Patents

Literature

113results about "Reflux condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

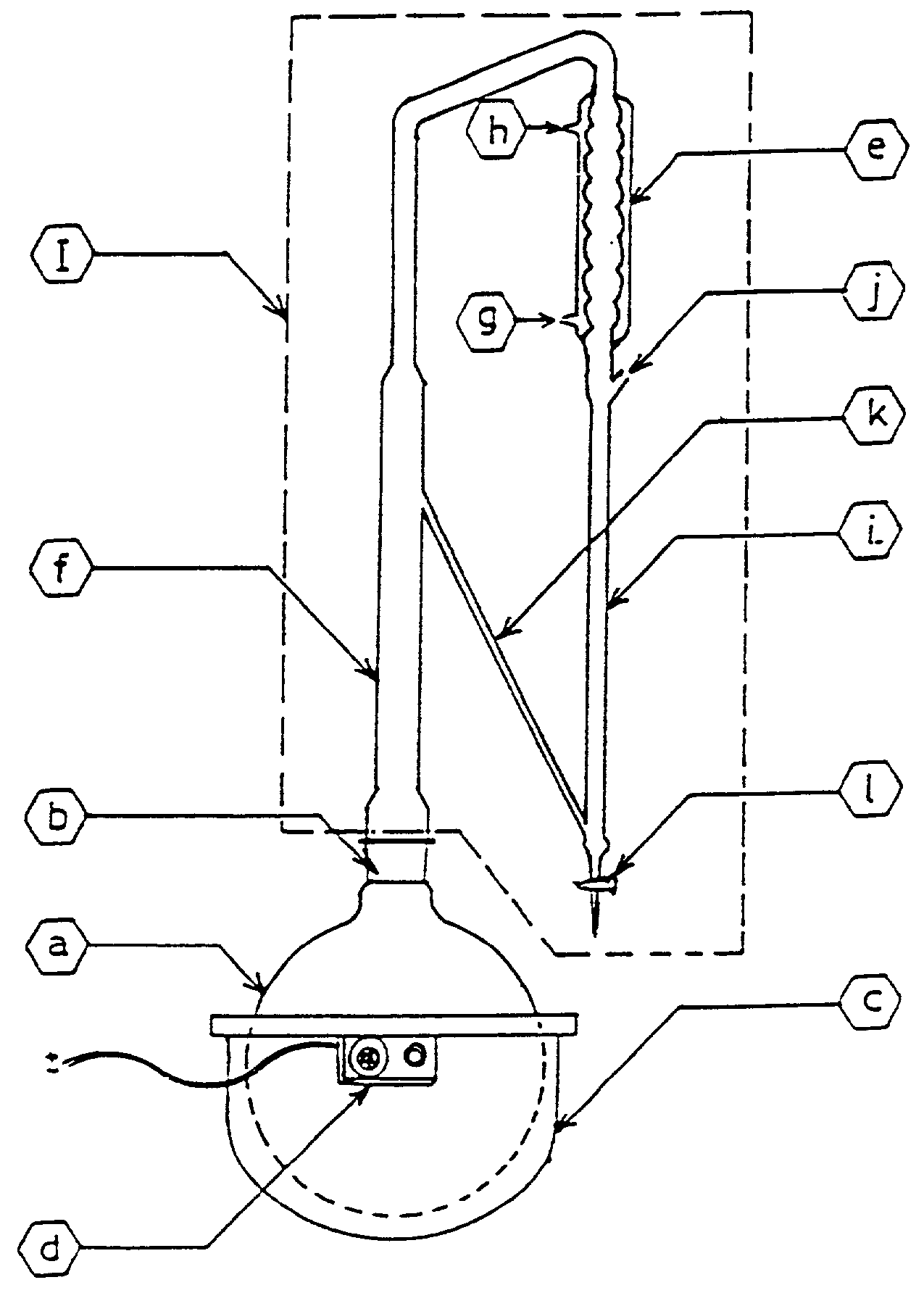

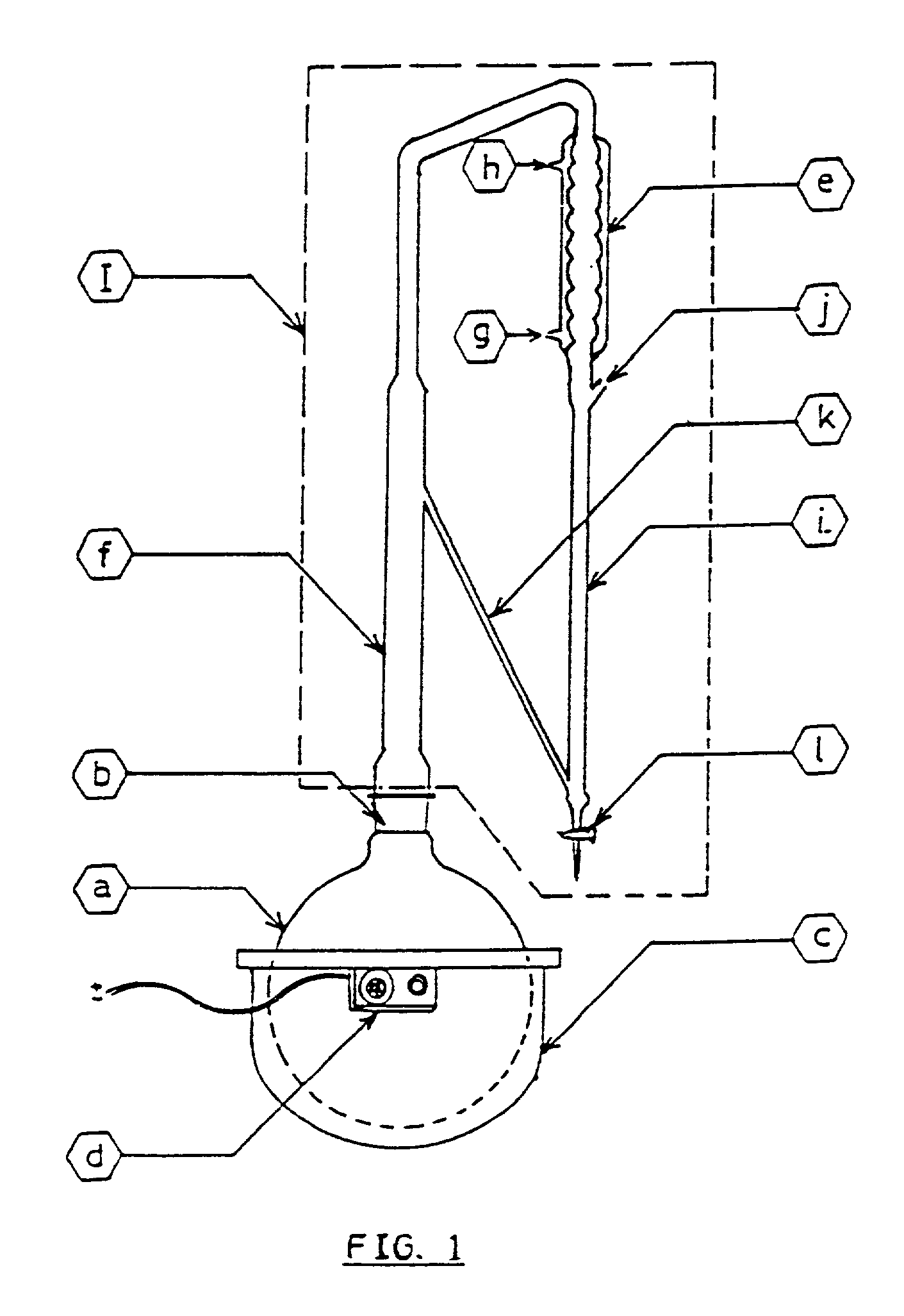

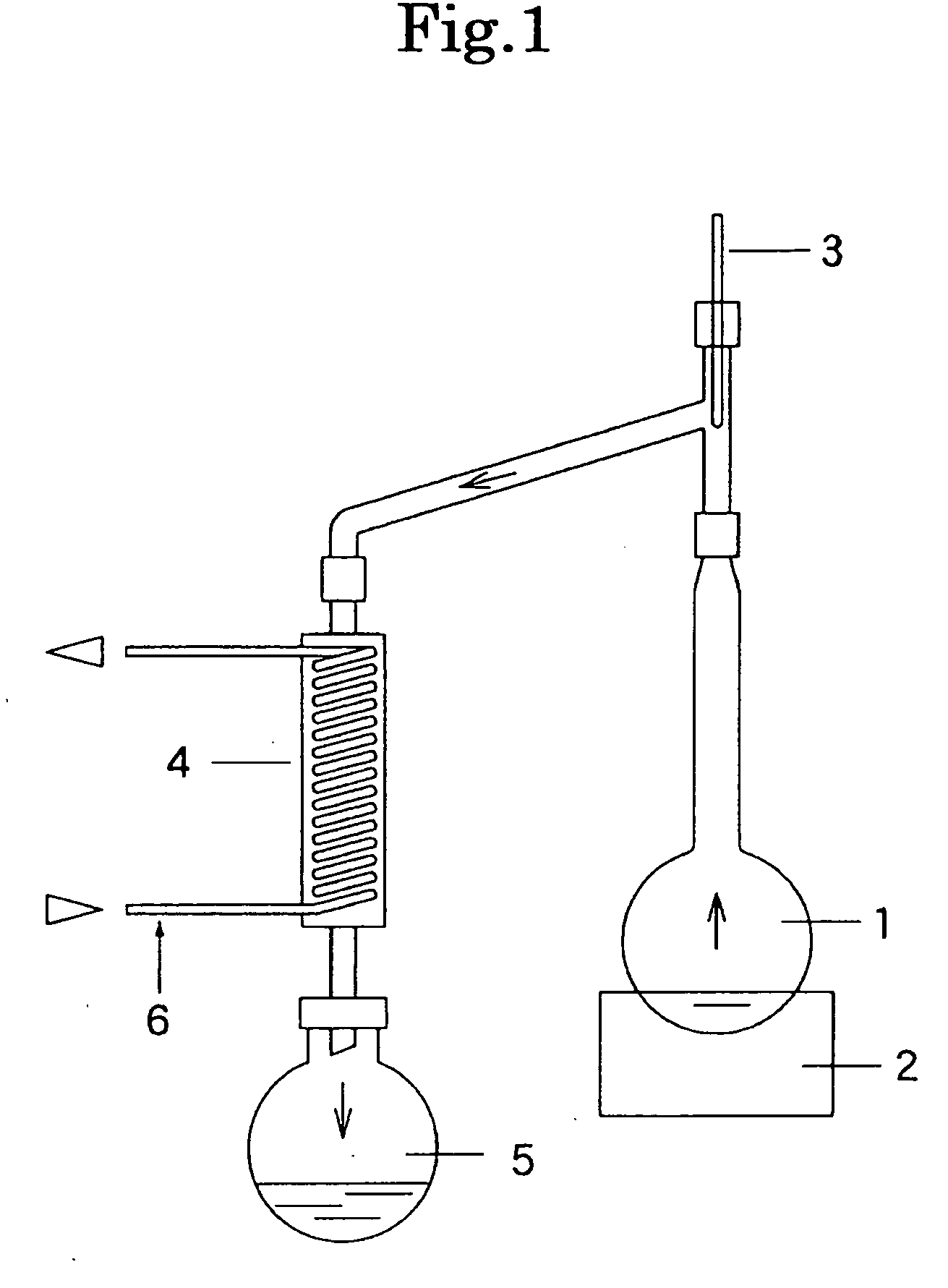

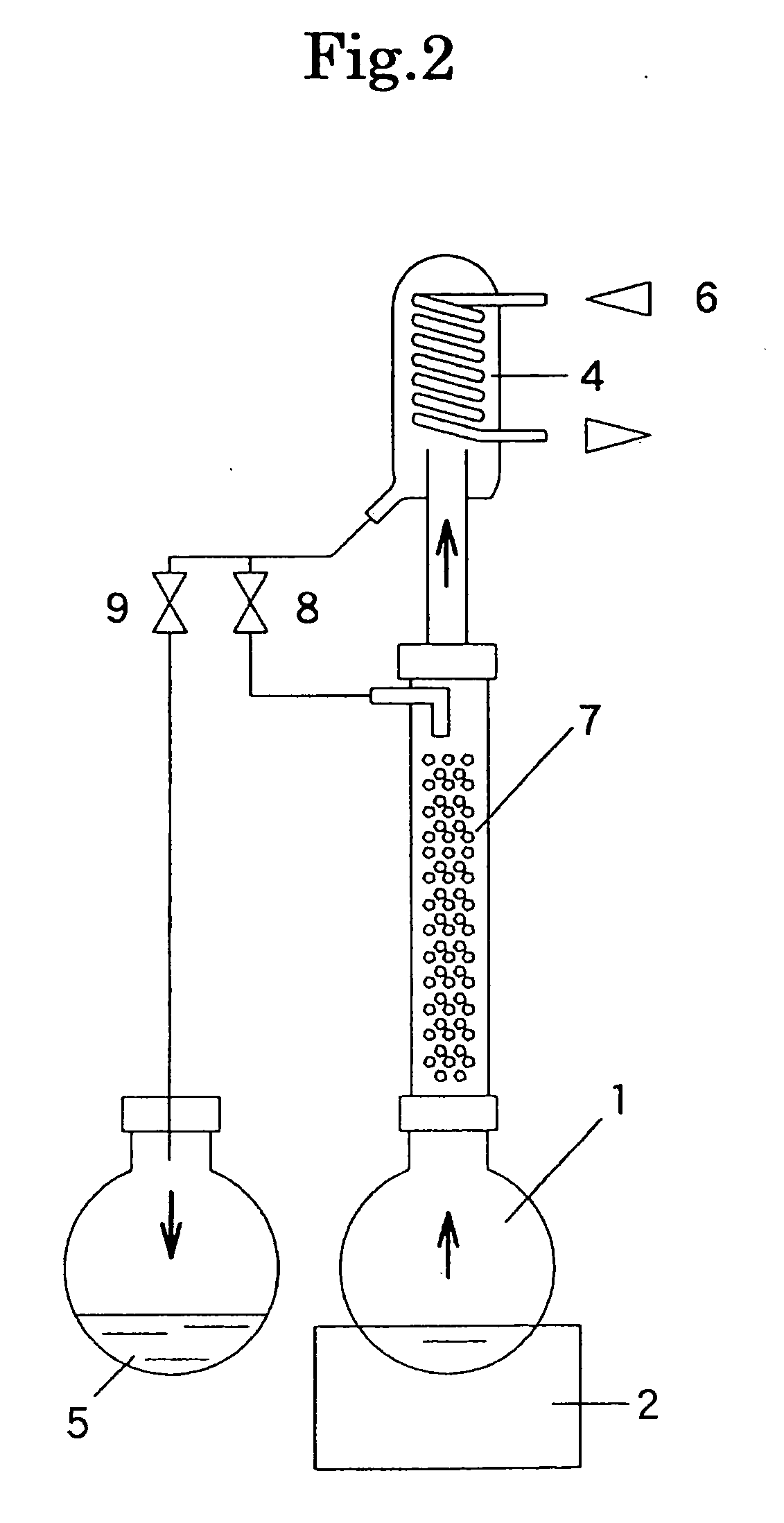

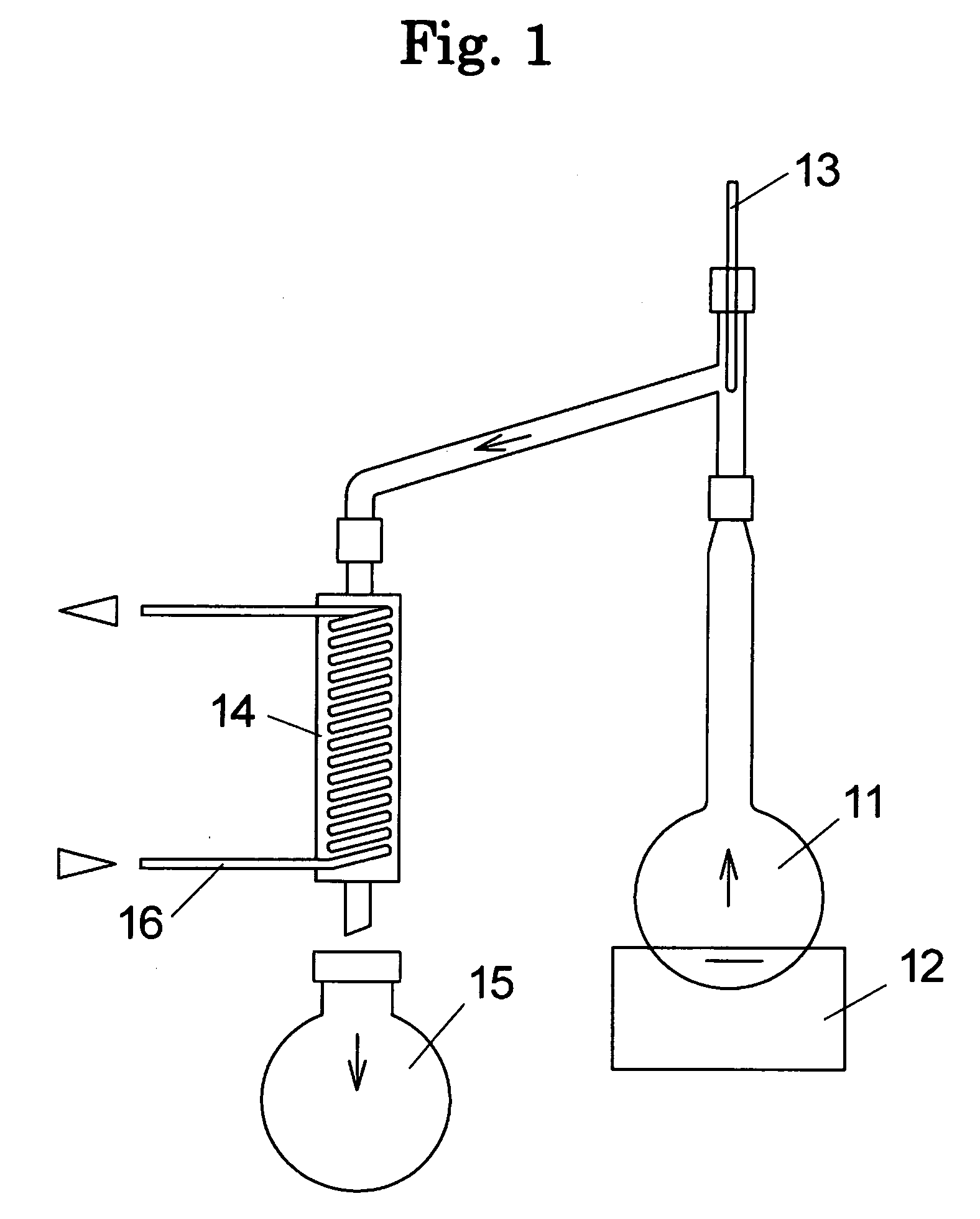

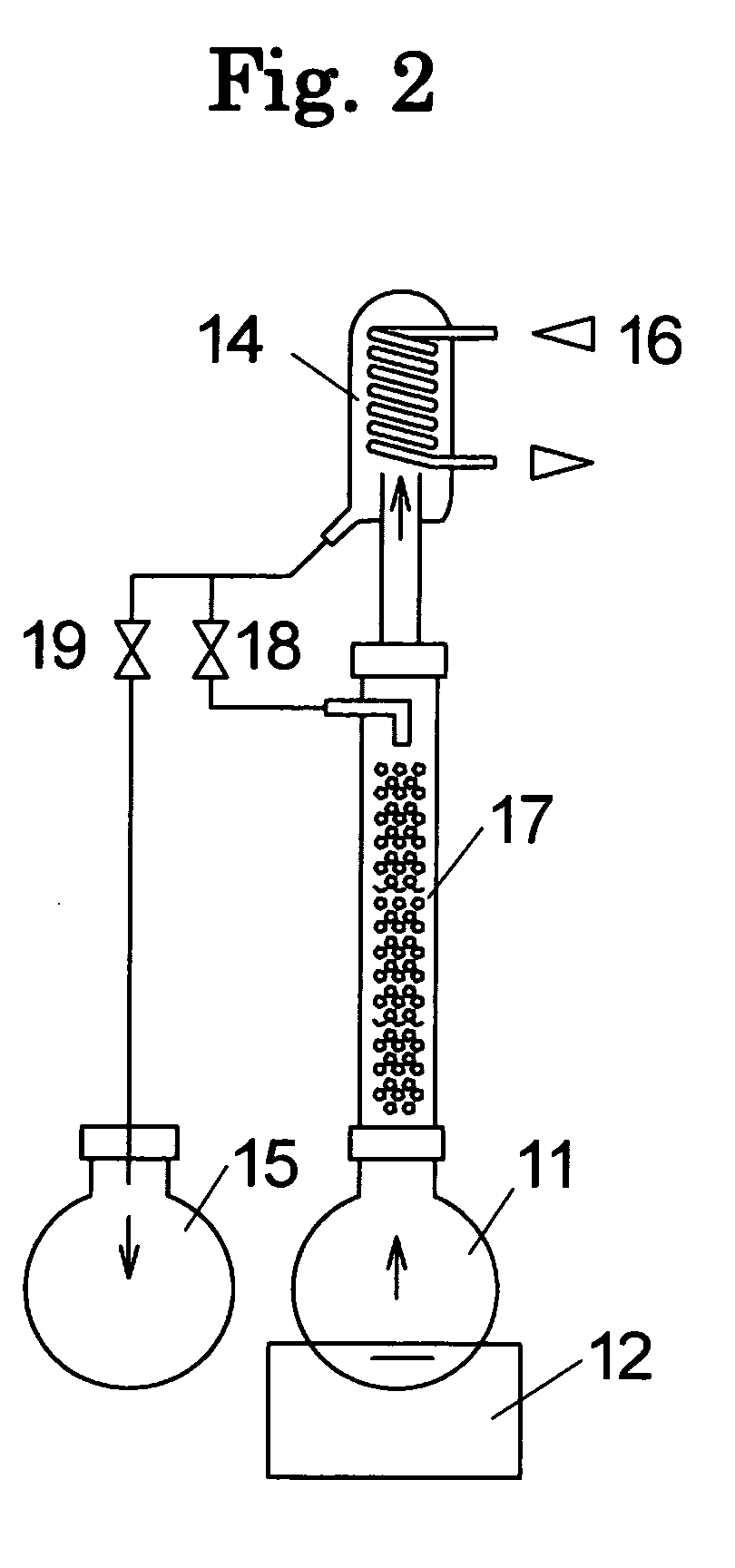

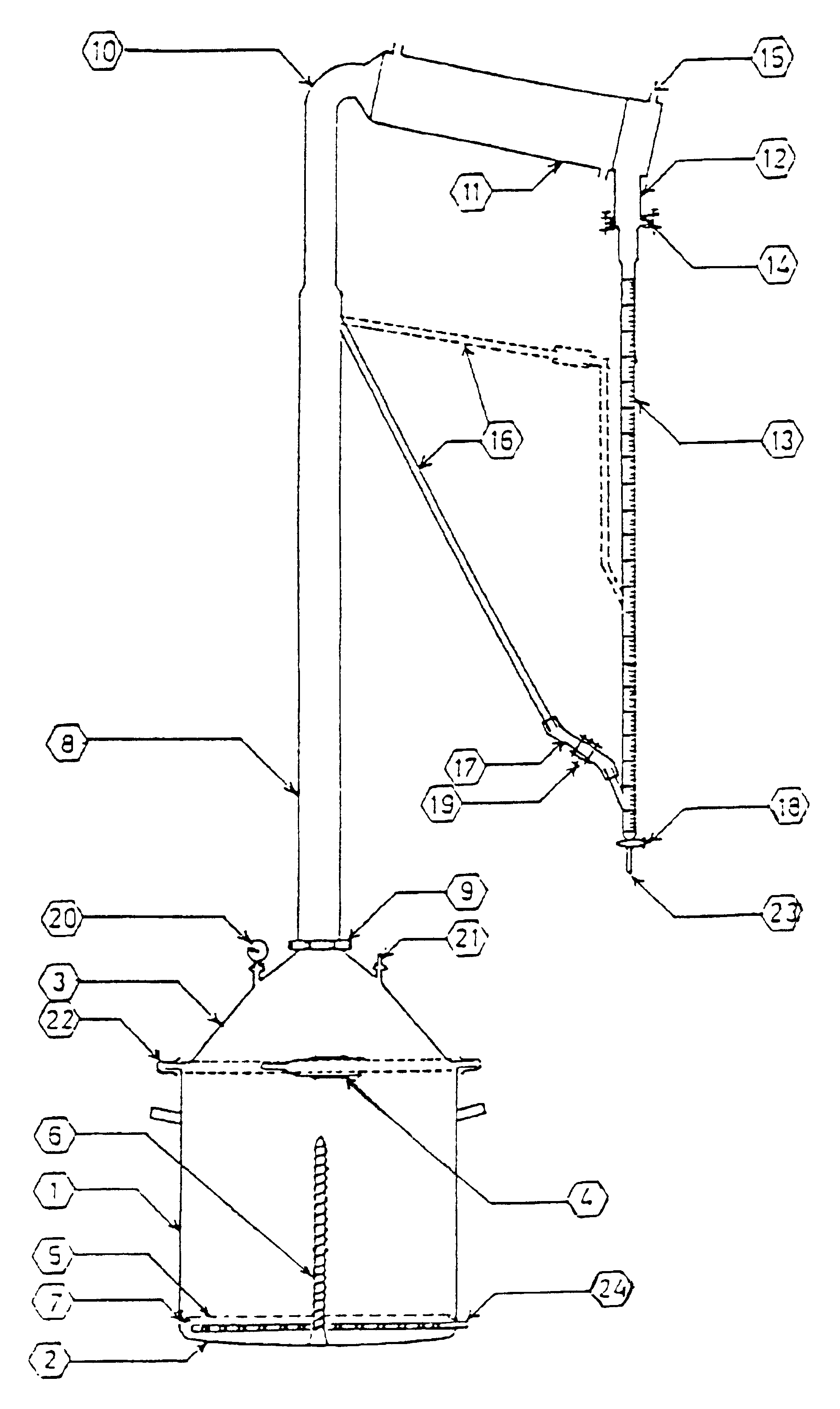

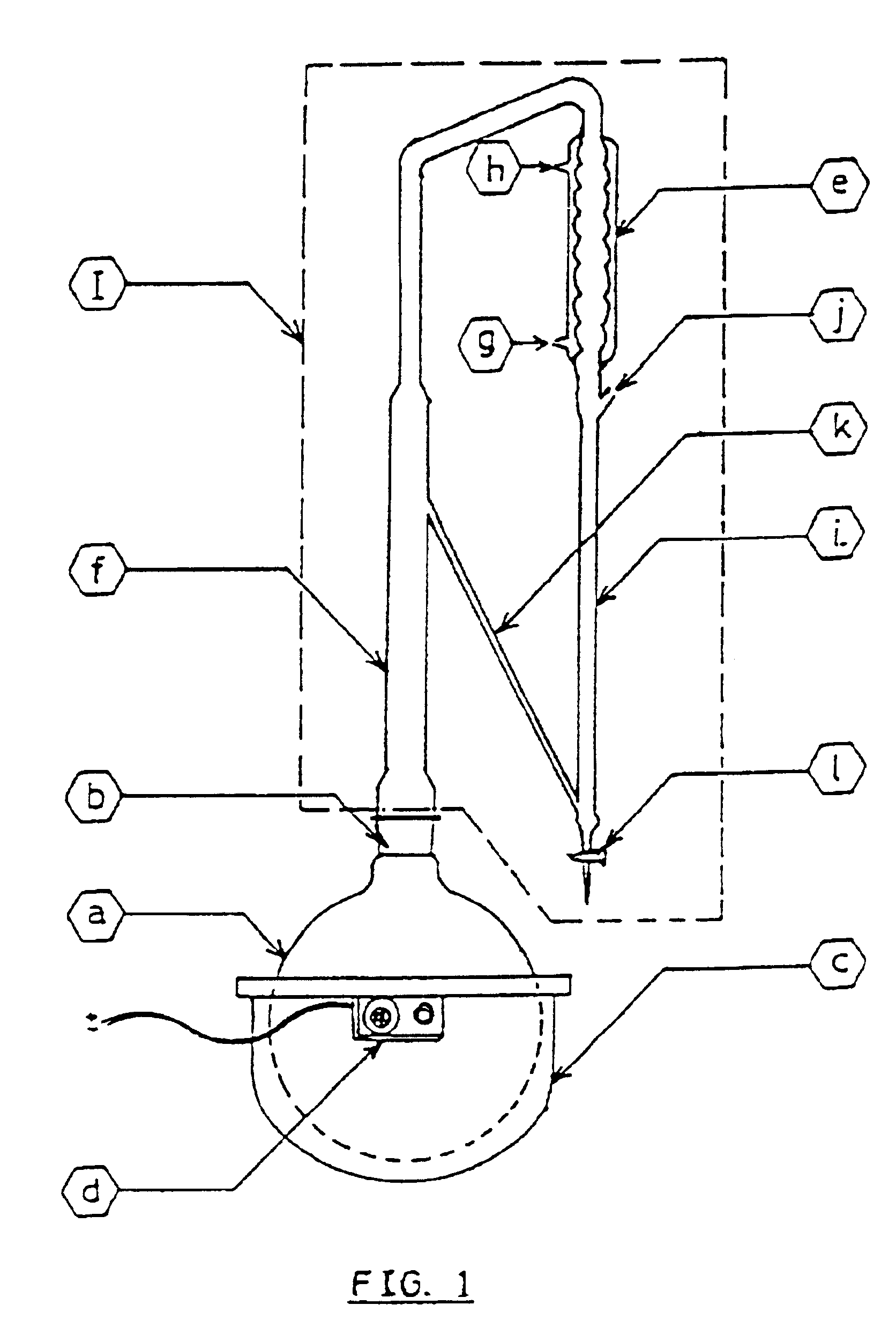

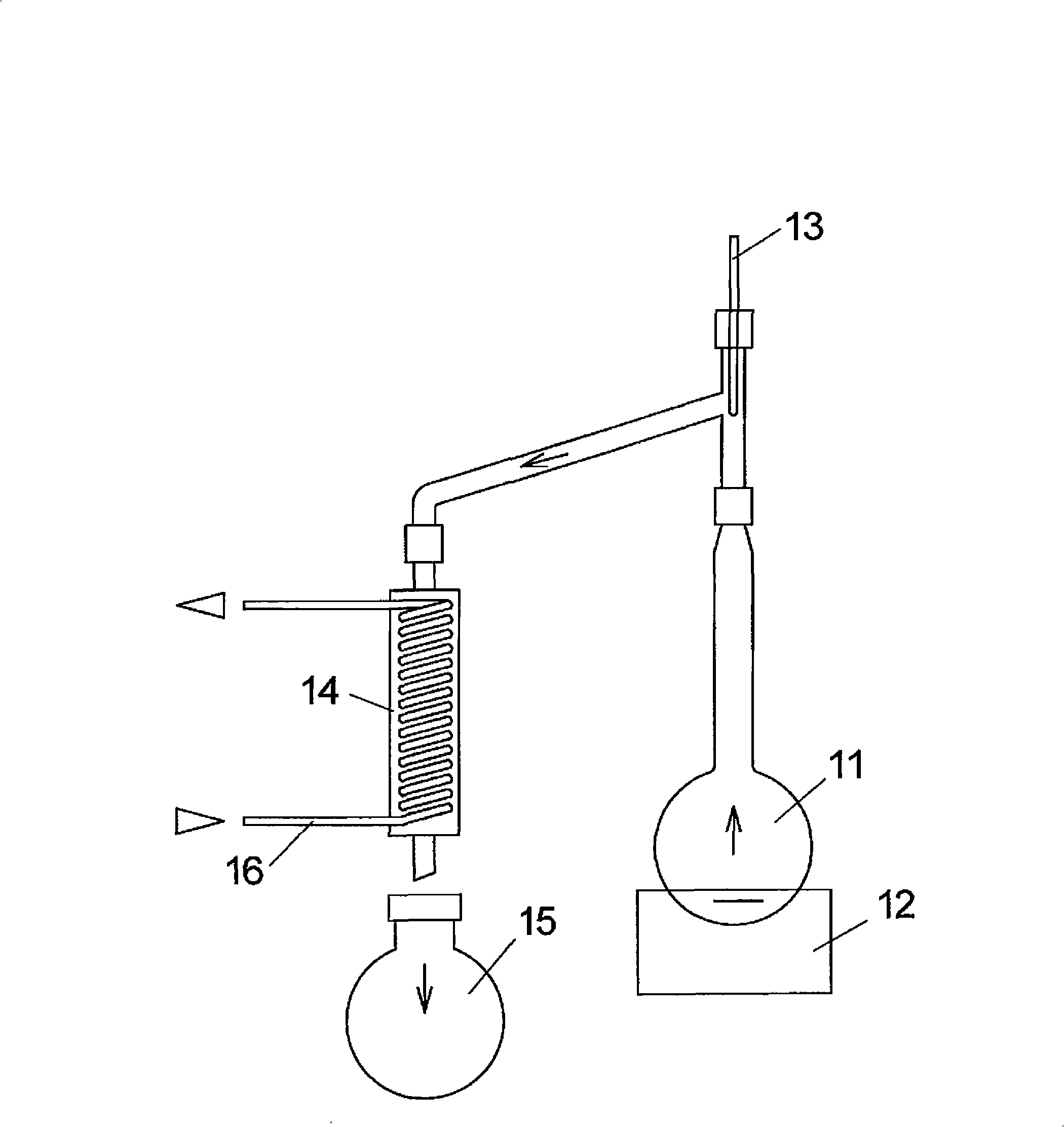

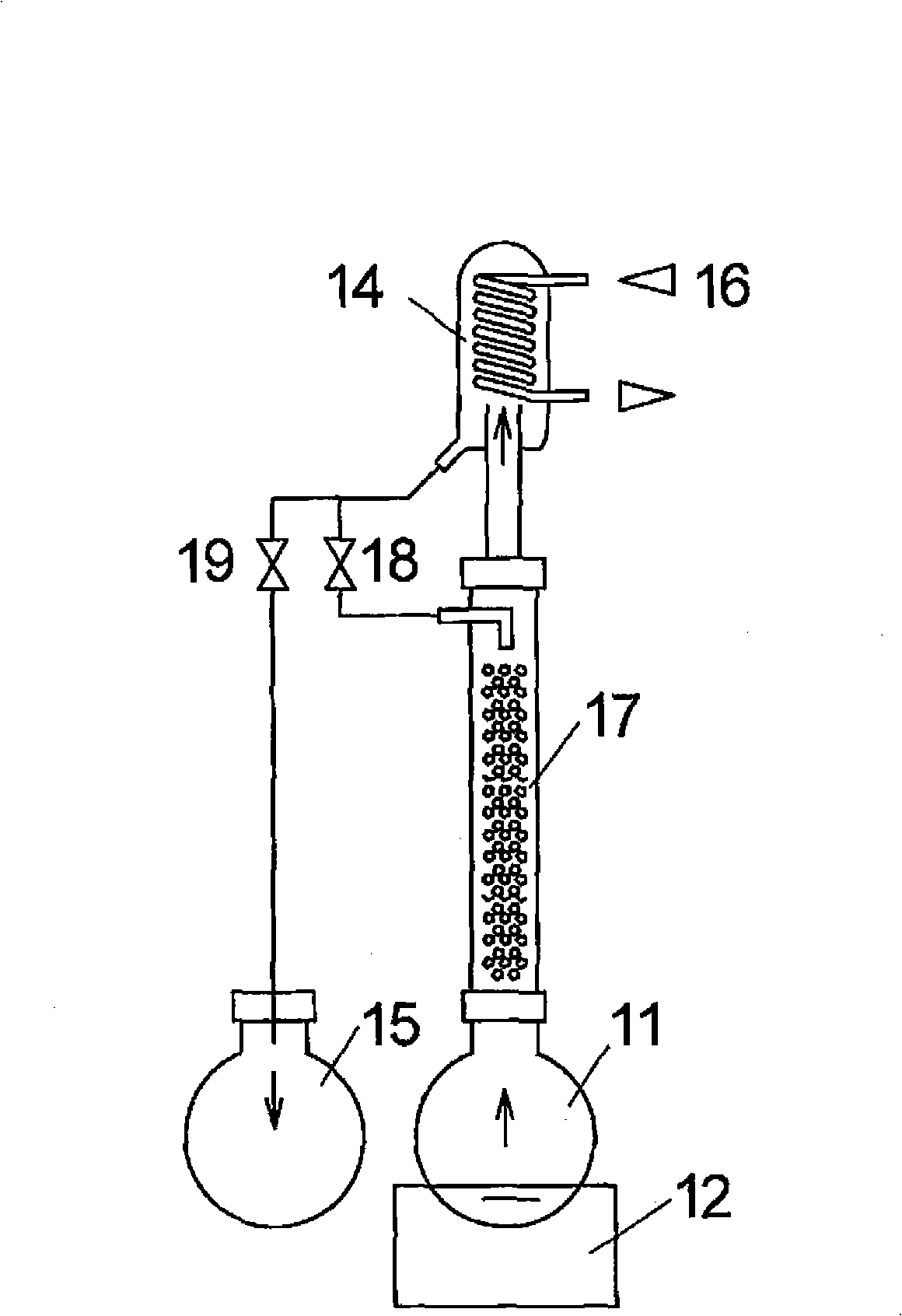

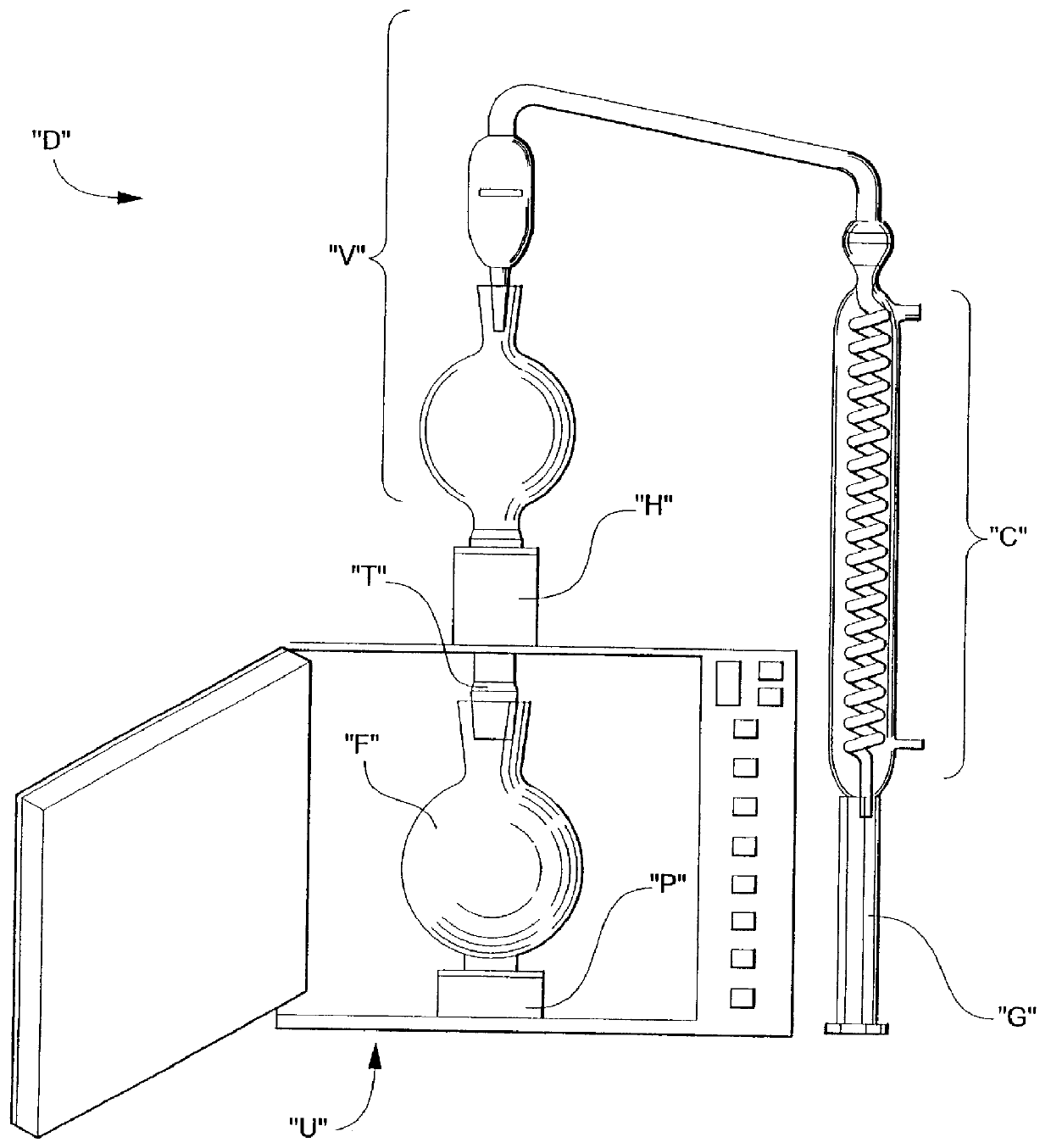

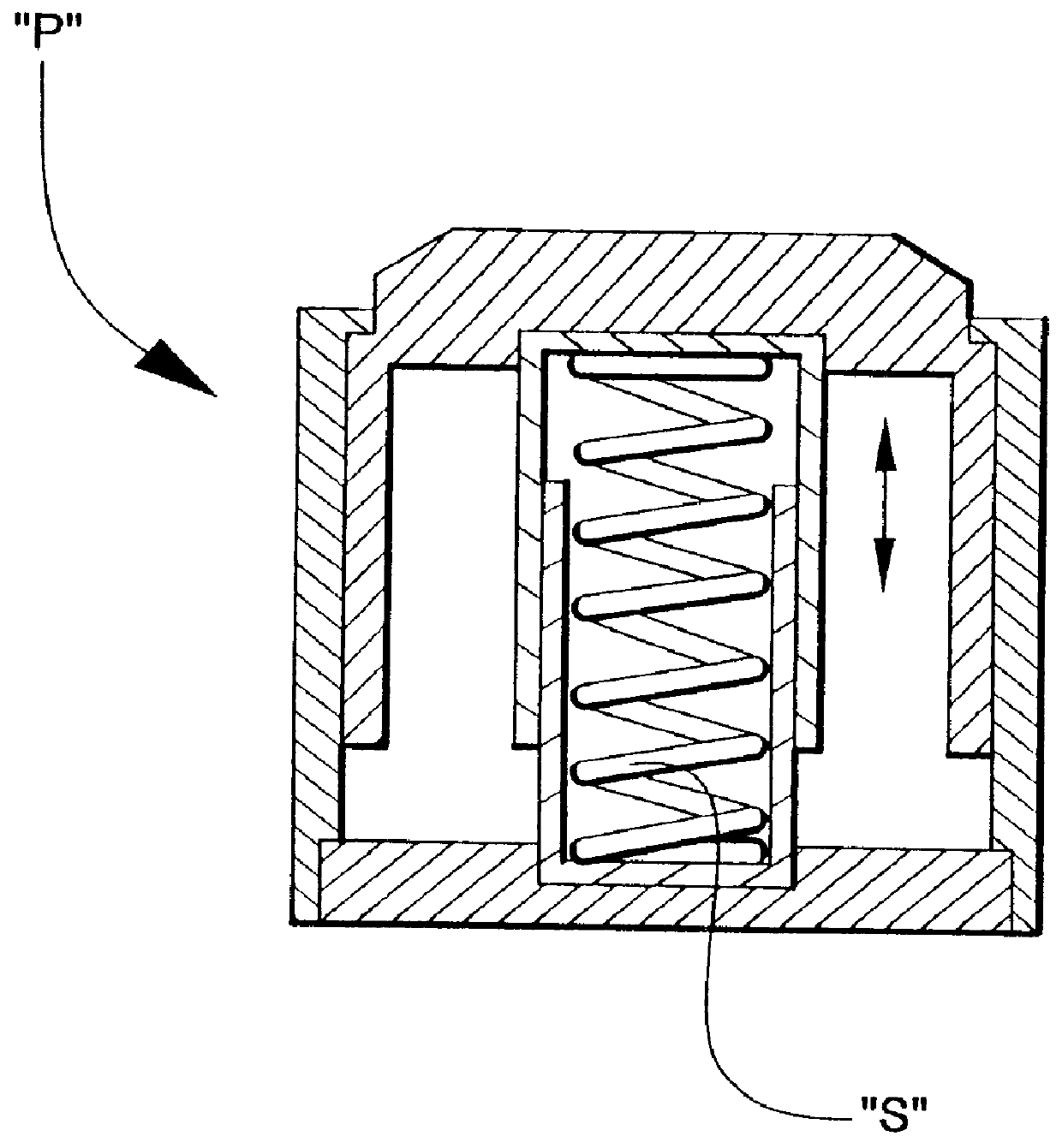

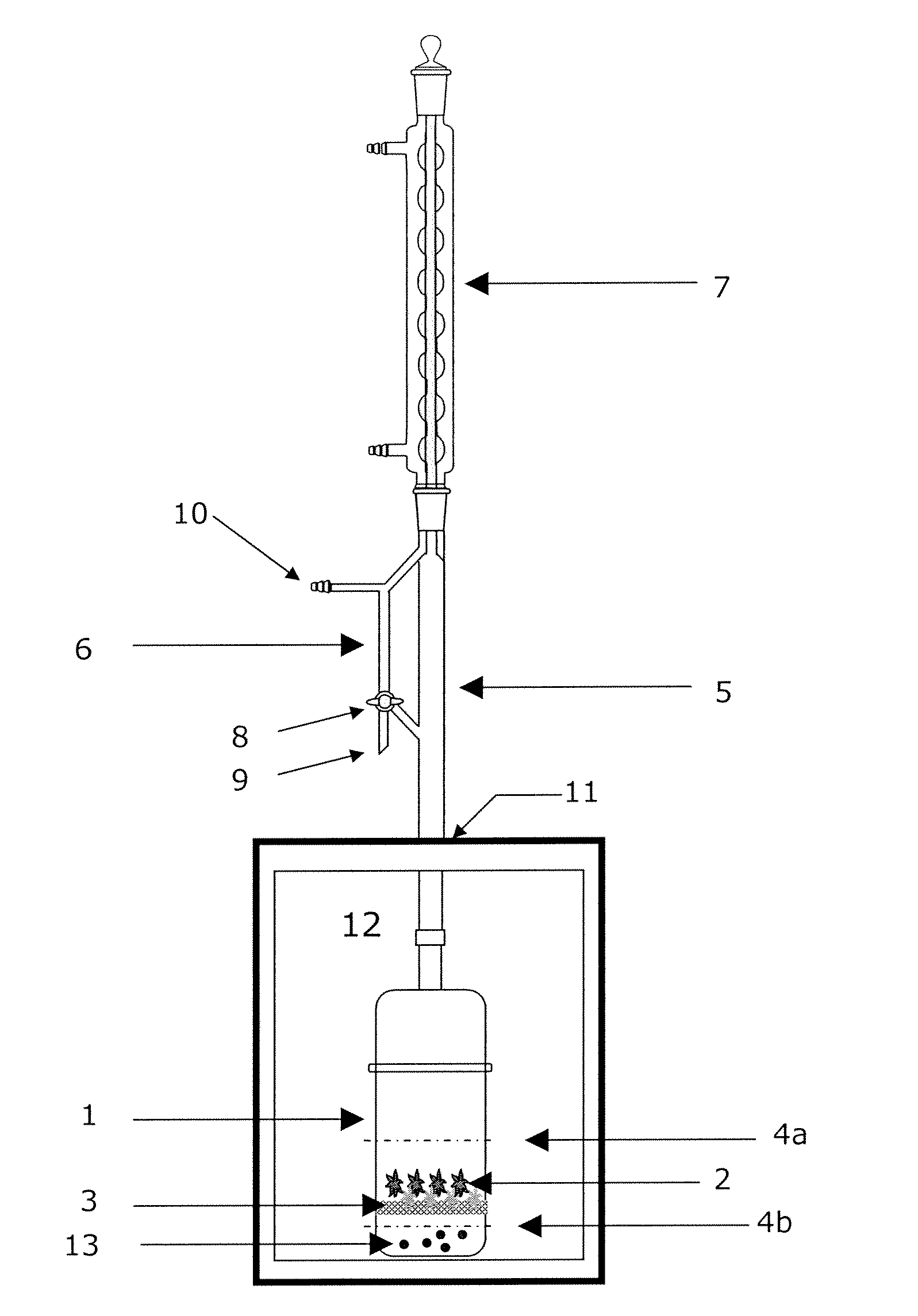

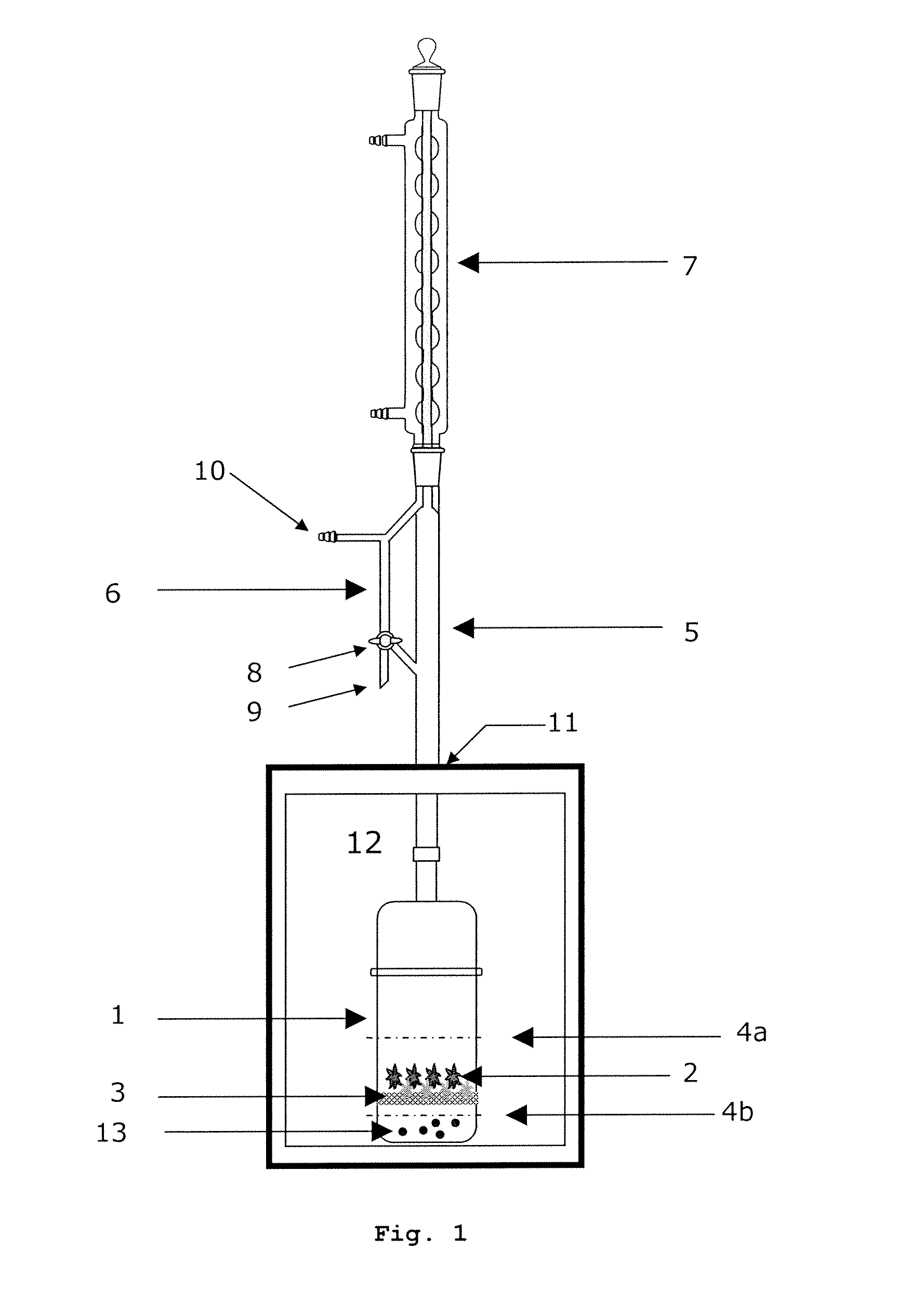

Simple portable mini distillation apparatus for the production of essential oils and hydrosols

This invention relates to a simple, convenient, portable mini-distillation apparatus for the production of essential oils and hydrosols, said apparatus is useful to distill essential oils and hydrosols such as rose water, ajowain water from fresh and dried plant material like leaves, flowers, roots and rhizomes by water distillation, water and steam distillations and as an optional, steam distillation can also be performed at atmospheric pressure as well as slightly higher and lower than atmospheric pressure, said apparatus can be heated on brick-clay furnace with small agro-waste, LPG cooking gas, electrically heated stove or kerosene / diesel burner etc. and requires minimum attention during handling; since the apparatus is made of stainless steel and glass, the essential oil distilled is of better quality.

