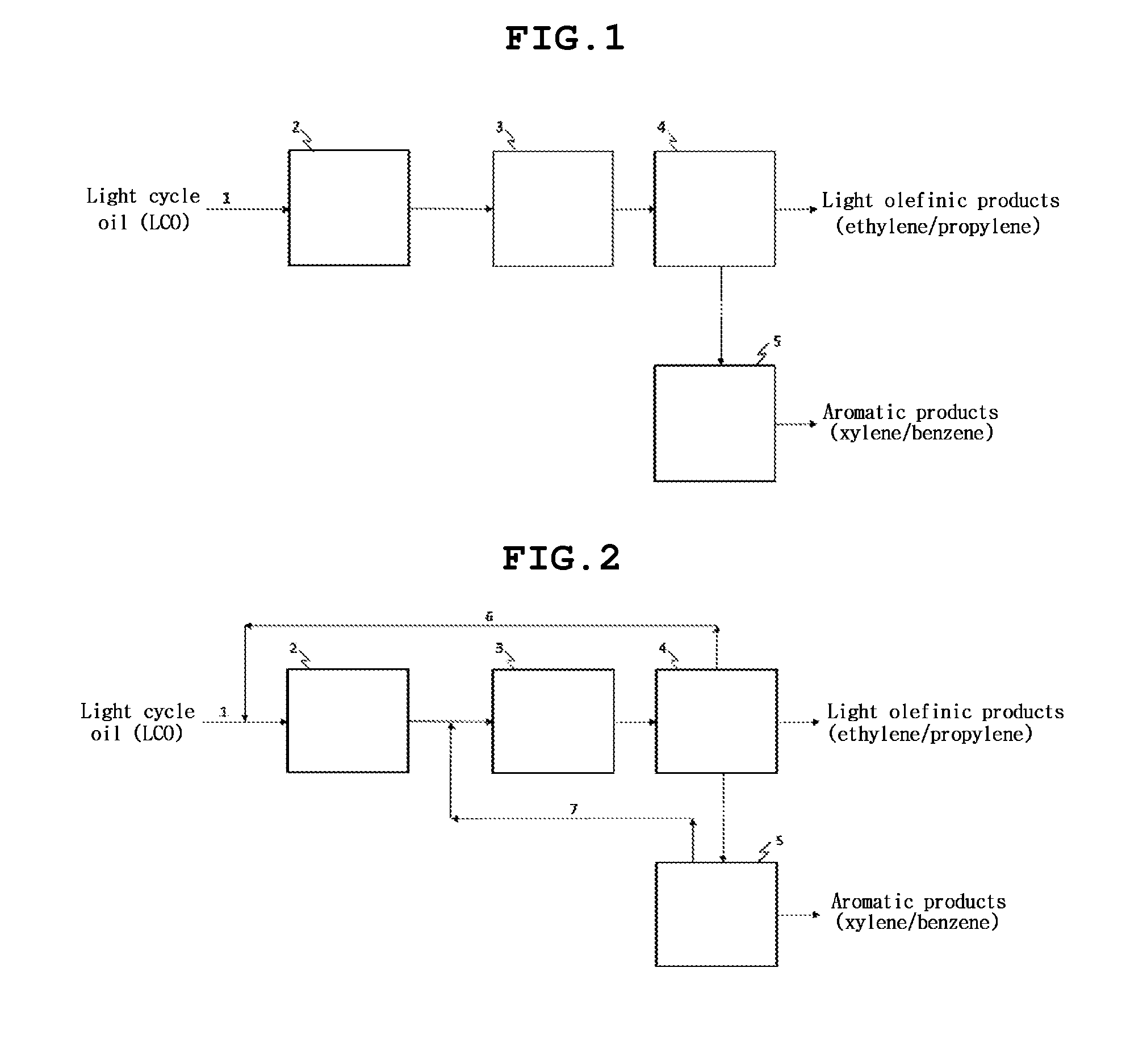

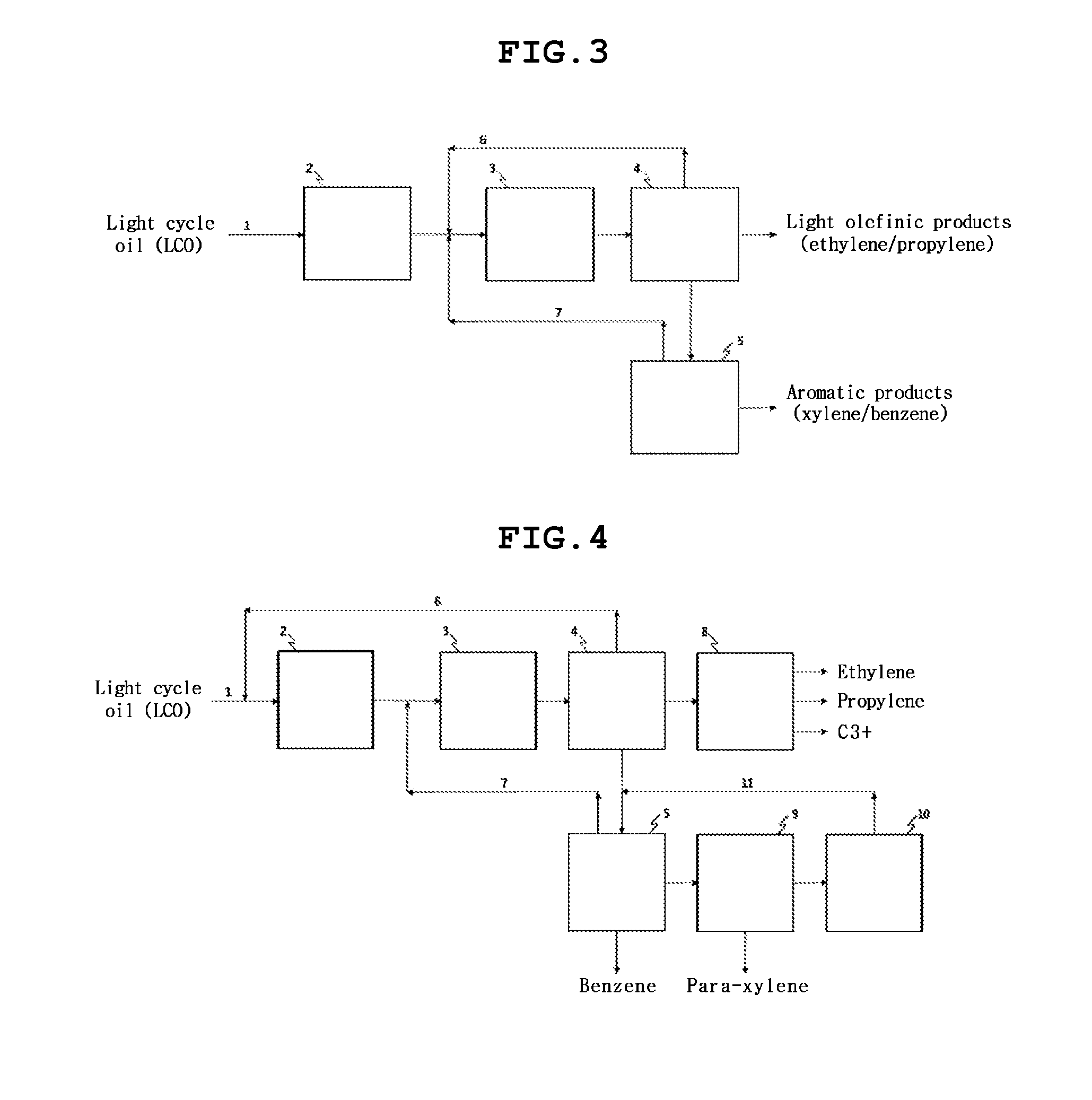

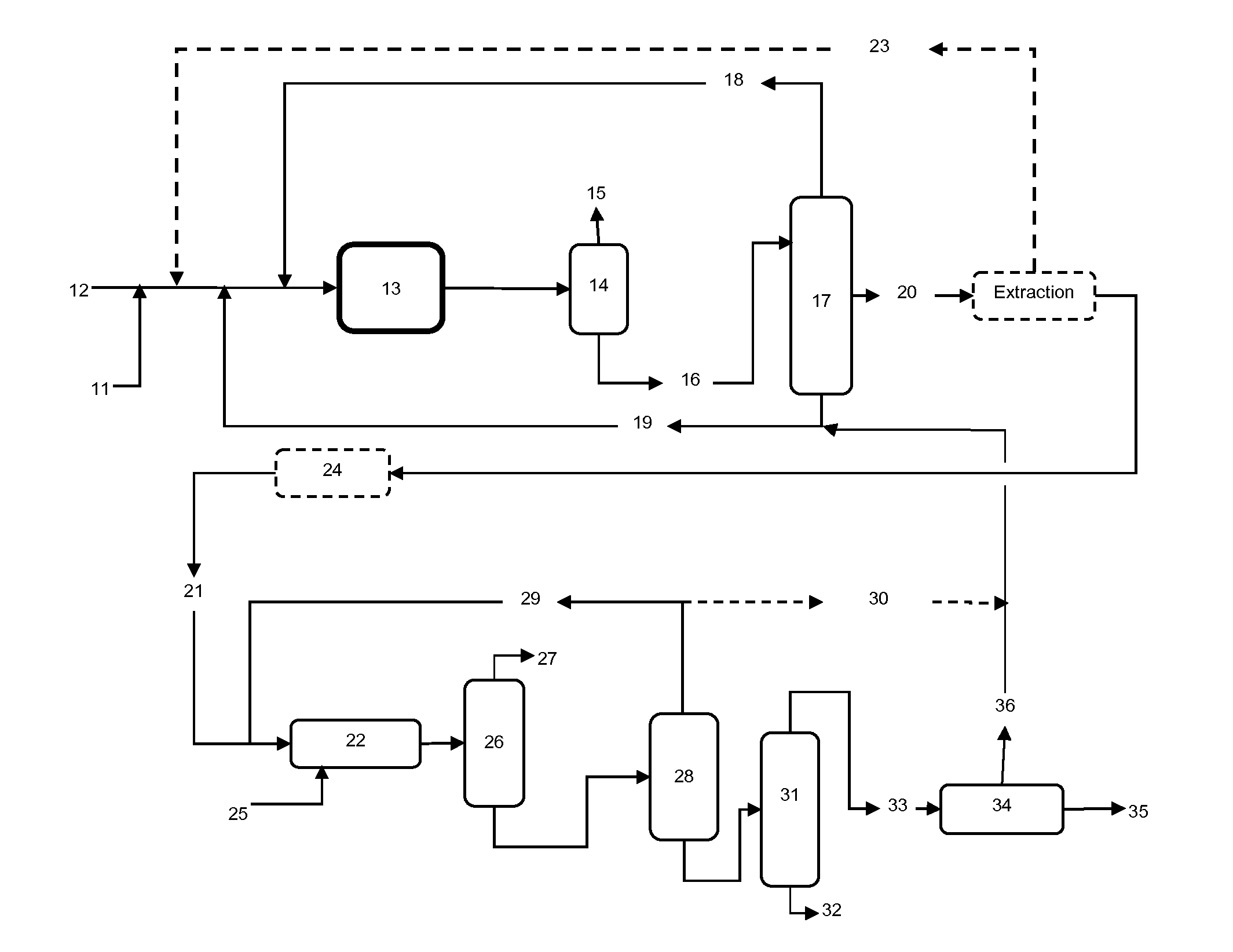

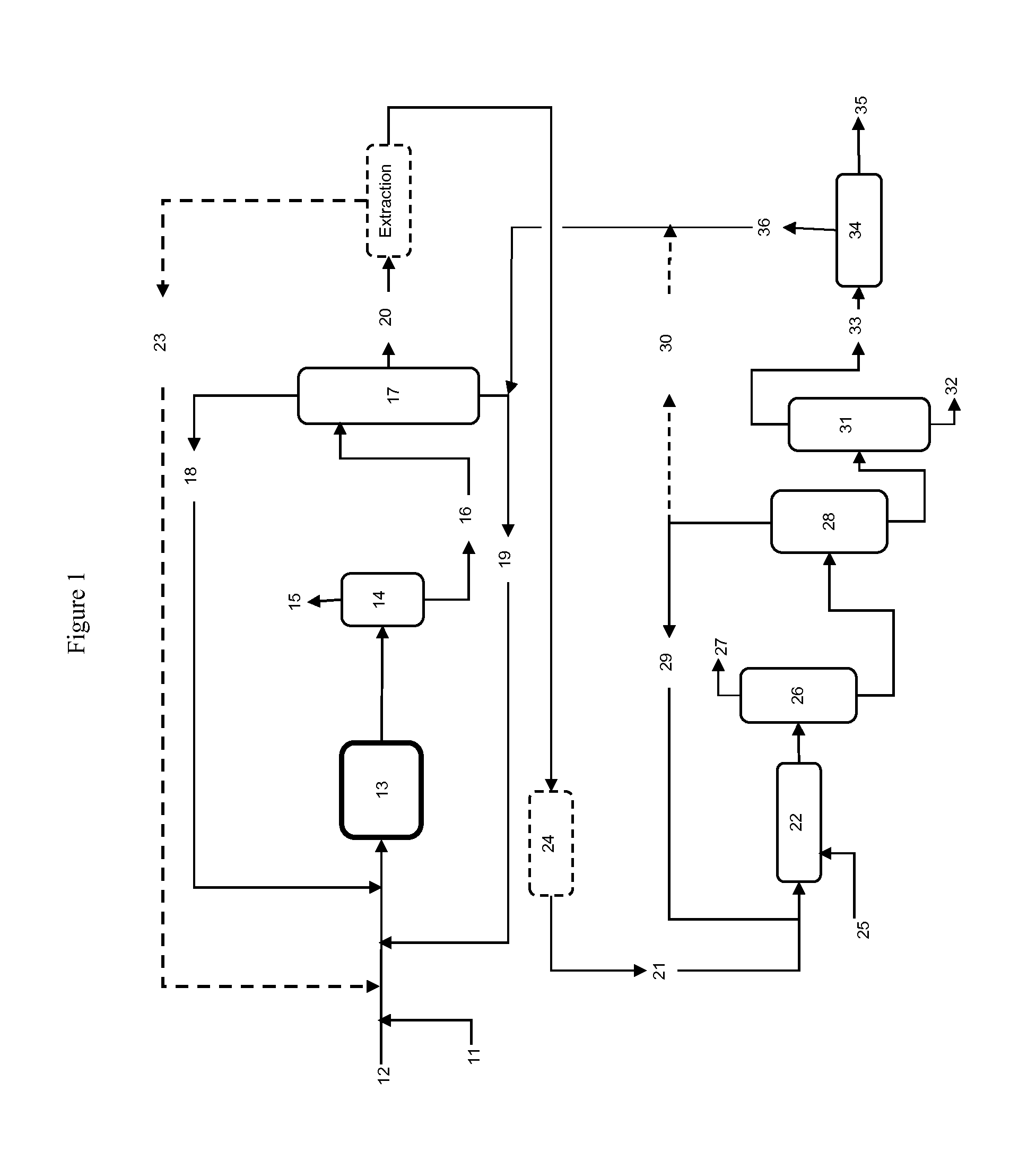

Method for producing high-added-value aromatic products and olefinic products from an aromatic-compound-containing oil fraction

ActiveUS8975462B2Increase productionIncrease valueHydrocarbon by isomerisationCatalytic crackingNaphthaHydrogen

The present invention relates to a method for manufacturing aromatic products (benzene / toluene / xylene) and olefinic products from an aromatic-compound-containing oil fraction, whereby it is possible to substitute naphtha as a feedstock for aromatic production and so make stable supply and demand, and it is possible to substantially increase the yield of high-added-value olefinic and high-added-value aromatic components, by providing a method for manufacturing olefinic and aromatic products from light cycle oil comprising a hydrogen-processing reaction step, a catalytic cracking step, an separation step and a transalkylation step, and optionally also comprising a recirculation step.

Owner:SK INNOVATION CO LTD

Aliphatic gasoline component and process to prepare said gasoline component

InactiveUS20070215519A1Catalytic crackingTreatment with plural serial stages onlyMolecular sieveAlkyl transfer

An aliphatic gasoline component comprising more than 90 wt % of a mixture of trimethyl substituted compounds and monomethyl substituted compounds in a weight ratio of trimethyl to monomethyl compounds of at least 0.03 and wherein the compounds may be paraffins and olefins. The invention is also directed to a process to prepare an aliphatic gasoline component by (a) contacting a Fischer-Tropsch synthesis product with a catalyst system comprising a catalyst, which catalyst comprises an acidic matrix and a large pore molecular sieve in a riser reactor at a temperature of between 450 and 650° C. at a contact time of between 1 and 10 seconds and at a catalyst to oil ratio of between 2 and 20 k.g / kg, (b) isolating from the product of step (a) a gasoline fraction and a fraction comprising iso-butane and isobutylene; (c) subjecting the iso-butane and the iso-butylene obtained in step (b) to an alkylation step to prepare a trimethyl substituted pentane, and (d) combining the gasoline fraction obtained in step (b) with the product rich in trimethyl substituted pentane as obtained in step (c).

Owner:SHELL OIL CO

Method for producing high-added-value aromatic products and olefinic products from an aromatic-compound-containing oil fraction

ActiveCN103328416AIncrease productionIncrease added valueCatalytic crackingMolecular sieve catalystHydrogenNaphtha

Owner:SK INNOVATION CO LTD

Process for removing a contaminant from coal tar

InactiveUS20150136660A1Lower Level RequirementsRefining with metalsTreatment with plural serial stages onlyPolycyclic aromatic hydrocarbonSorbent

A process for removing at least one contaminant from coal tar is described. The process involves extraction with an extraction agent or adsorption with an adsorbent. The extraction agent includes at least one of amphiphilic block copolymers, inclusion complexes of poly(methyl methacrylate) and polycyclic aromatic hydrocarbons, cyclodextrins, functionalized cyclodextrins, and cyclodextrin-functionalized polymers, and the adsorbent includes exfoliated graphite oxide, thermally exfoliated graphite oxide or intercalated graphite compounds.

