Process for removing a contaminant from coal tar

A pollutant, coal tar technology, applied in tar processing, tar processing by chemical method, tar processing by selective solvent extraction, etc., can solve the problem of expensive petroleum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

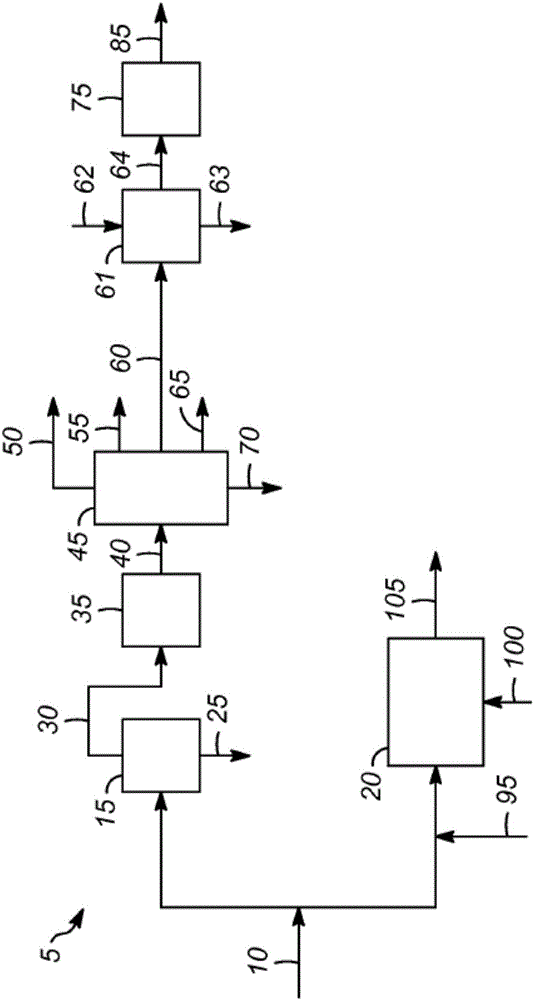

[0011] The Figure shows one embodiment of a coal conversion process 5 . The coal feed 10 can be sent to the pyrolysis zone 15, the gasification zone 20, or the coal feed 10 can be split into two parts and sent to both.

[0012] In pyrolysis zone 15, the coal is heated at high temperature, eg, up to 2,000°C (3600°F), in the absence of oxygen, to remove volatile components. Coking produces a coke stream 25 and a coal tar stream 30 . Coke stream 25 can be used in other processes such as steel production.

[0013] Coal tar stream 30 from the coking process, comprising volatile components, may be passed to optional pollutant removal zone 35, if desired.

[0014] Contaminant removal for the removal of one or more pollutants from a coal tar stream or another process stream, depending on the effect of the particular pollutant on the product or process and the reason for the removal of the pollutant, as further described below Zone 35 may be located at various locations along the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com