Owner:COUNCIL OF SCI & IND RES

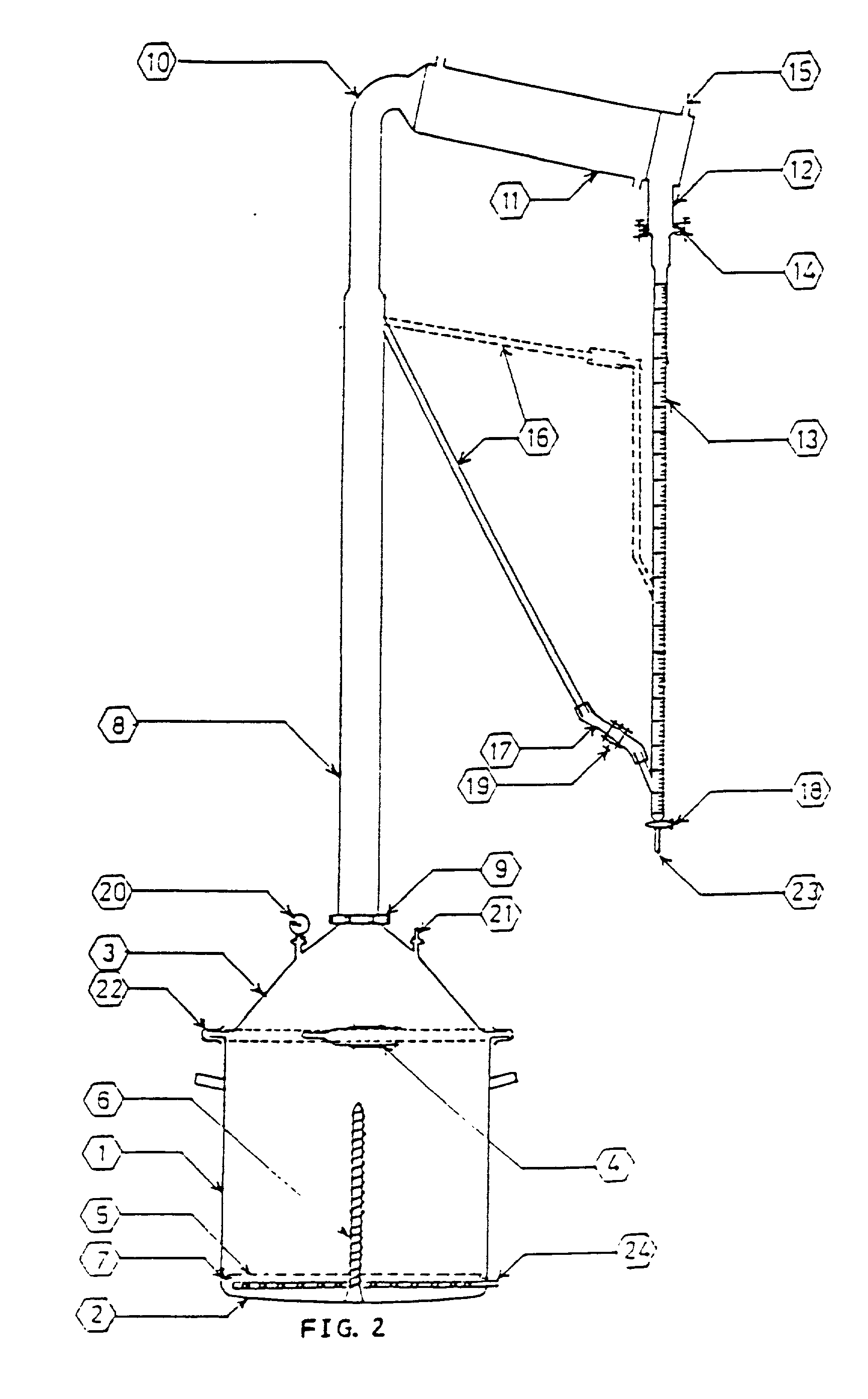

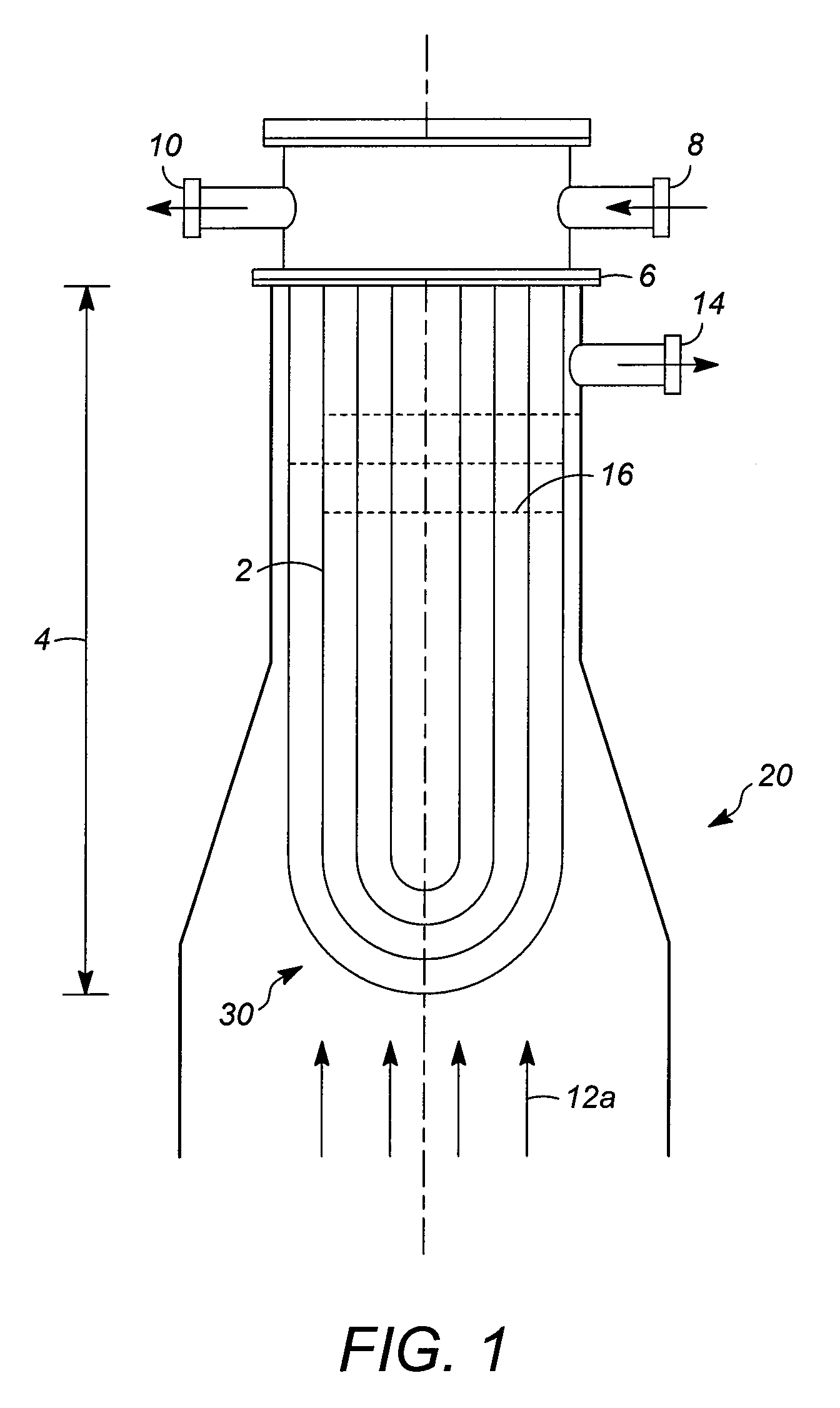

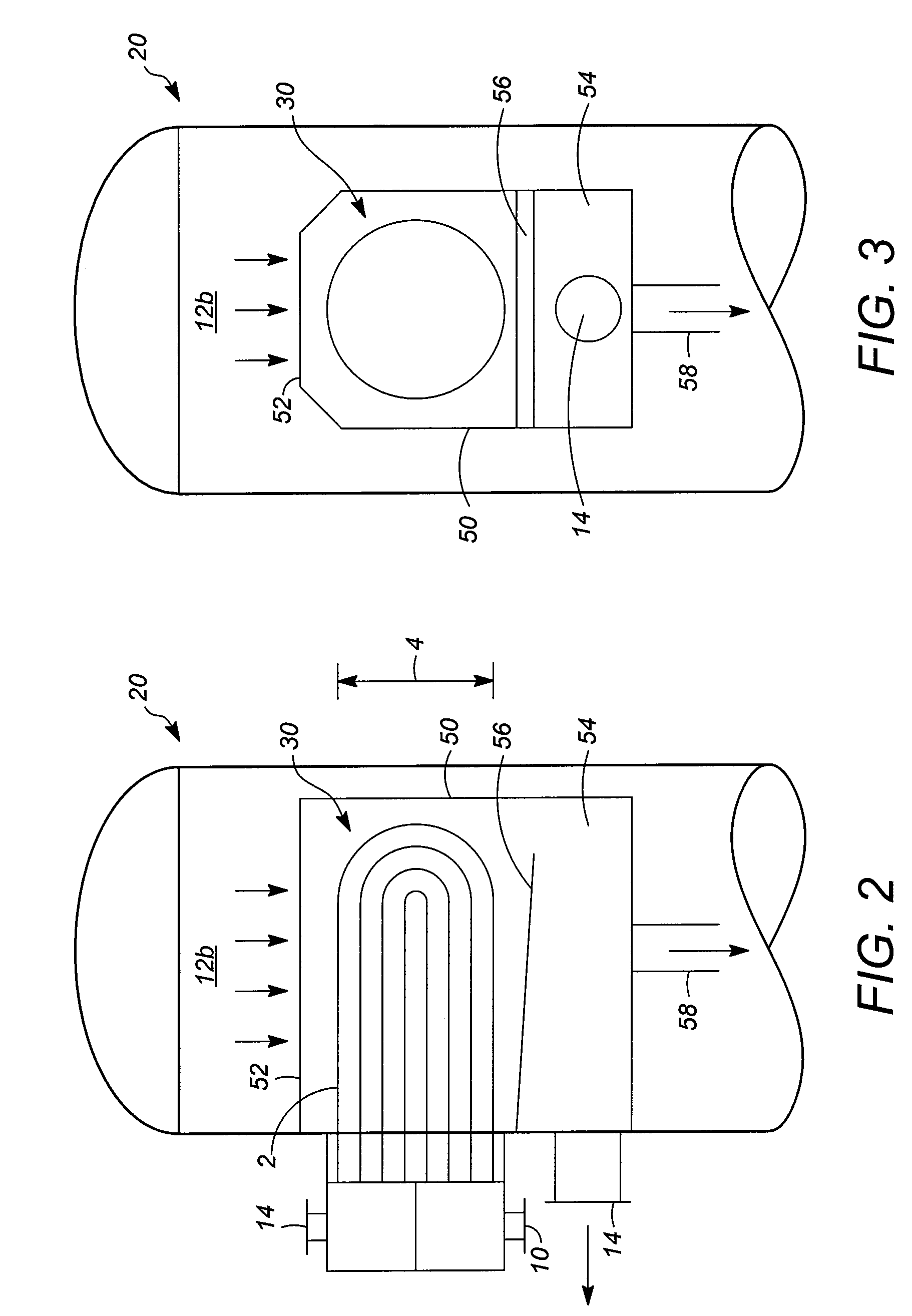

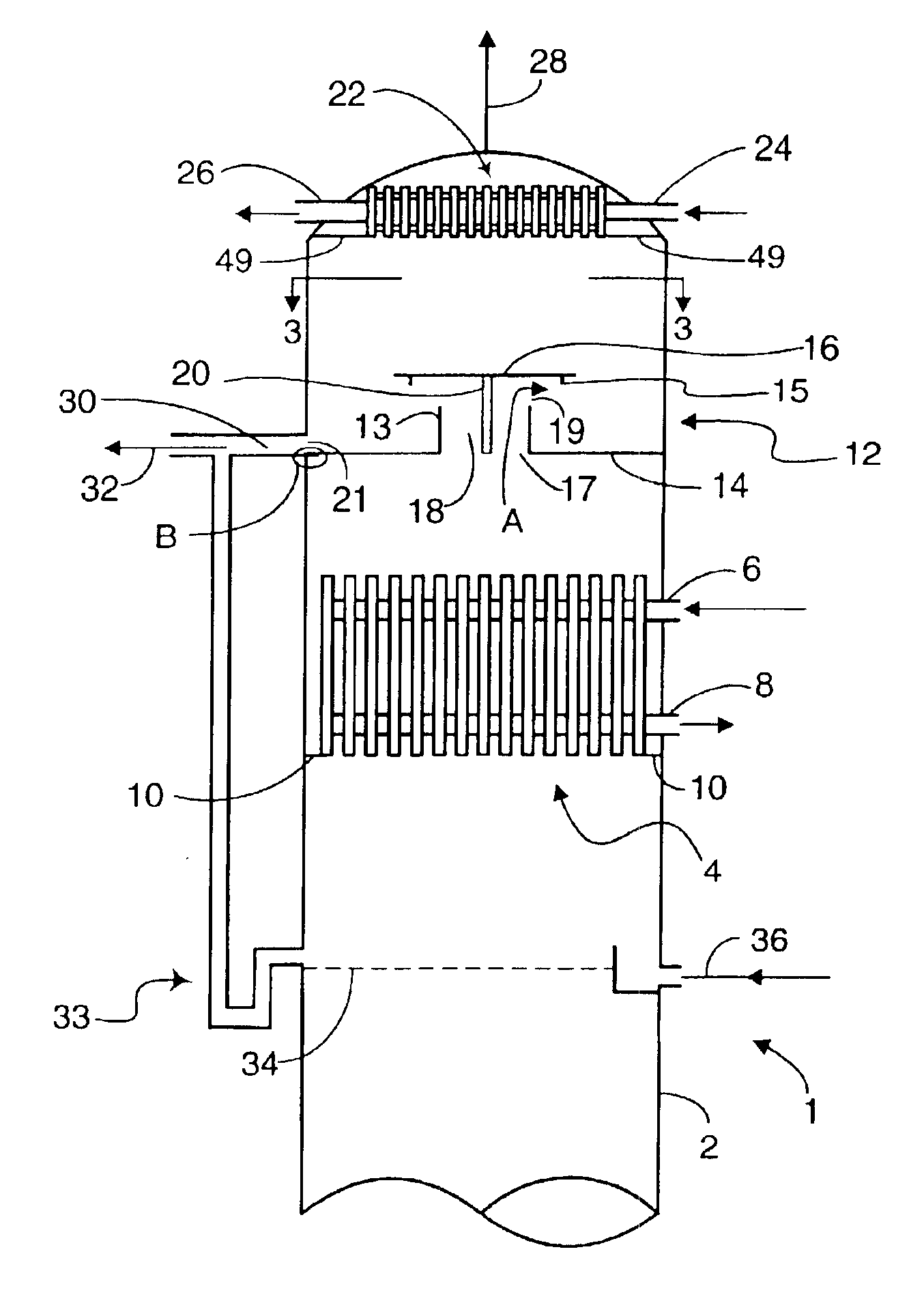

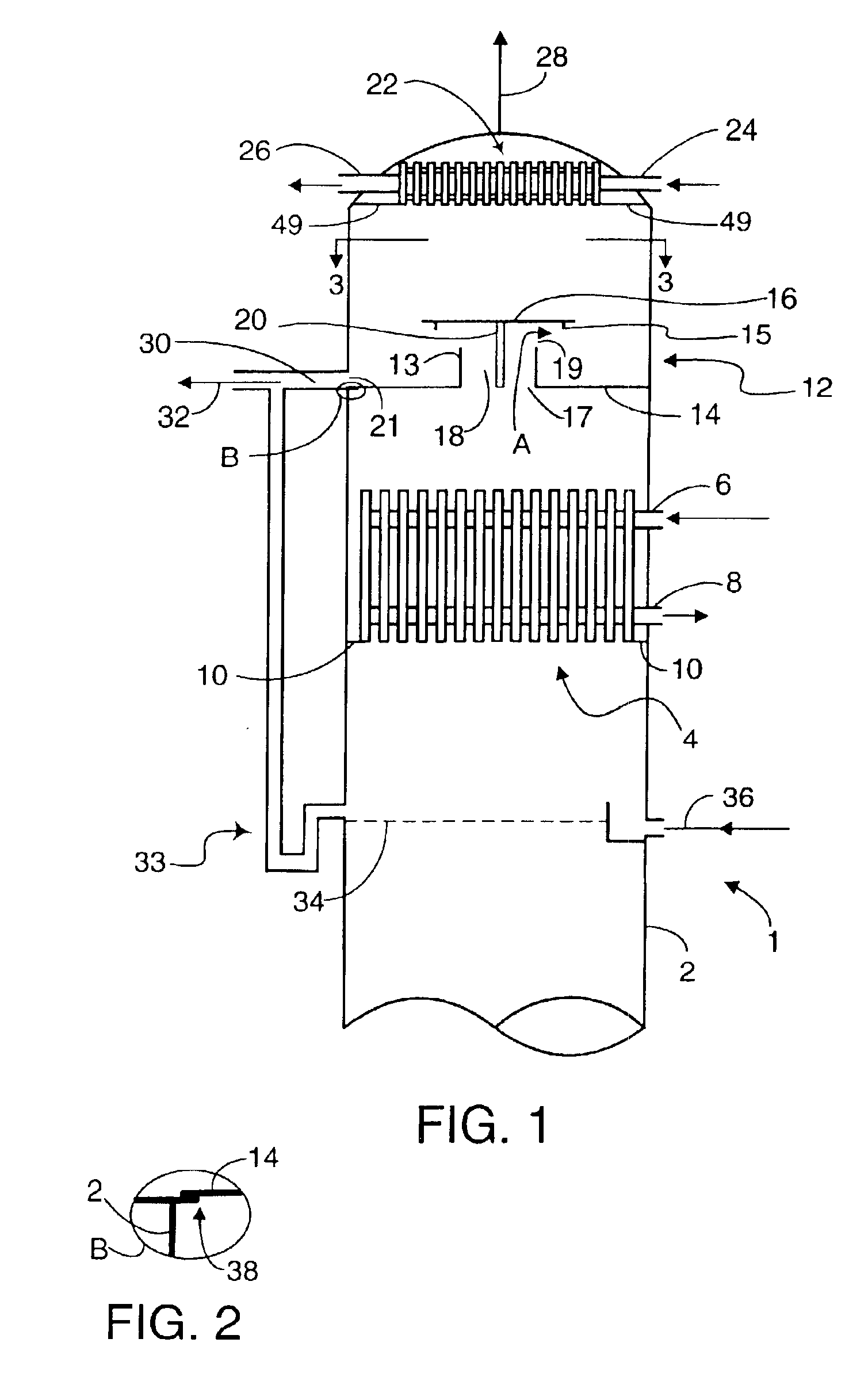

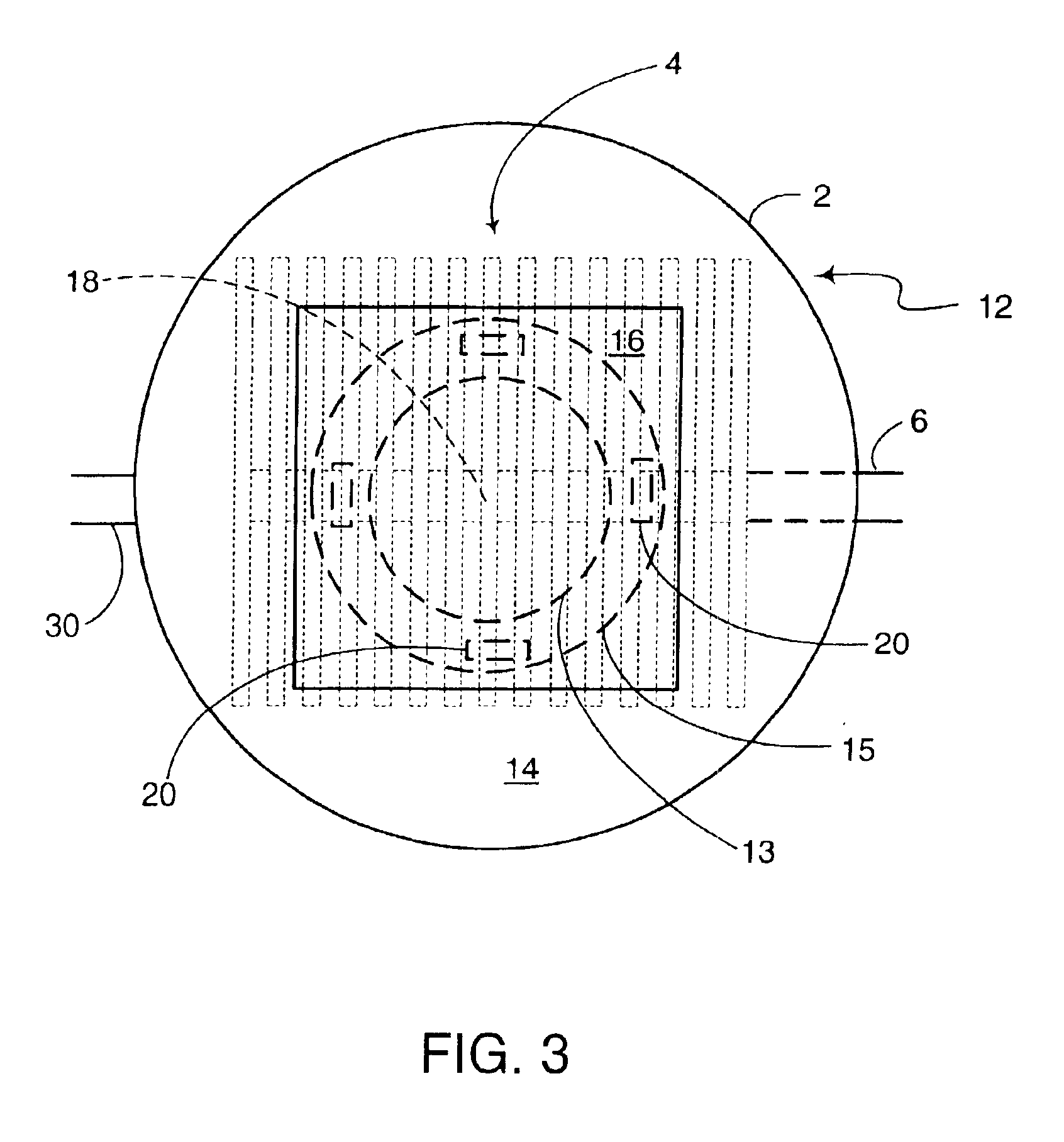

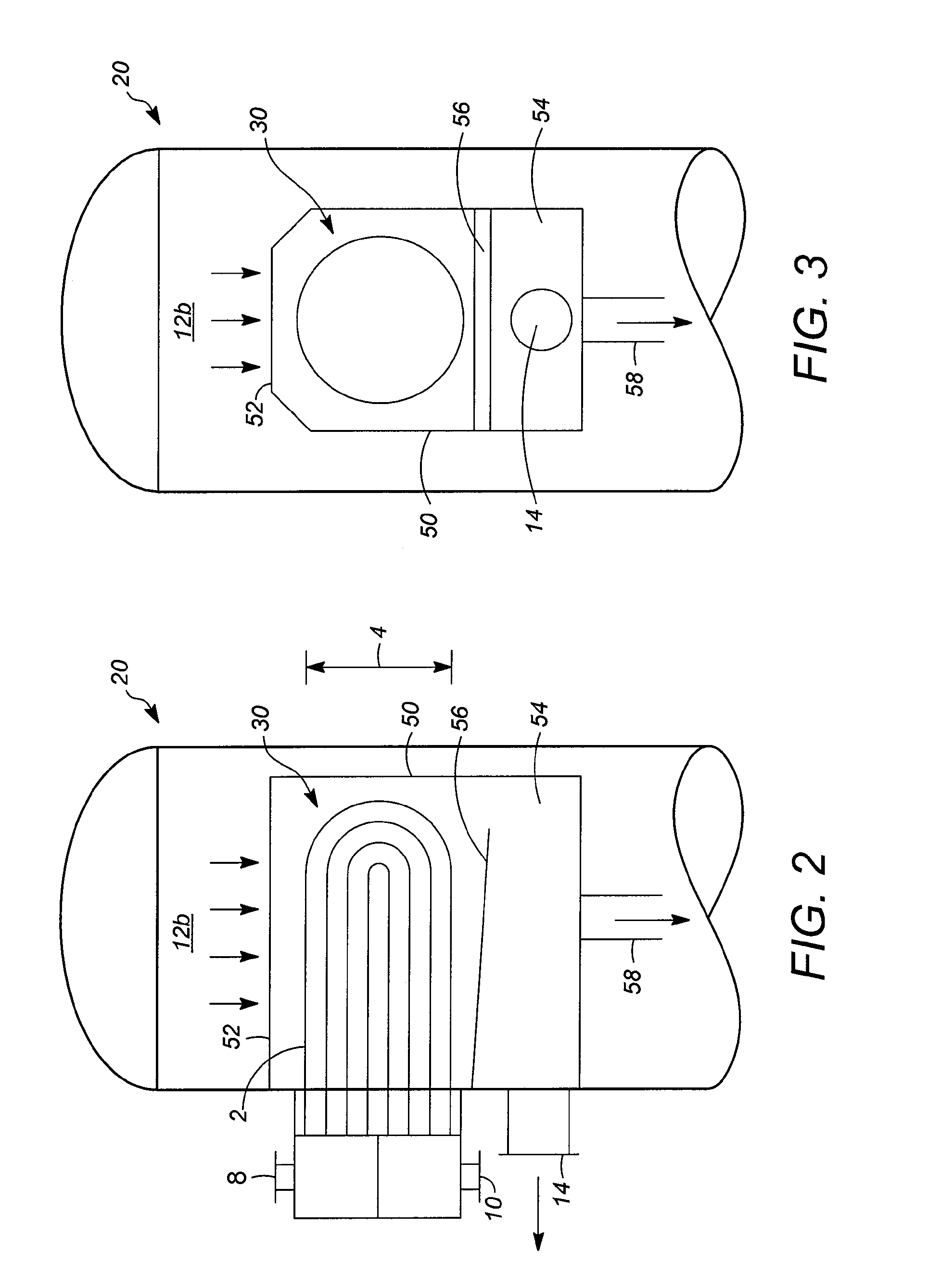

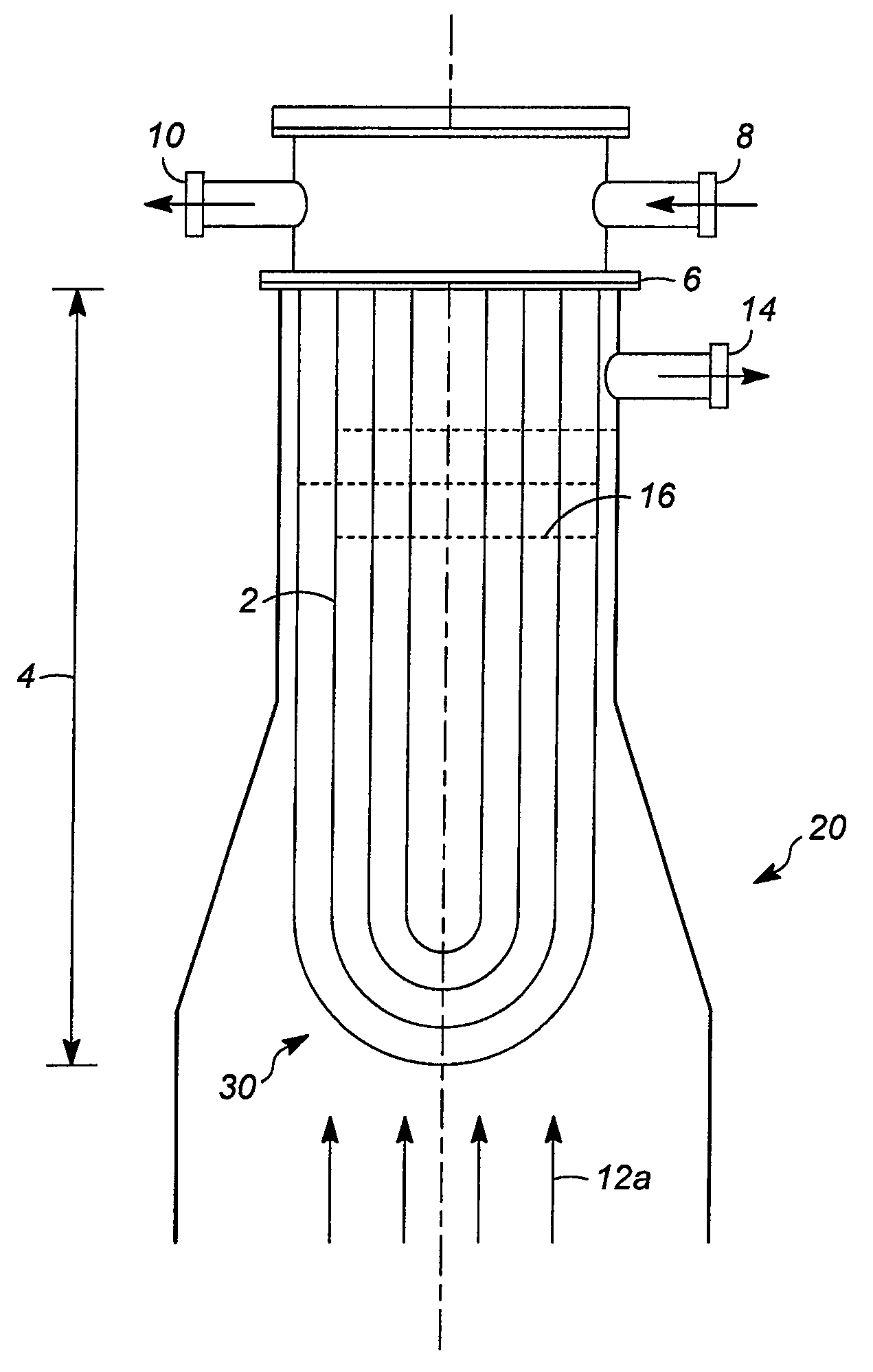

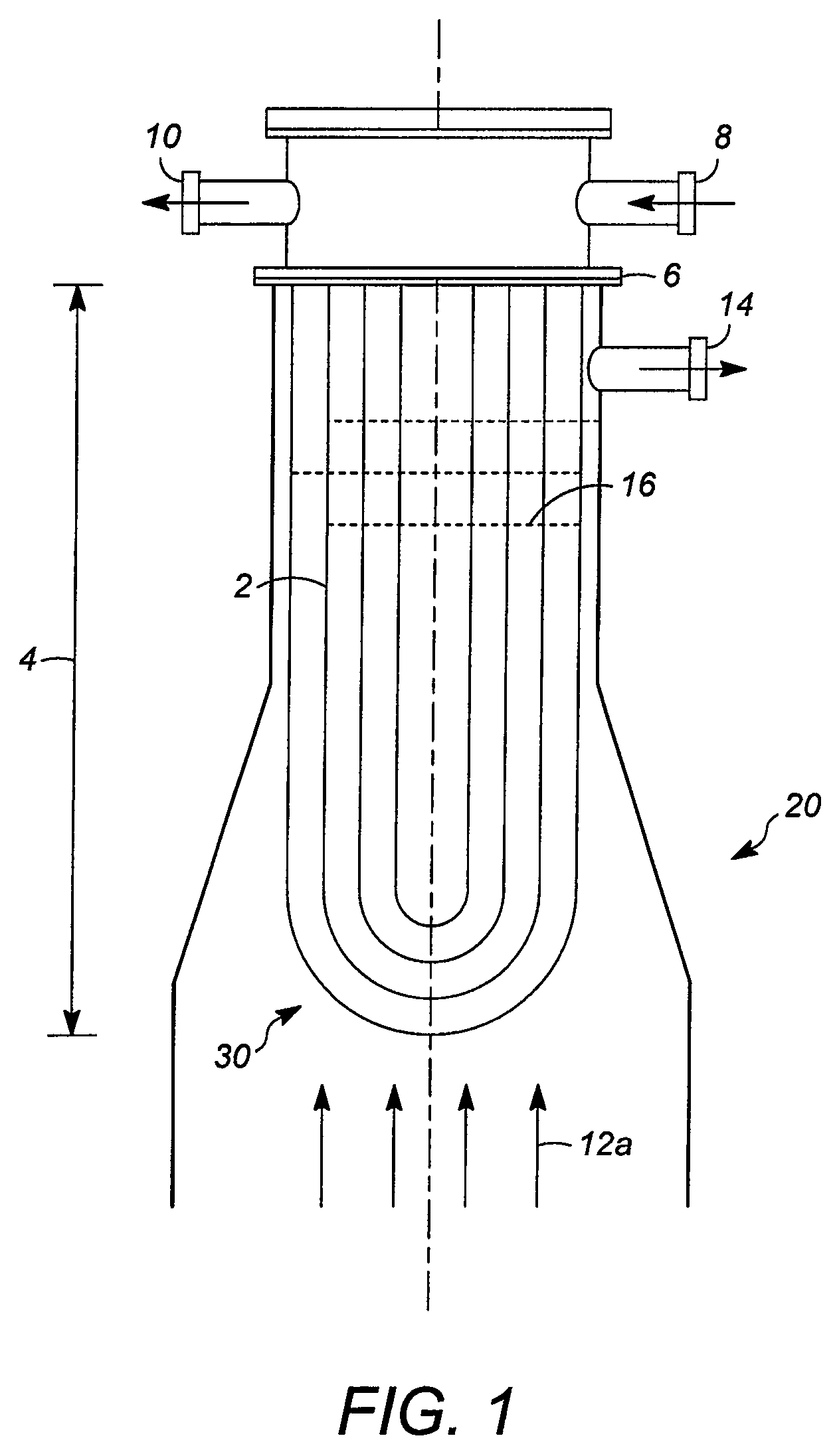

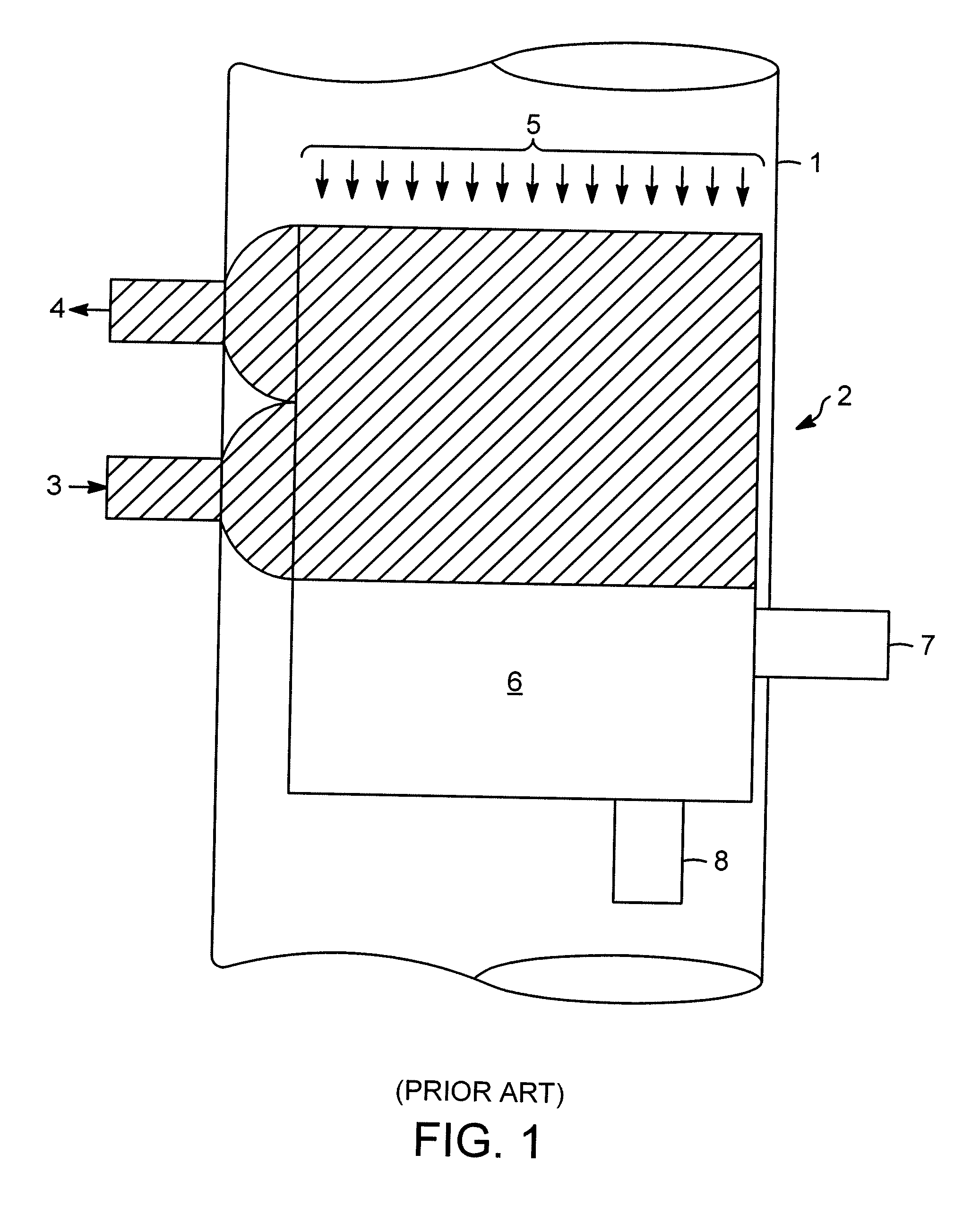

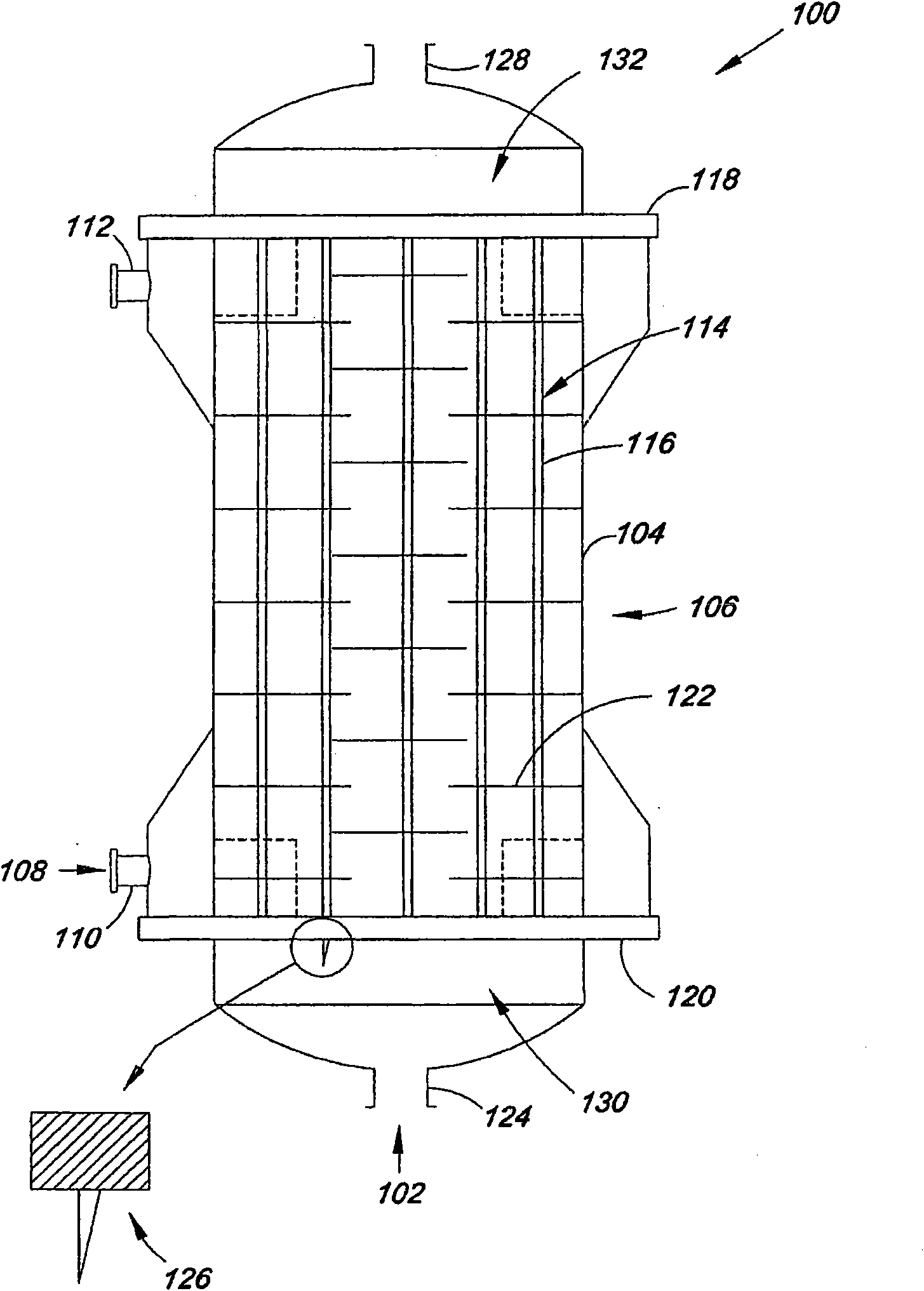

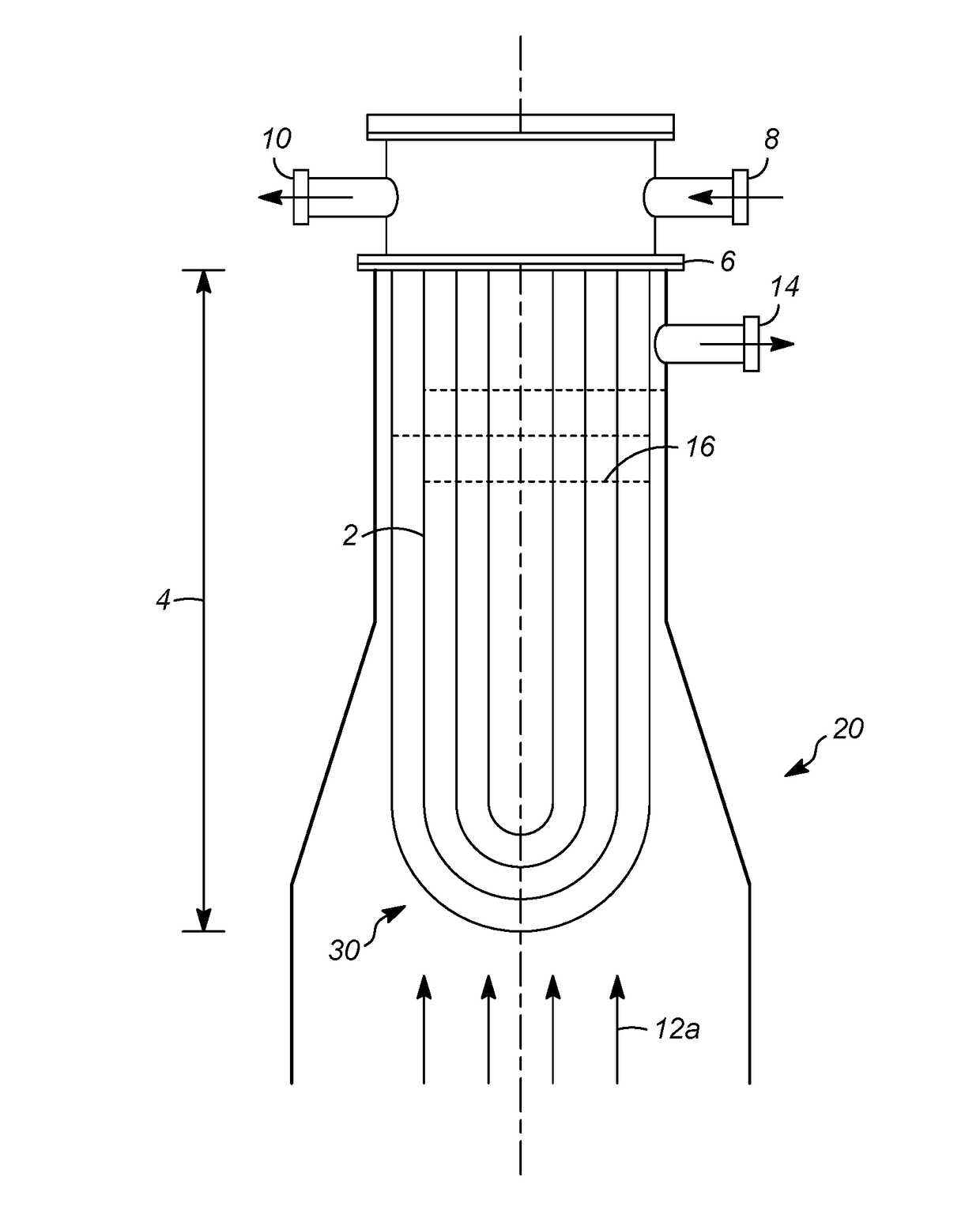

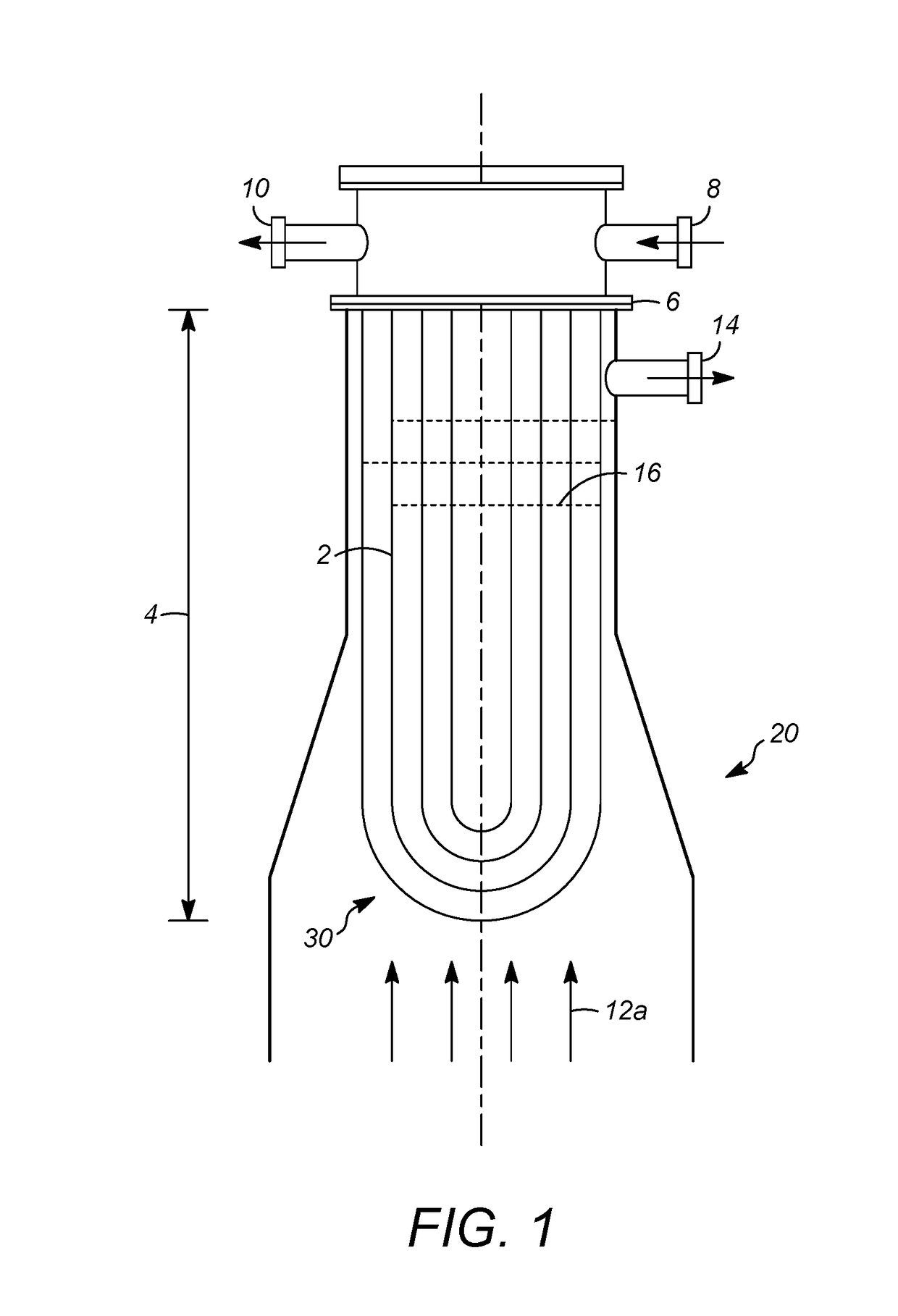

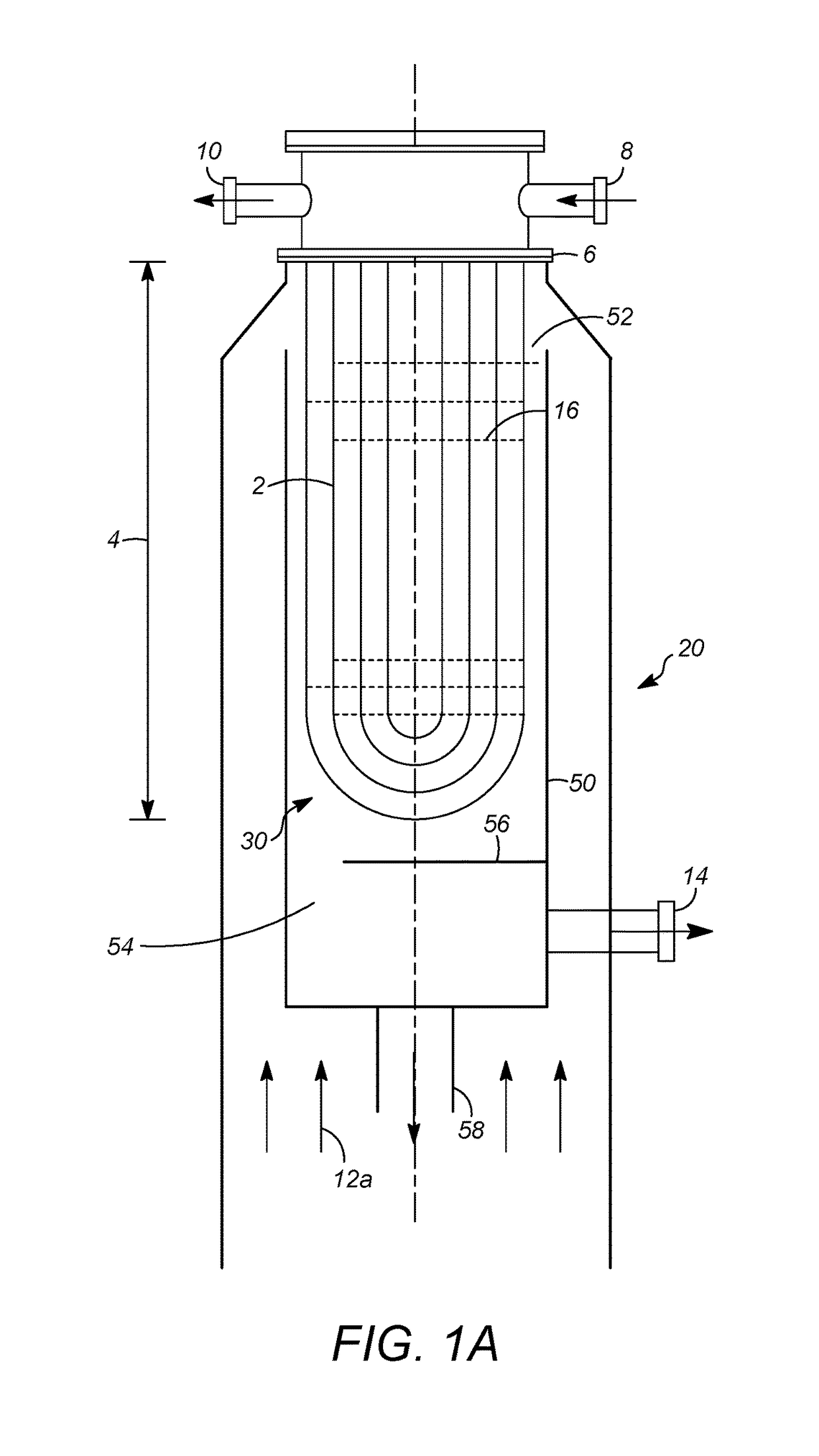

Re-direction of vapor flow across tubular condensers

ActiveUS20100276122A1Reduces and even eliminatesHeat exhanger conduitsSteam/vapor condensersVapor liquidDistillation

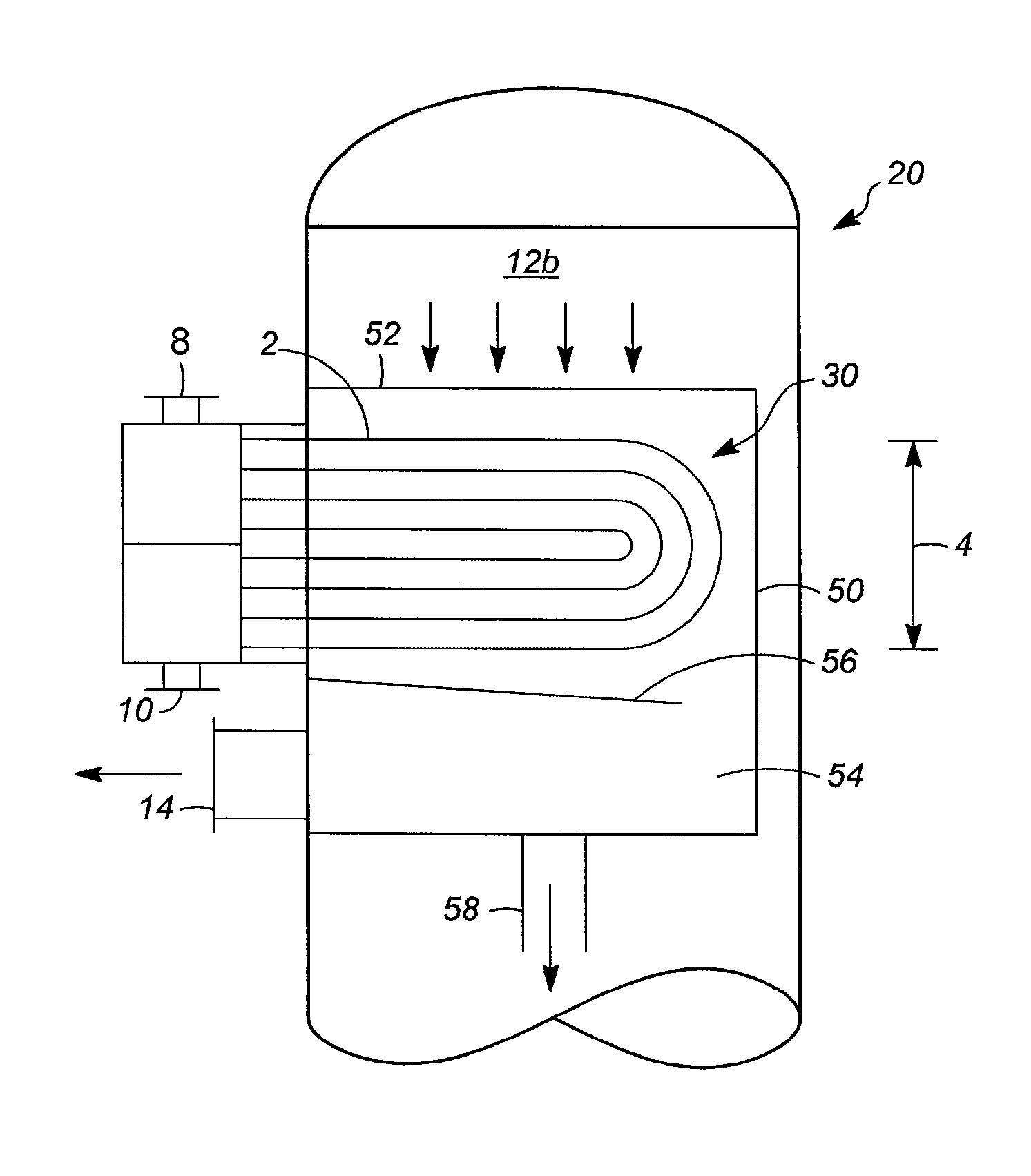

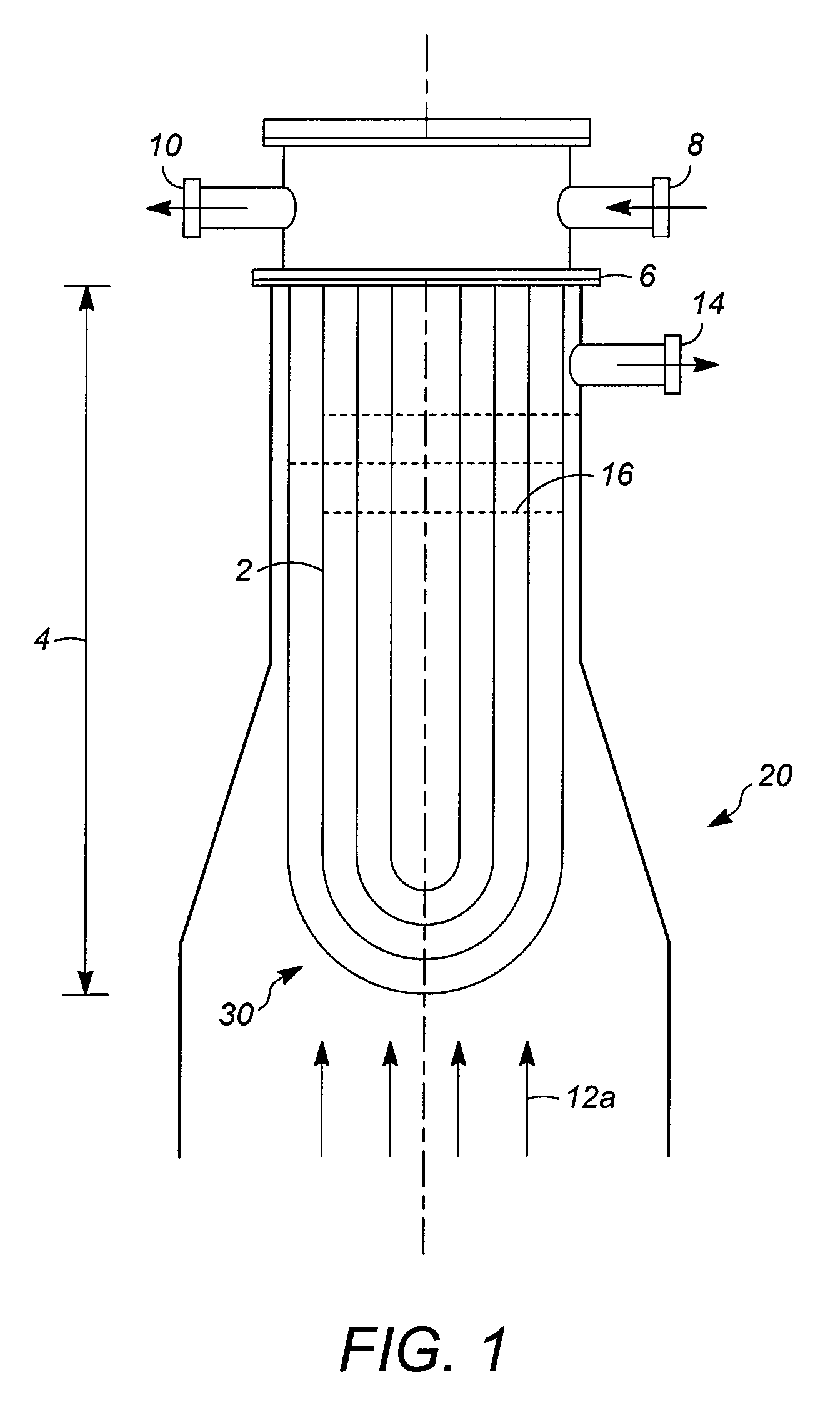

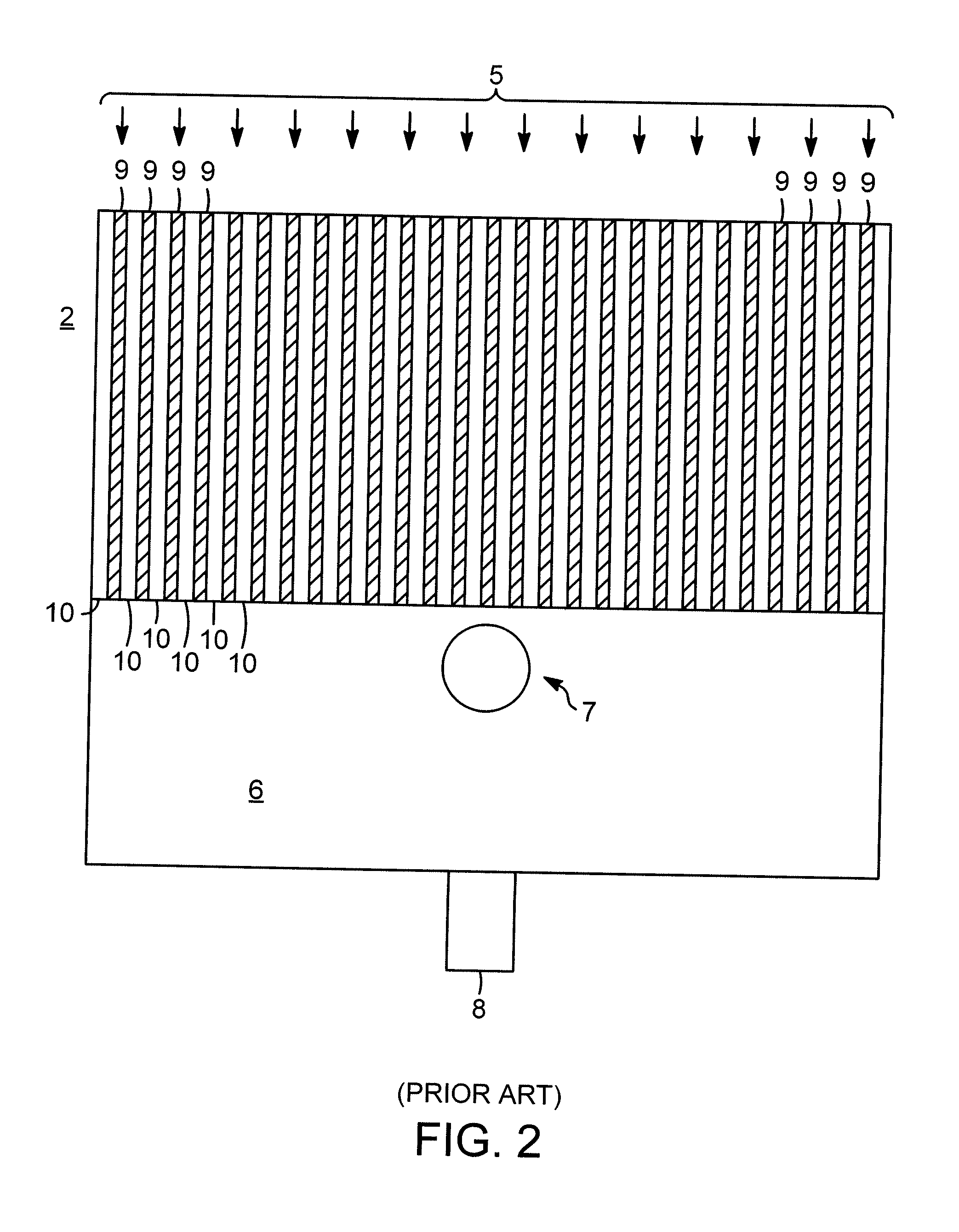

Vapor flow-diverting devices that re-direct upwardly flowing vapor, for example, in a downward direction across condenser tubes disposed in the upper or top section of a vapor-liquid contacting apparatus, are described. These devices are particularly beneficial in tubular condensers within distillation columns and may be used in combination with other associated equipment (e.g., a deflector plate and divider plate) as well as in combination with the tube surface enhancements to improve the heat transfer coefficient.

Owner:UOP LLC

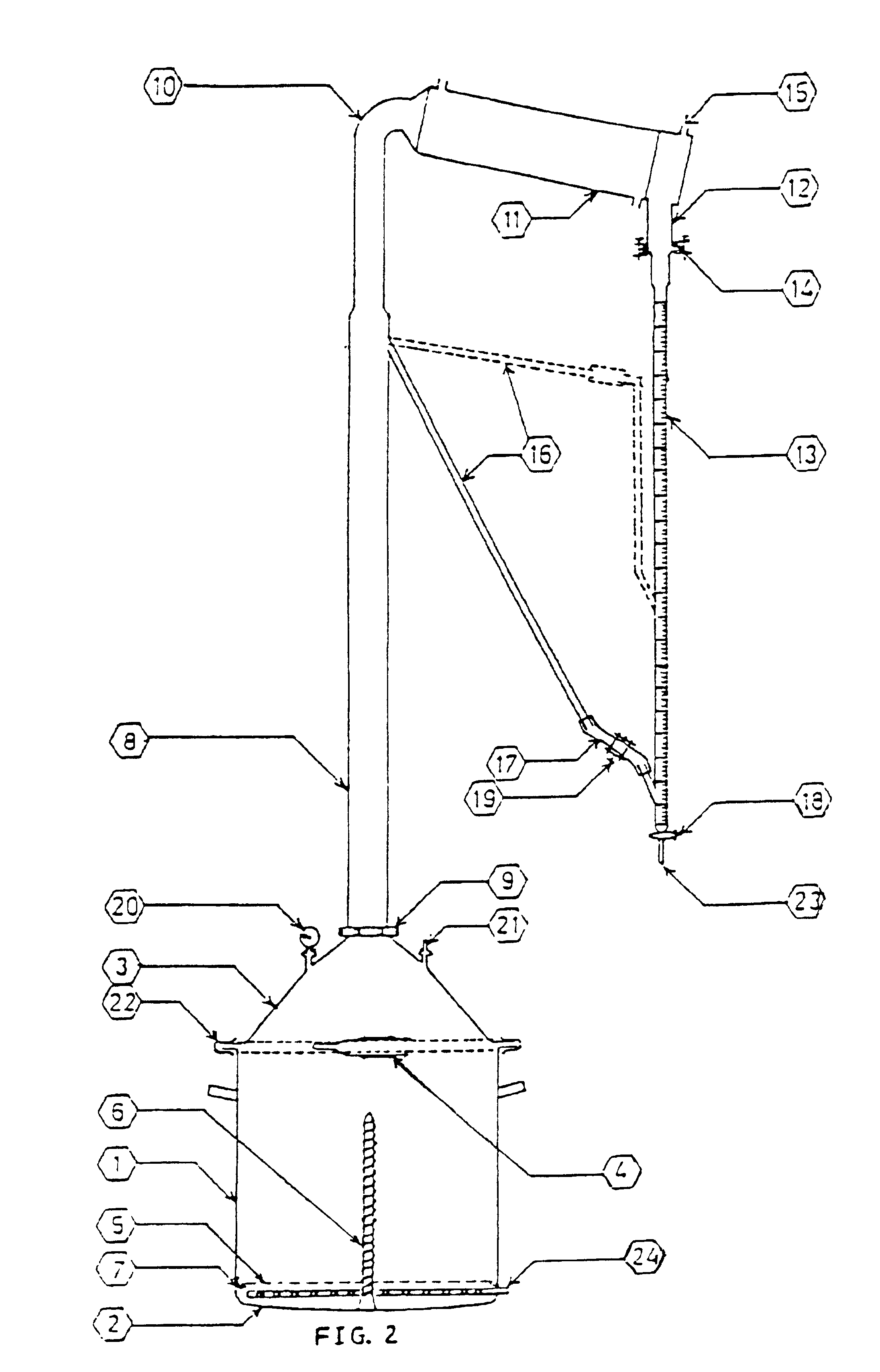