Owner:UOP LLC

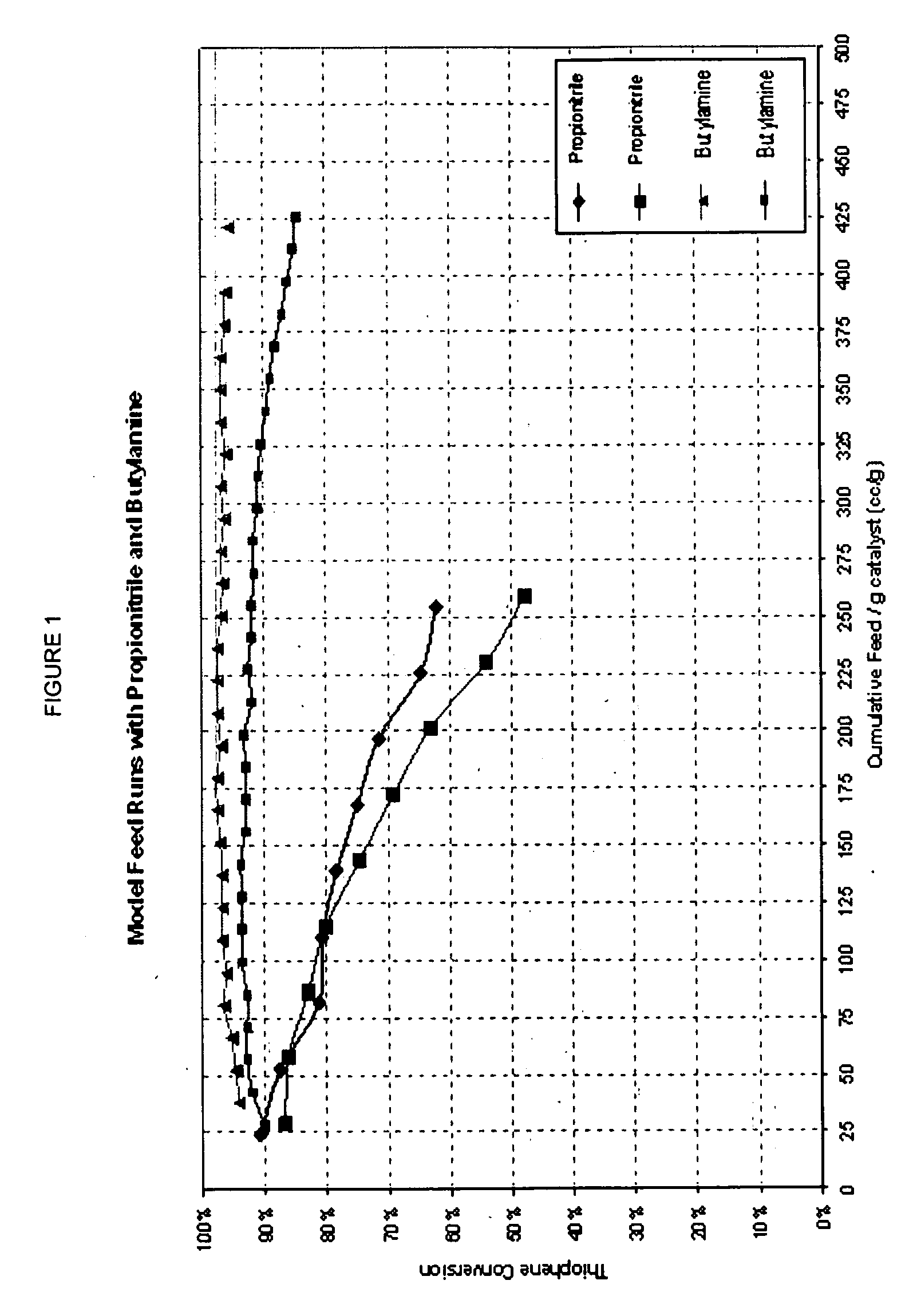

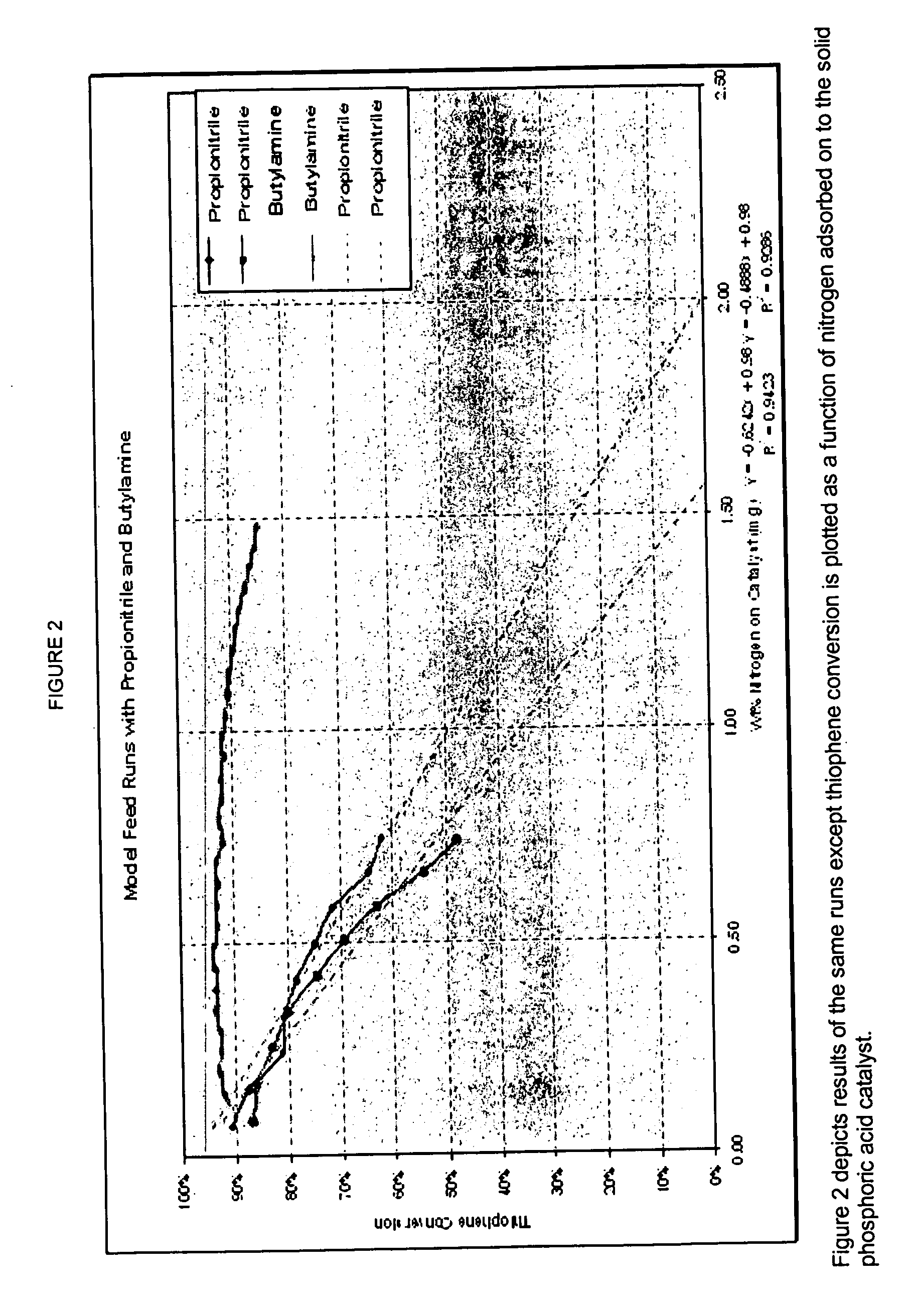

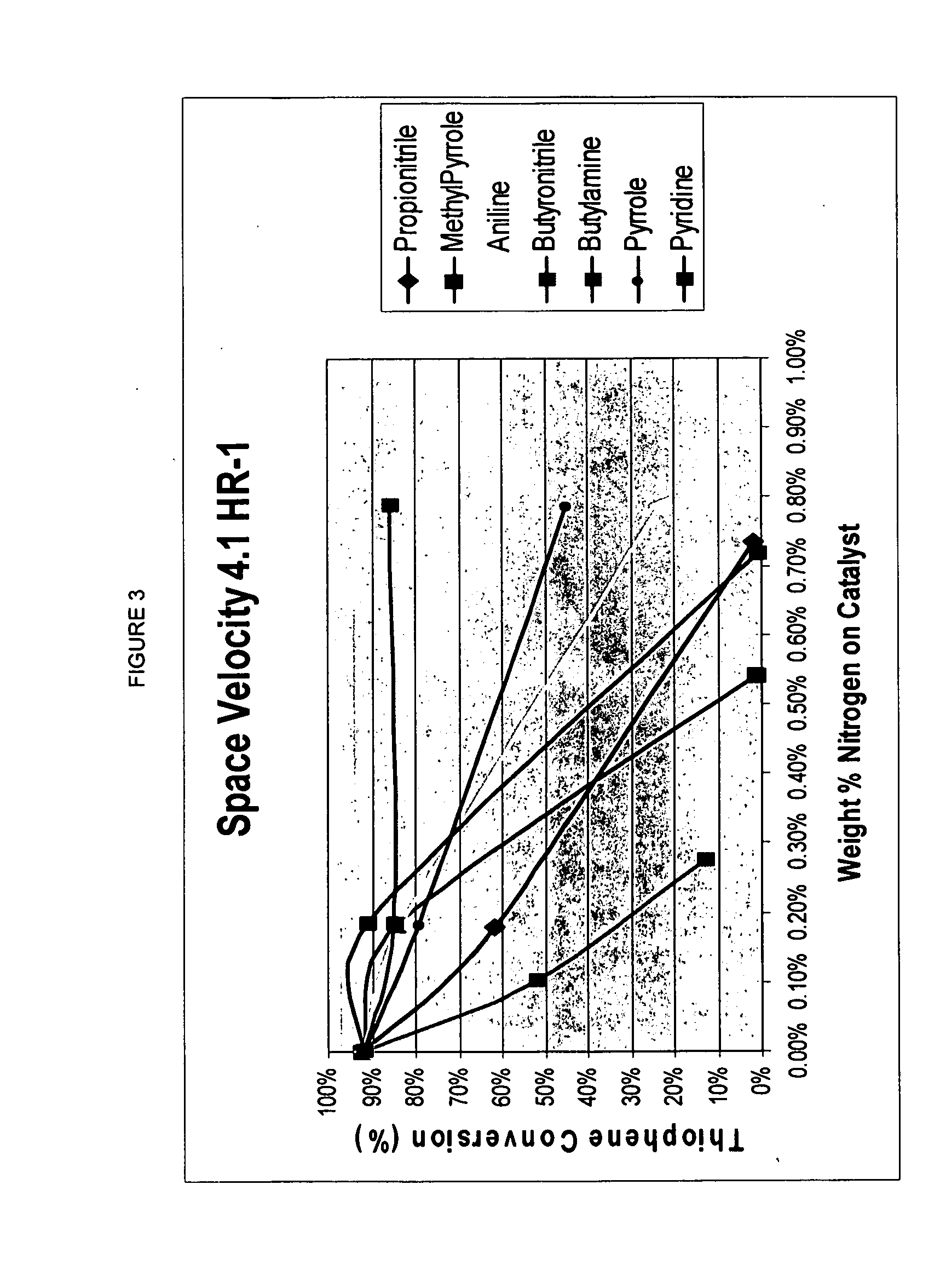

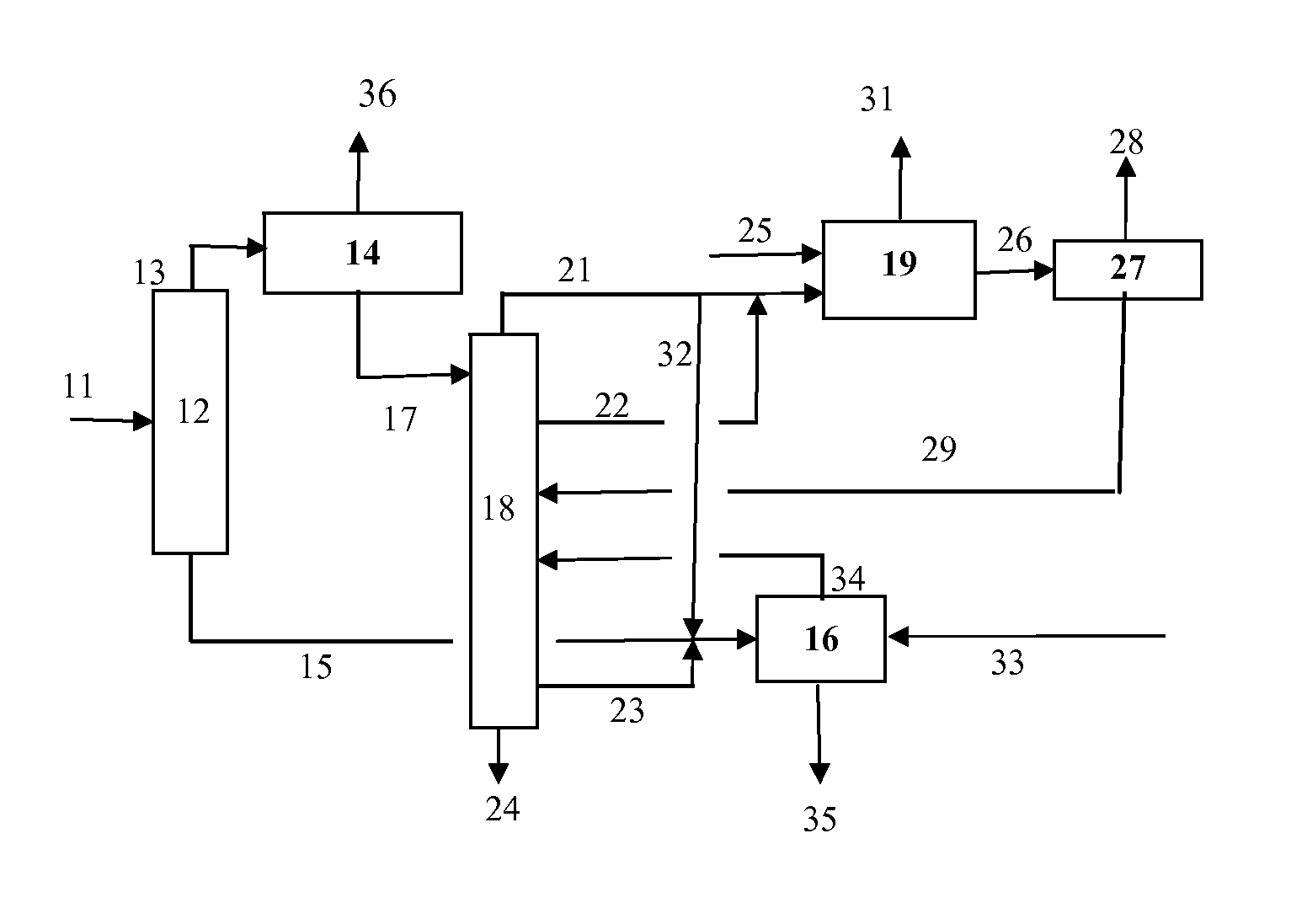

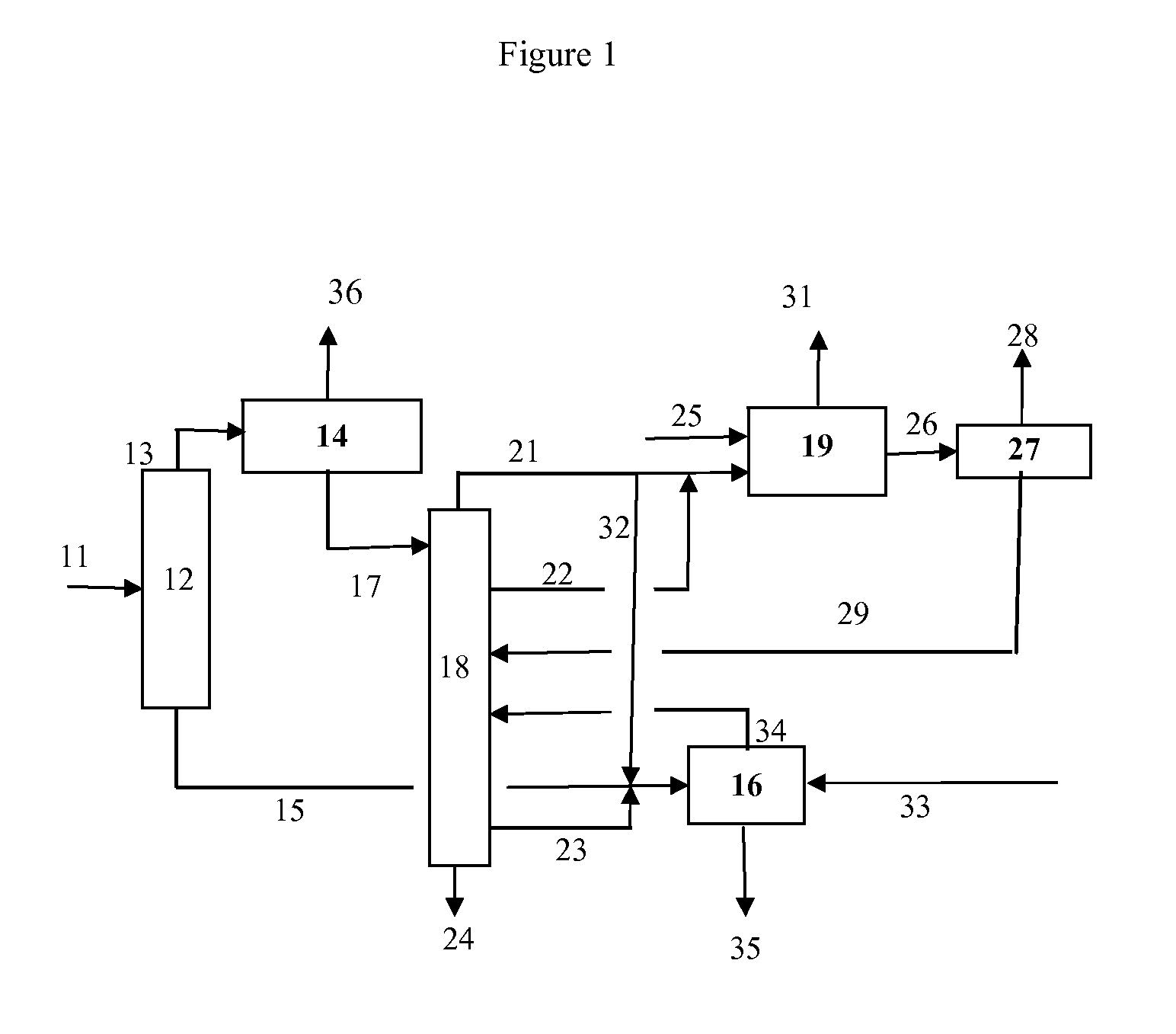

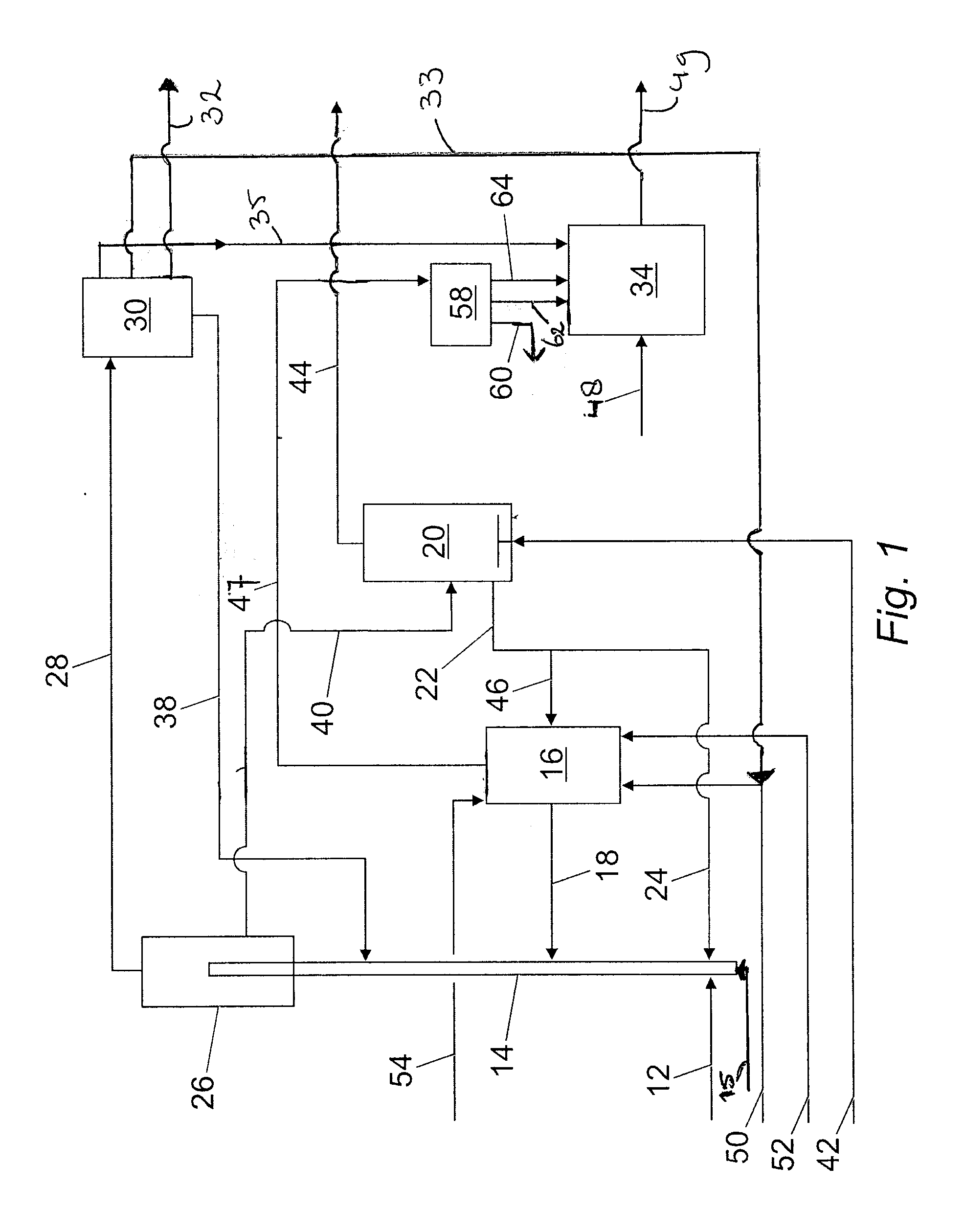

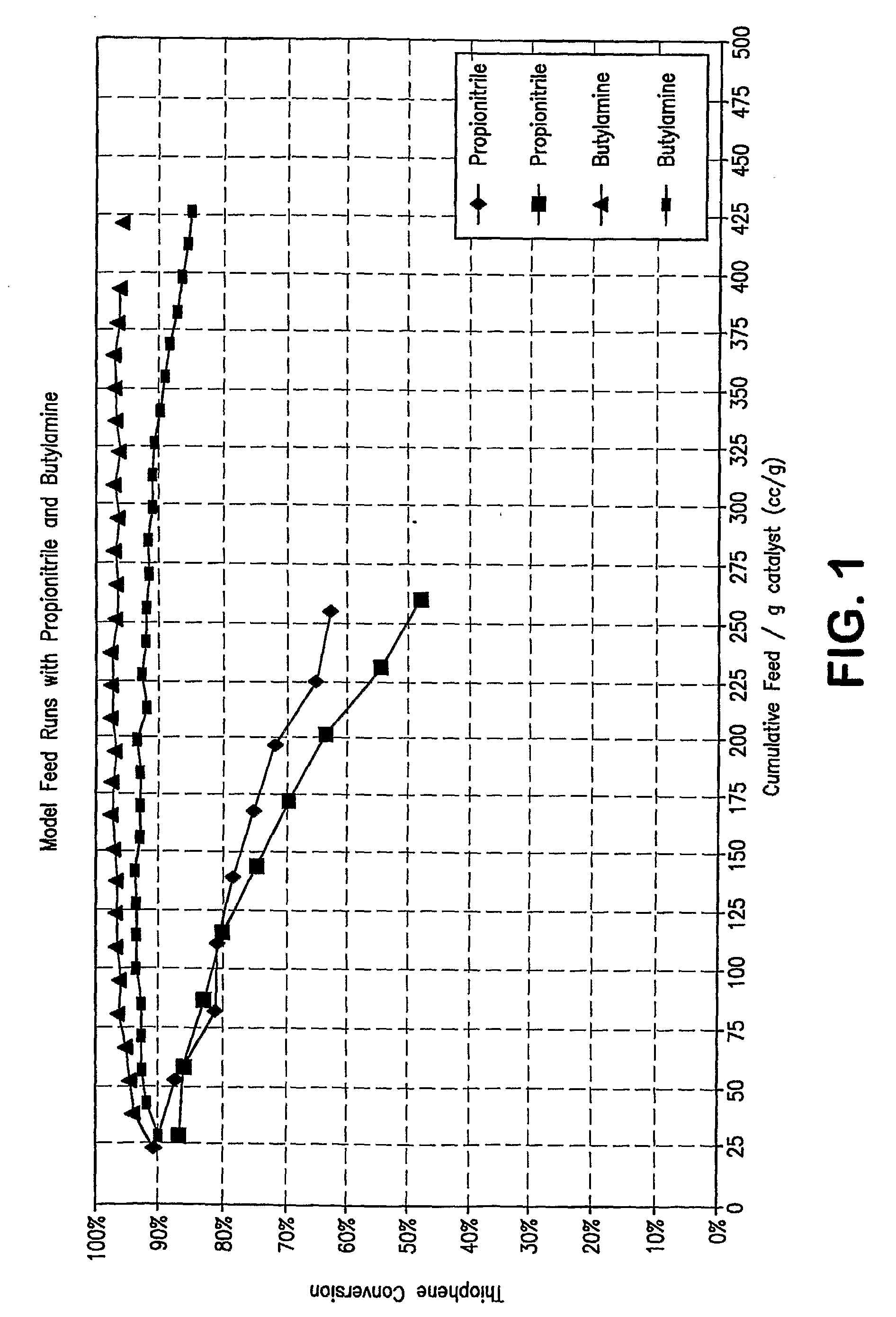

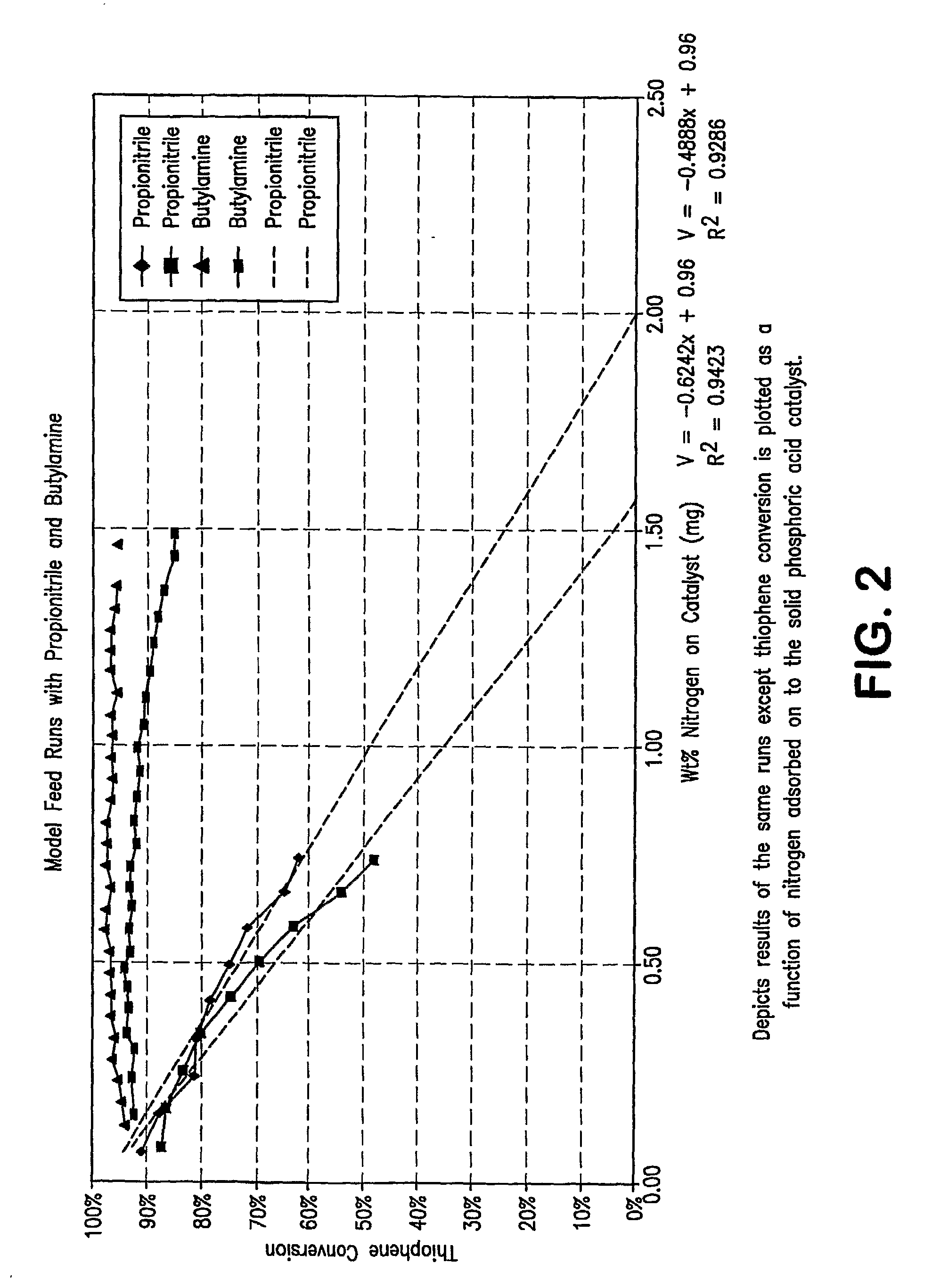

