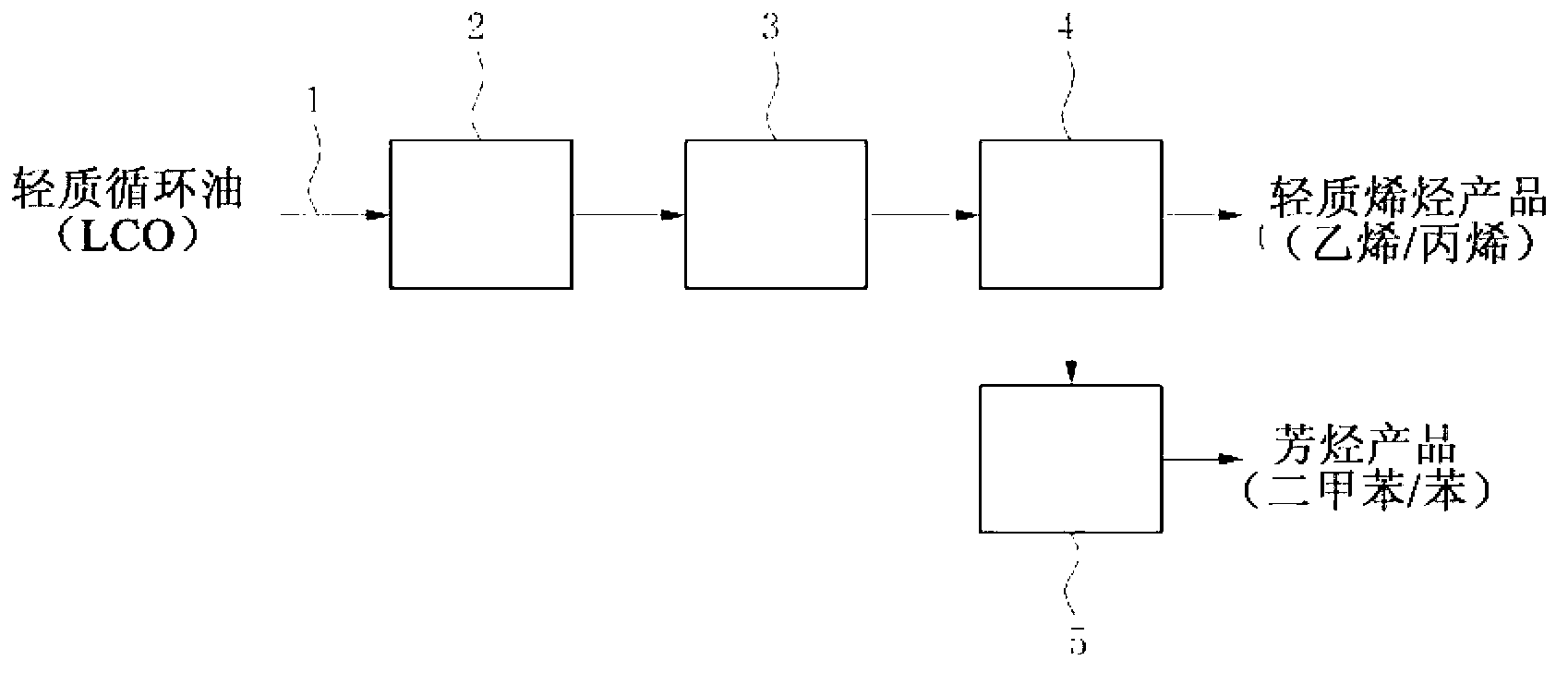

Method for producing high-added-value aromatic products and olefinic products from an aromatic-compound-containing oil fraction

一种芳族化合物、馏分的技术,应用在化学仪器和方法、烃裂化制烃、碳氢化合物等方向,能够解决不适合等问题,达到提高产量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] As the light cycle oil used in the method of the present invention, the light cycle oil shown in the following Table 1 is provided. The light cycle oil is produced by the fluid catalytic cracking process and has a boiling point range of 170° C. to 360° C. ℃ oil fraction.

[0094] [Table 1]

[0095]

Feed

Paraffins + Olefins

4.680

Vinyl

-

Acrylic

-

Butene

-

Naphthenic

0.502

Total Aromatics

84.121

1 ring aromatics

39.024

1-ring aromatics without naphthenic rings

26.951

BTX+C9

9.431

B+X

1.473

T+C9

7.958

B

0.024

T

0.344

X

1.449

C9

7.614

1-ring aromatic hydrocarbon with a cycloalkane ring

12.072

1-ring aromatic hydrocarbon with two naphthenic rings

-

2 ring aromatics

40.975

2-ring aromatics without naphthenic rings

38.398

2-ring aromatics with a cyc...