Methanol purification method and apparatus

The invention relates to a method and apparatus to recover and purify methanol from gases produced in the digester during the kraft pulping process. The gas is typically recovered as a foul gas (called stripper off gas or SOG) comprising methanol, water and various other contaminants. The gas is then treated with successive decanting and distillation steps to remove impurities, thereby producing highly purified methanol.

Owner:A H LUNDBERG SYST

Shielding of heat exchangers in columns

InactiveUS6883788B1Unstable operationPressure drop unstableMixing methodsSteam/vapor condensersEngineeringVapor phase

Disclosed is a method and an apparatus for exchanging heat in a column by passing a first vapor phase through a heat exchanger in the column to exchange heat with a first stream and produce a second vapor phase in the column. The second vapor phase is passed through a shielding device located above the heat exchanger and the shielding device prevents descending liquid from contacting the heat exchanger. The shielding device may be interposed between two heat exchangers in the column.

Owner:UOP LLC

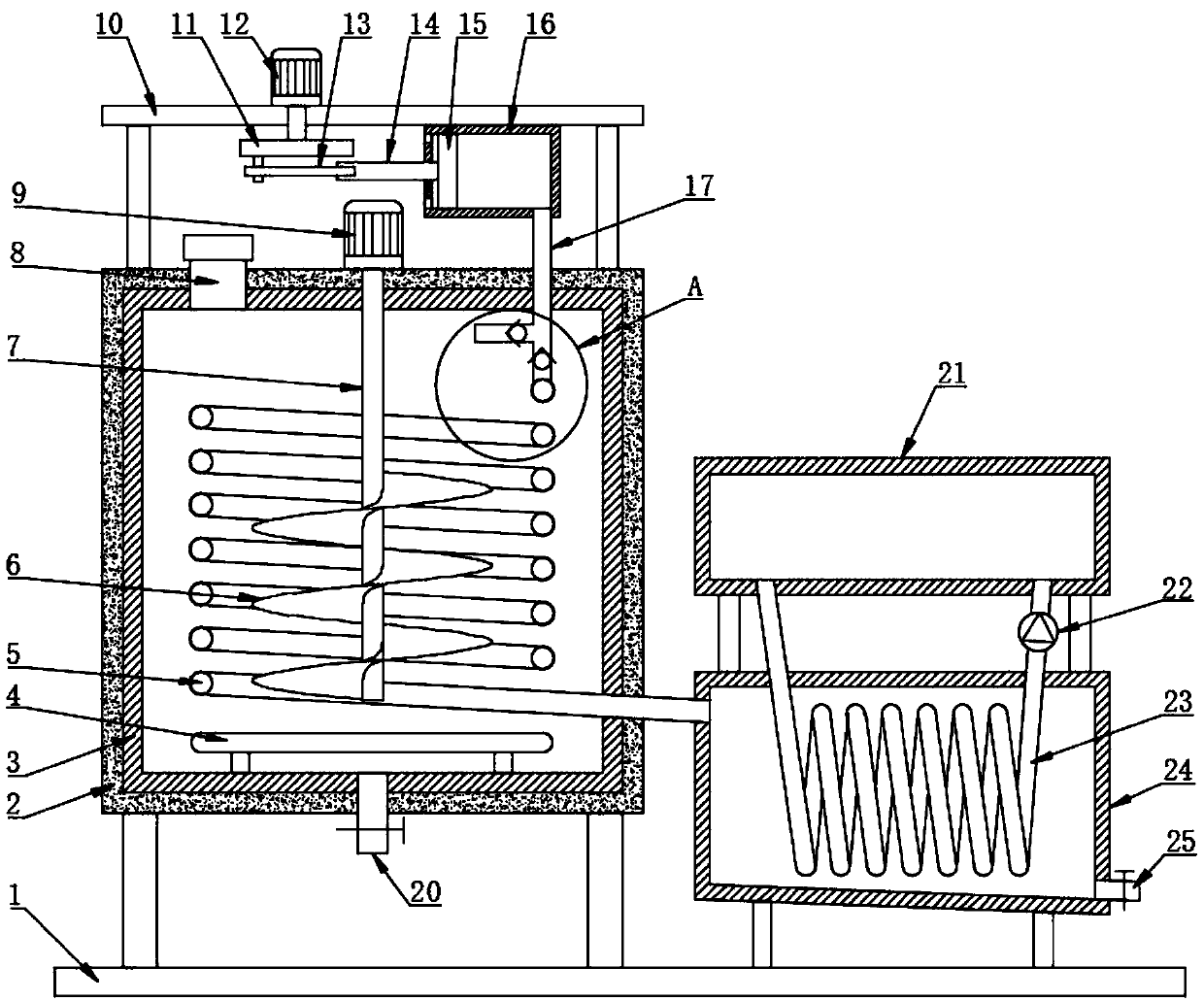

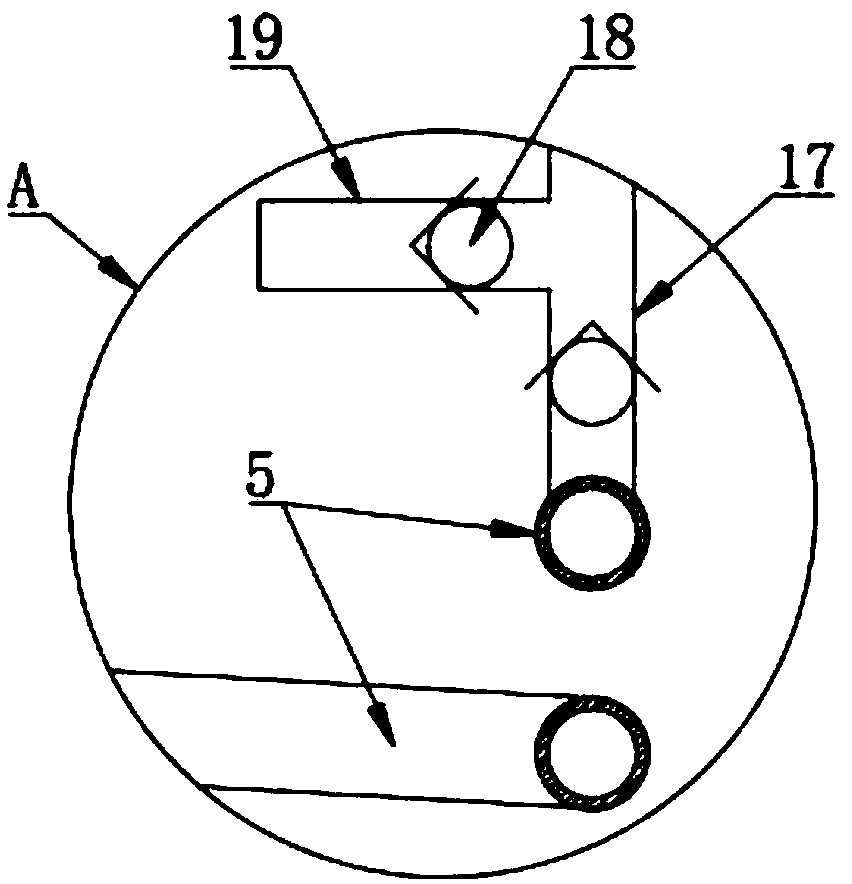

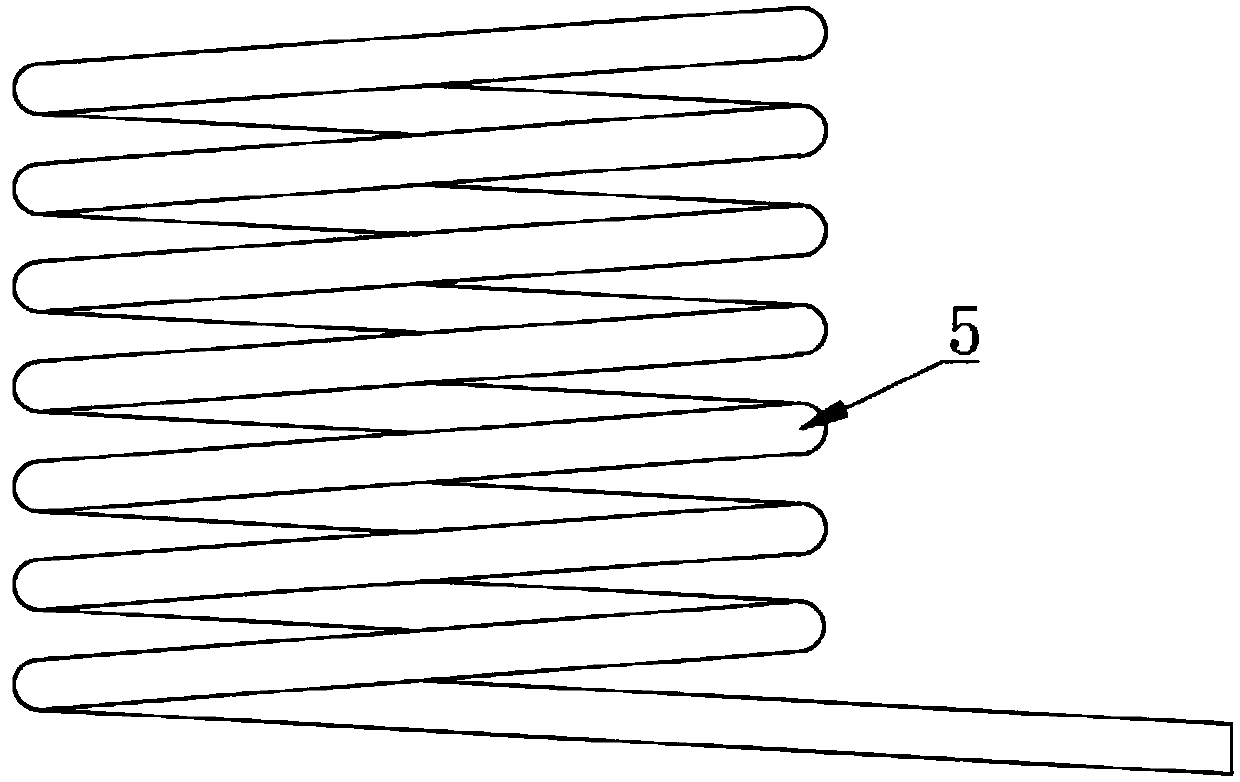

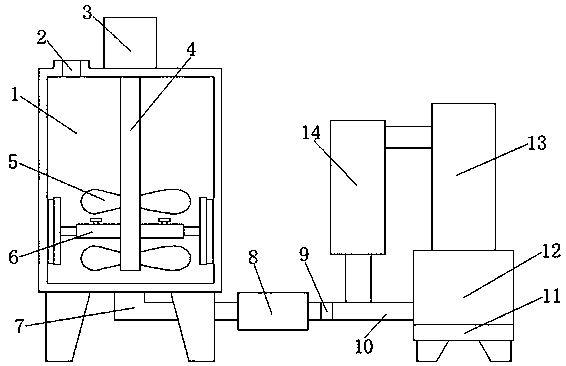

Heat circulation type quick solution distillation and condensation device

InactiveCN107899262AReduce lossEvenly dispersedDistillation in boilers/stillsReflux condensationInternal pressureDistillation