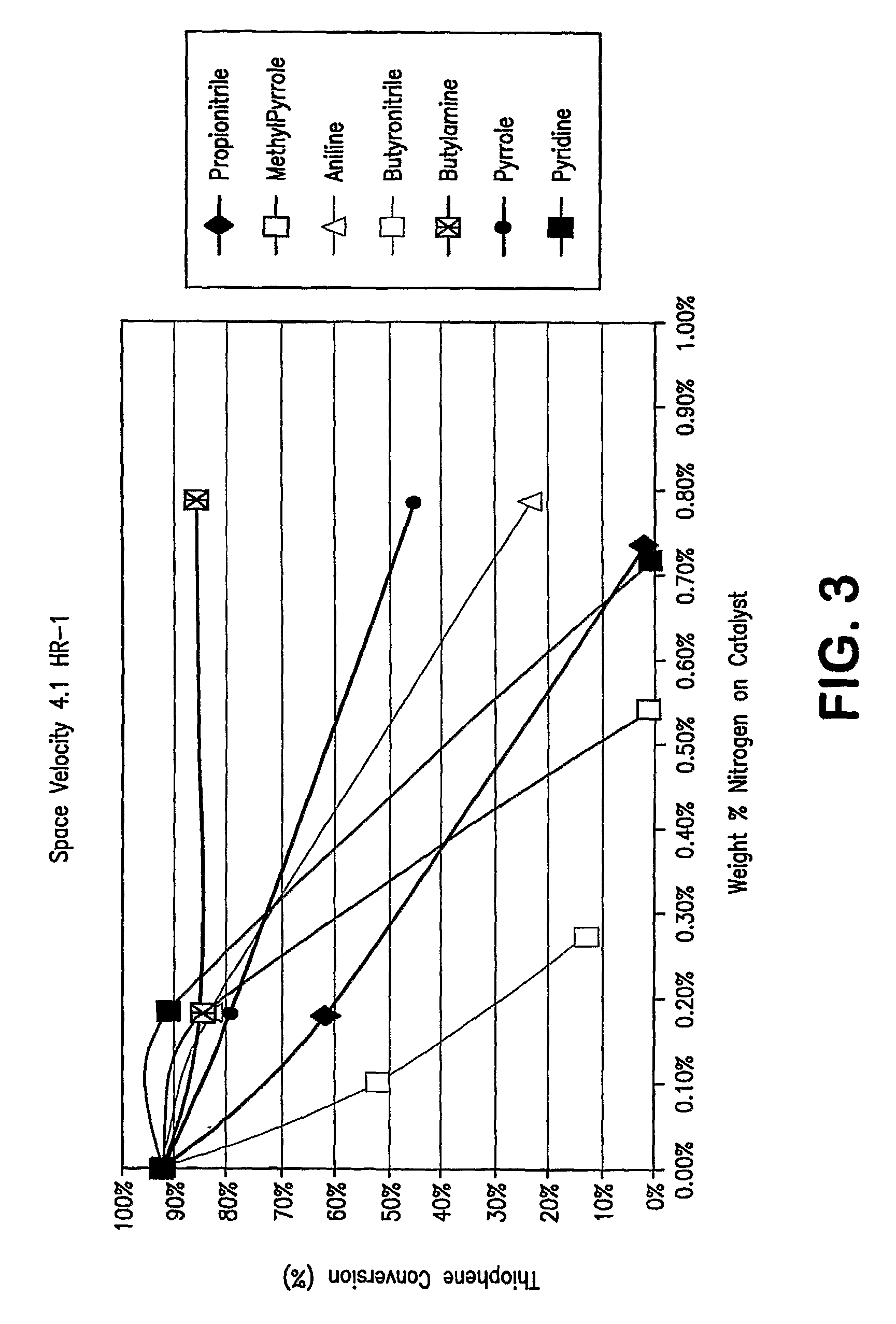

Process for removal of sulfur from components for blending of transportation fuels

A process is disclosed for removing highly deletenious non-basic nitrogen compounds upstream from an acid catalyzed thiophene alkylation process using adsorbents capable of adsorbing the non-basic nitrogen compounds.

