Method and apparatus for obtaining aromatics from diverse feedstock

A technology for aromatics and reforming units, applied in chemical instruments and methods, only multi-stage series refining and cracking process treatment, hydrocarbon oil treatment, etc., can solve low consumption and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

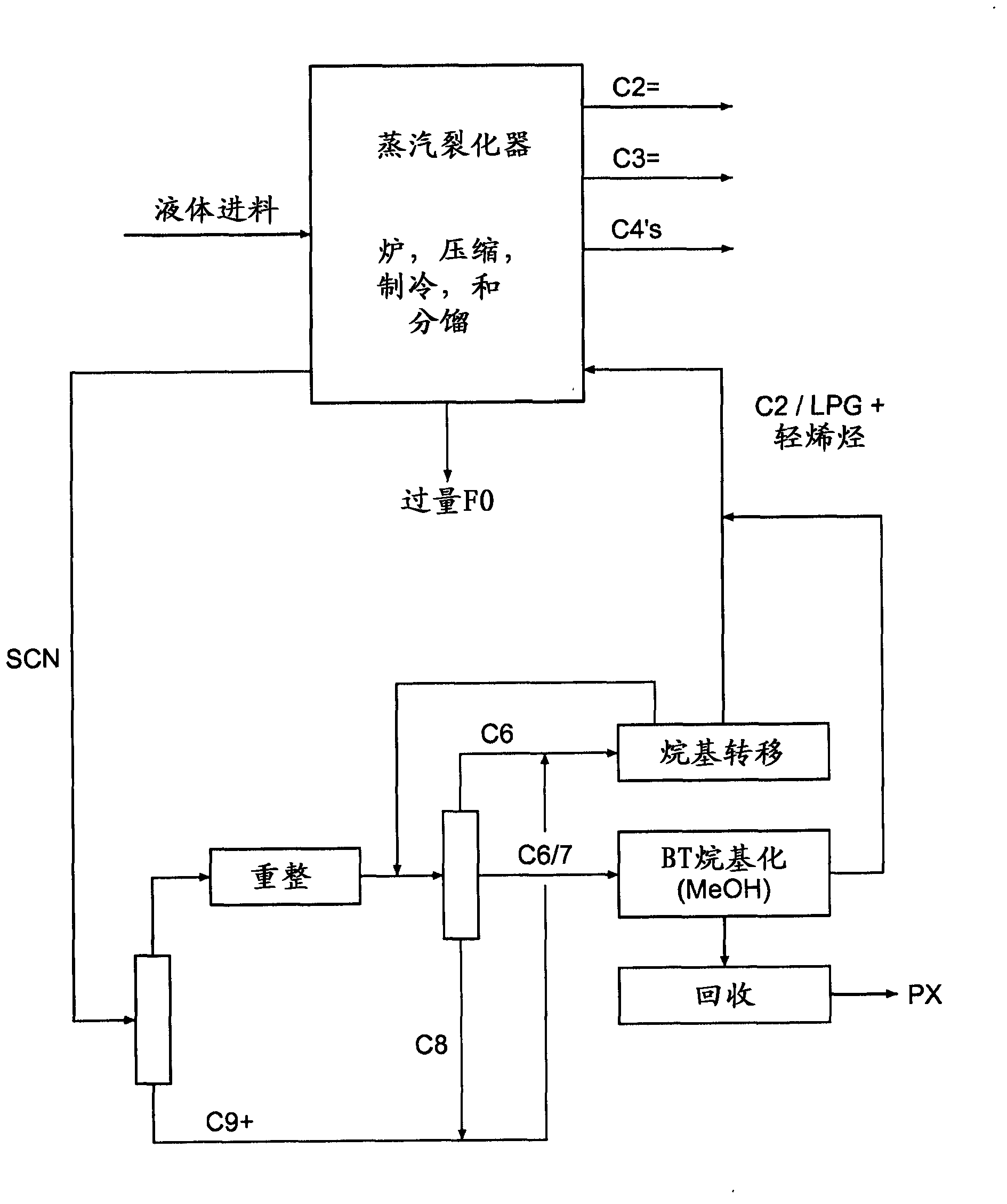

[0025] According to the present invention, in embodiments, there is a process for producing paraxylene using a feed stream comprising naphtha, and a system adapted thereto, for selective use in the production of paraxylene prior to contacting with a methylating agent. The naphtha-containing feed stream is treated in the presence of a toluene catalyst to increase its benzene and / or toluene content.