The invention discloses a heat circulation type quick solution distillation and condensation device which comprises a base. A distillation drum is fixedly arranged at the top of the base through a supporting frame, a heating pipe is fixedly arranged at the inner bottom of the distillation drum through supports, a spiral pipe is fixedly arranged in the distillation drum, and the bottom end of the spiral pipe penetrates the side wall of the distillation drum to the outside of the distillation drum. A pressure cylinder is arranged at the bottom of a supporting plate which is fixedly arranged at the top of the distillation drum through supports, a ventilation pipe is connected to the lower right corner of the pressure cylinder, the bottom end of the ventilation pipe penetrates the top wall ofthe distillation drum to be connected with the top end of the spiral pipe, and an air inlet pipe is connected to the ventilation pipe and positioned in the distillation drum. A piston is slidably arranged in the pressure cylinder, and a piston rod is fixedly connected to the left end face of the piston. By extraction of air in the distillation drum through the pressure cylinder, the internal air pressure of the distillation drum is reduced, a solution boiling point is lowered, and distillation efficiency is improved. In a distillation process, the pressure cylinder enables steam to internallypass through the spiral pipe to realize heat cyclic utilization.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

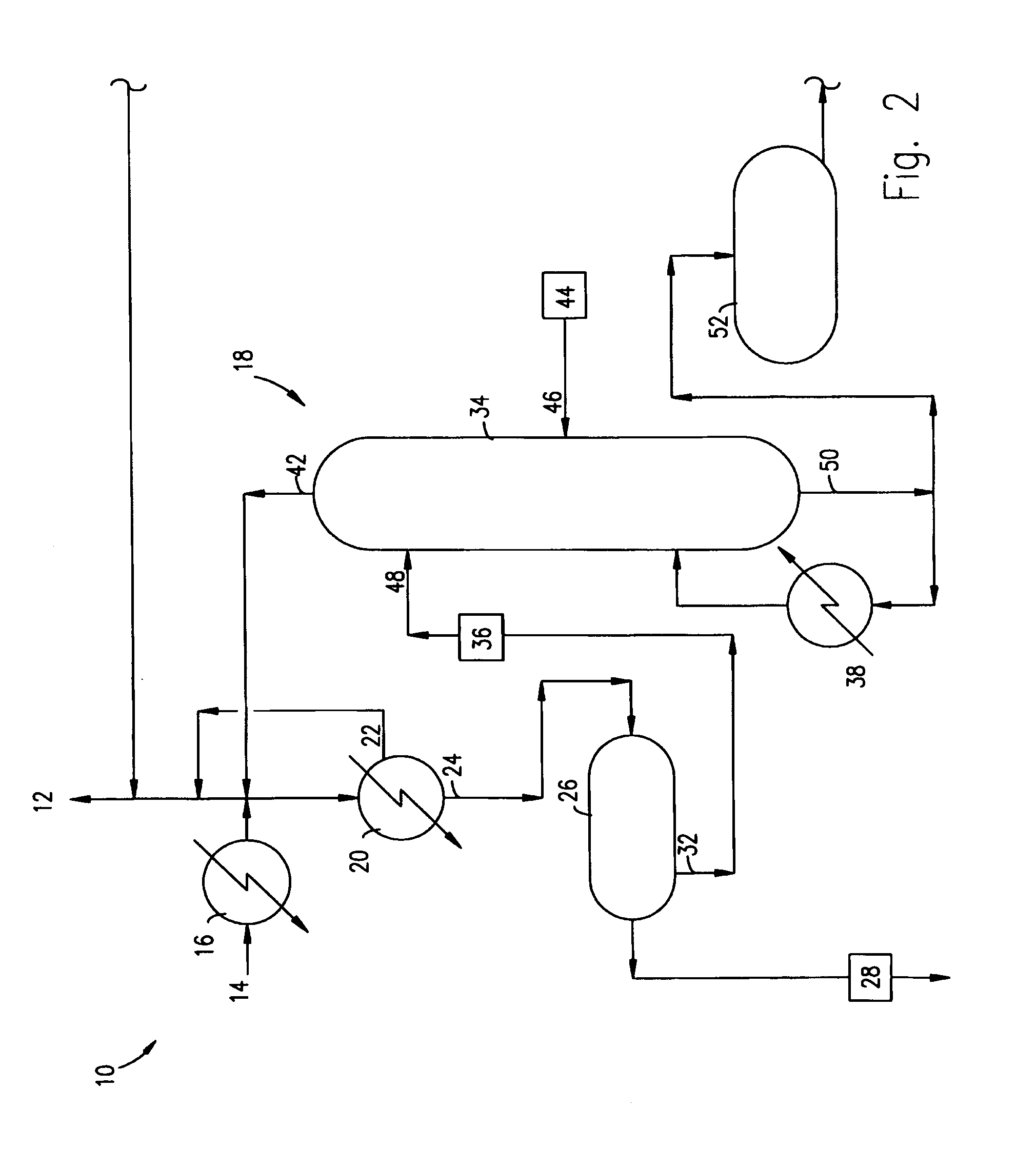

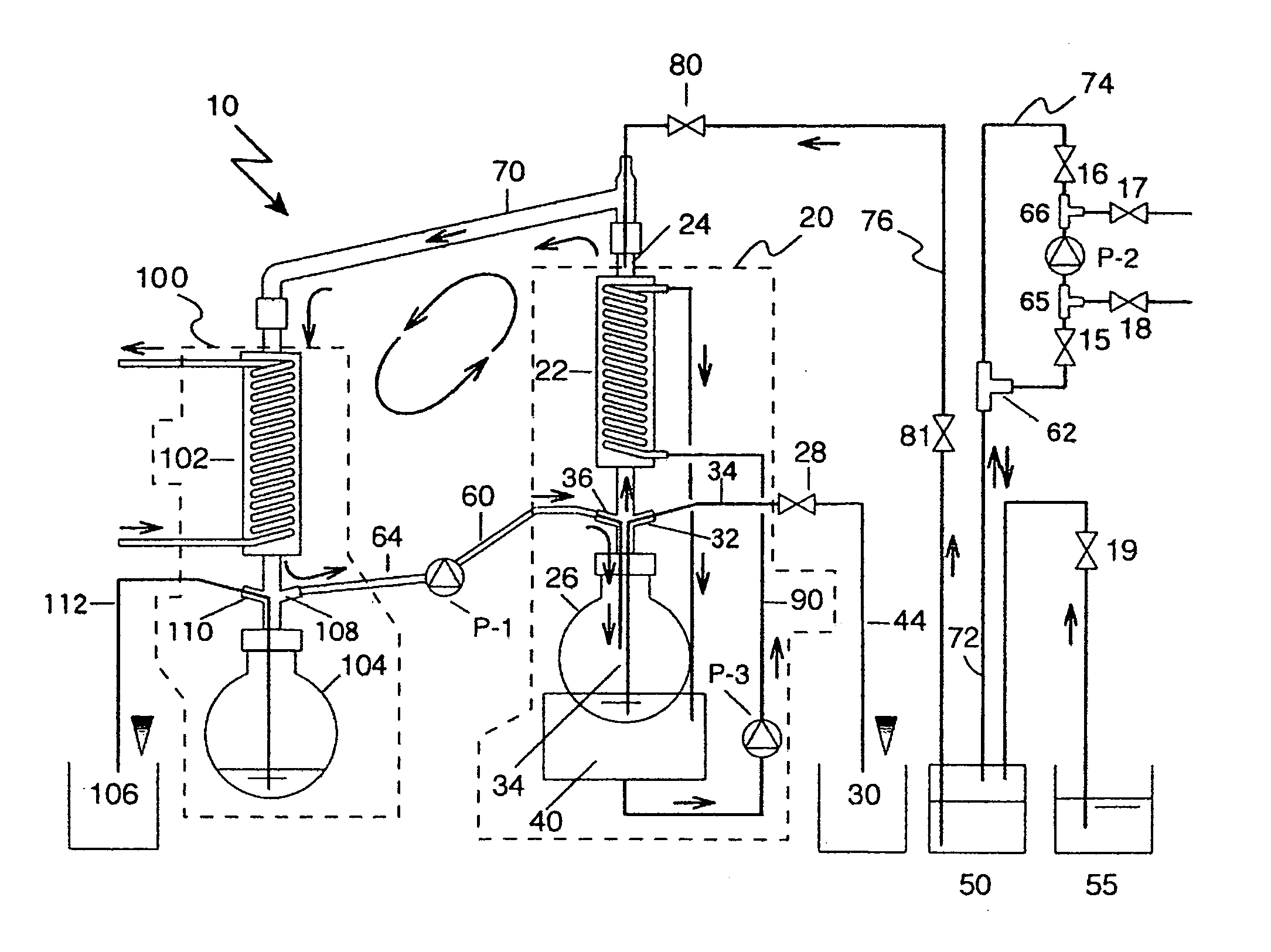

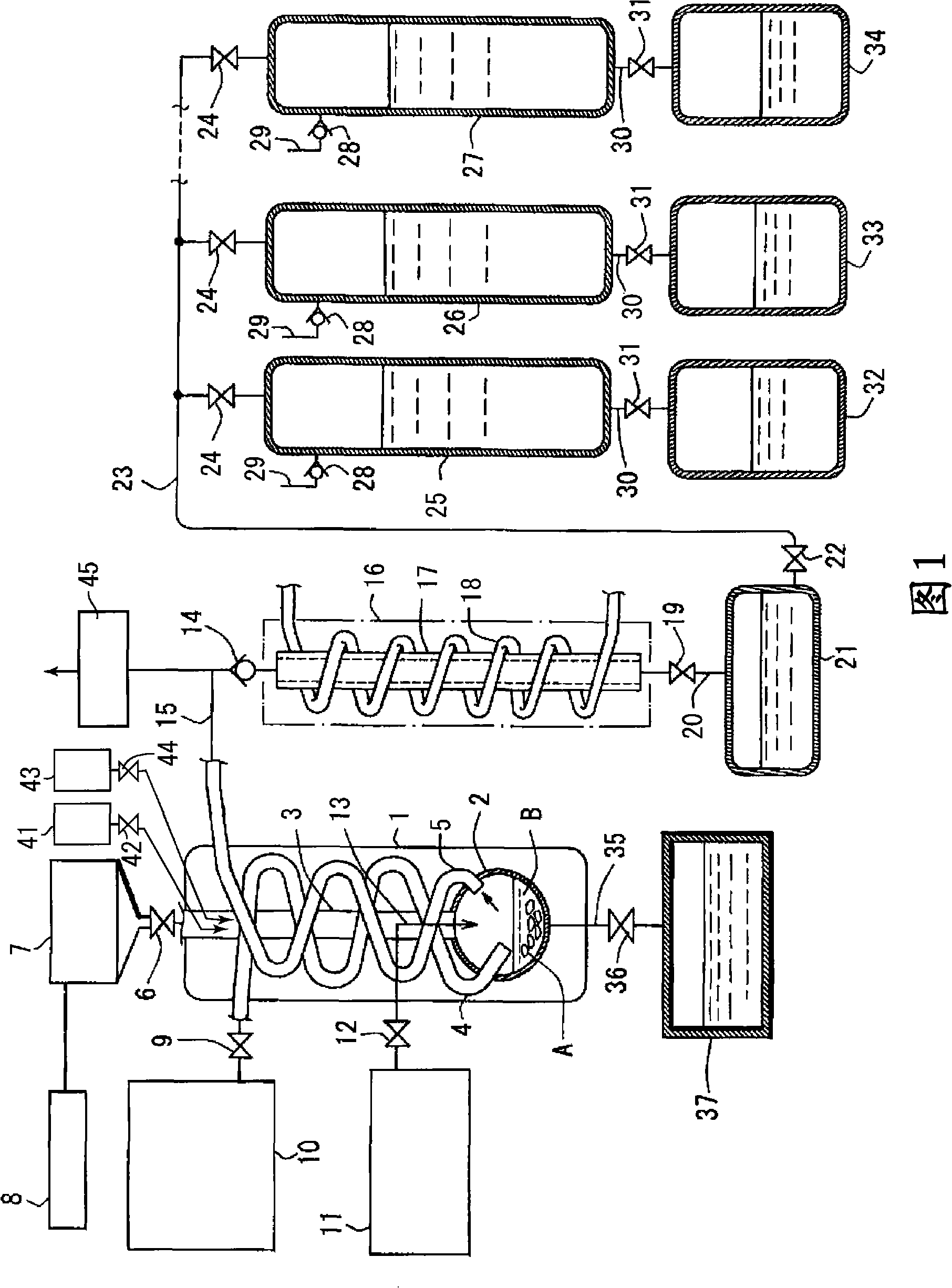

Method for Recovering a Liquid Medium and System for Recover a Liquid Medium

ActiveUS20080035467A1Drying using combination processesDistillation regulation/controlLiquid mediumProduct gas

A method for recovering a liquid medium, comprising gas to be compulsorily contacted with the liquid medium to gasify the liquid medium, and condensing the gasified medium, and a device for recovering a liquid medium. Further, the present invention is directed to a device for recovering a liquid medium, wherein the device comprises: a gasifying means for bringing gas into contact with a mixed liquid comprising a liquid medium and a nonvolatile substance to gasify the liquid medium; a condensing-separating means for cooling the gas and the gasified medium fed from the gasifying means to separate the condensed medium from the separated gas; and a gas feeding means for feeding the separated gas as the gas to the gasifying means.

Owner:INST OF CREATIVE CHEM

Re-direction of vapor flow across tubular condensers

ActiveUS8910702B2Reduces and even eliminatesHeat exhanger conduitsSteam/vapor condensersVapor liquidDistillation

Owner:UOP LLC

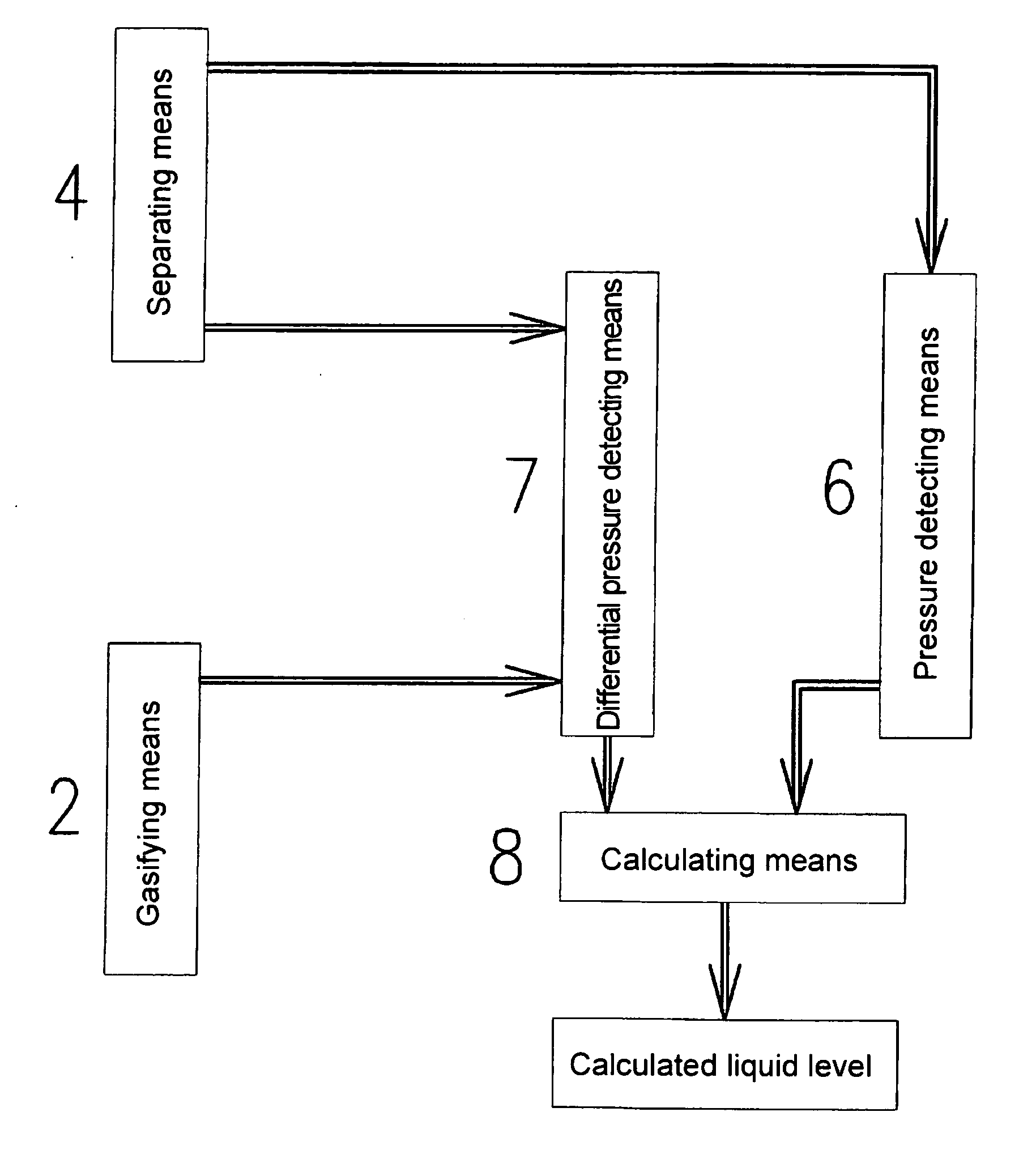

Apparatus for Gasifying and Separating a Liquid Medium or the Like

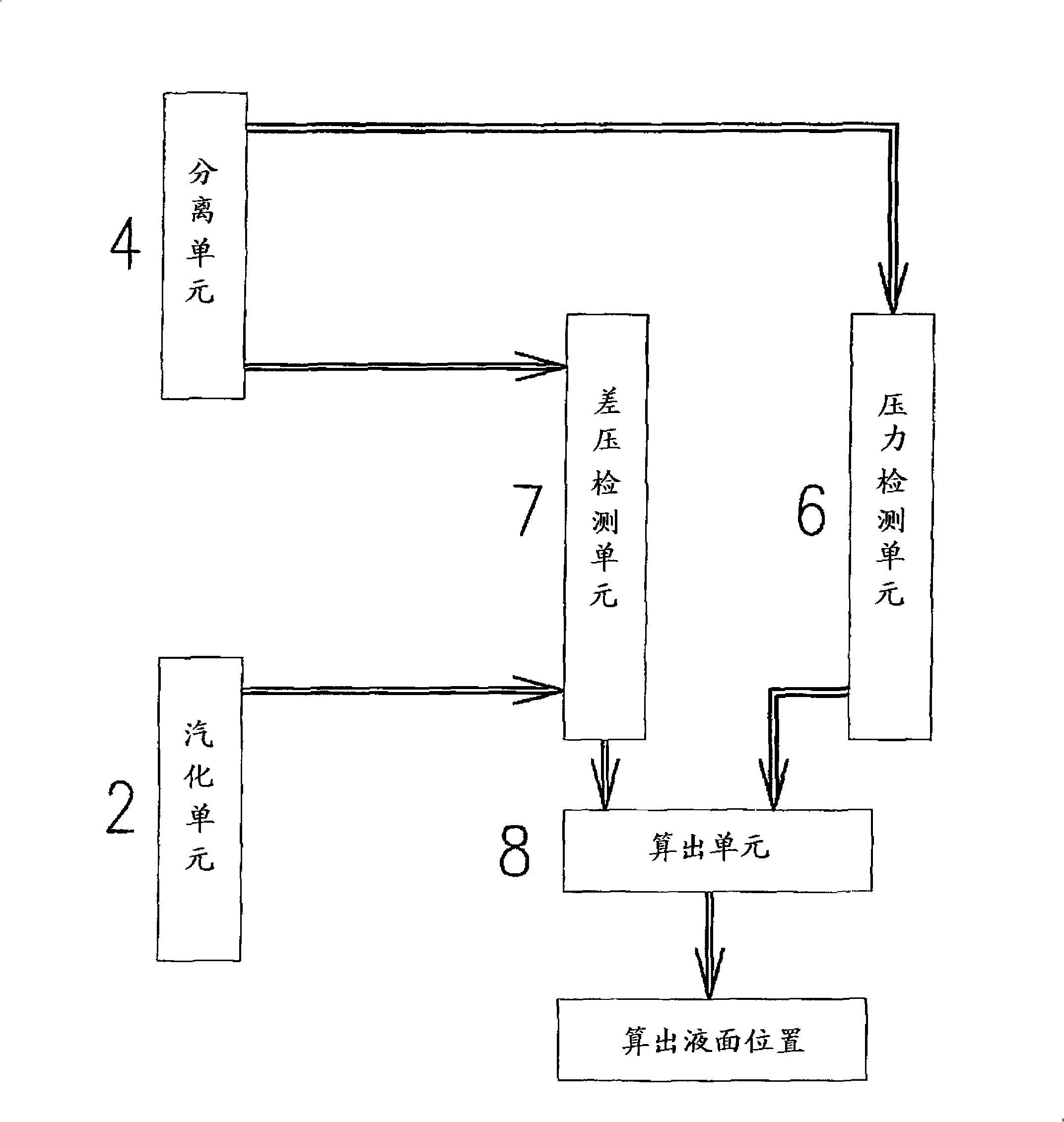

InactiveUS20090165653A1Increase in sizeImprove accuracyLiquid degasificationDistillation regulation/controlLiquid mediumDifferential pressure

To provide an apparatus for gasifying and separating a liquid medium, which is of an automatic type and which can be increased in size.An apparatus for gasifying and separating a liquid medium and a mixture, comprising a gasifying means, in which one liquid selected from a liquid medium and a mixture of the liquid medium and a nonvolatile substance is stored to form a liquid surface of the liquid, for gasifying the liquid medium to form a gasified medium, and a separating means for cooling gas and the gasified medium discharged from the gasifying means to condense the gasified medium, separating the condensed medium from the gas, the apparatus comprising: pressure detecting means for detecting a pressure of the gas; a differential pressure detecting means for detecting a differential pressure between a pressure in the gasifying means at a predetermined position and the pressure of the gas; and a calculating means for calculating the liquid surface position of the liquid from the predetermined position as abase position based on the pressure of the gas and the differential pressure to determine a calculated liquid surface position, wherein the surface position of the liquid varies due to gasification of the liquid, wherein the calculated liquid surface position is a liquid surface position corresponding to the surface position obtained when the liquid is still.