Owner:INST FR DU PETROLE

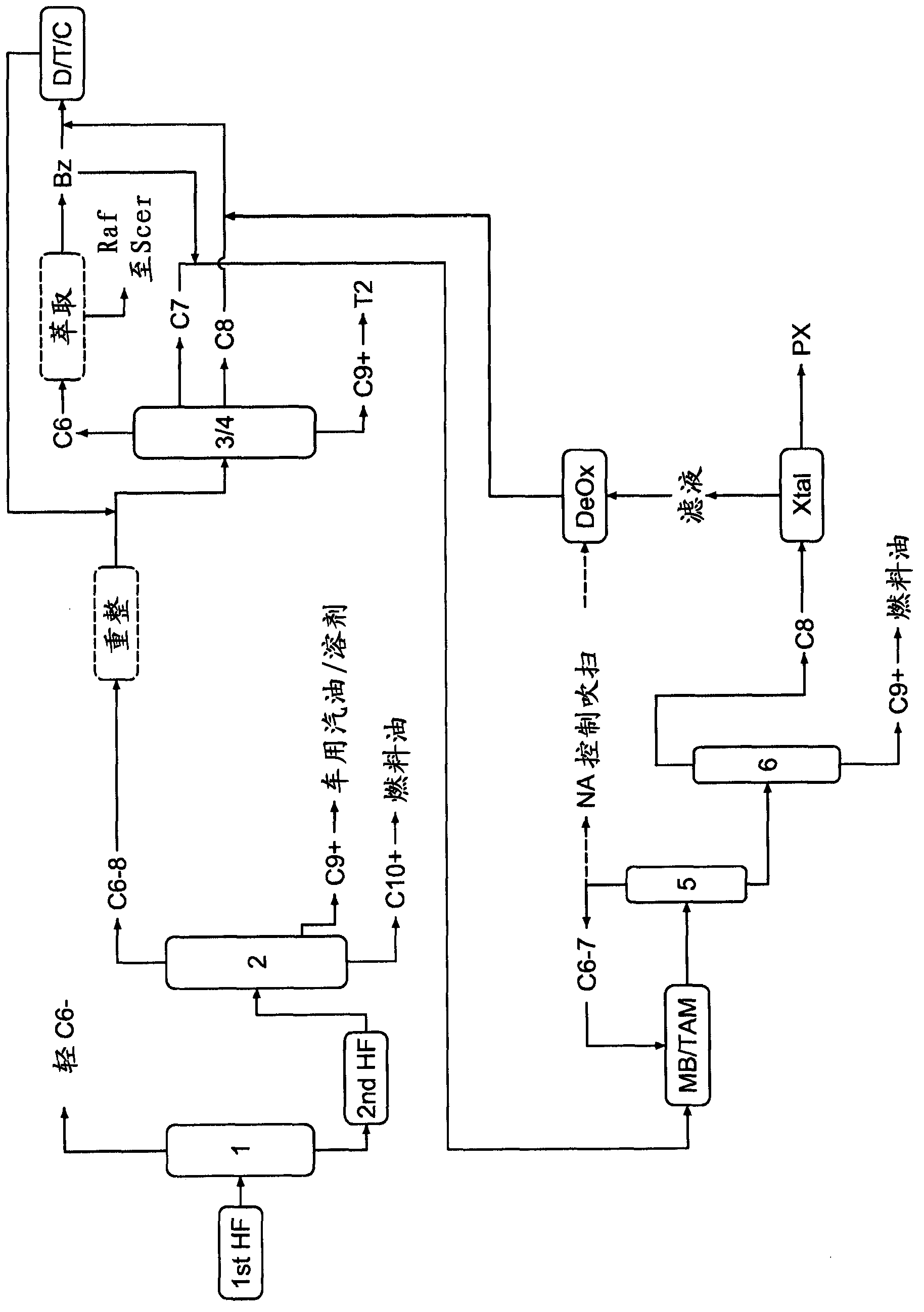

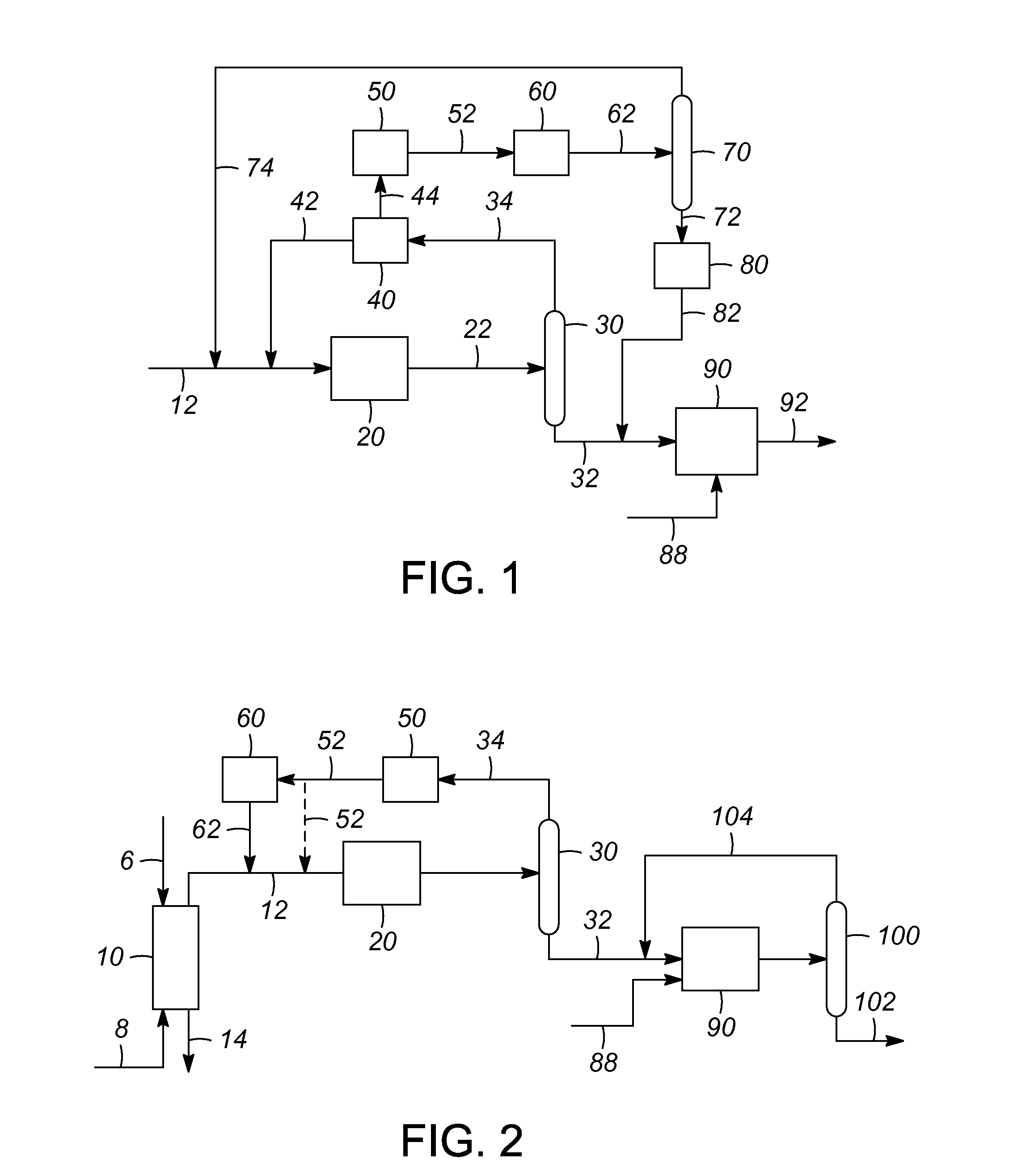

Process for the Production of Xylenes

ActiveUS20130296624A1Increased benzeneThermal non-catalytic crackingCatalytic crackingParaffin waxMethylating Agent

A hydrocarbon upgrading process is described in which a hydrocarbon feed is treated in at least one of a steam cracker, catalytic cracker, coker, hydrocracker, and reformer under suitable conditions to produce a first stream comprising aliphatic and aromatic hydrocarbons. A second stream comprising C6-C9 aliphatic and aromatic hydrocarbons is recovered from the first stream and aliphatic hydrocarbons are removed from at least part of the second stream to produce an aliphatic hydrocarbon-depleted stream. The aliphatic hydrocarbon-depleted stream is then dealkylated and / or transalkylated and / or cracked (D / T / C) by contact with a catalyst under suitable reaction conditions to produce a third stream having an increased benzene and / or toluene content compared with said aliphatic hydrocarbon-depleted stream and a light paraffin by-product. Benzene and / or toluene from the third stream is then methylated with a methylating agent to produce a xylene-enriched stream.

Owner:EXXONMOBIL CHEM PAT INC

Reduction of organic halide contamination in hydrocarbon products

ActiveUS20090163759A1Reducing organic halide concentrationCatalystsHydrocarbon preparation catalystsMolecular sieveHalogen

A method for reducing halide concentration in a hydrocarbon product having an organic halide content from 50 to 4000 ppm which is made by a hydrocarbon conversion process using an ionic liquid catalyst comprising a halogen-containing acidic ionic liquid comprising contacting at least a portion of the hydrocarbon product with at least one molecular sieve having pore size from 4 to 16 Angstrom under organic halide absorption conditions to reduce the halogen concentration in the hydrocarbon product to less than 40 ppm is disclosed.

Owner:CHEVROU USA INC

Process for the preparation of alkylate and middle distillate

InactiveUS20100076096A1High yieldTreatment with plural serial cracking stages onlyCatalytic crackingAlkylation unitReaction zone

A process for the preparation of alkylate and middle distillate, the process comprising: (a) catalytically cracking a first hydrocarbon feedstock by contacting the feedstock with a cracking catalyst comprising a shape-selective additive at a temperature in the range of from 450 to 650° C. within a riser or downcomer reaction zone to yield a first cracked product comprising middle distillate and a spent cracking catalyst; (b) regenerating the spent cracking catalyst to yield a regenerated cracking catalyst; (c) contacting, within a second reaction zone, at least part of the regenerated cracking catalyst obtained in step (b) with a second hydrocarbon feedstock at a temperature in the range of from 500 to 800° C. to yield a second cracked product and a used regenerated catalyst, the second feedstock comprising at least 70 wt % C5+ hydrocarbons obtained in a Fischer-Tropsch hydrocarbon synthesis process; (d) using the used regenerated catalyst as at least part of the cracking catalyst in step (a); and (e) alkylating at least a portion of the second cracked product in an alkylation unit to obtain alkylate.

Owner:SHELL OIL CO

Process For Removal Of Sulfur From Components For Blending Of Transportation Fuels

A process is disclosed for removing highly deleterious non-basic nitrogen compounds upstream from an acid catalyzed thiophene alkylation process using adsorbents capable of adsorbing the non-basic nitrogen compounds.

Owner:INST FR DU PETROLE

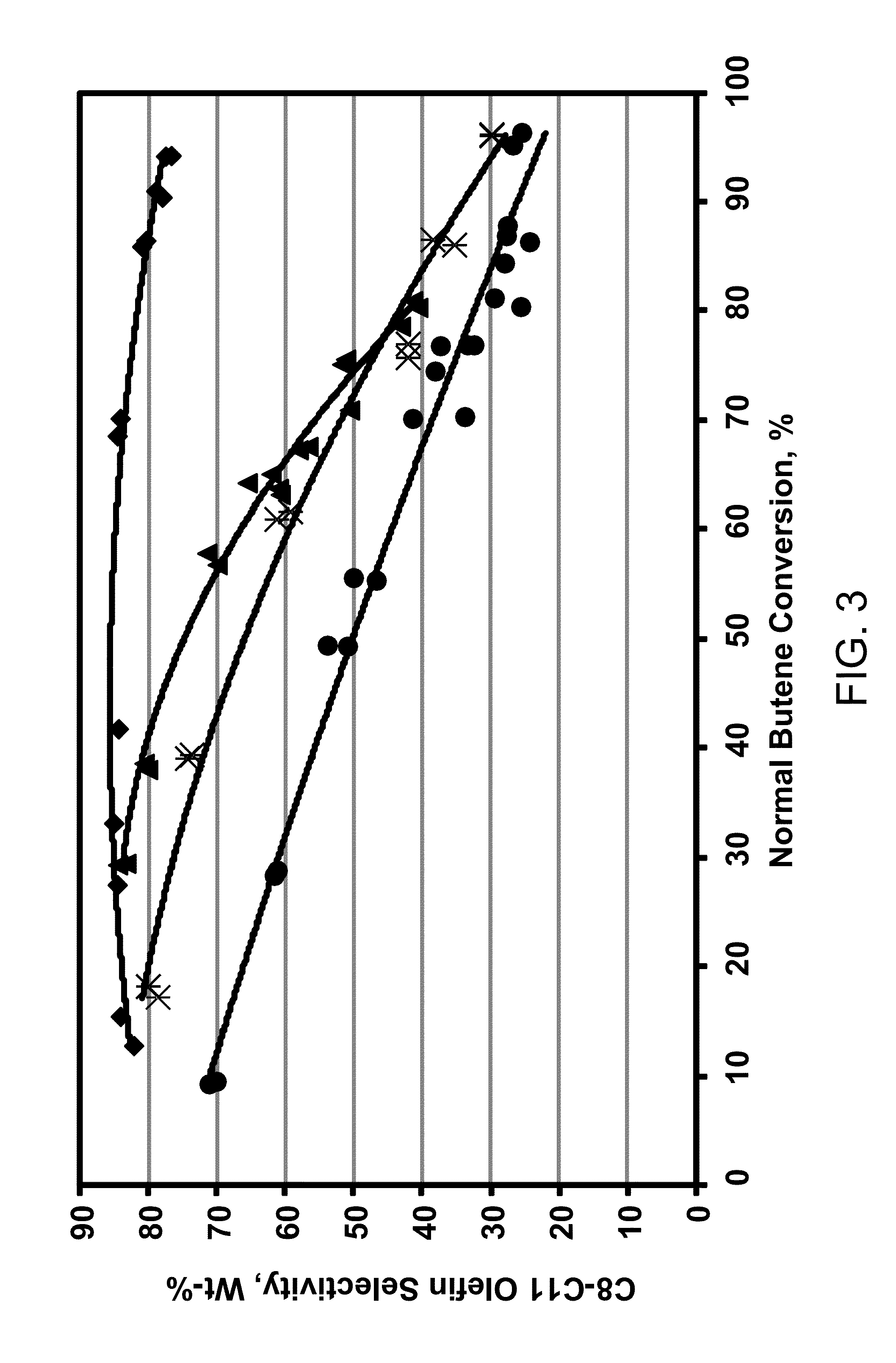

Process for making propylene from oligomerization and cracking

InactiveUS20140135546A1Easy to crackReadily cracked down to propylene moleculeCatalytic crackingMolecular sieve catalystOrganic chemistryZeolite

Disclosed is an oligomerate produced over a uni-dimensional 10-ring pore structured zeolite catalyst that is readily fluid catalytically cracked to propylene.

Owner:UOP LLC

Method for producing high-added-value aromatic products and olefinic products from an aromatic-compound-containing oil fraction

ActiveUS20130253242A1Increase productionIncrease valueCatalytic crackingMolecular sieve catalystHydrogenNaphtha

The present invention relates to a method for manufacturing aromatic products (benzene / toluene / xylene) and olefinic products from an aromatic-compound-containing oil fraction, whereby it is possible to substitute naphtha as a feedstock for aromatic production and so make stable supply and demand, and it is possible to substantially increase the yield of high-added-value olefinic and high-added-value aromatic components, by providing a method for manufacturing olefinic and aromatic products from light cycle oil comprising a hydrogen-processing reaction step, a catalytic cracking step, an separation step and a transalkylation step, and optionally also comprising a recirculation step.