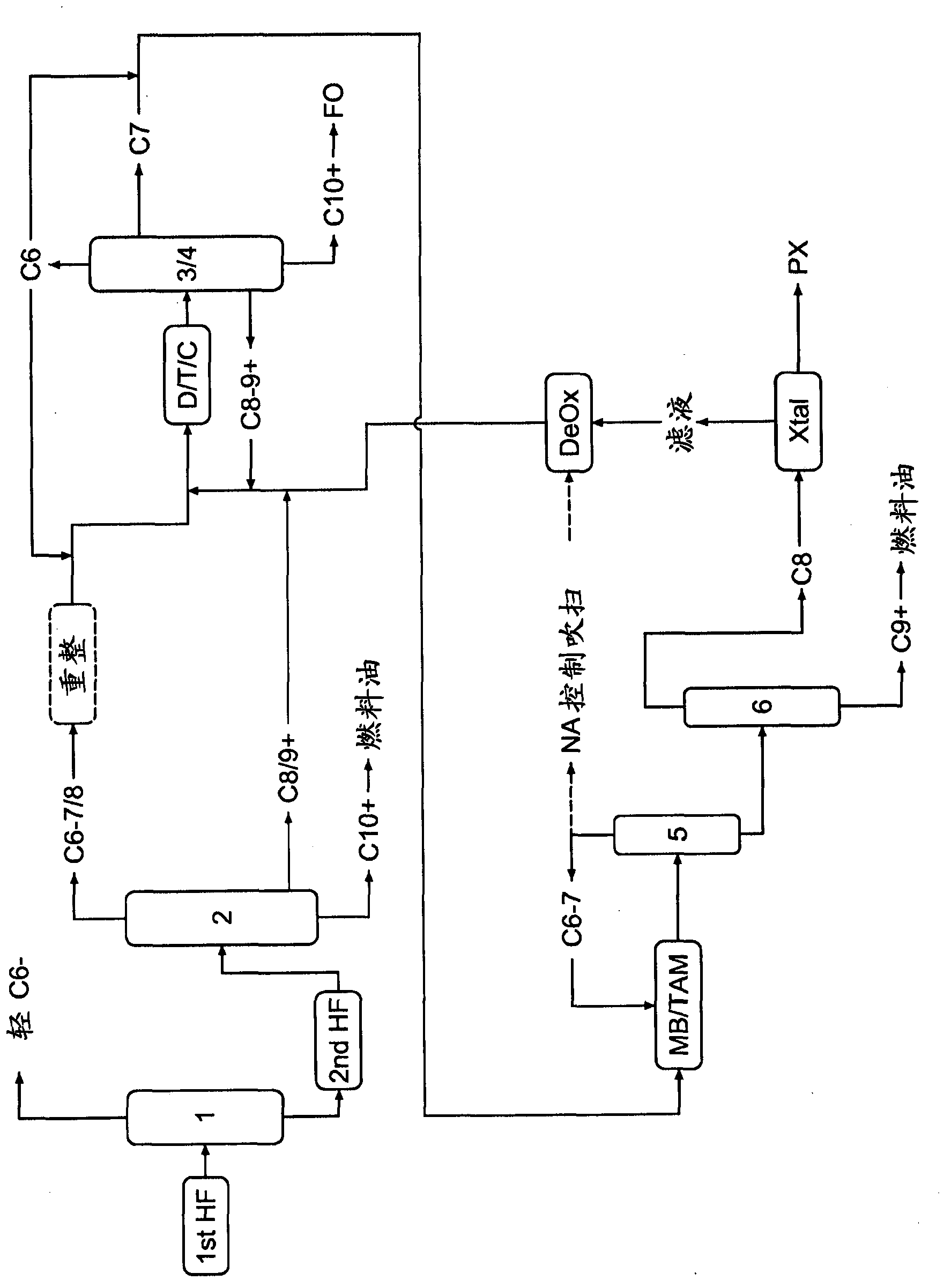

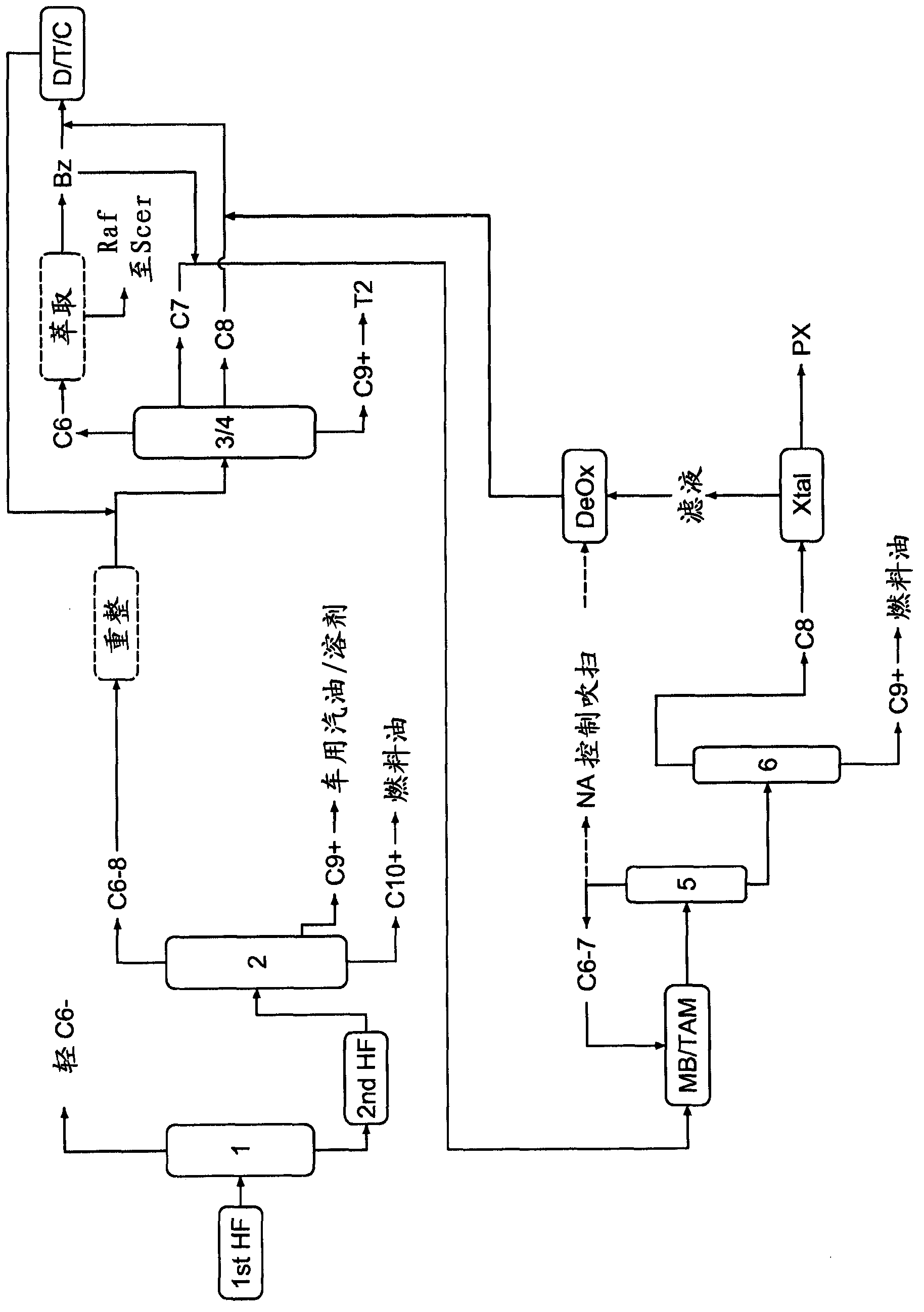

[0026] In embodiments, the process comprises: (a) dealkylation and / or transalkylation and / or cracking (D / T / C) of a naphtha stream via a catalyst under reaction conditions to enrich benzene and and / or toluene and the production of light paraffinic by-products; (b) adding a methylating agent to all or part of at least the benzene / toluene component of the product from step (a) and subjecting the mixture to selectivity for the production of Catalyst contacting of para-xylene to produce para-xylene and light olefinic or light paraffinic by-products; (c) recovering purified para-xylene f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com