Owner:TECHNO SIGMA

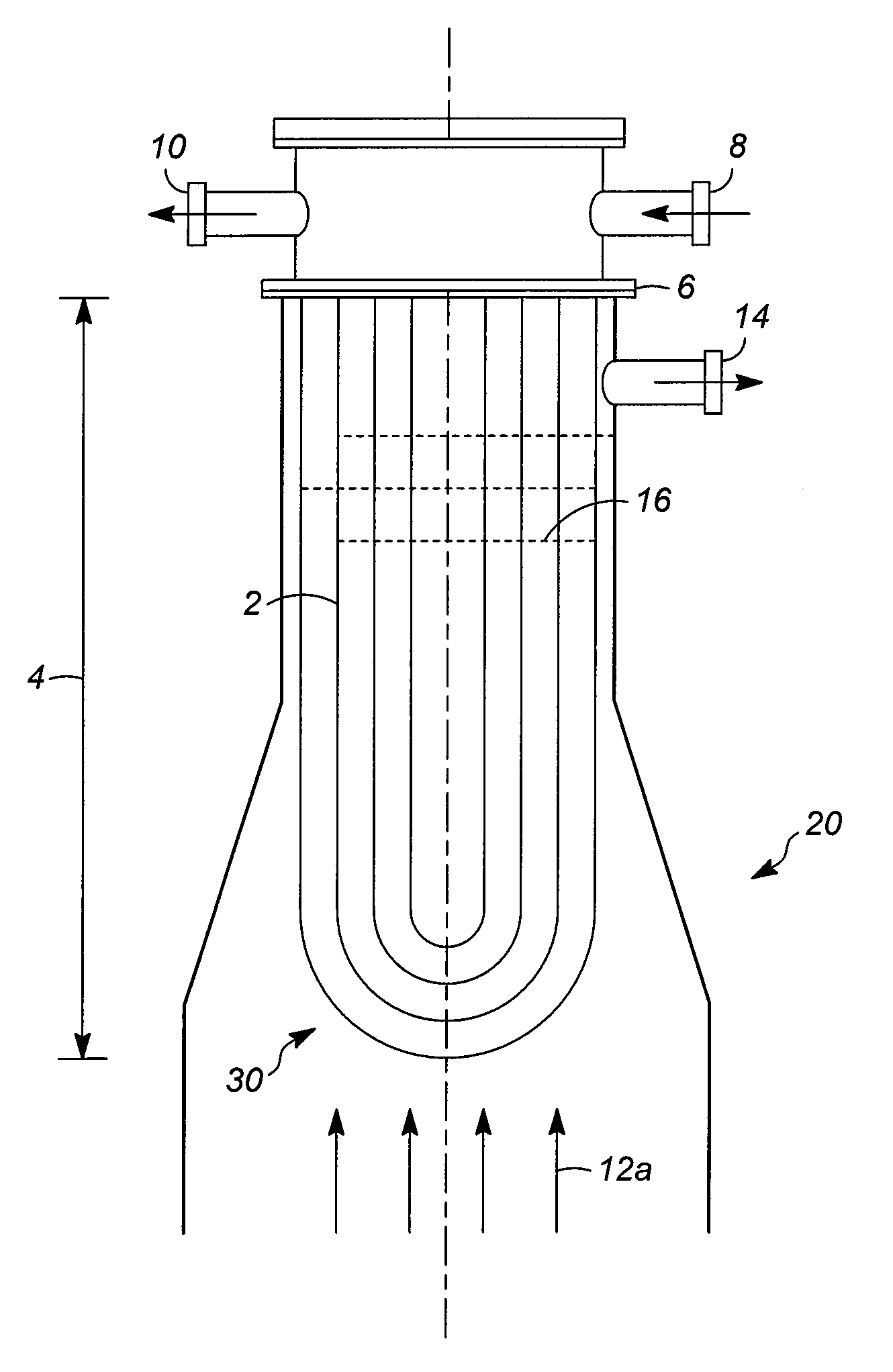

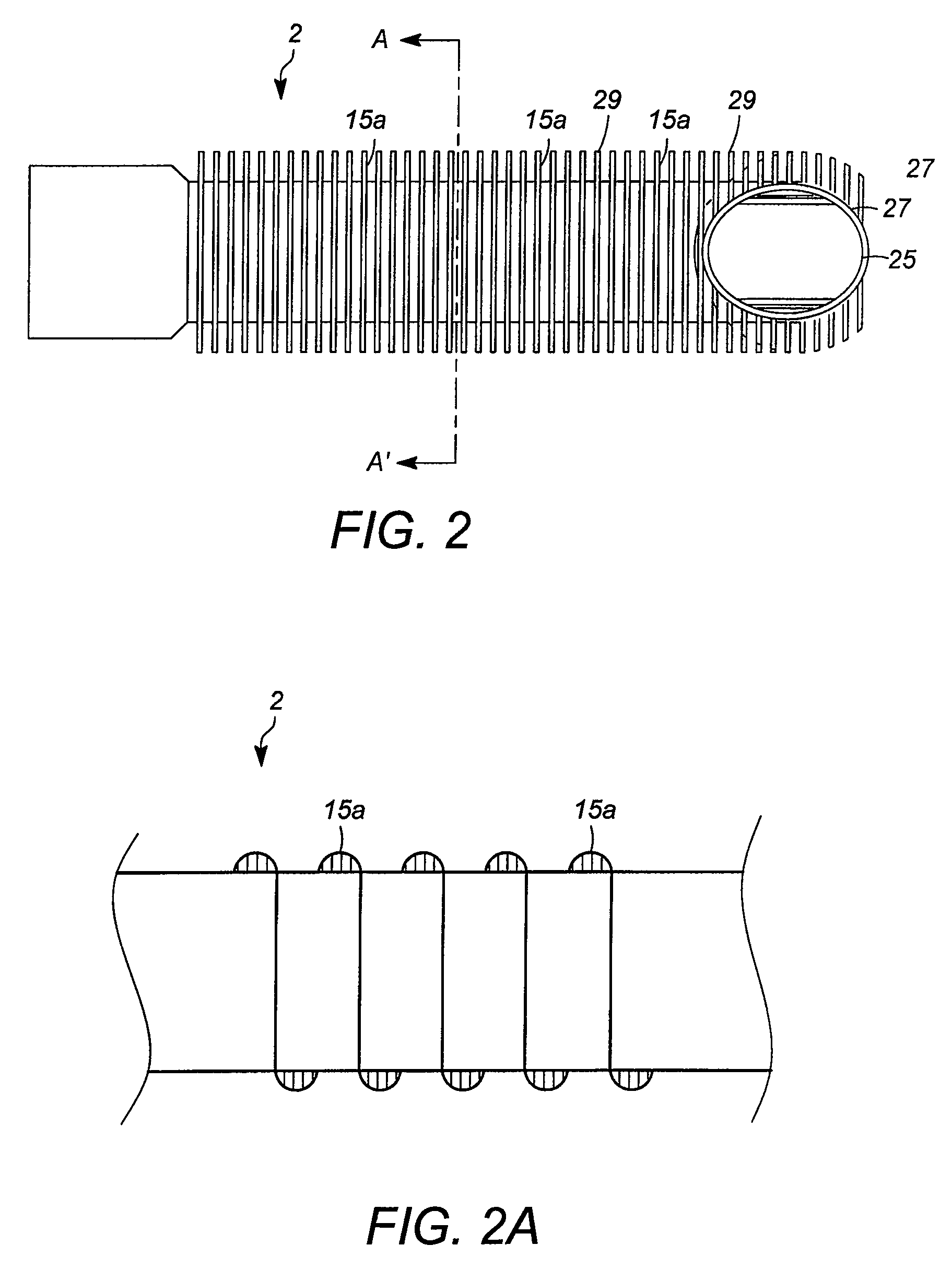

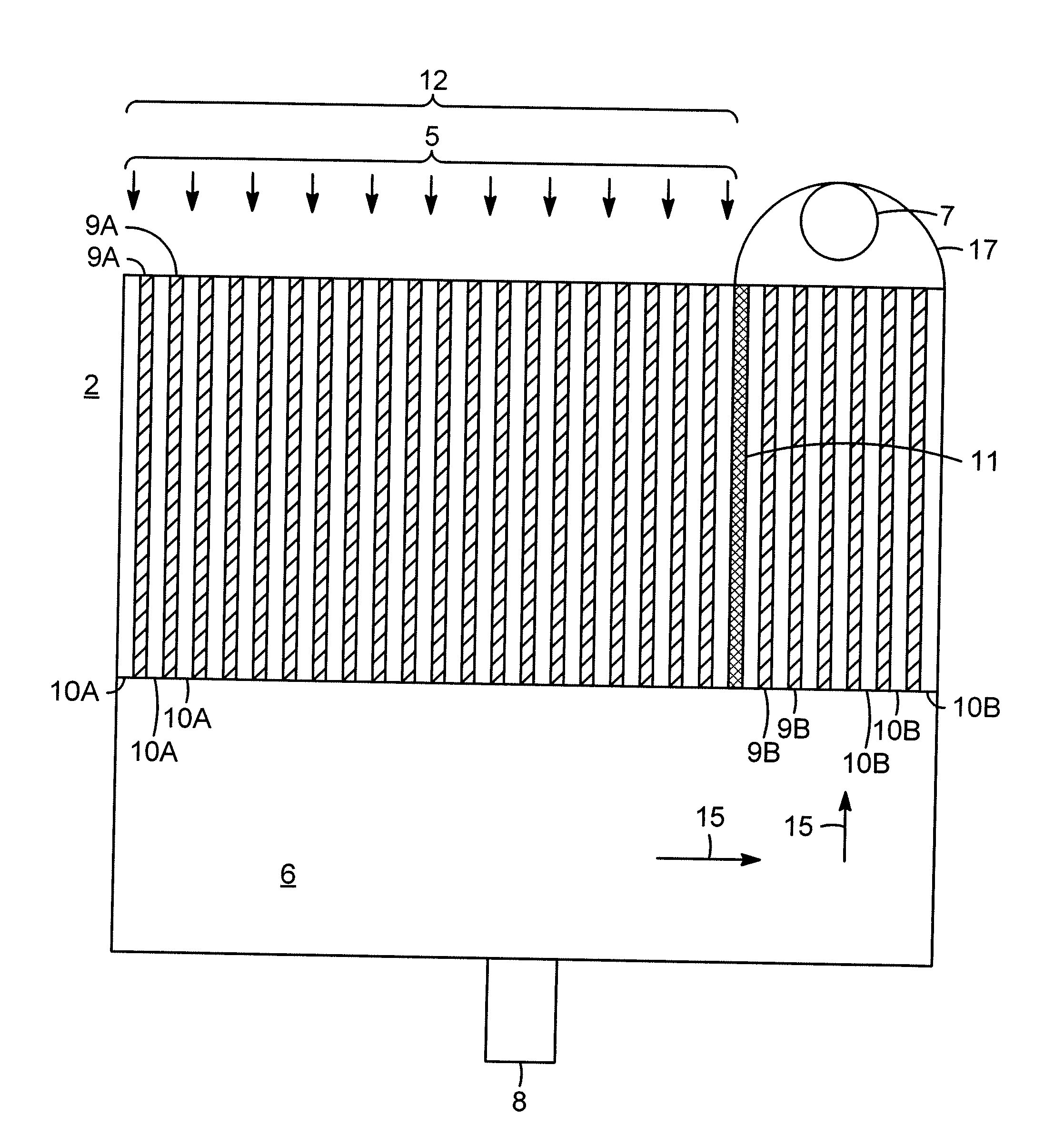

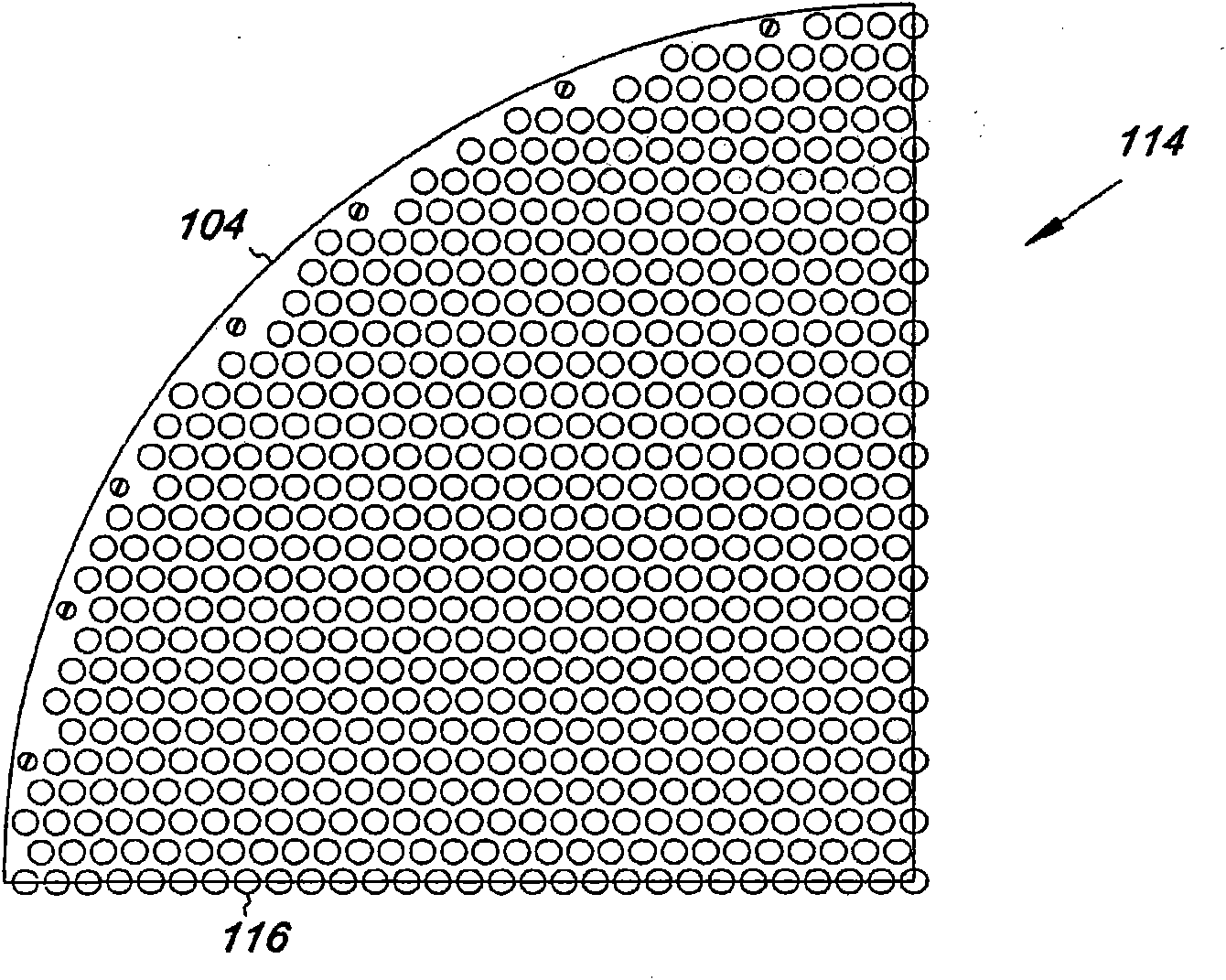

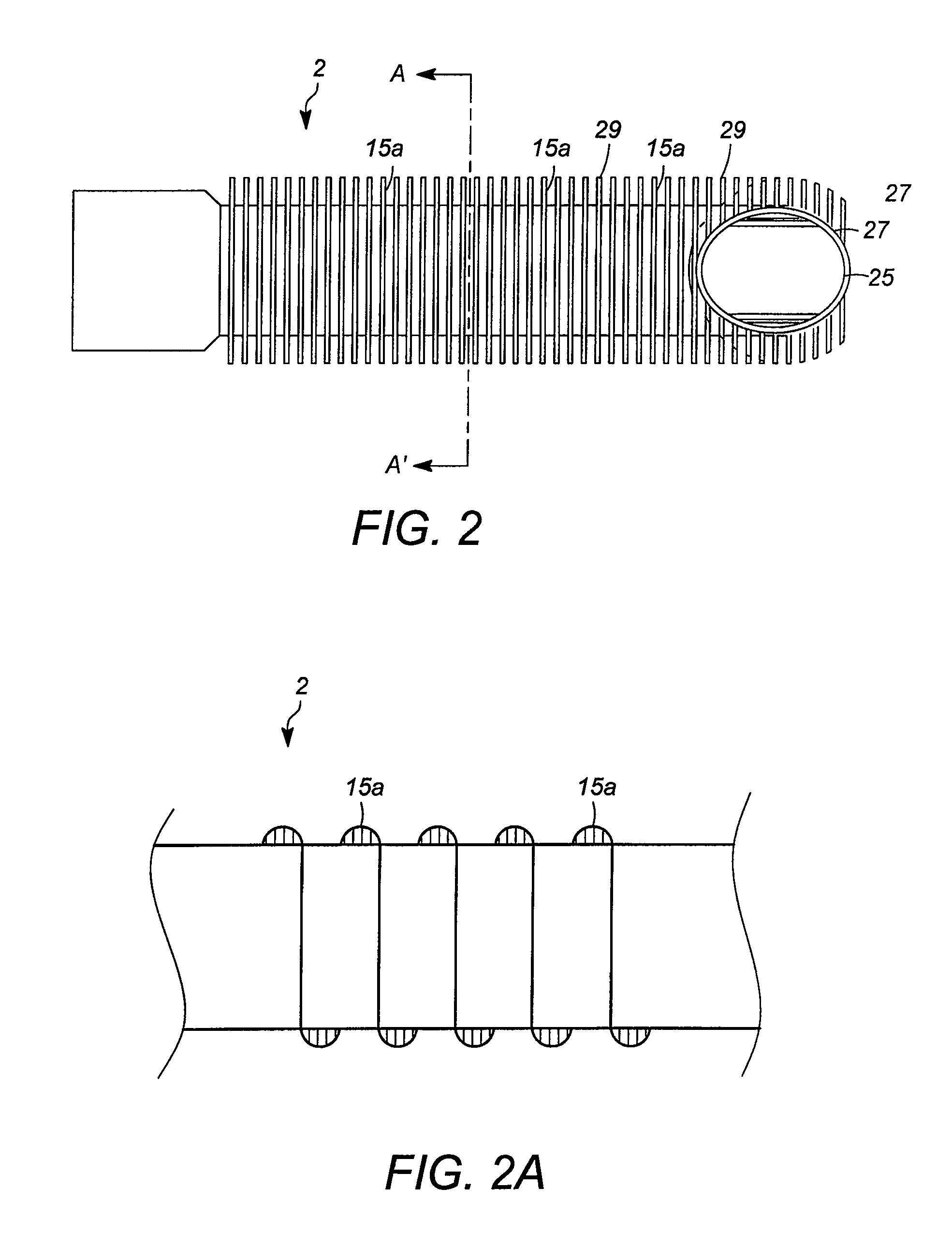

Tubular condensers having tubes with external enhancements

ActiveUS8196909B2Improve their performnanceIncrease in heat transfer coefficientSolidificationLiquefactionVapor liquidDistillation

Improvements in tubes, which increase the heat exchange capacity of tubular heat exchangers using the tubes, are described. These improvements involve the use of one or more external surface enhancements, optionally combined with an internal enhancement and / or differing tube geometries. These improvements apply, for example, to internal condensers, including those in which the tube bundles are oriented vertically, in vapor-liquid contacting apparatuses such as distillation columns.

Owner:UOP LLC

Simple portable mini distillation apparatus for the production of essential oils and hydrosols

This invention relates to a simple, convenient, portable mini-distillation apparatus for the production of essential oils and hydrosols, said apparatus is useful to distill essential oils and hydrosols such as rose water, ajowain water from fresh and dried plant material like leaves, flowers, roots and rhizomes by water distillation, water and steam distillations and as an optional, steam distillation can also be perform at atmospheric pressure as well as slightly higher and lower than atmospheric pressure, said apparatus can be heated on brick-clay furnace with small agro-waste, LPG cooking gas, electrically heated stove or kerosene / diesel burner etc. and requires minimum attention during handling; since the apparatus is made of stainless steel and glass, the essential oil distilled is of better quality.

Owner:COUNCIL OF SCI & IND RES

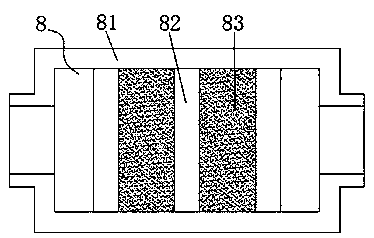

Column Installed Condenser

A reactor-installed or column-installed vertical plate heat exchanger having channels for flow of cooling fluid and vertical passageways between the cooling fluid channels for flow of product. A divider is located between a first fraction and a second fraction of the product vertical passageways and a vapor product inlet communicates with the tops of the product vertical passageways in the first fraction. A product collection volume communicates with the bottoms of the product vertical passageways and an outlet communicates with the product collection volume for recovering condensed product. An uncondensed vapor outlet communicates with the tops of the vertical passageways in the second fraction for removing uncondensed vapor from the heat exchanger.

Owner:UOP LLC

Vaporizing separator for liquid medium and the like

InactiveCN101330950AAvoid bumpingFully automatedDistillation regulation/controlEvaporationLiquid mediumSize increase

Provided is a fully automatic vaporizing separator for liquid media which is capable of coping with size increase. The vaporizing separator, which is for separating a liquid medium and a liquid mixture, comprises: a vaporizing means in which either of a liquid medium and a liquid mixture comprising the liquid medium and a nonvolatile substance is stored to thereby form a liquid surface and which vaporizes the liquid medium to give a vaporized medium; a separation means which cools a gas discharged from the vaporizing means and the vaporized medium to condense the vaporized medium and thereby convert it into a condensed medium and which thus separates the condensed medium from the gas. The vaporizing separator for a liquid medium and the liquid mixture includes: a pressure-measuring means which measures the pressure of the gas; a pressure-difference determination means which determines the difference between the pressure in a given position in the vaporizing means and the pressure of the gas; and a calculation means which calculates the position of the surface of the liquid relative to that given position from the pressure of the gas and the pressure difference.

Owner:TECHNO SIGMA

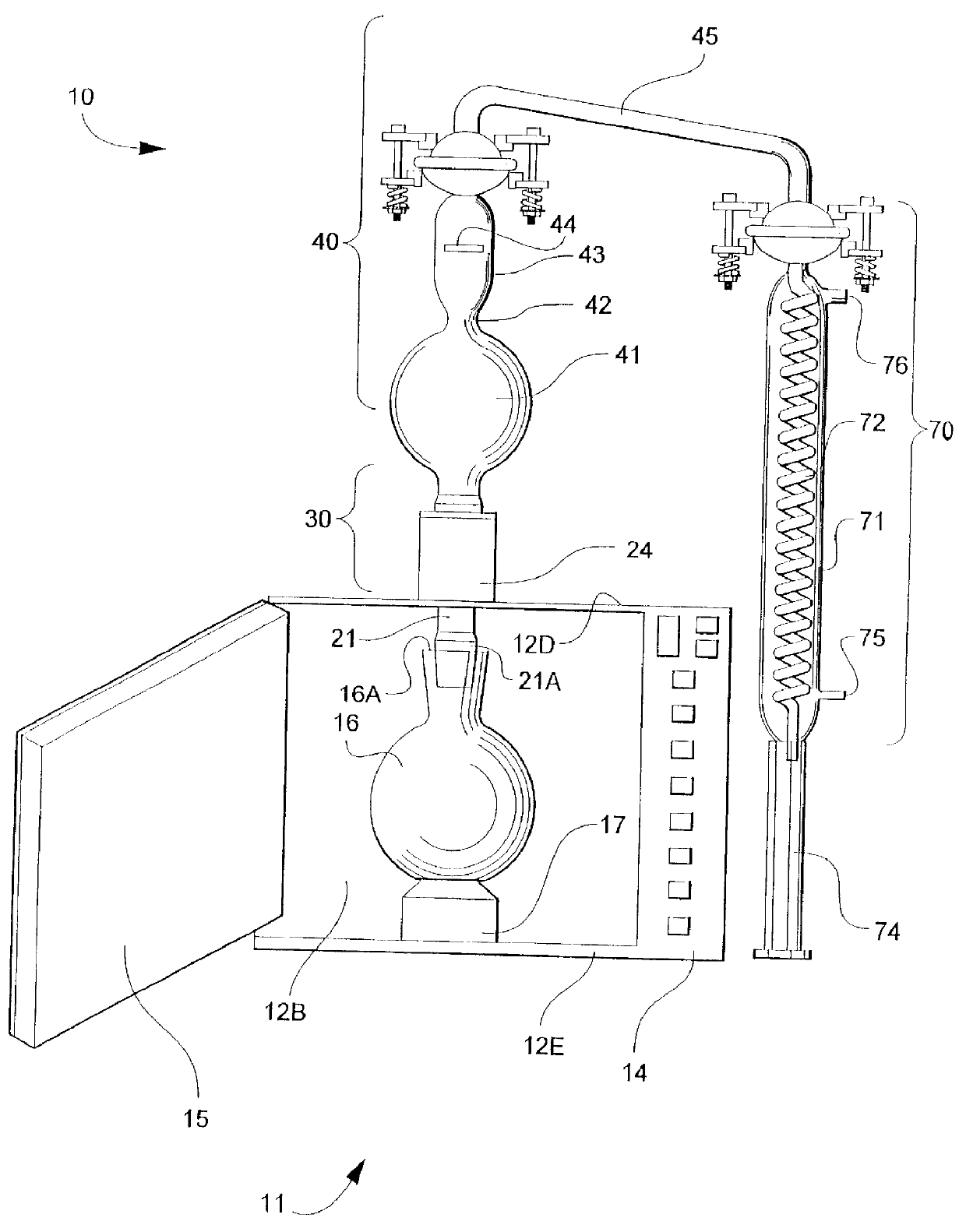

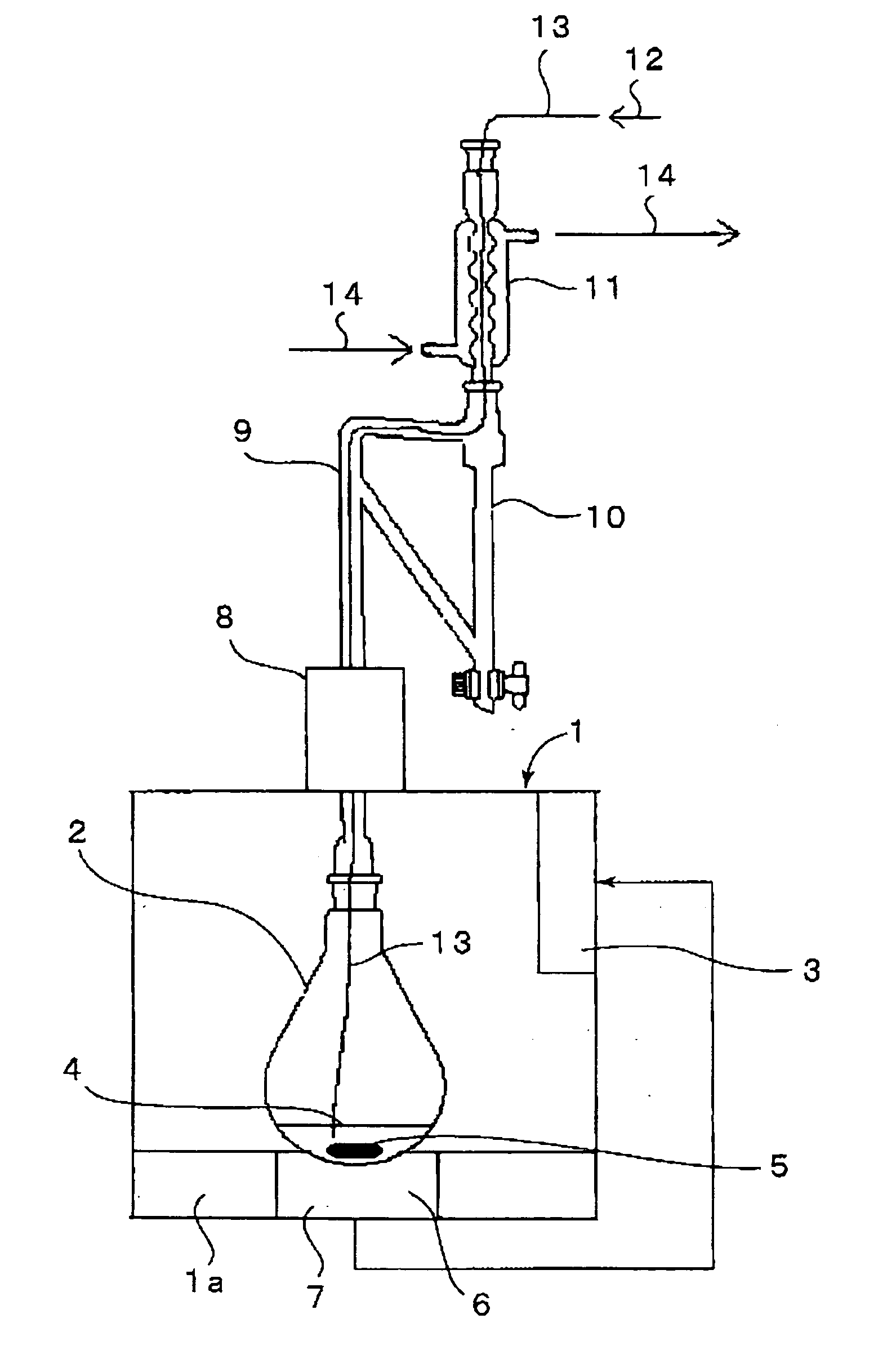

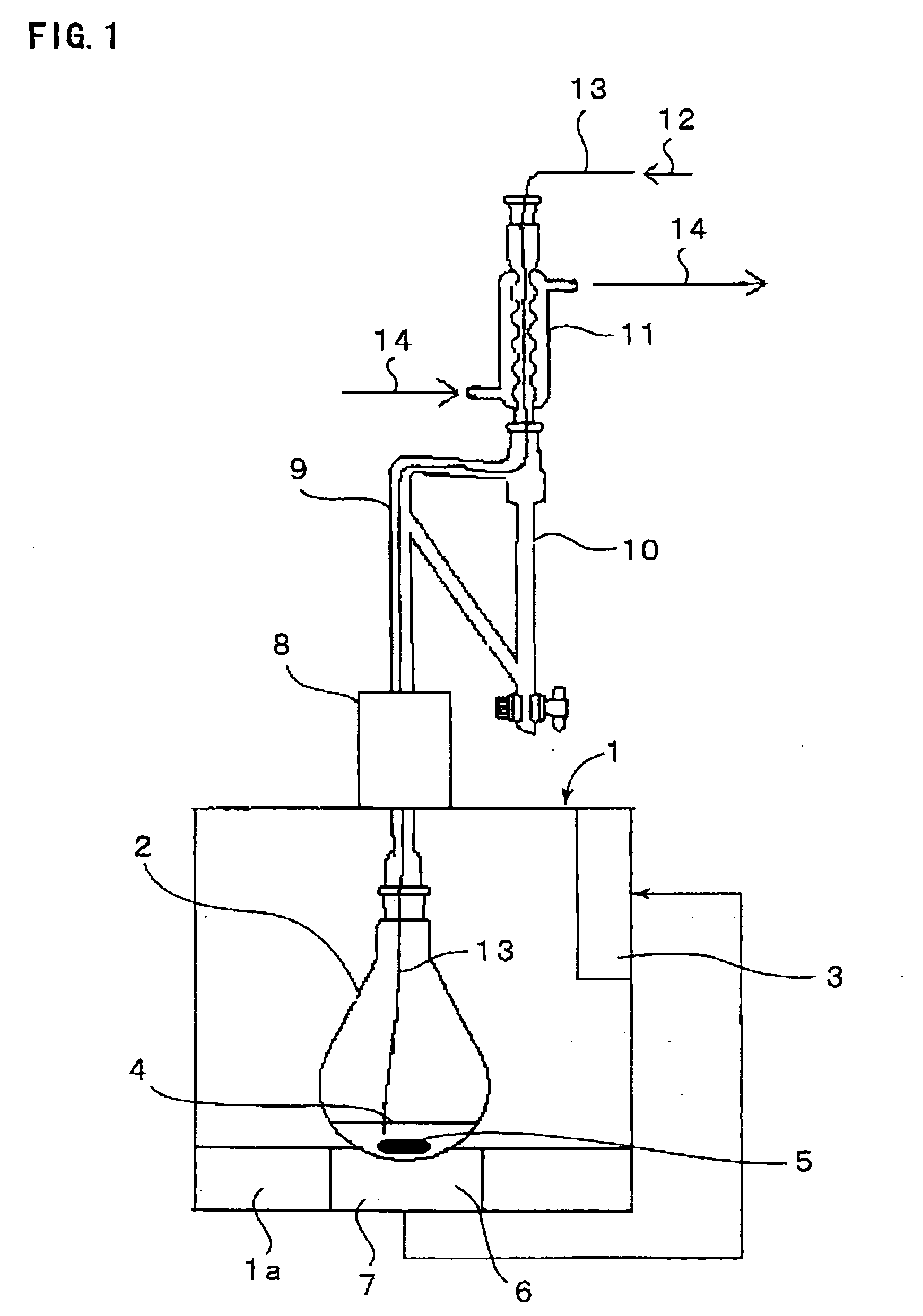

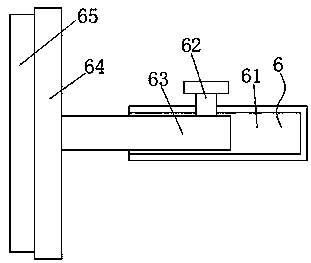

Microwave distillation apparatus, and vessel-biasing assembly

InactiveUS6015968AHeated quickly and efficientlyPreparing sample for investigationEvaporators/condensersMicrowaveDistillation

A microwave distillation apparatus is provided. The apparatus includes a microwave heating chamber having a plurality of walls. A vessel is located within the chamber for containing a liquid to be distilled. The vessel has a mouth for receiving the liquid. A connecting tube extends though an opening formed in one of the plurality of chamber walls. The connecting tube has a first end thereof for sealably engaging the mouth of the vessel, and a second end thereof extending outwardly from the chamber. A biasing assembly is located outside of the chamber, and engages the connecting tube with a biasing force to maintain the seal between the connecting tube and the mouth of the vessel. A distillate capture assembly is connected to the connecting tube for receiving vapors emitted from the liquid when heated, and for condensing the vapors into a liquid distillate for capture and storage.

Owner:ARMSTRONG BERNARD

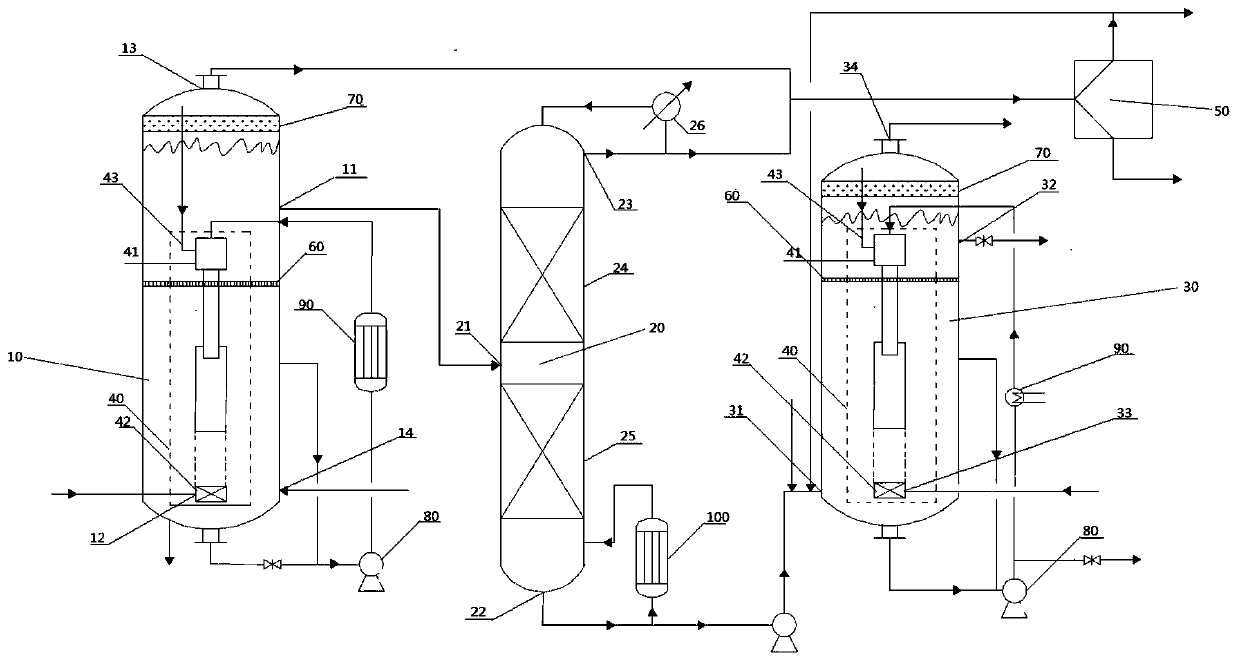

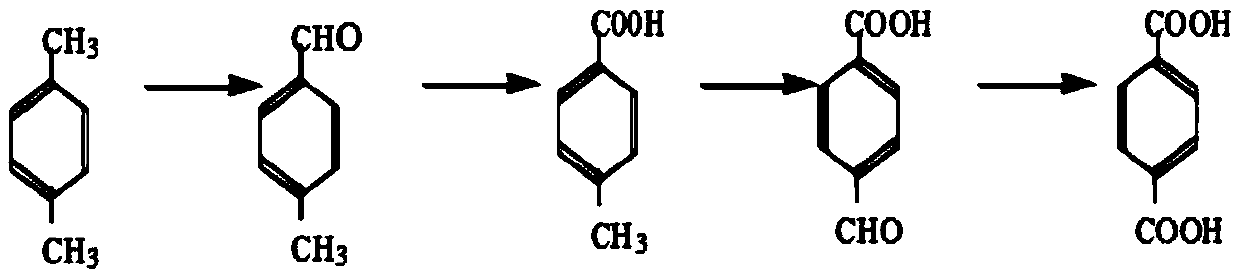

Built-in micro-interface oxidation system and built-in micro-interface oxidation method for preparing terephthalic acid from p-xylene

ActiveCN111569454AReduce consumptionSolve the contradiction of not being able to withstand high temperature oxidation conditionsLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationXylyleneThermodynamics

The invention provides a built-in micro-interface oxidation system for preparing terephthalic acid from p-xylene. The oxidation system comprises a first reactor, a rectifying tower and a second reactor which are sequentially connected, wherein a first outlet is formed in the side wall of the first reactor; a first inlet is formed in the side wall of the second reactor; a material inlet is formed in the side wall of the rectifying tower; a material outlet is formed in the bottom of the rectifying tower; the first outlet is connected with the material inlet of the rectifying tower; the first inlet is connected with the material outlet of the rectifying tower; micro-interface units are arranged in the first reactor and the second reactor; and the micro-interface units are used for dispersingbroken air into bubbles. According to the built-in micro-interface oxidation system, the micro-interface units are arranged in the reactors, and a sectional process is adopted, so the problems of highenergy consumption, high raw material consumption and low reaction efficiency in traditional processes are solved, and the effect of saving cost for enterprises is achieved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