Owner:SK INNOVATION CO LTD

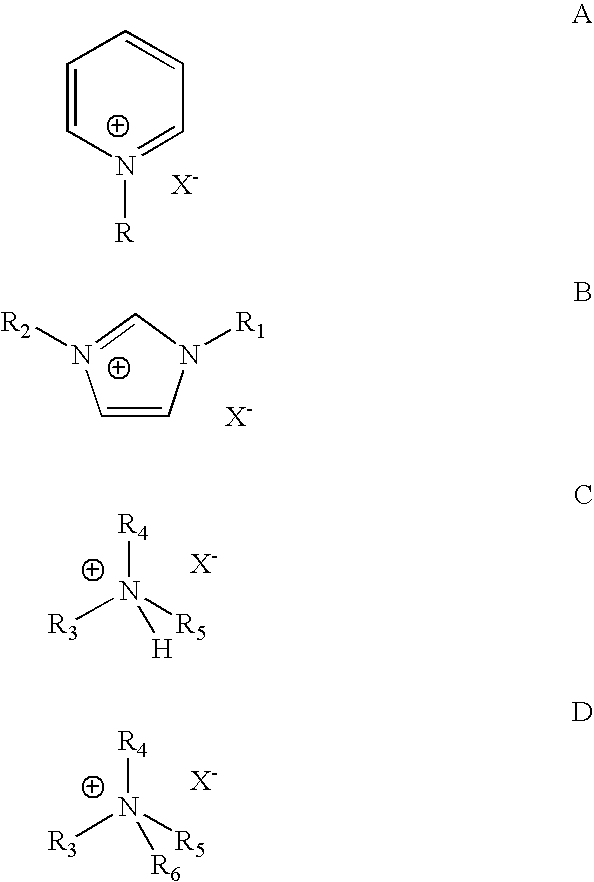

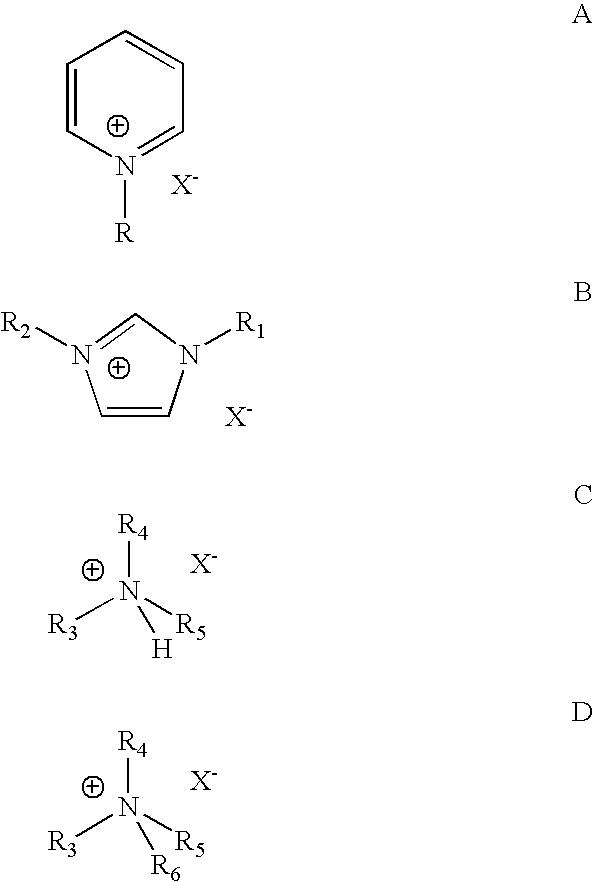

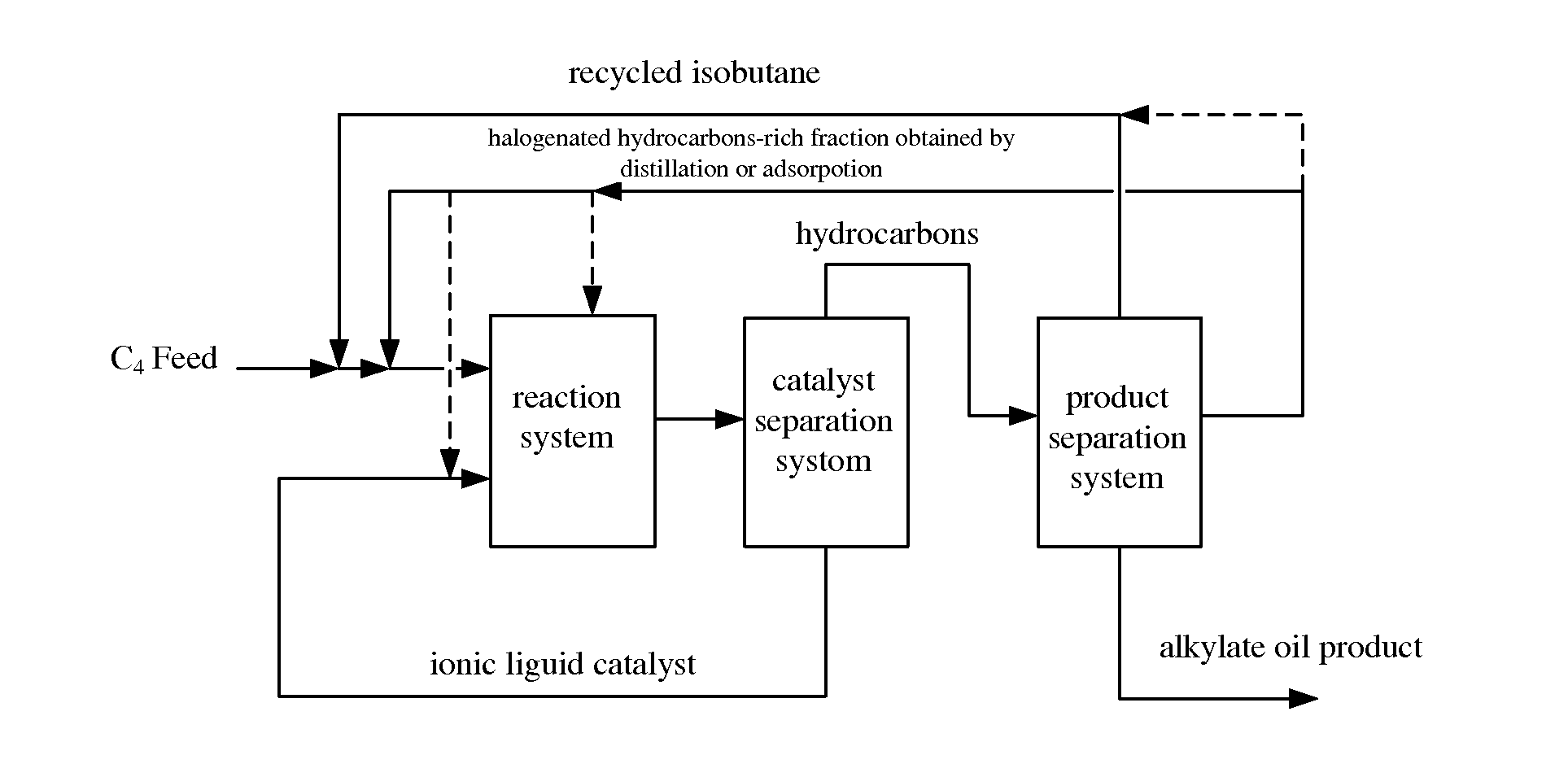

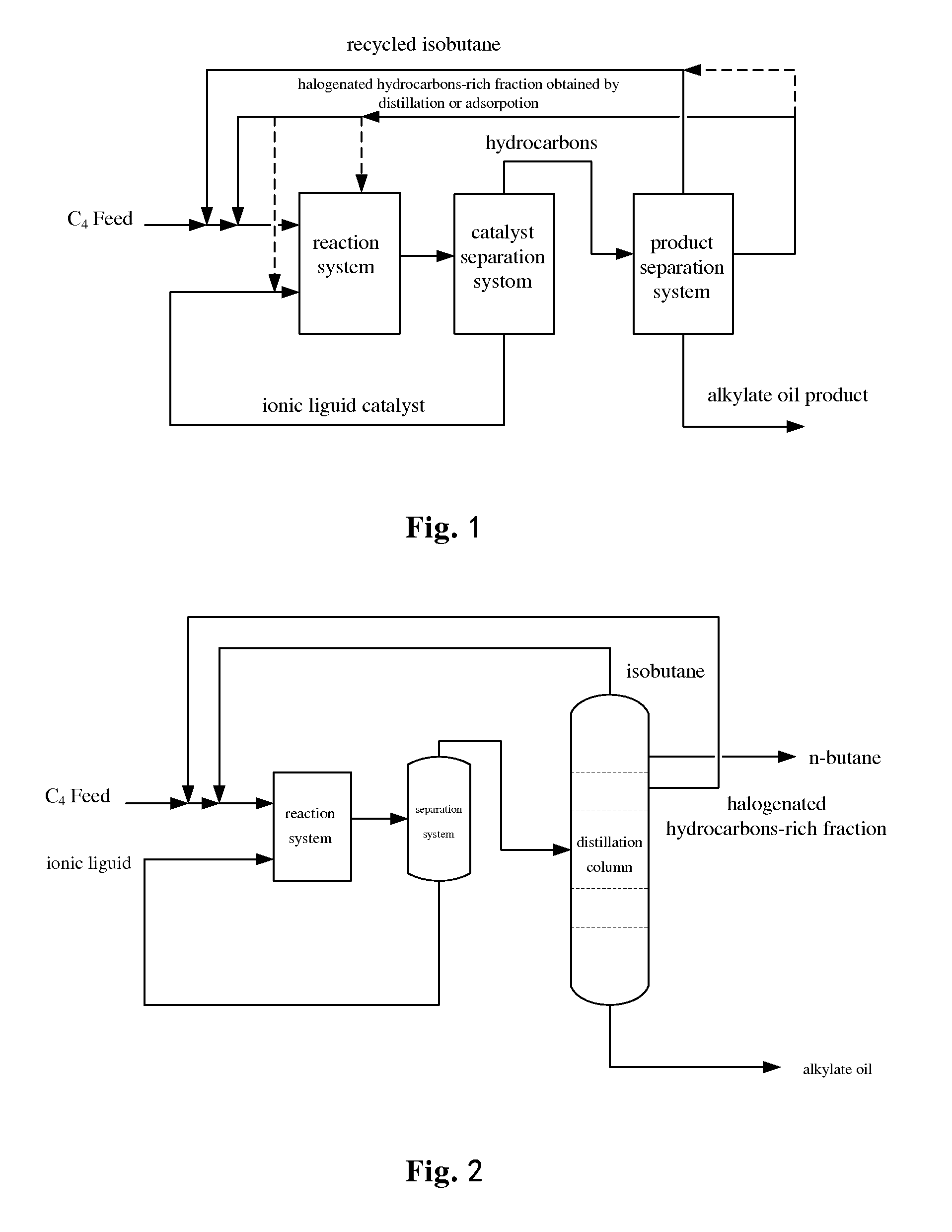

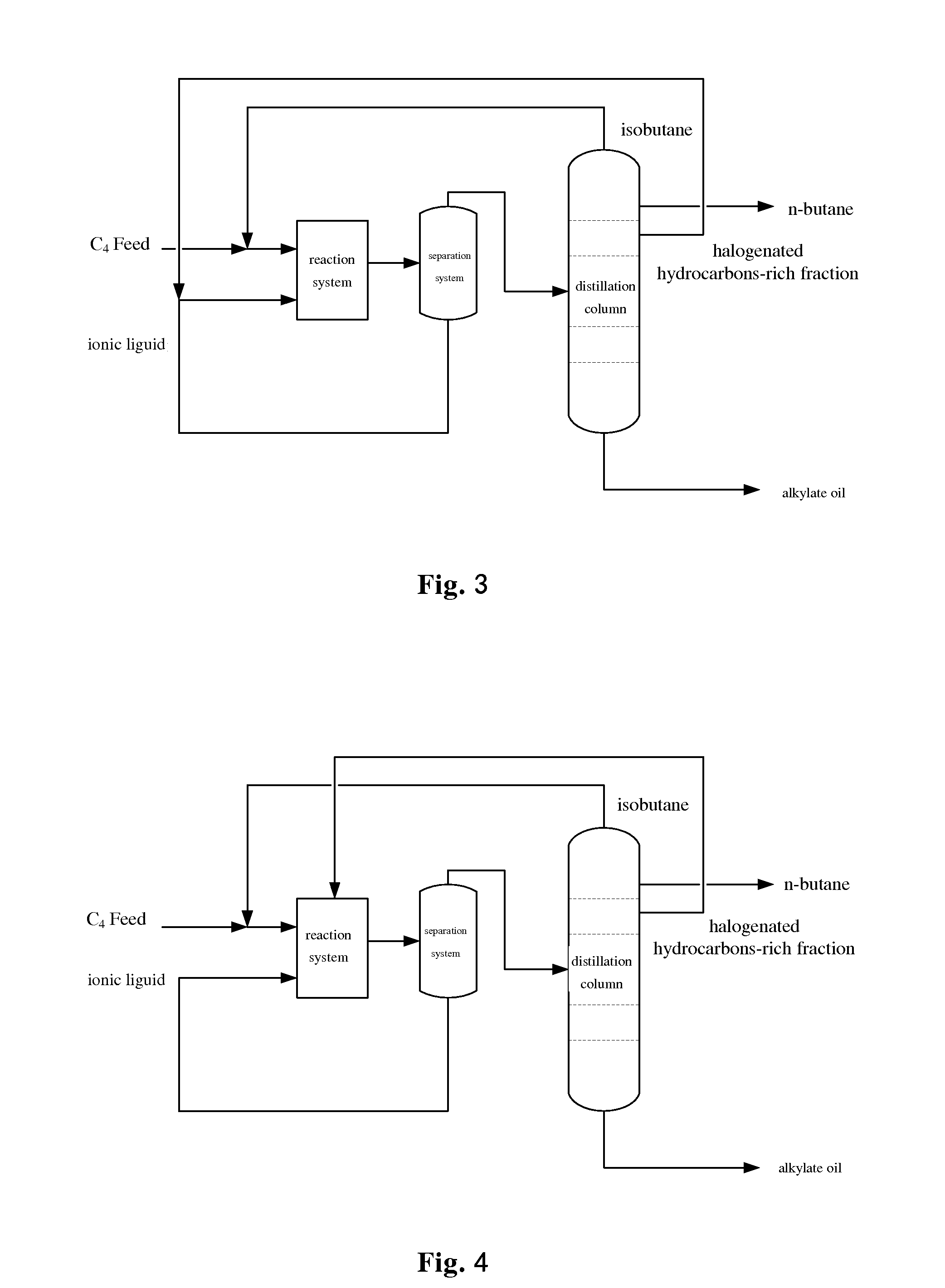

Alkylation method using ionic liquid as catalyst

ActiveUS20130331625A1Quality improvementRaise the ratioOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsAlkyl transferHalogen

Disclosed is an alkylation process using ionic liquid as catalyst, which process comprises separating halogenated hydrocarbons-rich fraction from the alkylation product by distillation and / or adsorption and reintroducing the separated fraction into the reaction system during the alkylation reaction, wherein the ionic liquid catalyst used in the alkylation reaction has a cation derived from hydrohalide of alkyl amine, hydrohalide of imidazole or hydrohalide of pyridine and an anion derived from one or more metallic compounds. The inventive process effectively utilizes the halogenated hydrocarbons in the alkylation product, prolongs the life of the ionic liquid catalyst, and reduces the halogen content in the alkylate oil.