Embodiment 2

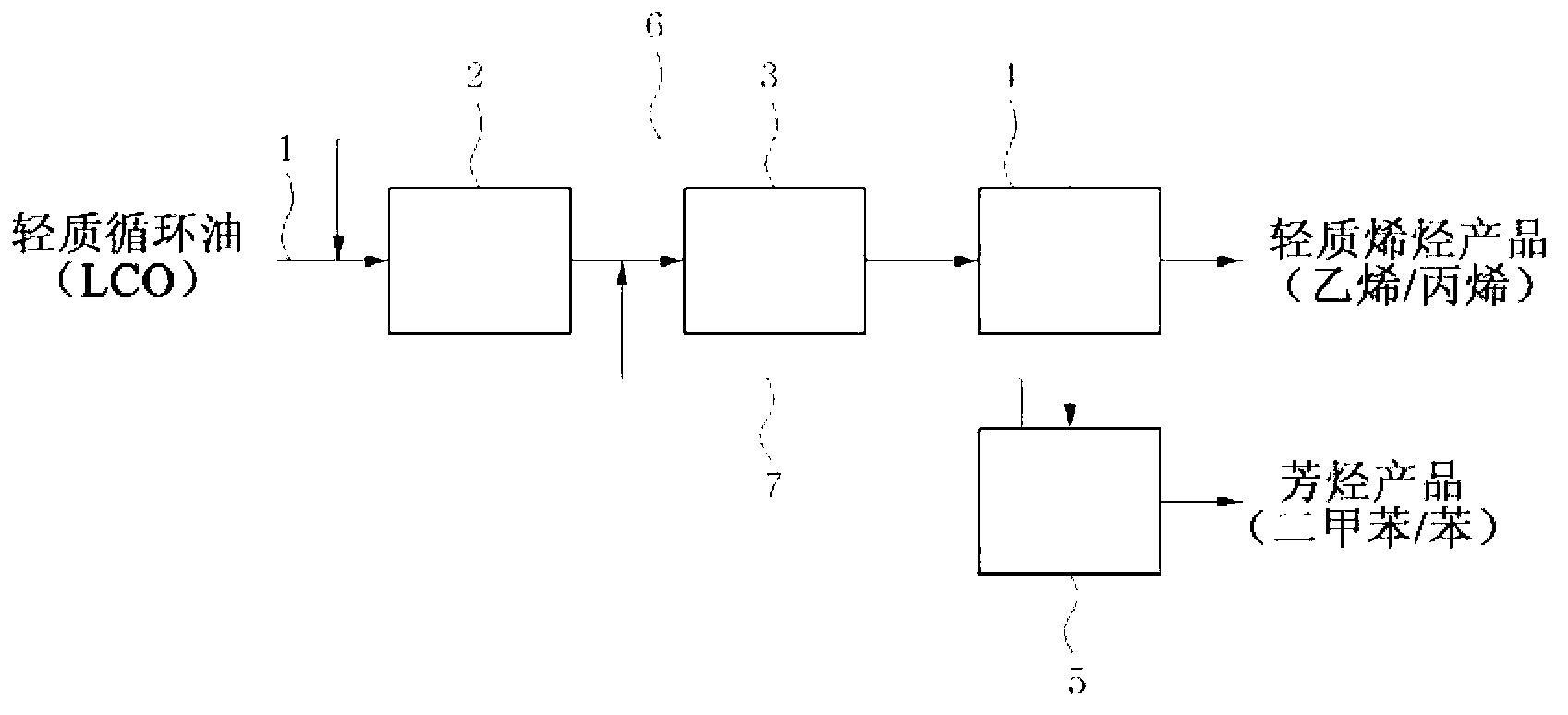

[0119] Example 2 was performed using the same feed and reaction conditions as Example 1.

[0120] Furthermore, Example 2 was carried out in the same manner as Example 1 except that the following components i), ii), iii) and iv) produced by the fluid catalytic cracking step after the hydrotreating step were recycled , such that components i), ii), iii) and iv) are mixed with light cycle oil introduced into the hydrotreating step, wherein components i), ii), iii) and iv) are: i) having 2 Aromatic components with 2 or more rings, ii) 1-ring aromatics that cannot be converted into raw materials for high value-added aromatic products due to hydrocarbon groups with 2 or more carbon atoms, iii) non-high value-added aromatic products 1-ring aromatics that cannot be converted into high-value-added aromatic products due to having a naphthenic ring, and iv) other components of raw materials that are not high-value-added aromatic products and cannot be converted into high-value-added arom...