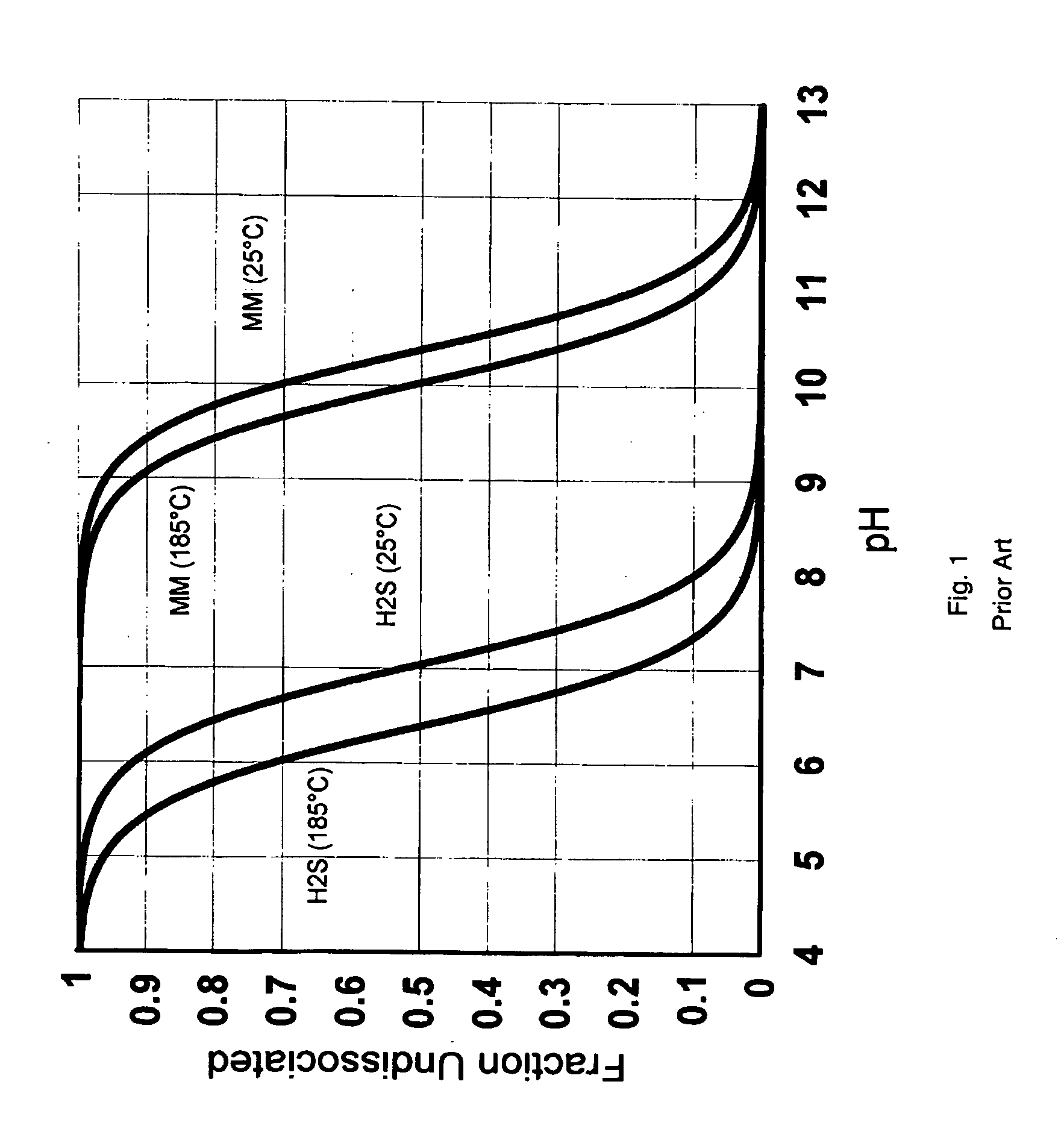

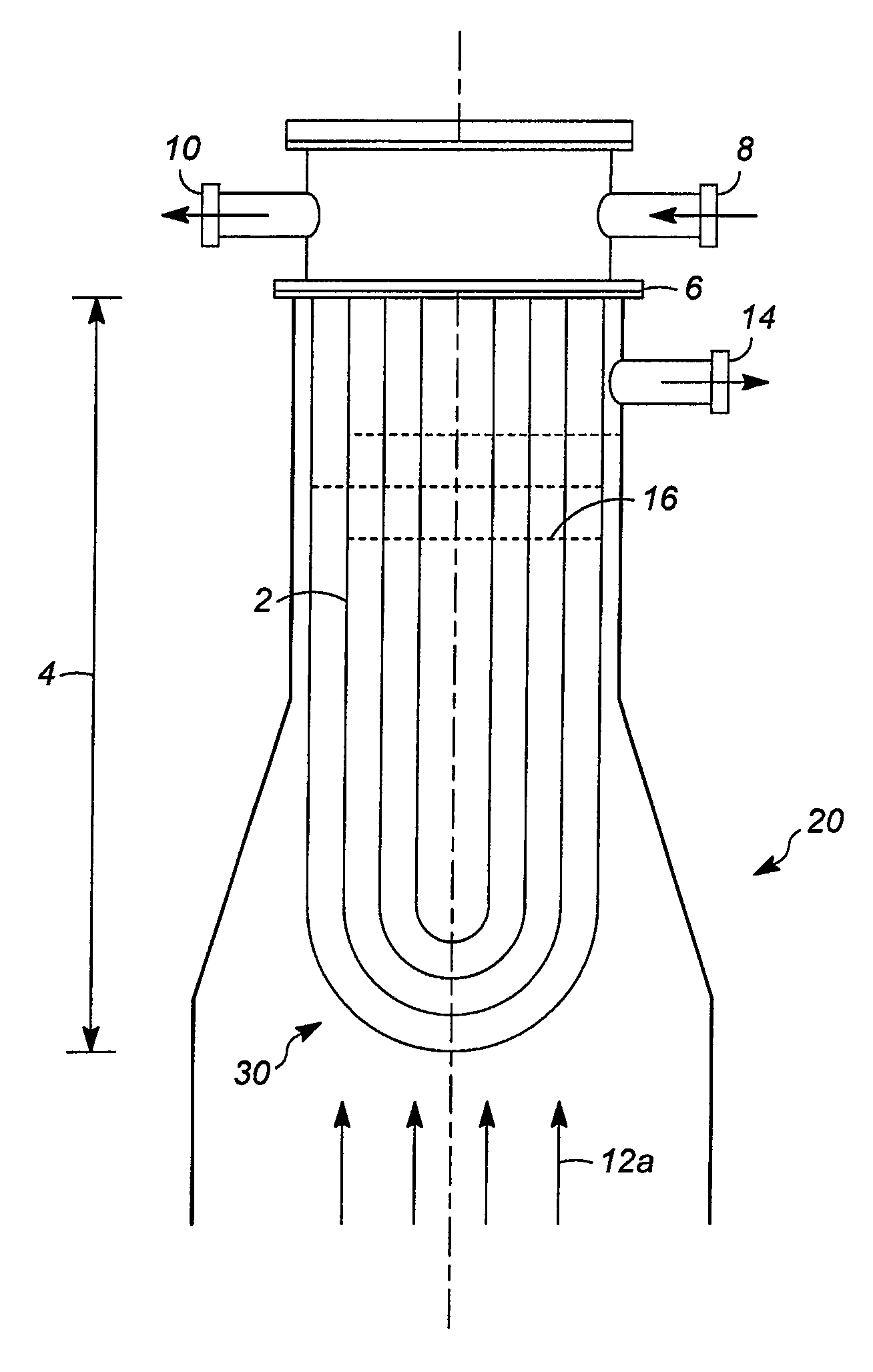

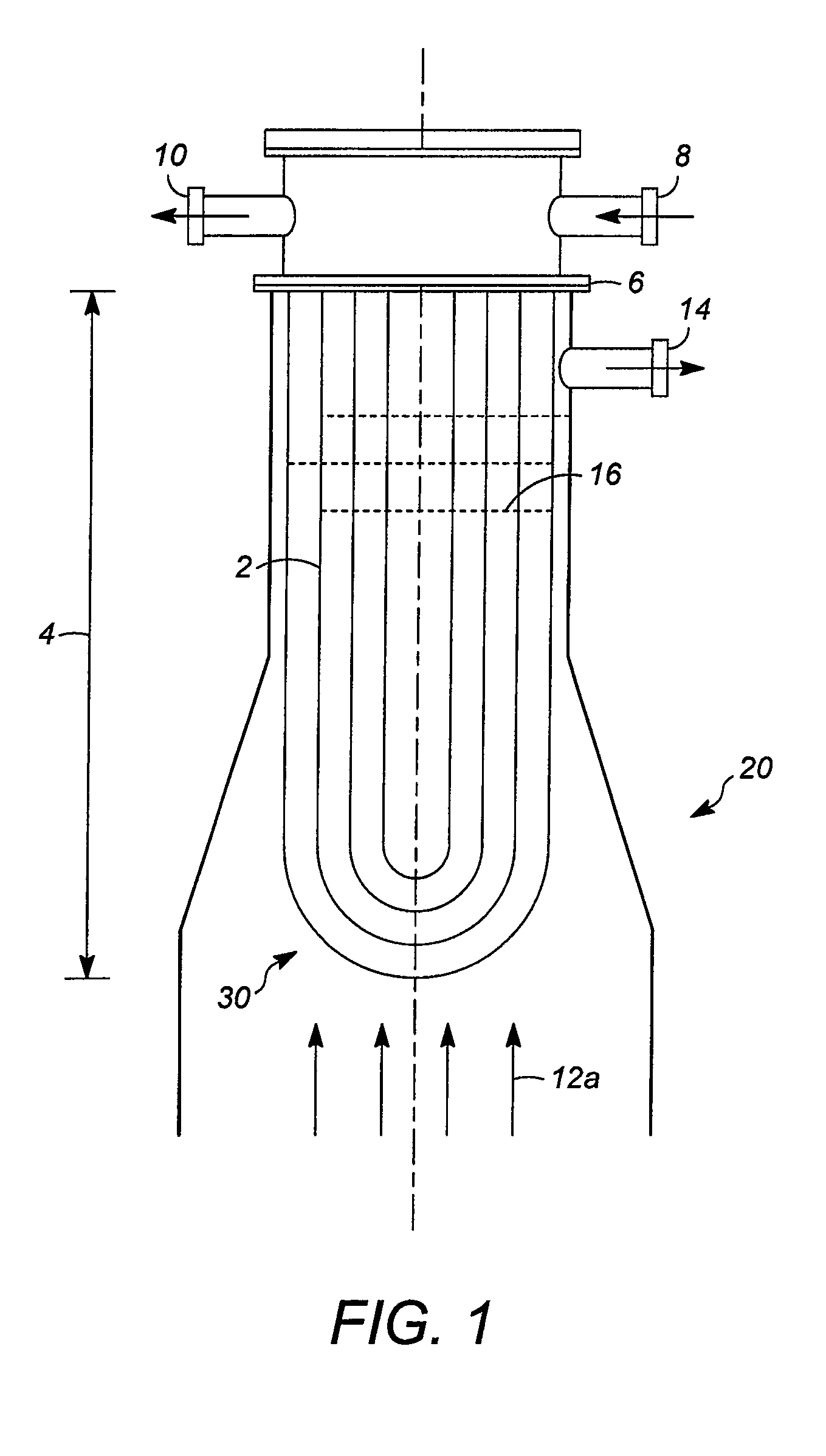

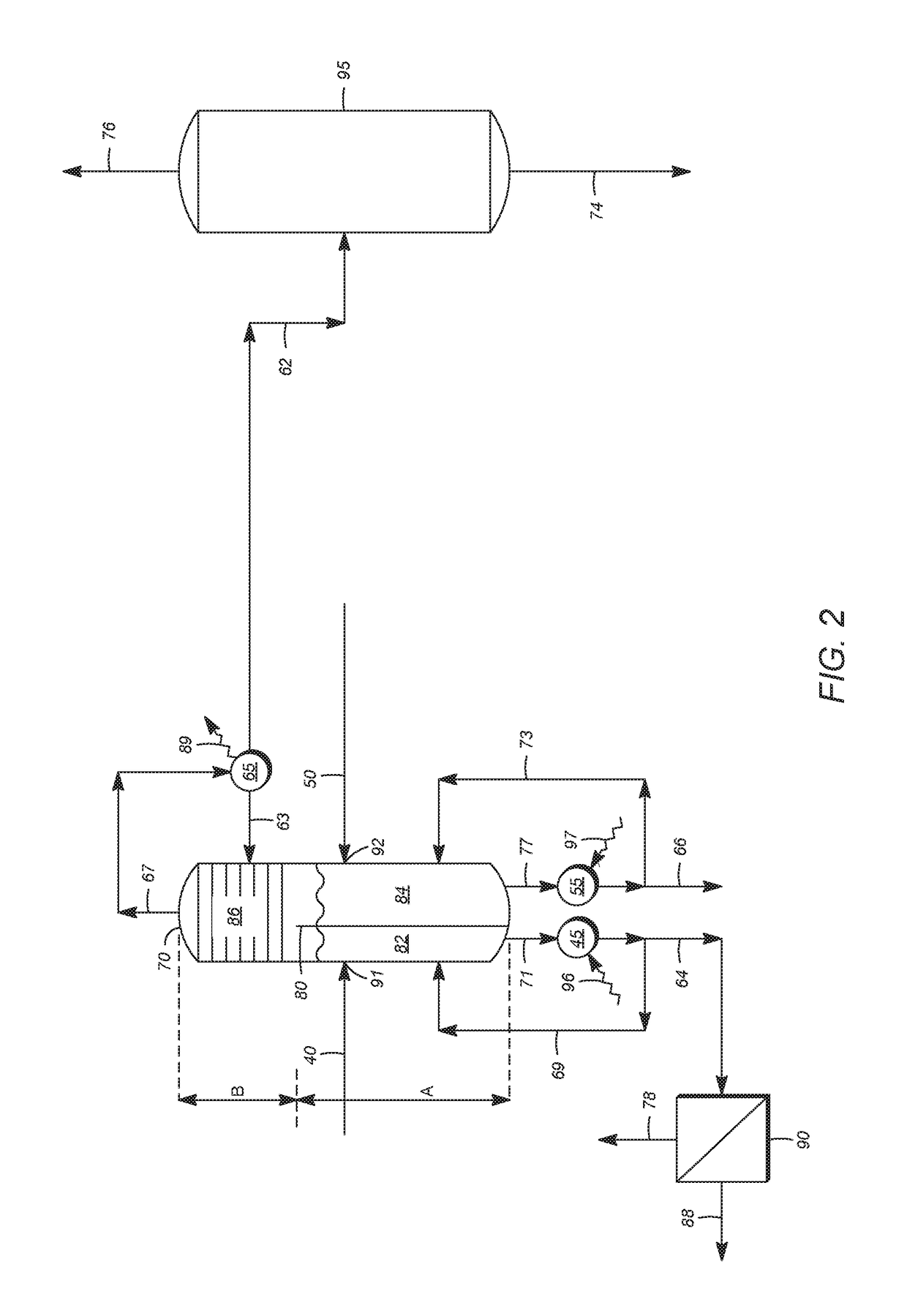

Reflux condenser

Methods, apparatus, and processes are provided for a condenser including flowing a vapor stream including formaldehyde into a tube bundle in a vertical upflow reflux condenser, where a tube in the tube bundle has a length to outside diameter ratio of greater than about 170:1, flowing a cooling fluid on a shell-side of the vertical upflow reflux condenser to condense at least a portion of the vapor stream, where the condensed portion of the vapor stream forms a wetted tube internal surface area on each tube in the generally upright tube bundle; and maintaining the vapor stream velocity at a rate that provides a liquid residence time where formaldehyde condensed on the wetted internal surface area of each tube can react with water to form methylene glycol, removing at least sixty percent (60%) of formaldehyde from the vapor stream fed to the condenser.

Owner:DOW TECH INVESTMENTS

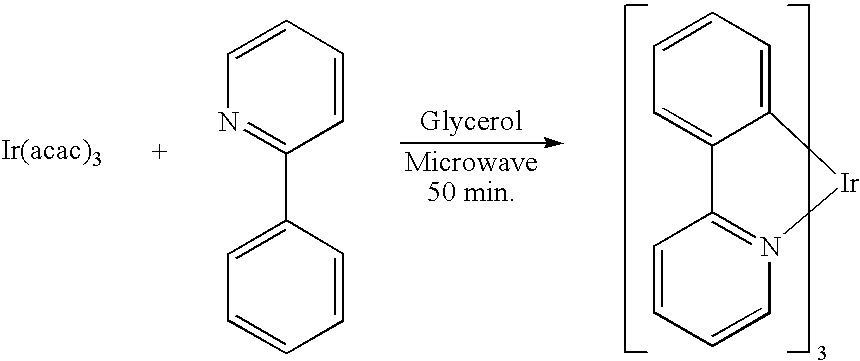

Method and apparatus of producing organic compound

InactiveUS20050002485A1Efficient productionReflux condensationLuminescent compositionsSimple Organic CompoundsBoiling point

A method of producing an organic compound, which includes the steps of irradiating a reaction solution with an electromagnetic wave having a wavelength range of 900 MHz to 30 GHz to heat the solution, thereby producing the organic compound, and removing a low-boiling point component produced through the reaction from a reaction system to facilitate the reaction.

Owner:SANYO ELECTRIC CO LTD

Extraction device for preparation of levofloxacin intermediates

InactiveCN108114501AResidue reductionHigh extraction rateSolvent extractionRotary stirring mixersLevofloxacinStock solution

The invention relates to the technical field of medicine extraction and in particular relates to an extraction device for preparation of levofloxacin intermediates. The extraction device comprises a stirring tank, wherein a feeding hole is formed in the top of the stirring tank; a motor is arranged in the center of the top of the stirring tank; an output end of the motor is connected with a stirring shaft; two groups of stirring blades are arranged at the bottom of the stirring shaft; a scraper mechanism is arranged between the two groups of stirring blades; the scraper mechanism comprises a sleeve and a connecting rod; the sleeve is connected with the stirring shaft; the connecting rod is inserted into the sleeve; a locking bolt is arranged on the sleeve; the other end of the connecting rod is connected with an arc plate; multiple scraping bars are arranged on the other side of the arc plate; the bottom of the stirring tank is communicated with a delivery pipe; the other end of the delivery pipe is communicated with an evaporator; the top of the evaporator is connected with a cooler; the top of the cooler is connected with a condenser; and the bottom of the condenser is connectedwith a second delivery pipe. According to the extraction device, stock solution residues in the stirring tank can be effectively decreased, and by virtue of circulation of the evaporator, the cooler and the condenser, the stock solution extraction rate is increased.

Owner:YANCHENG XINANZHOU PHARMA

Tubular condensers having tubes with external enhancements

ActiveUS20100276123A1Increase in heat transfer coefficientImprove their performnanceSolidificationLiquefactionVapor liquidDistillation

Improvements in tubes, which increase the heat exchange capacity of tubular heat exchangers using the tubes, are described. These improvements involve the use of one or more external surface enhancements, optionally combined with an internal enhancement and / or differing tube geometries. These improvements apply, for example, to internal condensers, including those in which the tube bundles are oriented vertically, in vapor-liquid contacting apparatuses such as distillation columns.

Owner:UOP LLC

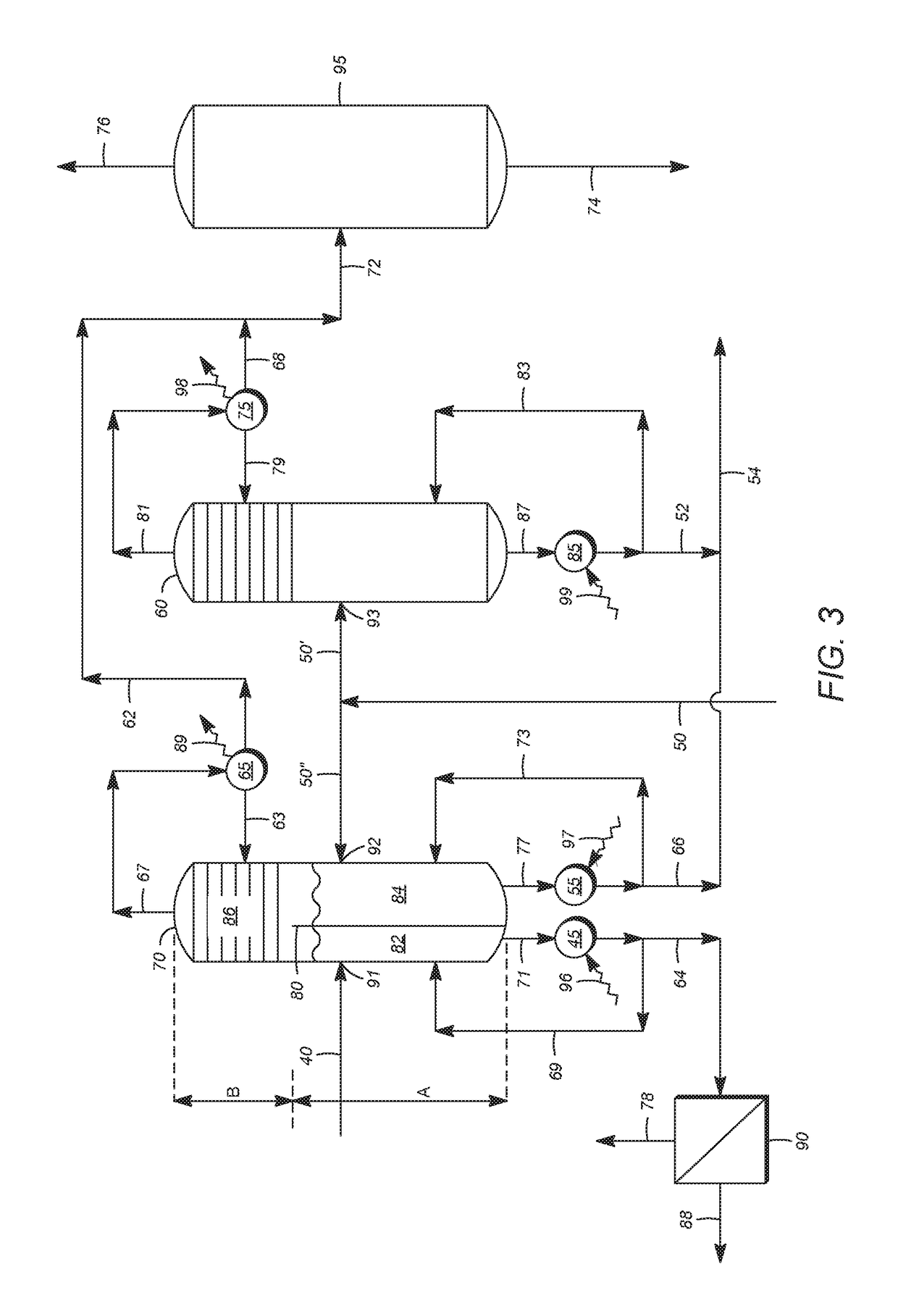

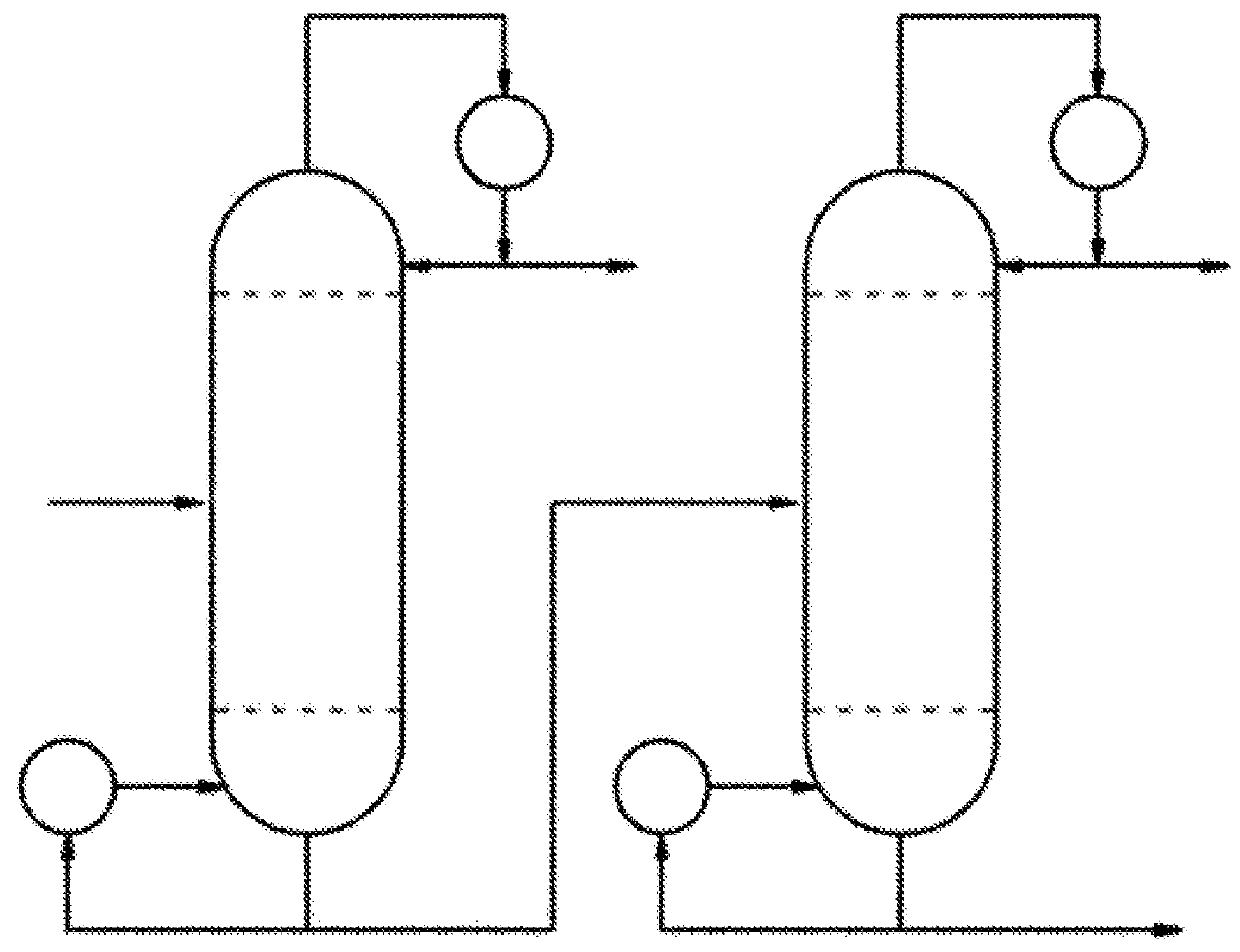

Alkylation product separation method, alkylation reaction separation method and alkylation reaction separation device

ActiveCN110876855AIncrease temperatureTo achieve the purpose of saving energy and reducing consumptionHydrocarbon distillationChemical industryAlkaneFluid phase

The invention discloses an alkylation product separation method. According to the method, a liquid-phase alkylation product is pressurized by an optional booster pump; the pressurized liquid-phase alkylation product is introduced into a first heat exchanger, and is subjected to heat exchange with a gas-phase material from a high-pressure fractionating tower; the heat exchanged material is furtherheated to 100-180 DEG C in a second heat exchanger; the heated material enters the high-pressure fractionating tower, and is fractionated under a condition of 2.0-6.0 MPa; the gas-phase material at the top of the high-pressure fractionating tower is subjected to heat exchange with the liquid-phase alkylation product; the liquid-phase material at the bottom of the high-pressure fractionating towerenters a low-pressure fractionating tower and is fractionated under a condition of 0.2-1.0 MPa; low-carbon alkane is obtained at the top of the low-pressure fractionating tower, and an alkylation oilproduct is obtained at the bottom of the low-pressure fractionating tower; and the low-pressure fractionating tower is provided with an intermediate reboiler, and the gas-phase material at the top ofthe high-pressure fractionating tower after heat exchange of the first heat exchanger is used as a heat source of the intermediate reboiler. The method provided by the invention can improve the heat utilization efficiency and reduce the separation operation energy consumption in the alkylation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