Owner:SHELL OIL CO +1

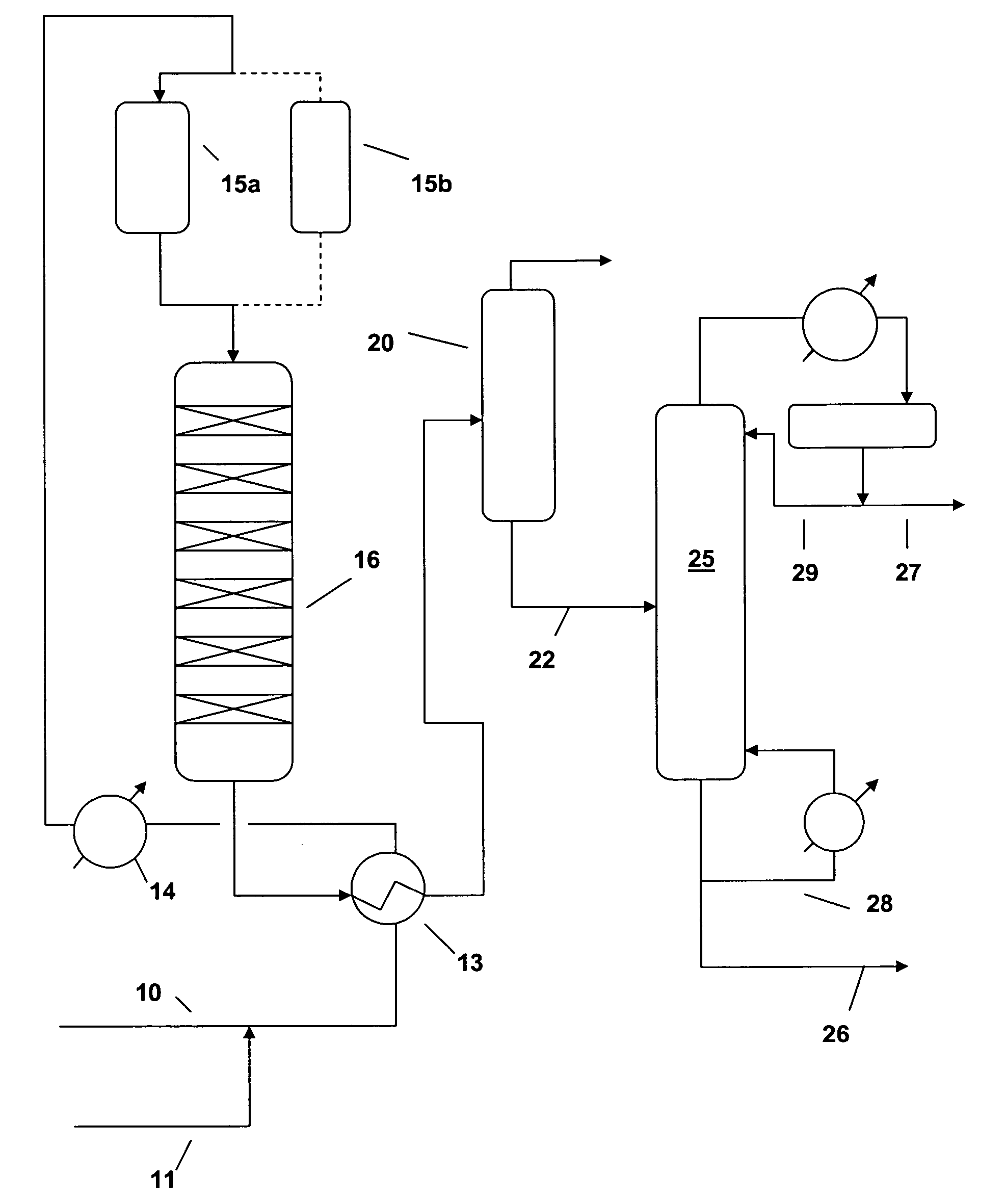

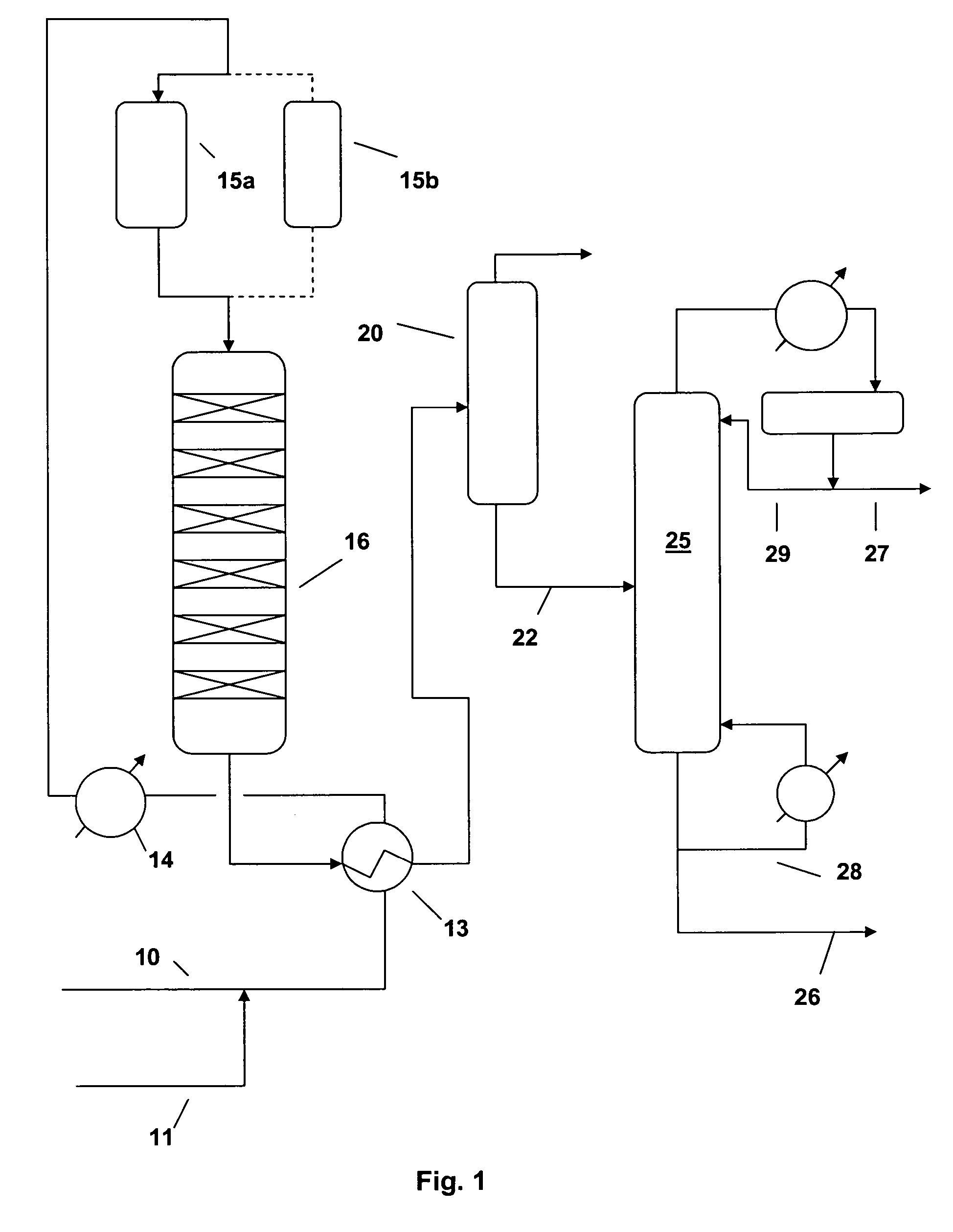

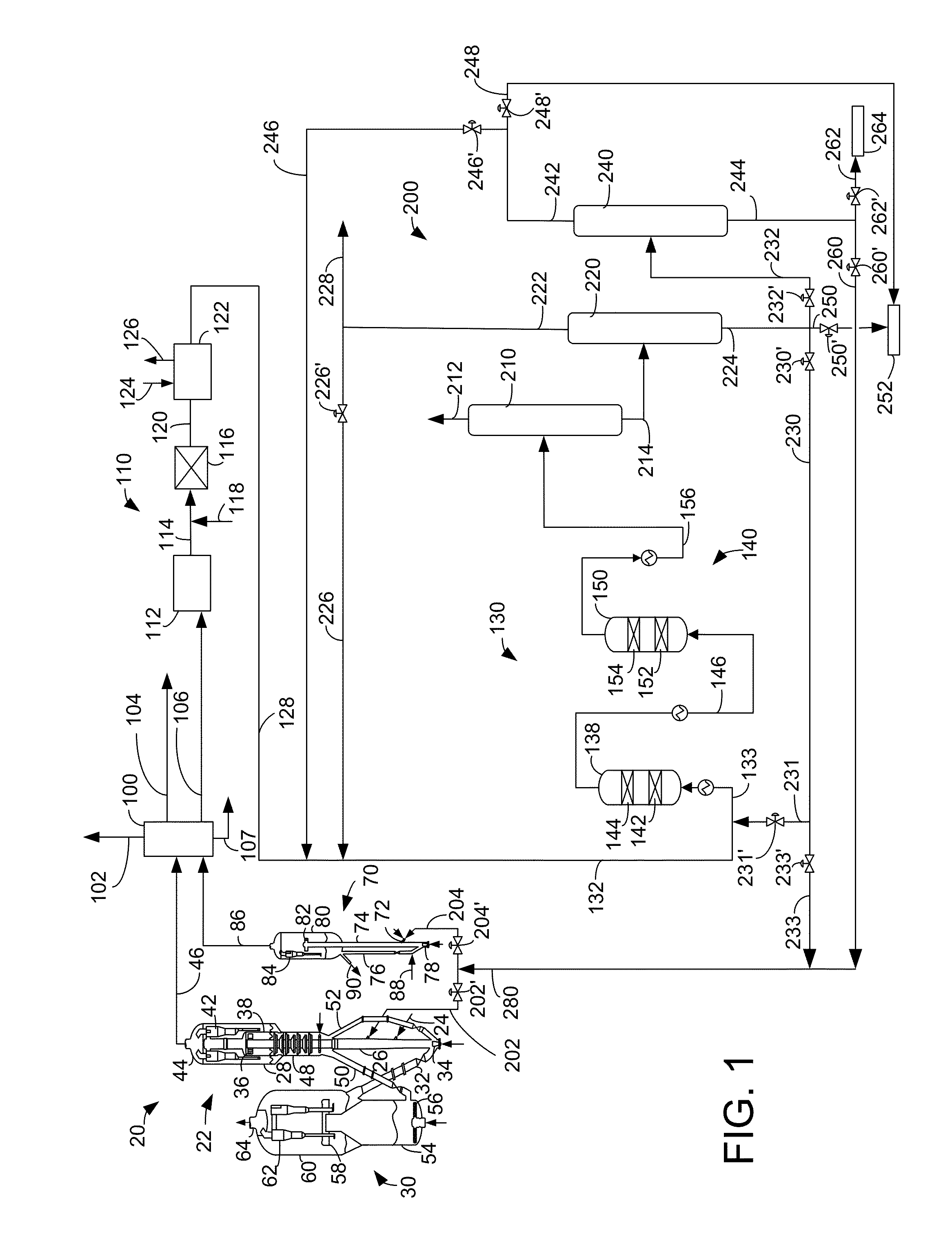

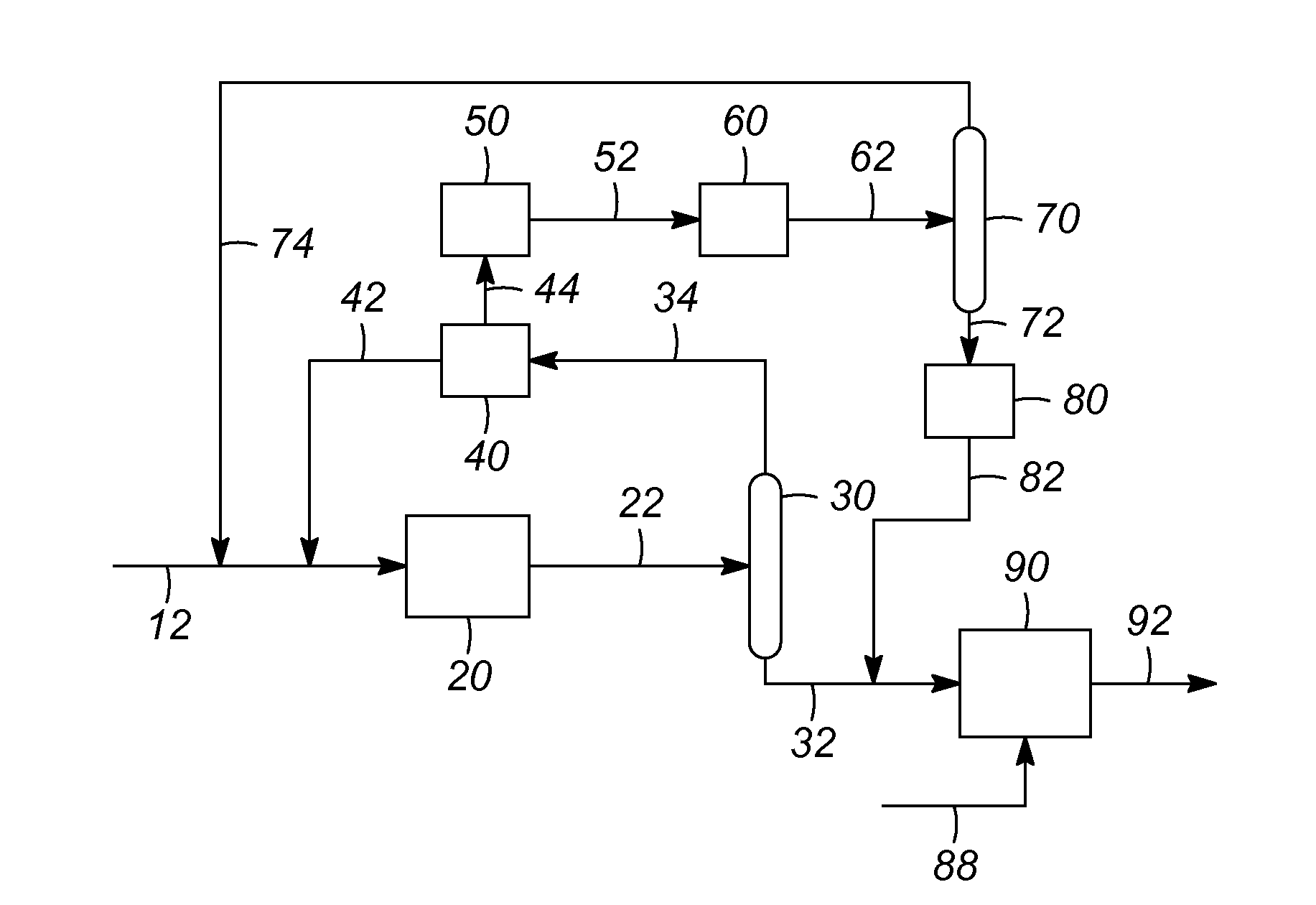

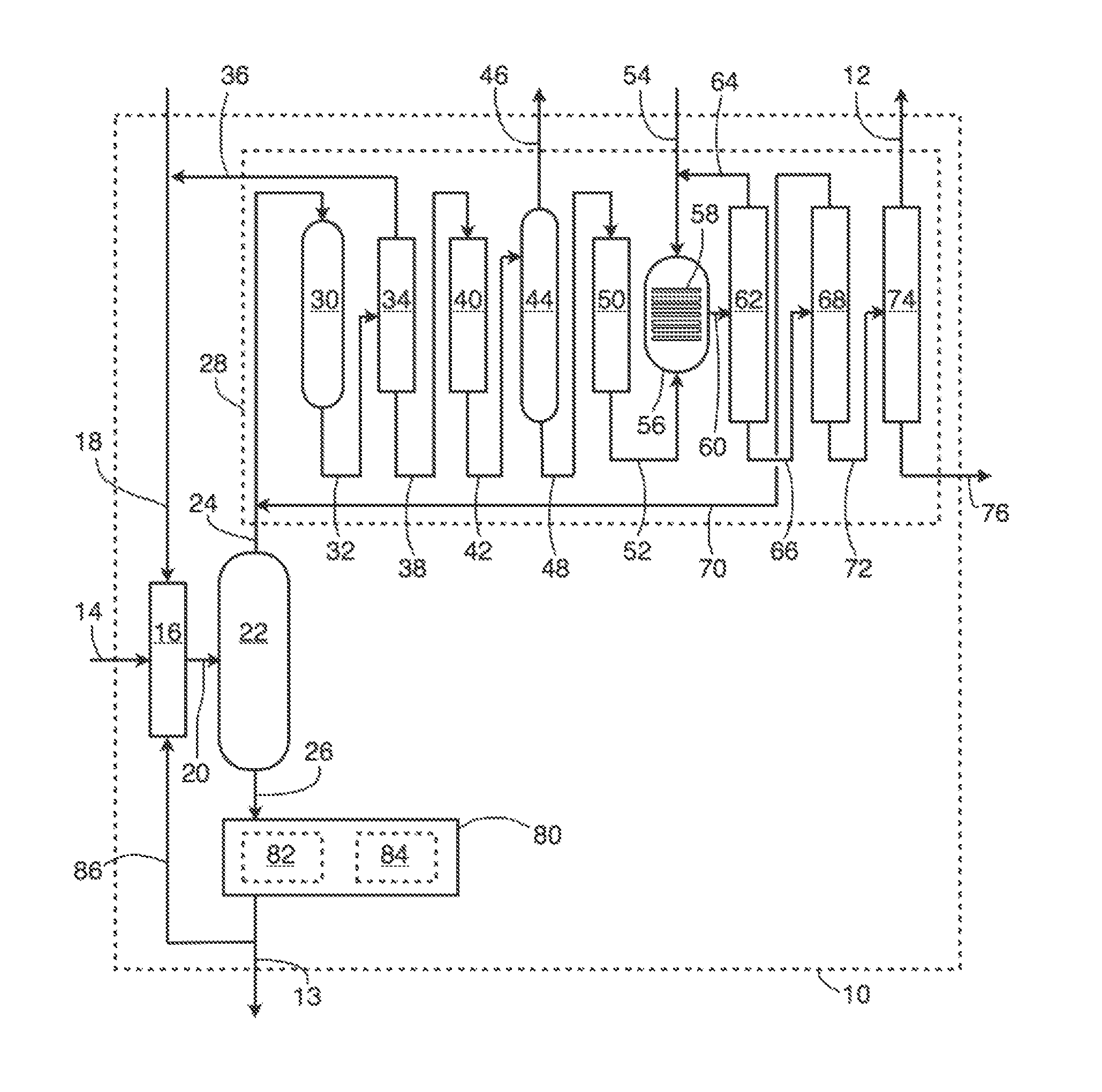

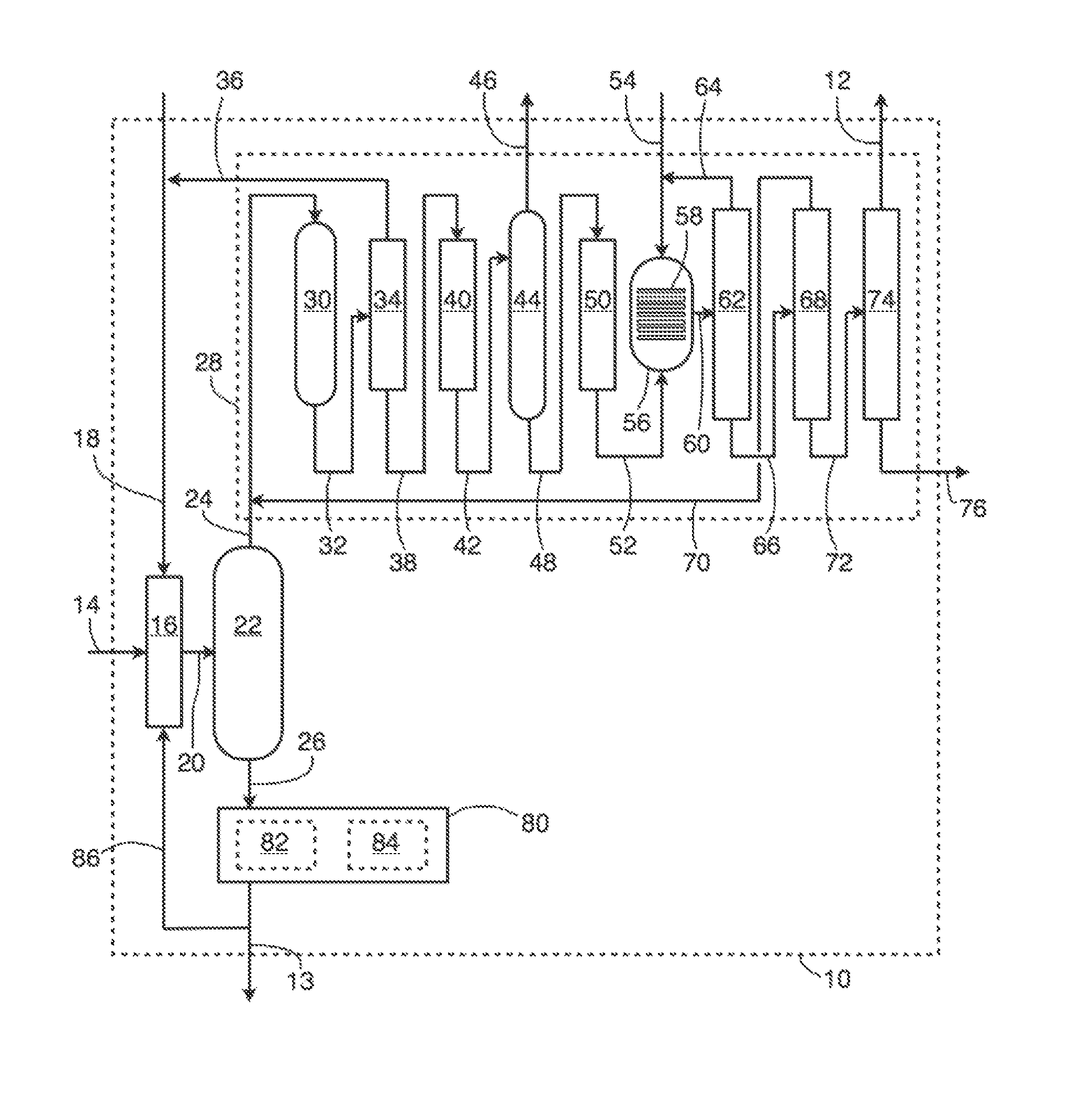

Apparatus for the reduction of gasoline benzene content by alkylation with dilute ethylene

InactiveUS20110305602A1Reduce concentrationEasy to separatePhysical/chemical process catalystsCatalytic crackingBenzeneHydrogen

The apparatus converts ethylene in a dilute ethylene stream and dilute benzene in an aromatic containing stream via alkylation to heavier hydrocarbons. The catalyst may be a zeolite such as UZM-8. The catalyst is resistant to feed impurities such as hydrogen sulfide, carbon oxides, and hydrogen and selectively converts benzene. At least 40 wt-% of the ethylene in the dilute ethylene stream and at least 20 wt-% of the benzene in the dilute benzene stream can be converted to heavier hydrocarbons.

Owner:UOP LLC

Process for the Production of Xylenes and Light Olefins

In a hydrocarbon upgrading process, a hydrocarbon feed is treated in at least one of a steam cracker, catalytic cracker, coker, hydrocracker, and reformer under suitable conditions to produce a first stream comprising olefinic and aromatic hydrocarbons. A second stream composed mainly of C4+ olefinic and aromatic hydrocarbons is recovered from the first stream and is fed together with a methylating agent to a reaction zone containing a catalyst under reaction conditions including a temperature of about 450° C. to about 700° C., such that aromatics components in the second stream undergo dealkylation, transalkylation and / or methylation and aliphatic components undergo cracking and aromatization to produce a third stream having an increased xylene content compared with said second stream and a C3− olefin by-product. The C3− olefin by-product is recovered and para-xylene is removed from at least part of said third stream.