Embodiment 3

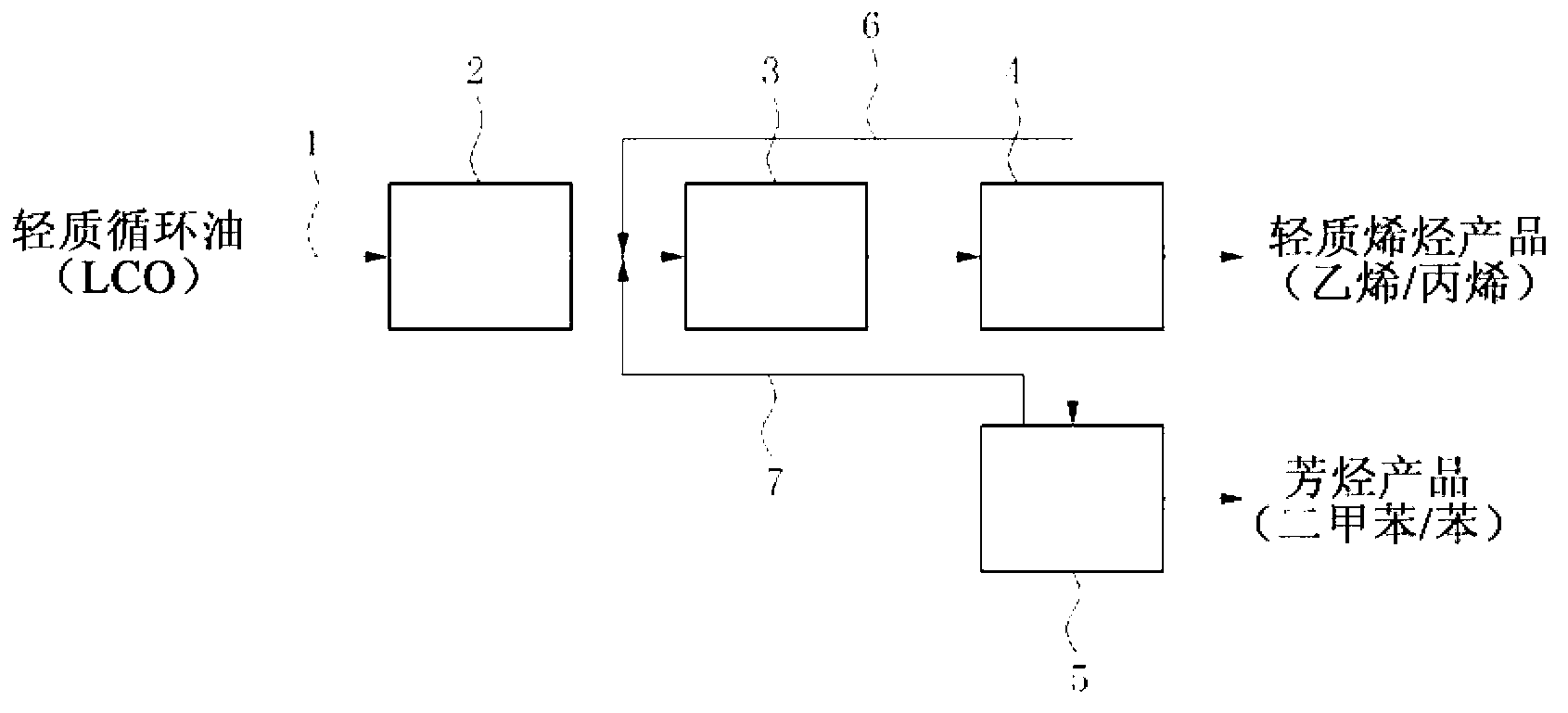

[0127] Example 3 was carried out using the same starting materials and reaction conditions as in Example 1.

[0128] In addition, Example 3 was carried out in the same manner as Example 1, except that the following step was additionally carried out: the following components i), ii), and iii produced by the fluid catalytic cracking step after the hydrotreating step were ) and iv) are recycled to mix components i), ii), iii) and iv) with light cycle oil introduced into the hydrotreating step, wherein components i), ii), iii) and iv) are : i) aromatic components with 2 or more rings, ii) 1-ring aromatics that cannot be converted into raw materials for high value-added aromatic products due to hydrocarbon groups with 2 or more carbon atoms, iii) non- 1-ring aromatics that are high-value-added aromatic products and cannot be converted into high-value-added aromatic products due to having a naphthenic ring, and iv) raw materials that are not high-value-added aromatic products and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com