Owner:EXXONMOBIL CHEM PAT INC

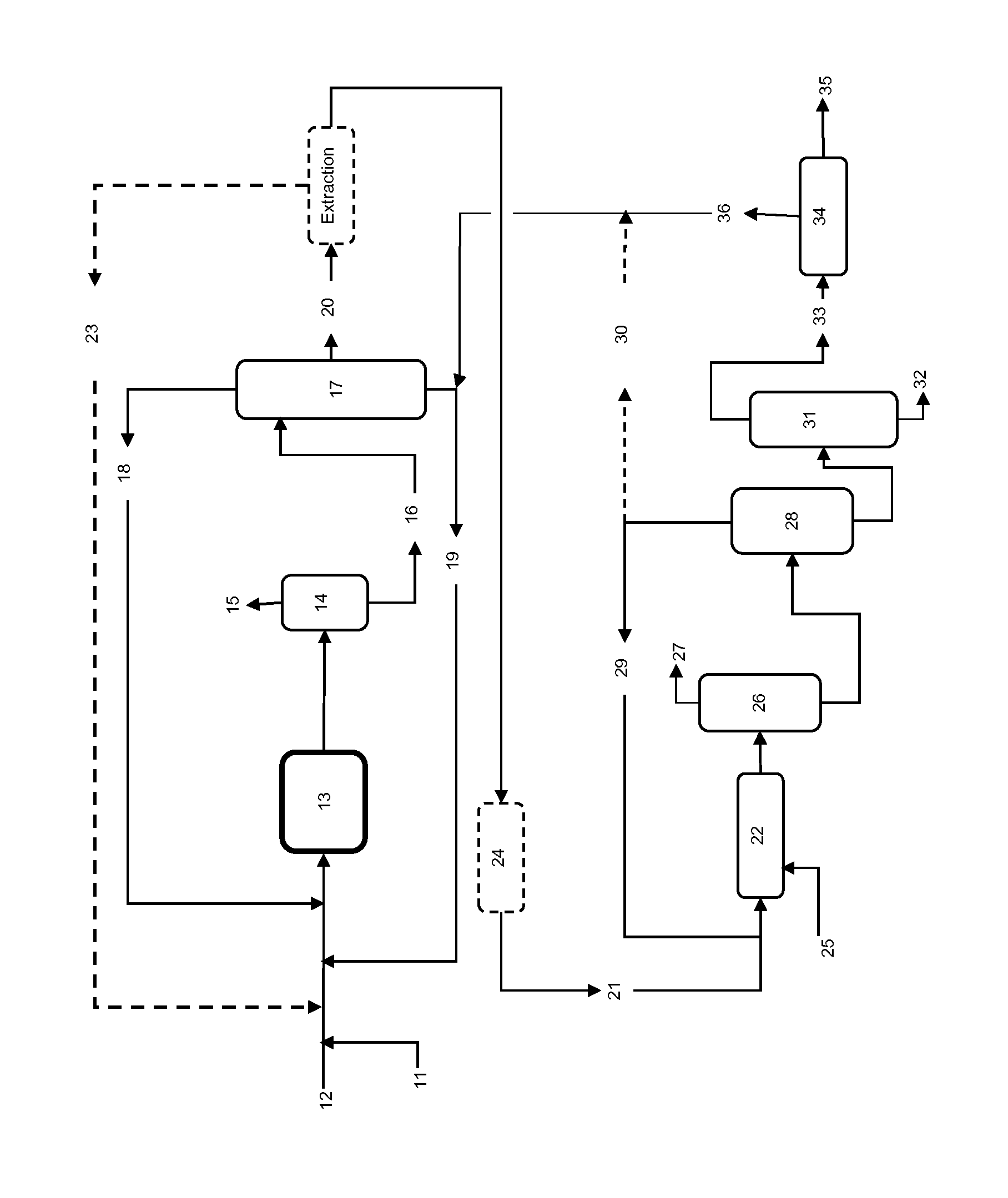

Process for recovering oligomerate

InactiveUS20140135549A1Promote recoveryCatalytic crackingLiquid hydrocarbon mixtures productionChemistryFluid catalytic cracking

A process and apparatus that uses a debutanizer with a side stripper can recover a light stream, an intermediate stream and a liquid stream. One of the intermediate stream and the liquid stream can be recycled to oligomerization or to fluid catalytic cracking.

Owner:UOP LLC

Process for the production of xylenes and light olefins

In a hydrocarbon upgrading process, a hydrocarbon feed is treated in at least one of a steam cracker, catalytic cracker, coker, hydrocracker, and reformer under suitable conditions to produce a first stream comprising olefinic and aromatic hydrocarbons. A second stream composed mainly of C4 to C12+ olefinic and aromatic hydrocarbons is recovered from the first stream and blended said second stream with a residual fraction from a steam cracker or an atmospheric or vacuum distillation unit to produce a third stream. The third stream is then catalytically pyrolyzed in a reactor under conditions effective to produce a fourth stream having an increased benzene and / or toluene content compared with said second stream and a C3-olefin by-product. The C3-olefin by-product is recovered and benzene and / or toluene are recovered from the fourth stream.

Owner:EXXONMOBIL CHEM PAT INC

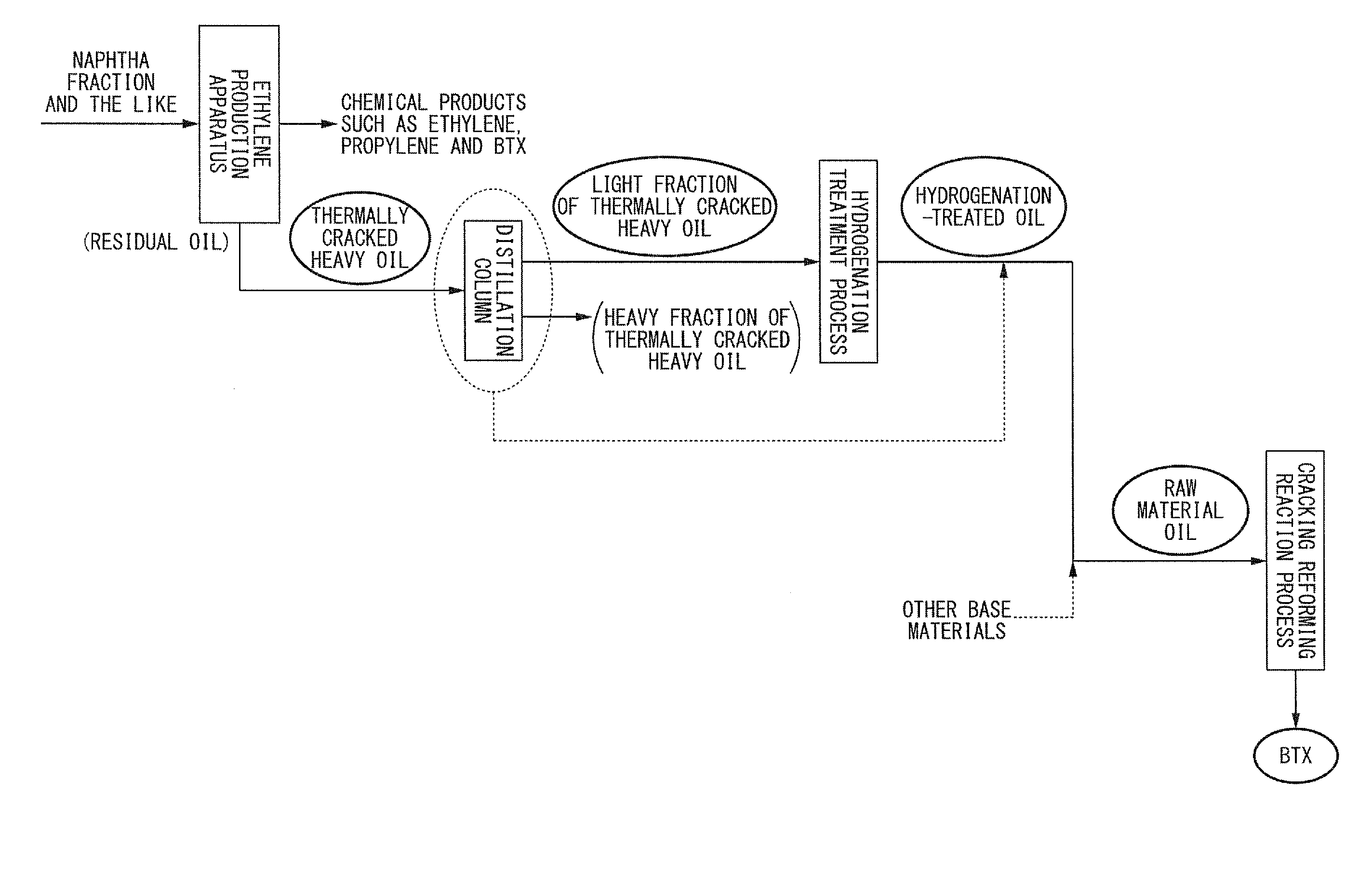

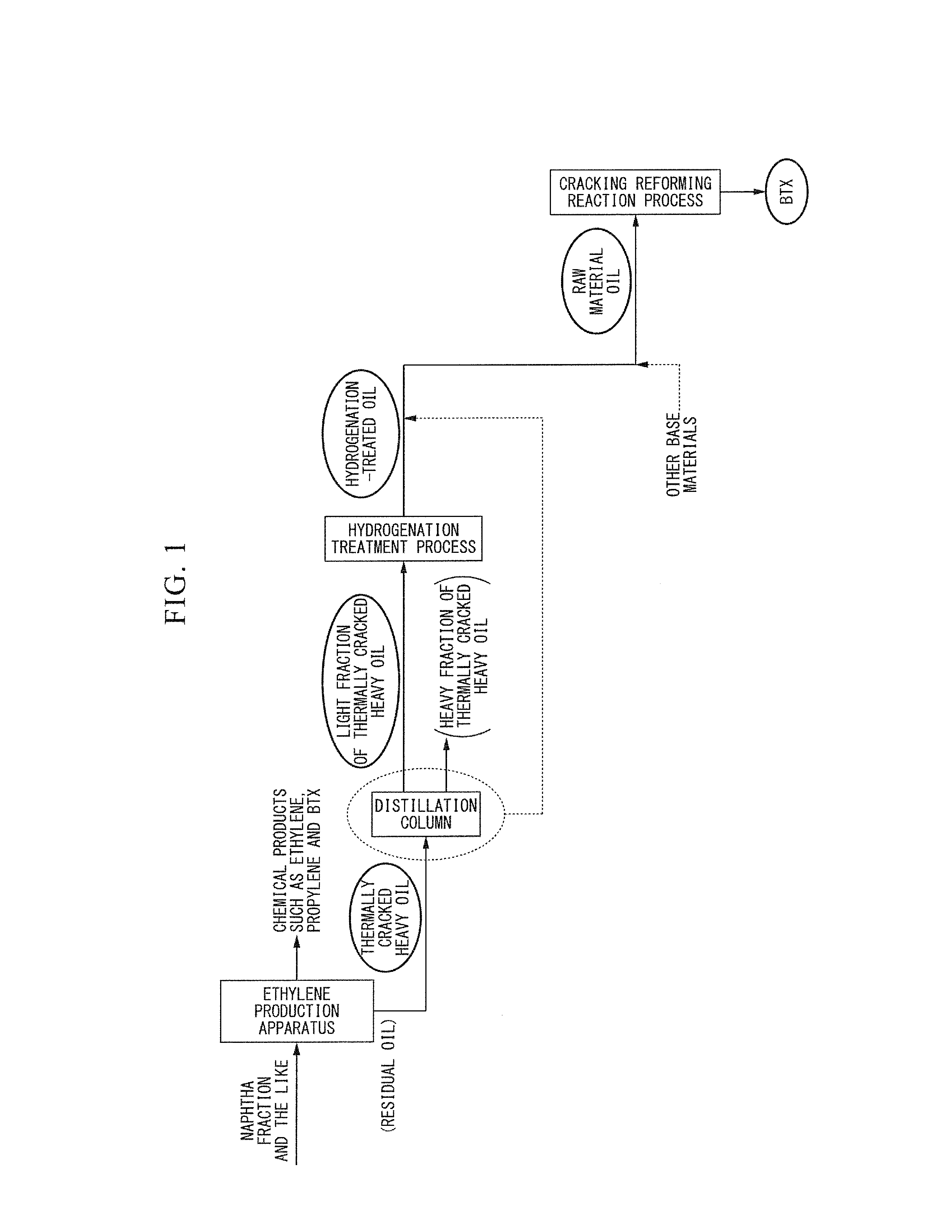

Method for producing aromatic hydrocarbons

ActiveUS20130172639A1Efficient productionThermal non-catalytic crackingTreatment with hydrotreatment processesDistillationFuel oil

Provided is a method for producing aromatic hydrocarbons, by which a feedstock containing a hydrogenation-treated oil of a thermally cracked heavy oil obtainable from an ethylene production apparatus is brought into contact with a catalyst for monocyclic aromatic hydrocarbon production containing a crystalline aluminosilicate, and thereby aromatic hydrocarbons are produced. A raw material having an end point of the distillation characteristics of 400° C. or lower is used as the feedstock. The contact between the feedstock and the catalyst for monocyclic aromatic hydrocarbon production is carried out at a pressure of 0.1 MPaG to 1.5 MPaG.

Owner:JX NIPPON OIL & ENERGY CORP

Heavy Alkylbenzene Production Through Oligomerization

InactiveUS20130253239A1Thermal non-catalytic crackingLiquid hydrocarbon mixtures productionAlkyl transferAlkene

A process for producing heavy alkyl aromatics is presented. The process utilizes low molecular weight hydrocarbons for generating larger alkyl groups. The hydrocarbons can be generated from a variety of sources including Fischer-Tropsch liquids. The process includes oligomerization of low molecular weight olefins to larger olefins. The larger olefins are passed to an alkylation reactor to alkylate aromatic compounds.

Owner:UOP LLC

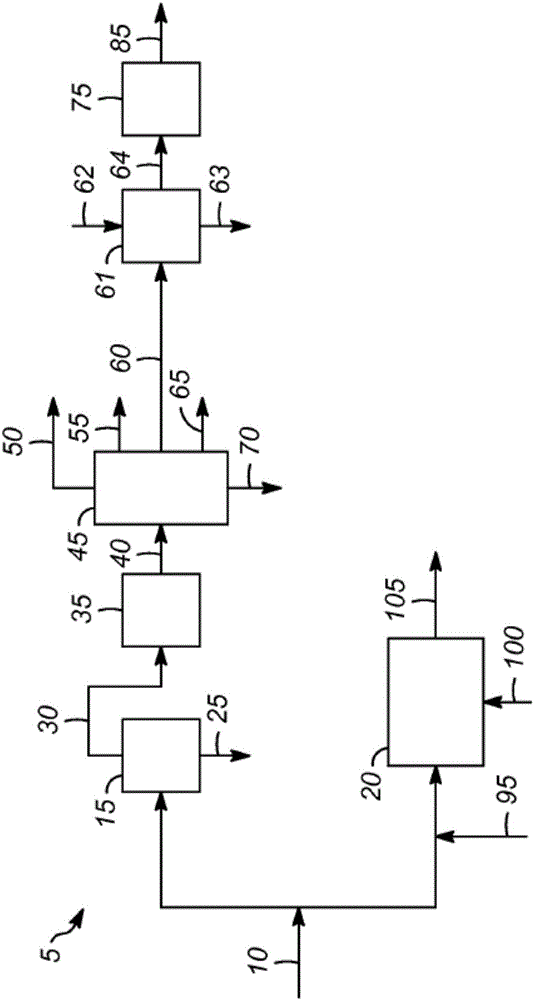

Use of Olefin Cracking to Produce Alkylate

ActiveUS20090030251A1Increase volumeQuality improvementHydrocarbon by metathesis reactionHydrocarbonsGasolineAlkene

A process for producing a feedstock for gasolines having very little aromatic concentrations is disclosed. The present process uses by-product olefins and alkanes to produce an alkylate for use in gasoline blending.

Owner:UOP LLC

Process for the Production of Xylenes and Light Olefins

ActiveUS20130296623A1Increased benzeneIncreased tolueneThermal non-catalytic crackingCatalytic crackingAromatic hydrocarbonAlkene

In a hydrocarbon upgrading process, a hydrocarbon feed is treated in at least one of a steam cracker, catalytic cracker, coker, hydrocracker, and reformer under suitable conditions to produce a first stream comprising olefinic and aromatic hydrocarbons. A second stream composed mainly of C4 to C12+ olefinic and aromatic hydrocarbons is recovered from the first stream and blended said second stream with a residual fraction from a steam cracker or an atmospheric or vacuum distillation unit to produce a third stream. The third stream is then catalytically pyrolyzed in a reactor under conditions effective to produce a fourth stream having an increased benzene and / or toluene content compared with said second stream and a C3-olefin by-product. The C3-olefin by-product is recovered and benzene and / or toluene are recovered from the fourth stream.

Owner:EXXONMOBIL CHEM PAT INC

Process for the desulfurization of olefinic gasolines by increasing the weight of sulfur-containing compounds with regeneration of the catalyst

InactiveUS20070241032A1Weight increaseImprove compoundMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlkyl transferGasoline

This invention relates to a process for the desulfurization of olefinic gasolines that employs a reaction for increasing the weight of sulfur-containing compounds by alkylation on the olefins of the feedstock, by means of an acidic catalyst, and that comprises a regeneration of the catalyst that can be carried out sequentially or continuously.

Owner:INST FR DU PETROLE

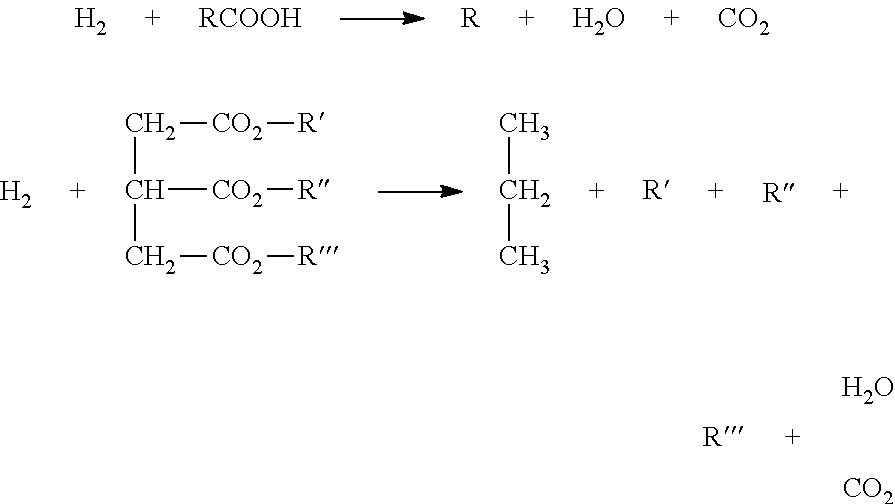

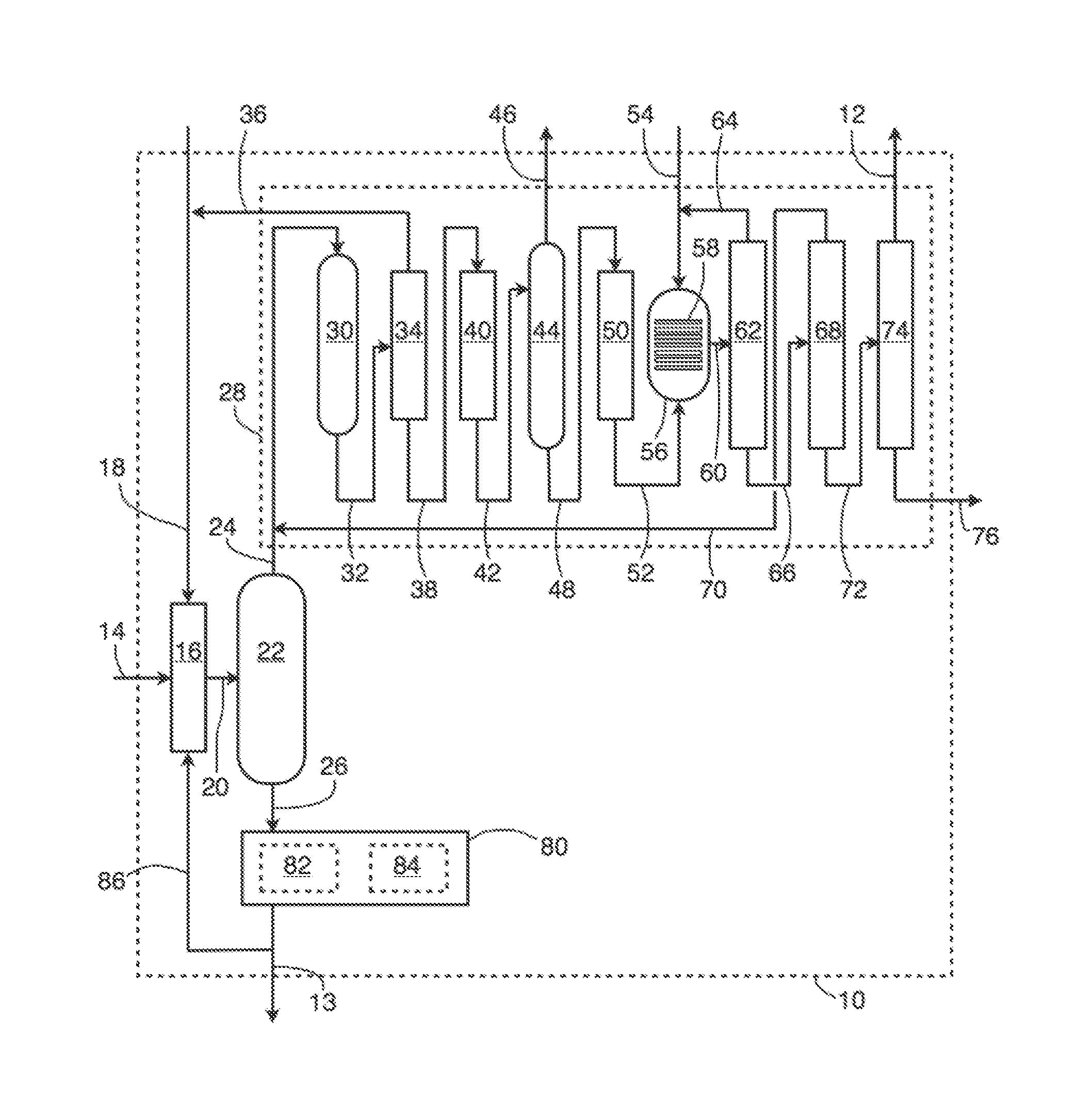

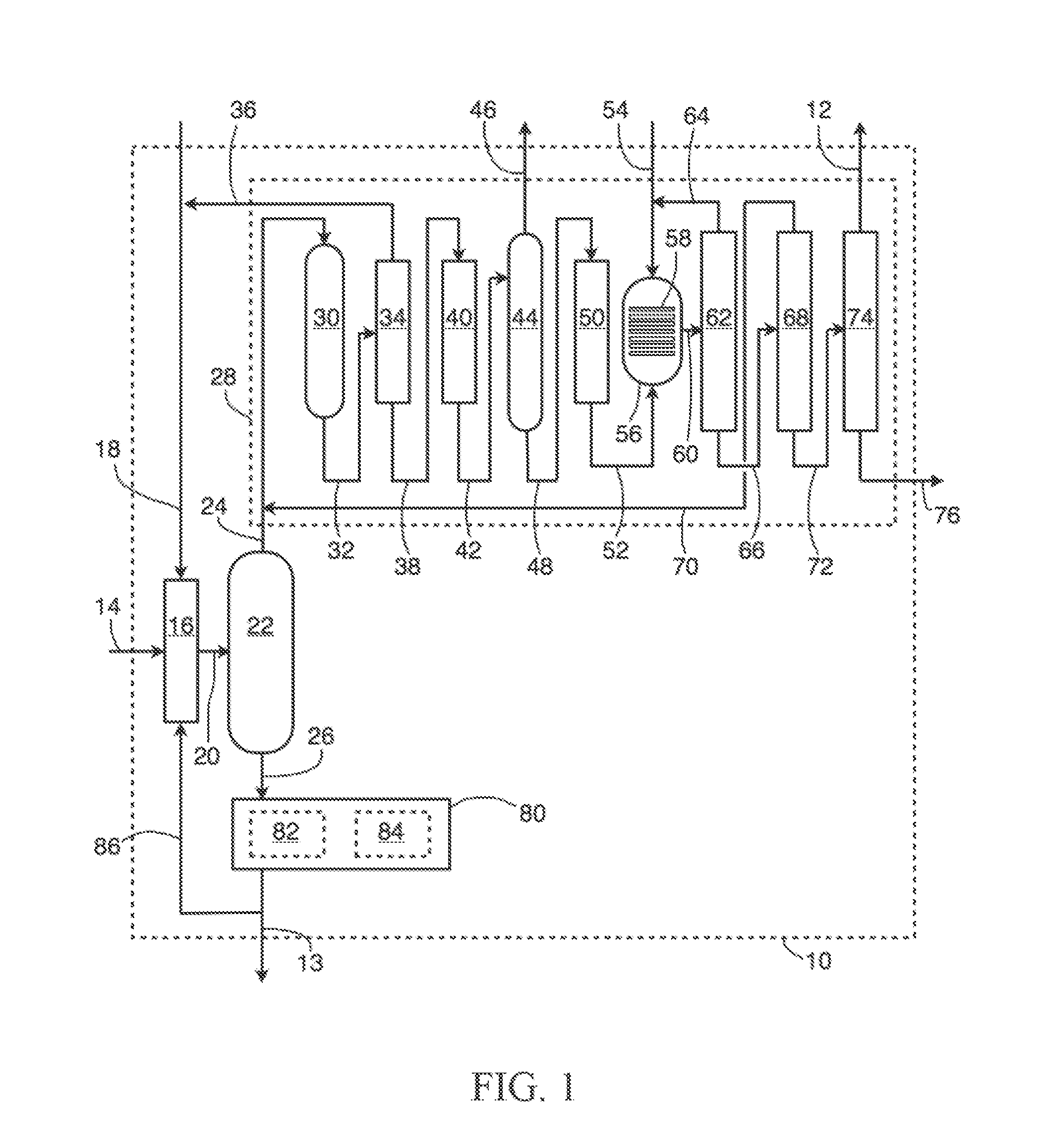

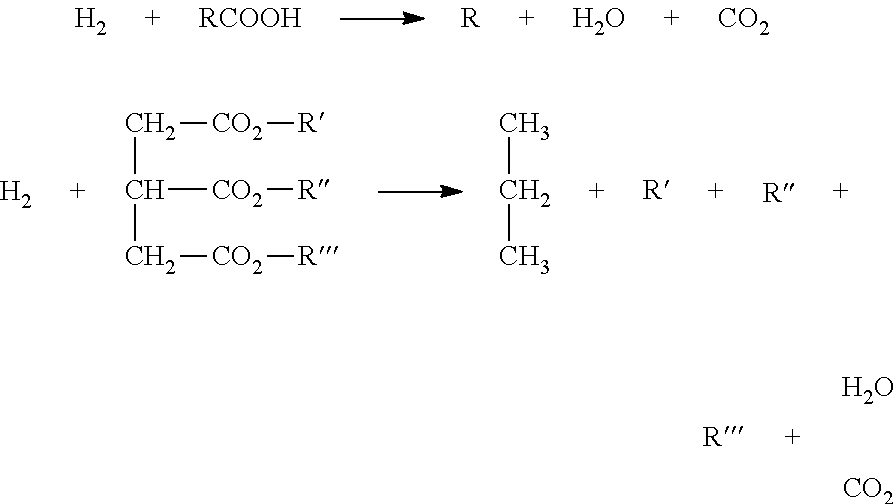

Methods for co-production of alkylbenzene and biofuel from natural oils

Embodiments of methods for co-production of linear alkylbenzene and biofuel from a natural oil are provided. A method comprises the step of deoxygenating the natural oils to form a stream comprising paraffins. A first portion of the paraffins are dehydrogenated to provide mono-olefins. Then, benzene is alkylated with the mono-olefins under alkylation conditions to provide an alkylation effluent comprising alkylbenzenes and benzene. Thereafter, the alkylbenzenes are isolated to provide the alkylbenzene product. A second portion of the paraffins is processed to form biofuel.

Owner:UOP LLC

Process for removing a contaminant from coal tar

InactiveCN105705612AReduce contentTreatment with plural serial stages onlyTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonSorbent

A process for removing at least one contaminant from coal tar is described. The process involves extraction with an extraction agent or adsorption with an adsorbent. The extraction agent includes at least one of amphiphilic block copolymers, inclusion complexes of poly(methyl methacrylate) and polycyclic aromatic hydrocarbons, cyclodextrins, functionalized cyclodextrins, and cyclodextrin-functionalized polymers, and the adsorbent includes exfoliated graphite oxide, thermally exfoliated graphite oxide or intercalated graphite compounds.

Owner:UOP LLC

Ionic liquid catalyst treating system

PendingCN108368005ALiquid separation by electricitySolid sorbent liquid separationElectrostatic separationFiltration

A process removing ionic liquid from a process stream is described. The process stream is introduced into a coalescer to form an ionic liquid stream and a first treated process stream which has less ionic liquid than the process stream. The first treated process stream is introduced into a separator to form a second treated process stream. The second treated process stream has less ionic liquid than the first treated process stream. The separator is selected from a filtration zone comprising sand or carbon, an adsorption zone, a scrubbing zone, an electrostatic separation zone, or combinationsthereof.

Owner:UOP LLC

Methods for co-production of alkylbenzene and biofuel from natural oils

Embodiments of methods for co-production of linear alkylbenzene and biofuel from a natural oil are provided. A method comprises the step of deoxygenating the natural oils to form a stream comprising paraffins. A first portion of the paraffins are dehydrogenated to provide mono-olefins. Then, benzene is alkylated with the mono-olefins under alkylation conditions to provide an alkylation effluent comprising alkylbenzenes and benzene. Thereafter, the alkylbenzenes are isolated to provide the alkylbenzene product. A second portion of the paraffins is processed to form biofuel.

Owner:UOP LLC

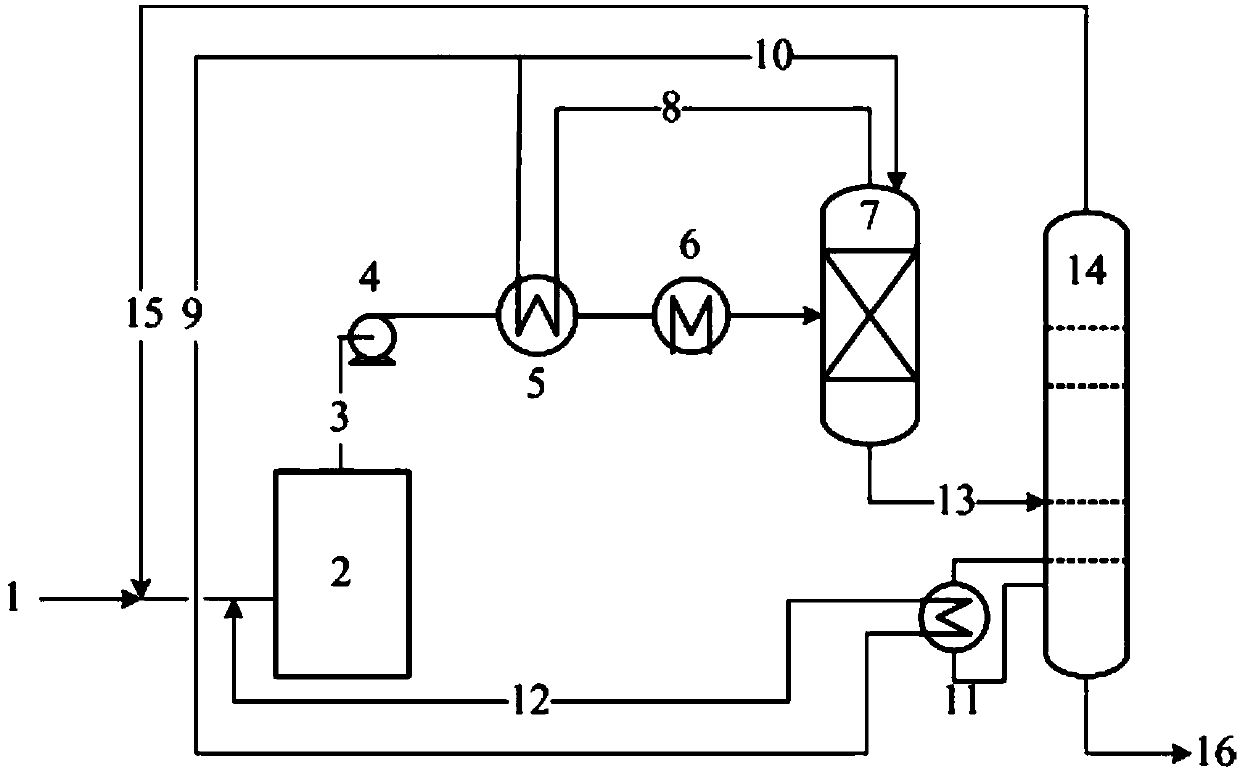

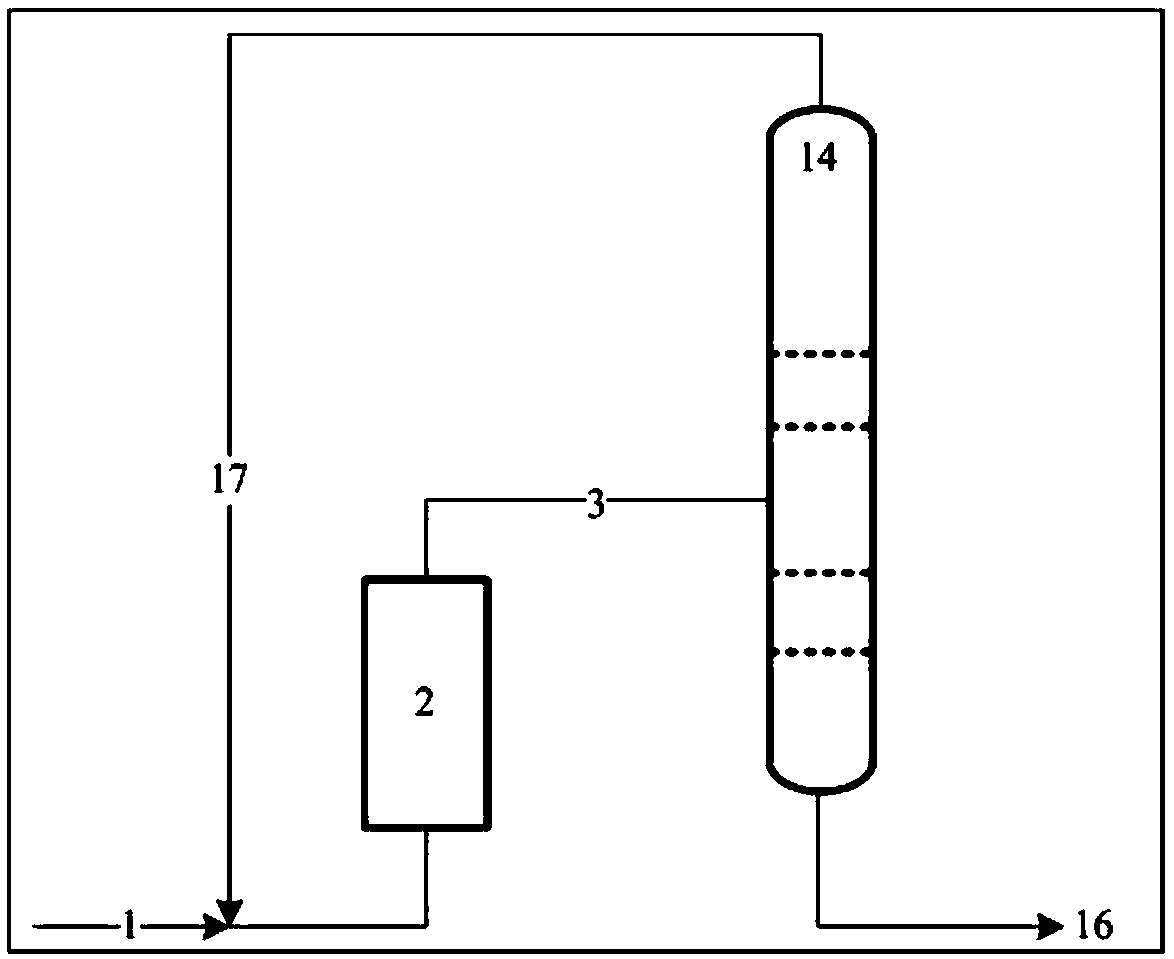

Alkylation product separation method, alkylation reaction separation method and alkylation reaction separation device

ActiveCN110876855AIncrease temperatureTo achieve the purpose of saving energy and reducing consumptionHydrocarbon distillationChemical industryAlkaneFluid phase

The invention discloses an alkylation product separation method. According to the method, a liquid-phase alkylation product is pressurized by an optional booster pump; the pressurized liquid-phase alkylation product is introduced into a first heat exchanger, and is subjected to heat exchange with a gas-phase material from a high-pressure fractionating tower; the heat exchanged material is furtherheated to 100-180 DEG C in a second heat exchanger; the heated material enters the high-pressure fractionating tower, and is fractionated under a condition of 2.0-6.0 MPa; the gas-phase material at the top of the high-pressure fractionating tower is subjected to heat exchange with the liquid-phase alkylation product; the liquid-phase material at the bottom of the high-pressure fractionating towerenters a low-pressure fractionating tower and is fractionated under a condition of 0.2-1.0 MPa; low-carbon alkane is obtained at the top of the low-pressure fractionating tower, and an alkylation oilproduct is obtained at the bottom of the low-pressure fractionating tower; and the low-pressure fractionating tower is provided with an intermediate reboiler, and the gas-phase material at the top ofthe high-pressure fractionating tower after heat exchange of the first heat exchanger is used as a heat source of the intermediate reboiler. The method provided by the invention can improve the heat utilization efficiency and reduce the separation operation energy consumption in the alkylation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Liquid carbonaceous fuels Treatment with alkylation Hydrocarbon oils refining Hydrocarbon oils treatment products Hydrocarbon preparation Adsorption purification/separation Chemical/physical/physico-chemical stationary reactors Gaseous mixture working up Hydrocarbon from saturated and unsaturated hydrocarbon addition Bulk chemical production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com