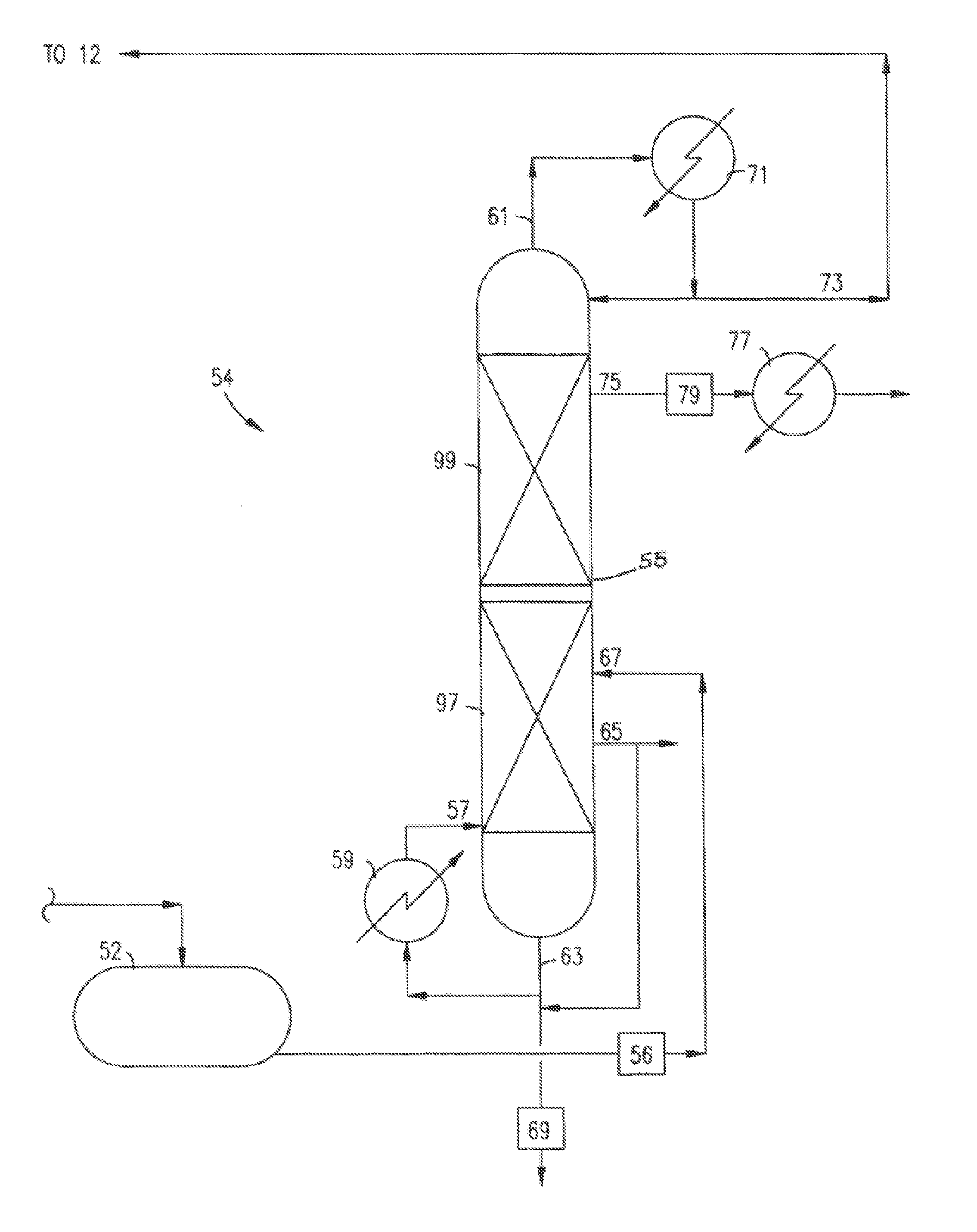

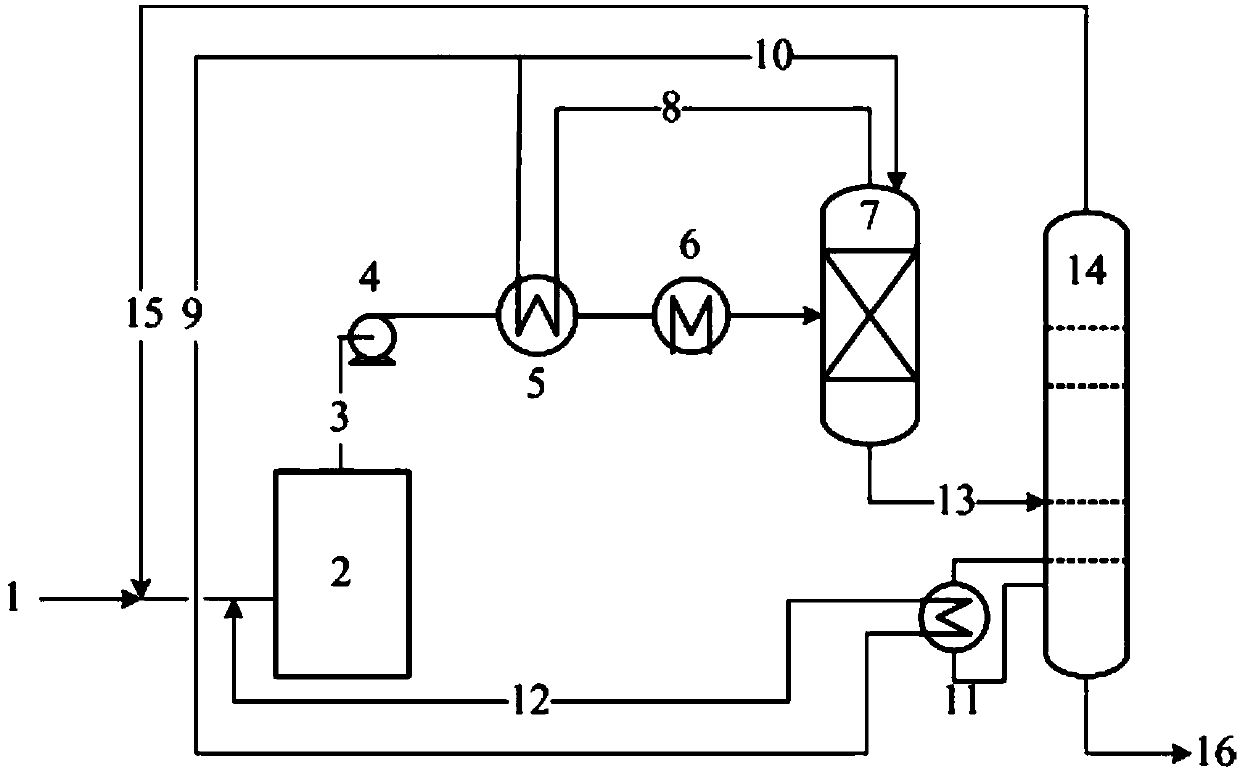

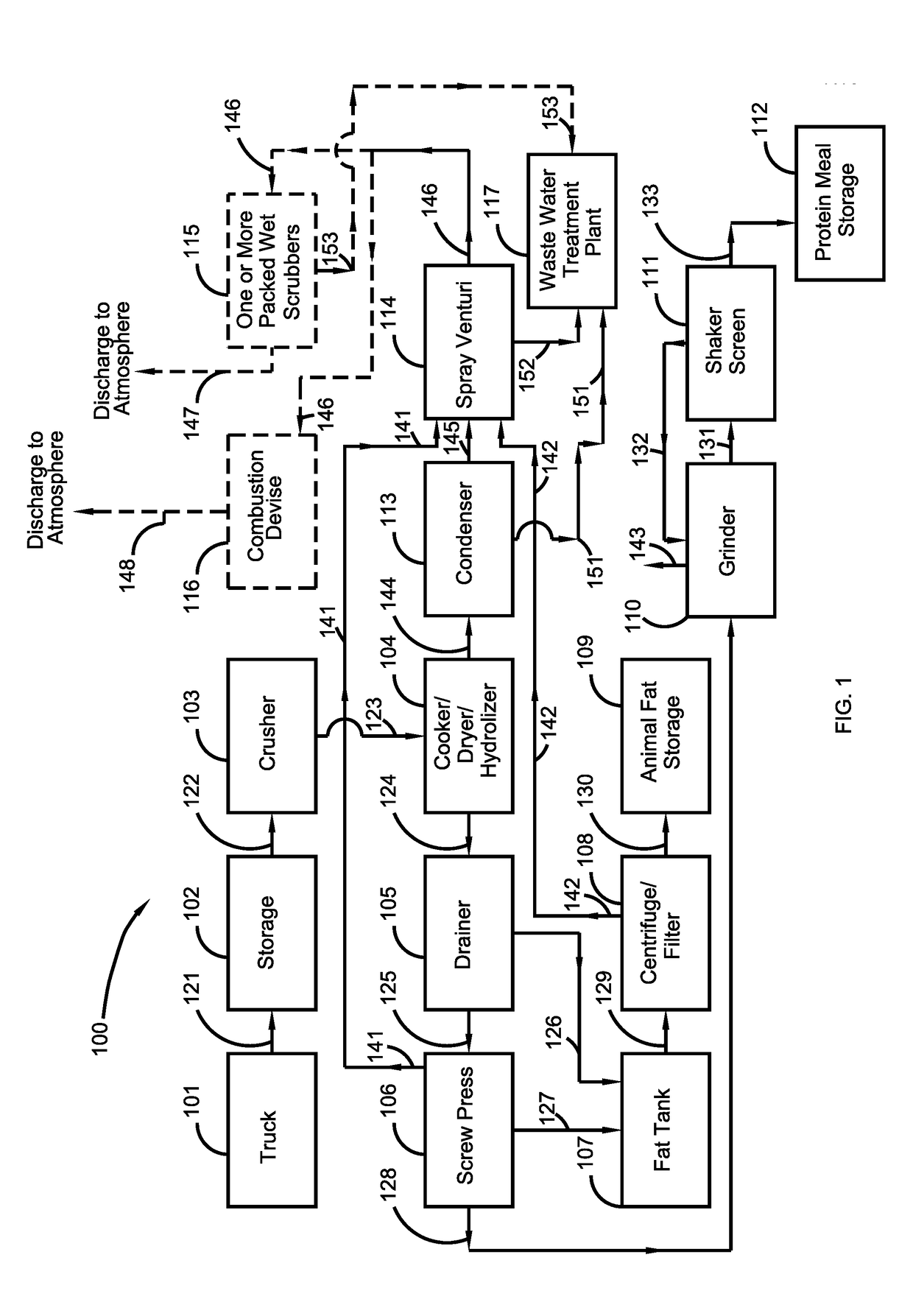

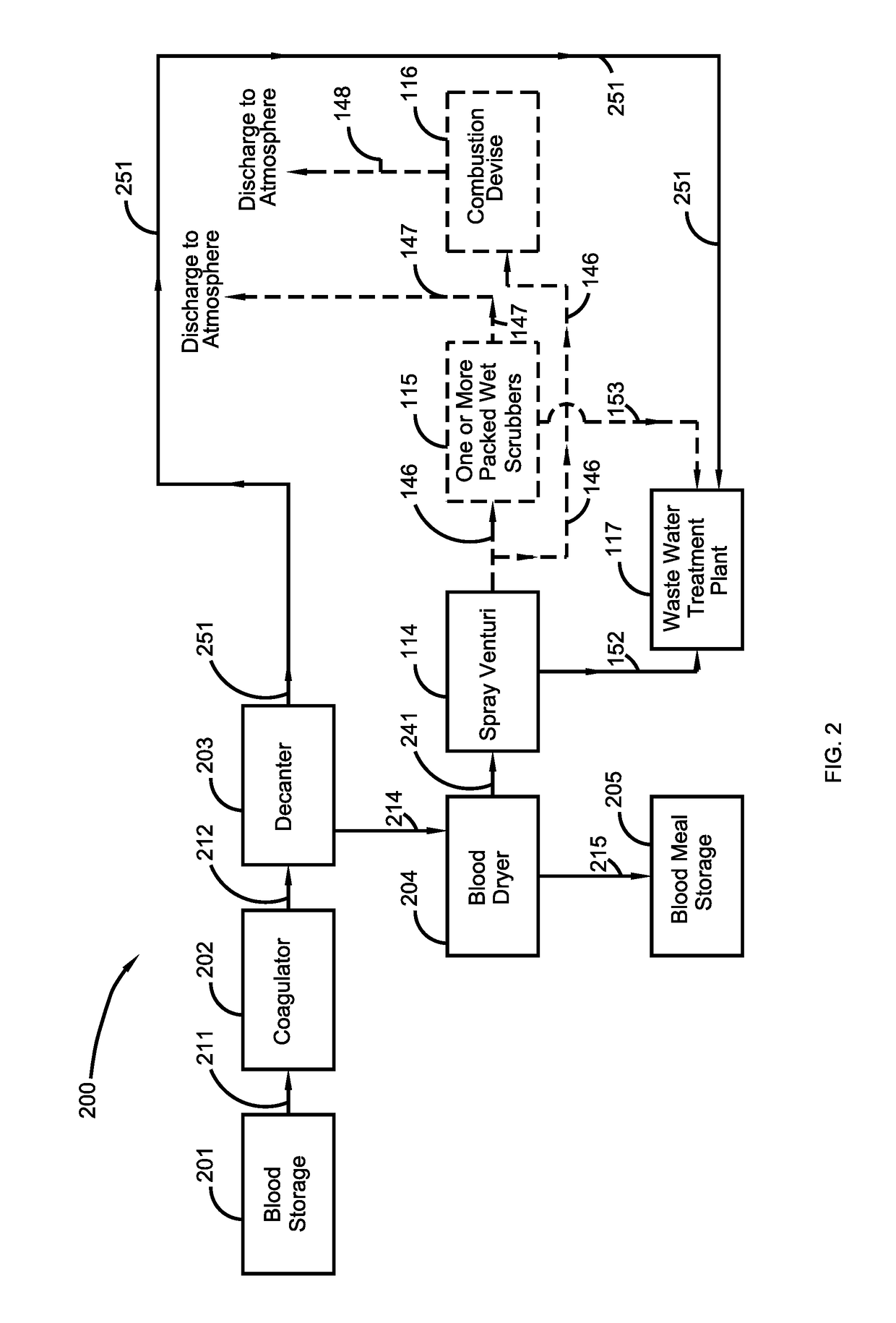

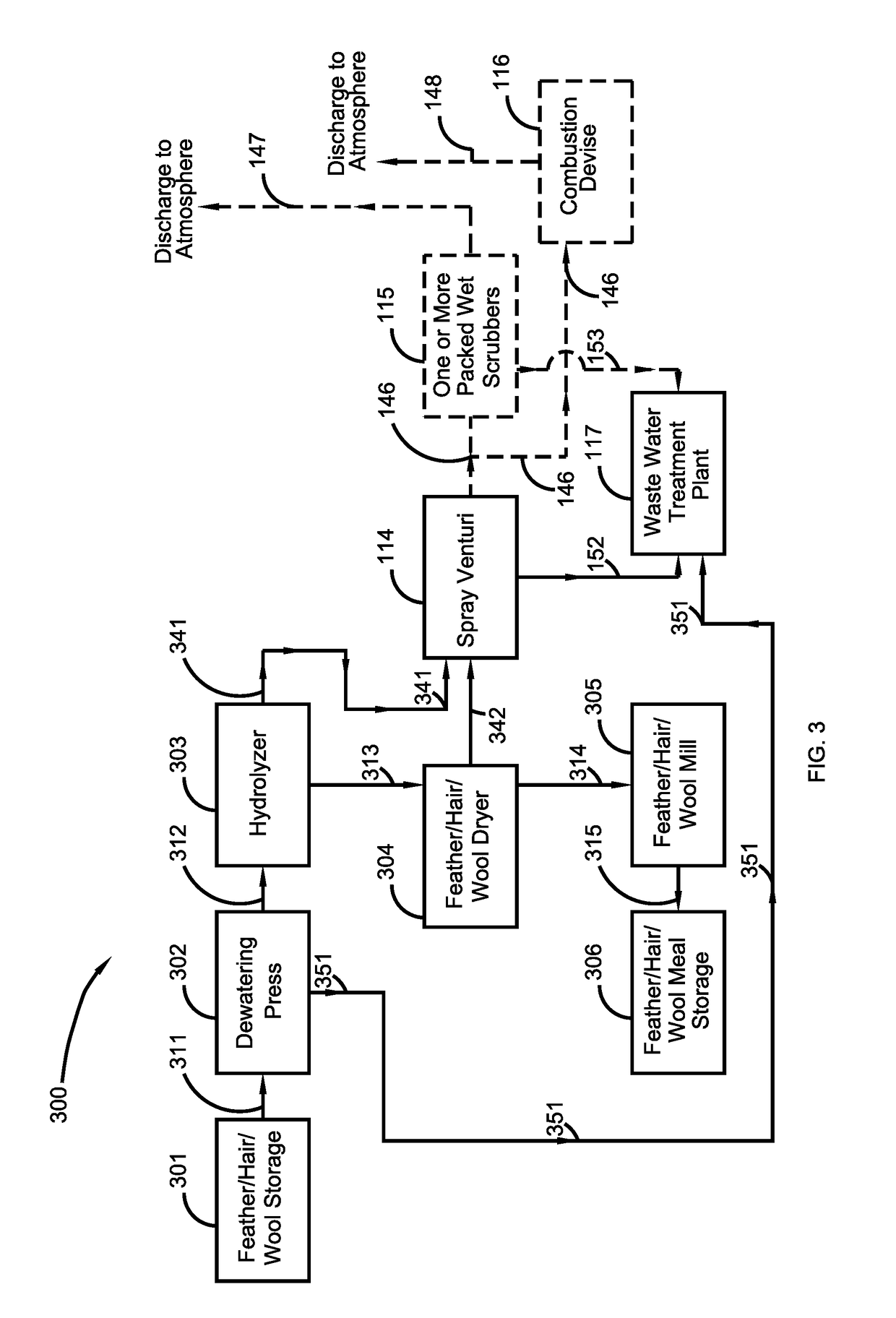

Methods for Treating Industrial Waste Streams and Recovering Certain Chemical Compounds

InactiveUS20170136386A1Easy to storeEasy to sellGas treatmentUsing liquid separation agentLiquid wasteWaste stream

The invention relates to methods and equipment for treating industrial vapor and liquid waste streams to remove certain compounds and concentrate those compounds to produce a chemical product. Specifically, the invention related to methods and equipment for condensing vapor waste streams and combining those streams with other liquid waste streams, and processing those combined streams to separate certain compounds for further processing into a chemical product, such as a fertilizer, and to thereby to reduce pollution, odor, and nutrient loading to air and water resources and wastewater processing systems.

Owner:TEMPLE STEPHEN R +1

Microwave Integrated Soxhlet

InactiveUS20100022788A1Overcome limitationsDistillation regulation/controlPreparing sample for investigationMicrowaveChemistry

The present invention relates to a new method of extraction of solid compounds by microwaves and to the apparatus used in said method.

Owner:MILESTONE SRL +1

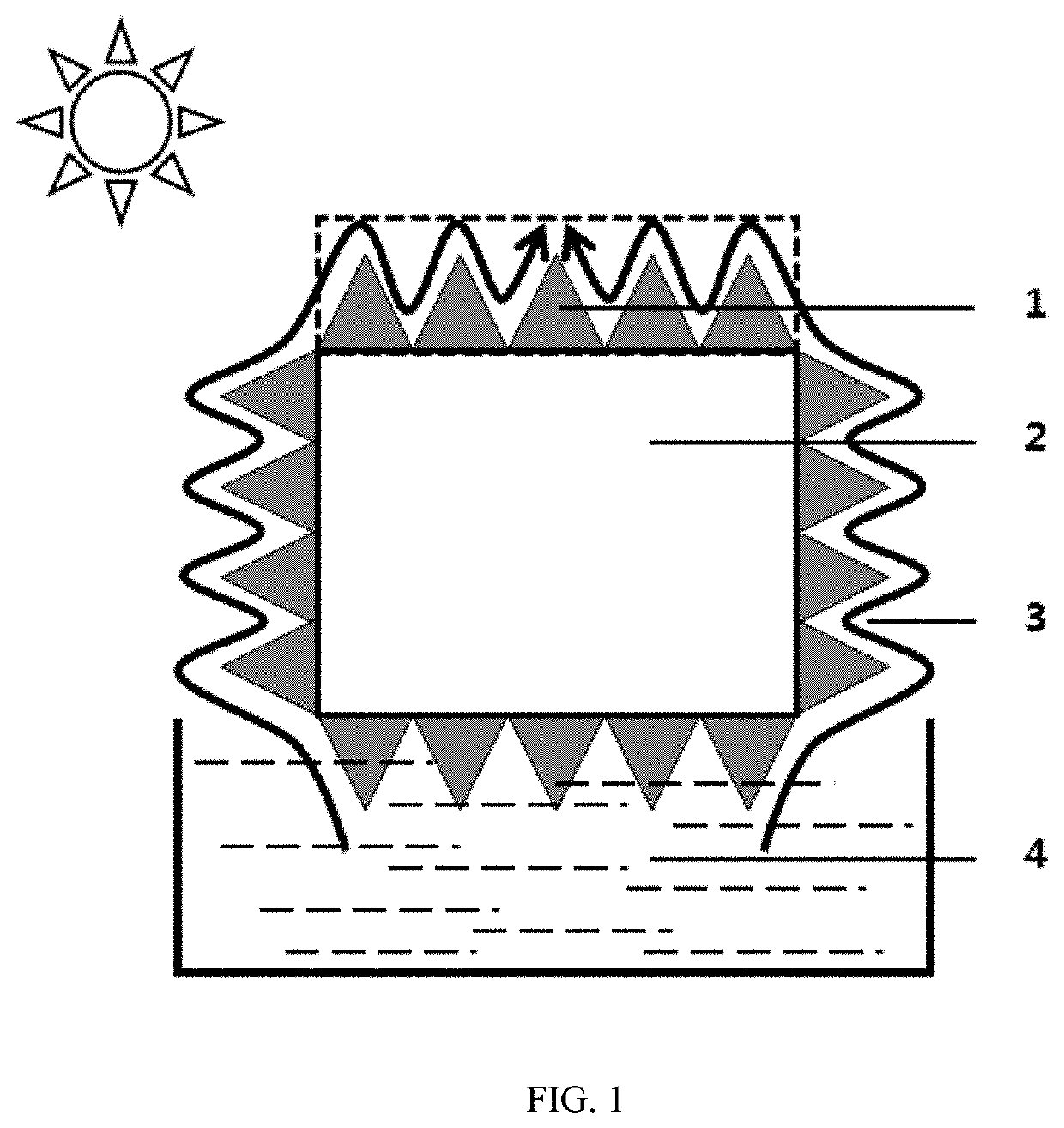

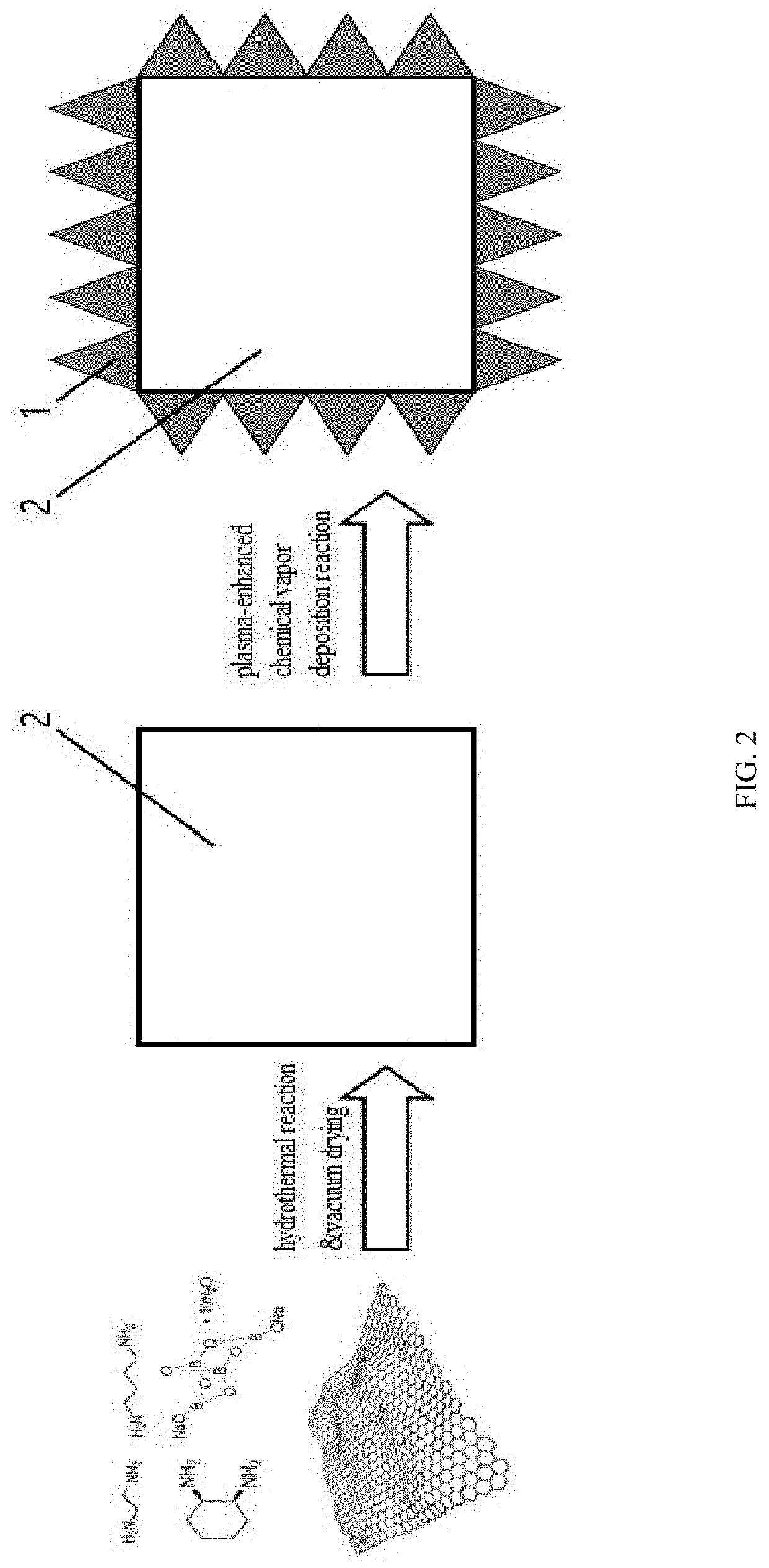

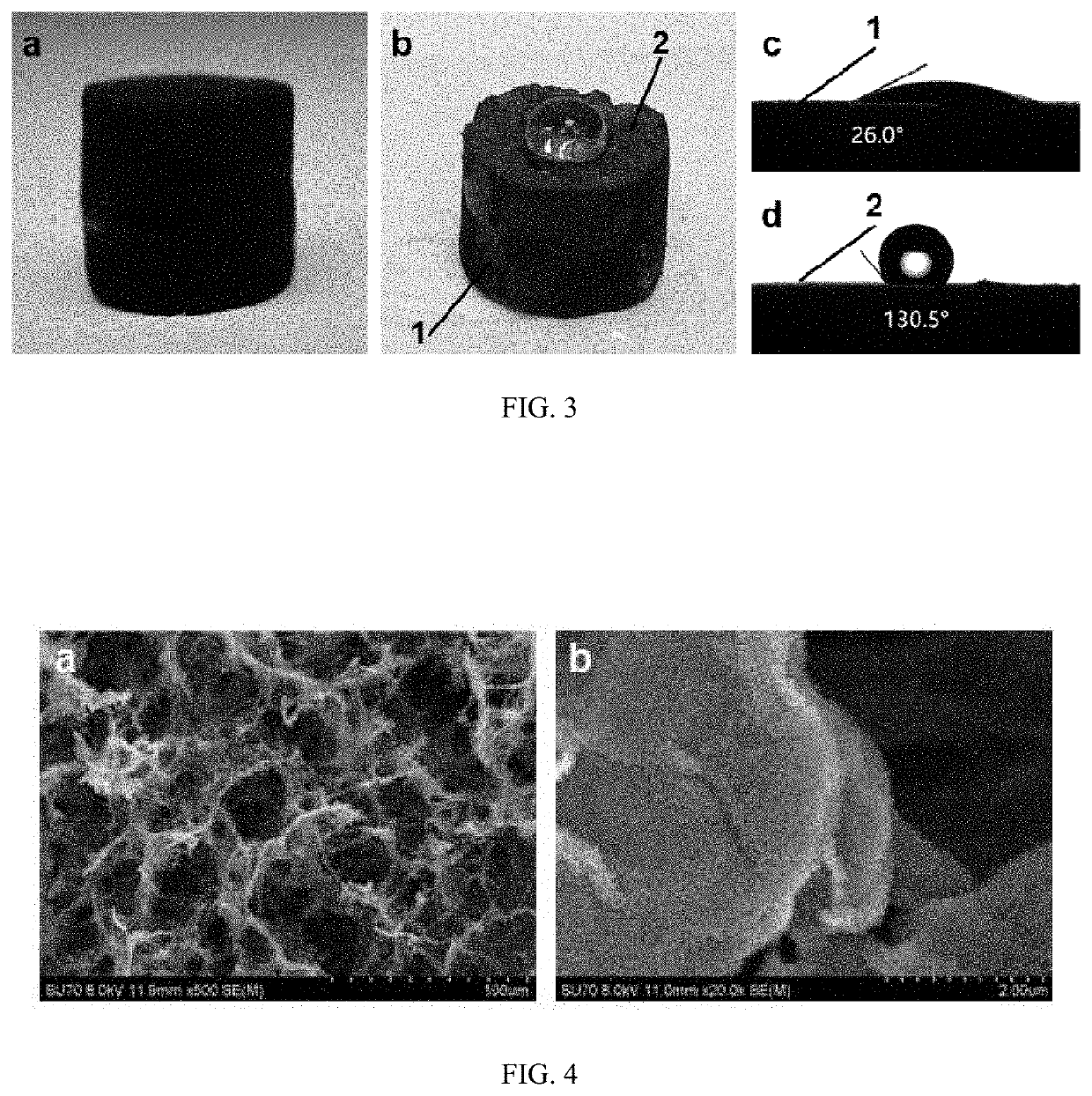

Photothermal evaporation material integrating light absorption and thermal insulation, preparation application thereof, use thereof

PendingUS20210253431A1Improve system stabilityEasy to separateGeneral water supply conservationGraphiteThermal insulationGraphene foam

The invention discloses a photothermal evaporation material integrating light absorption and thermal insulation, comprising a heat insulator and a light absorber that covers the external surface of the heat insulator, the light absorber is vertically-oriented graphene, the heat insulator is a graphene foam, and the vertically-oriented graphene and graphene foam are connected by covalent bonds; the light absorber is vertically-oriented graphene whose surface is modified with hydrophilic functional groups. The invention also discloses a method for fabricating the photothermal evaporation material integrating light absorption and thermal insulation. The invention also discloses a solar energy photothermal seawater desalination device and a high-temperature steam sterilization device. The photothermal evaporation material integrating light absorption and thermal insulation overcomes the problem of easy separation between the light absorber and the heat insulator, realizes rapid and efficient photothermal evaporation, and improves the stability and photothermal conversion efficiency of the solar photothermal seawater desalination device and the high-temperature steam sterilization device.

Owner:ZHEJIANG UNIV

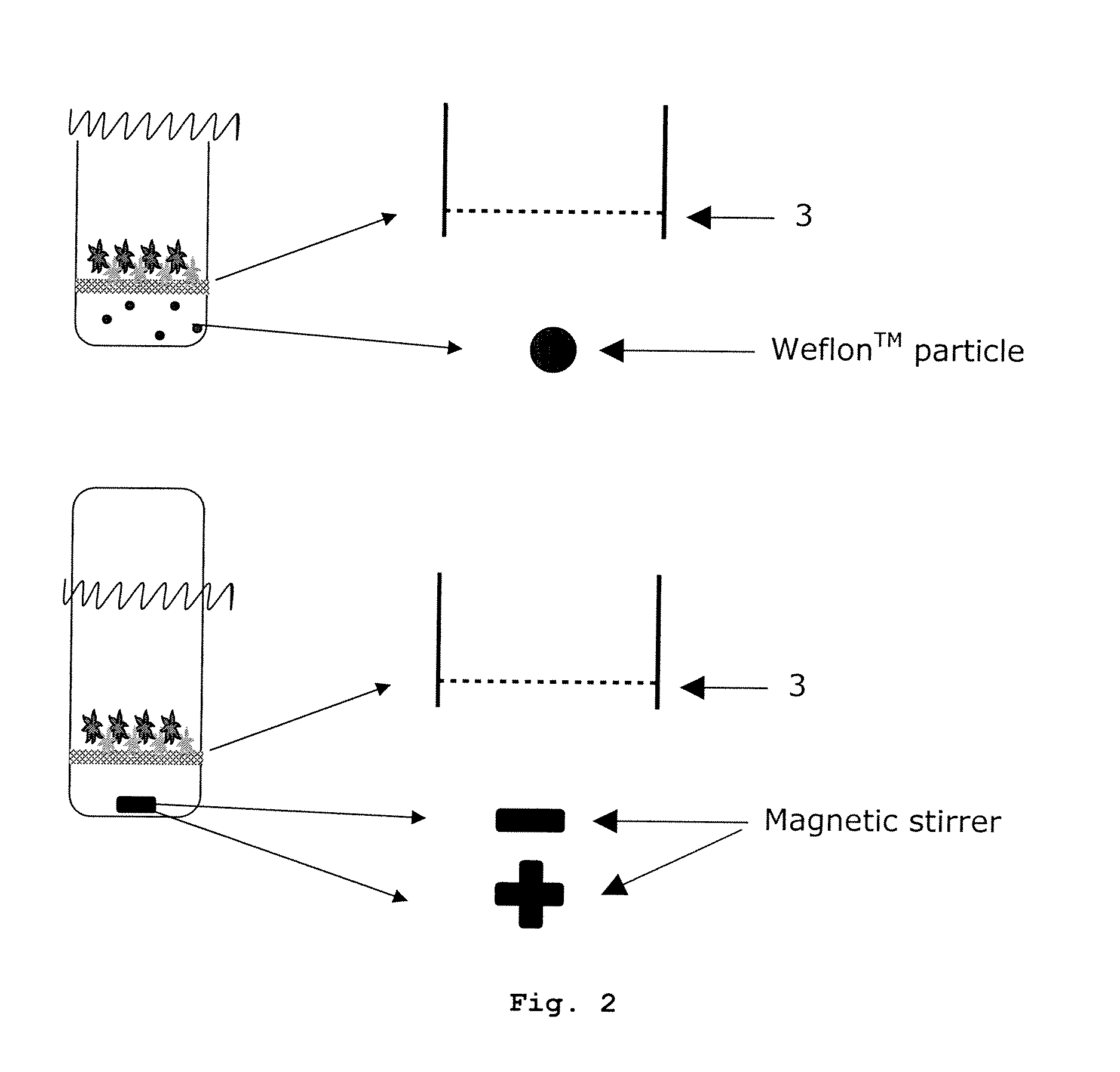

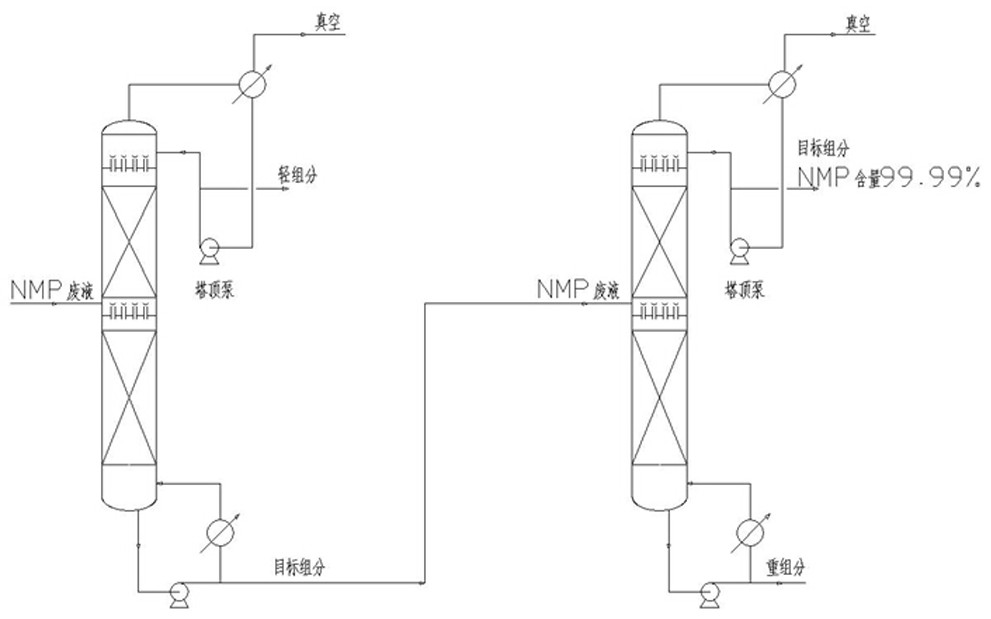

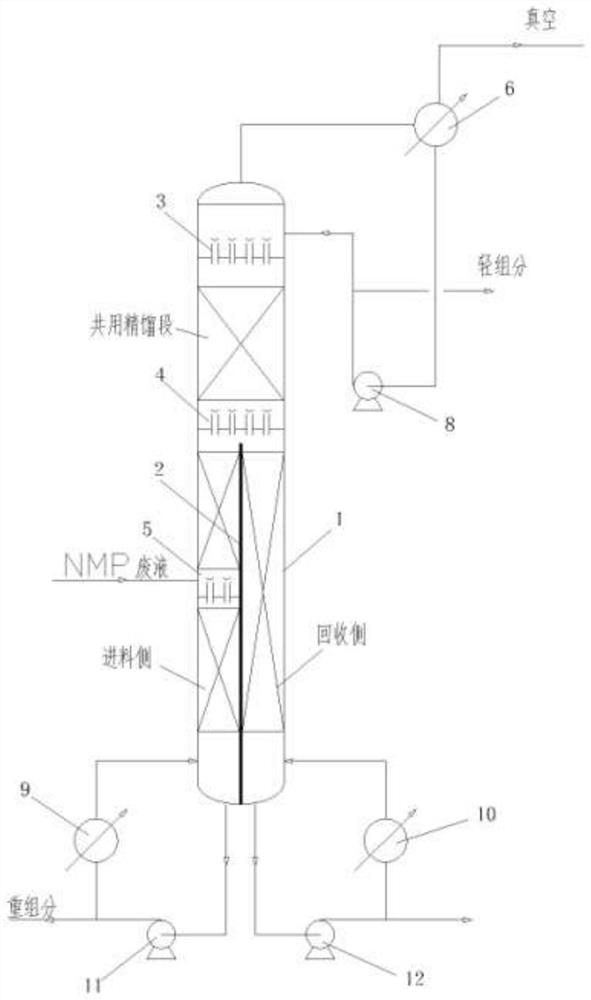

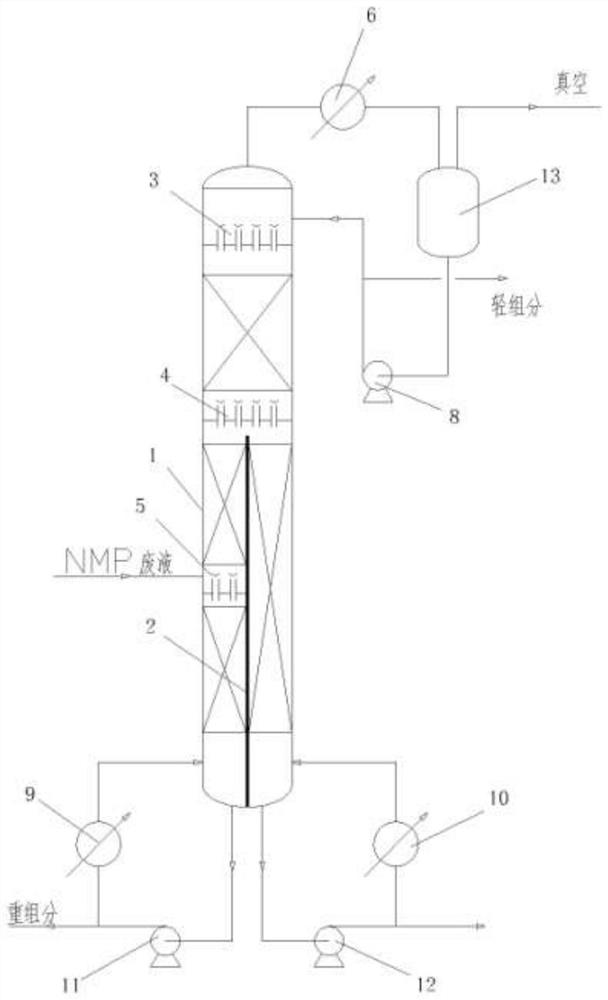

Organic waste liquid recovery equipment and method thereof

PendingCN112494973AAchieve enrichmentReduce in quantityOrganic chemistryReflux condensationProcess engineeringEnvironmental engineering

Owner:湖南化工设计院有限公司

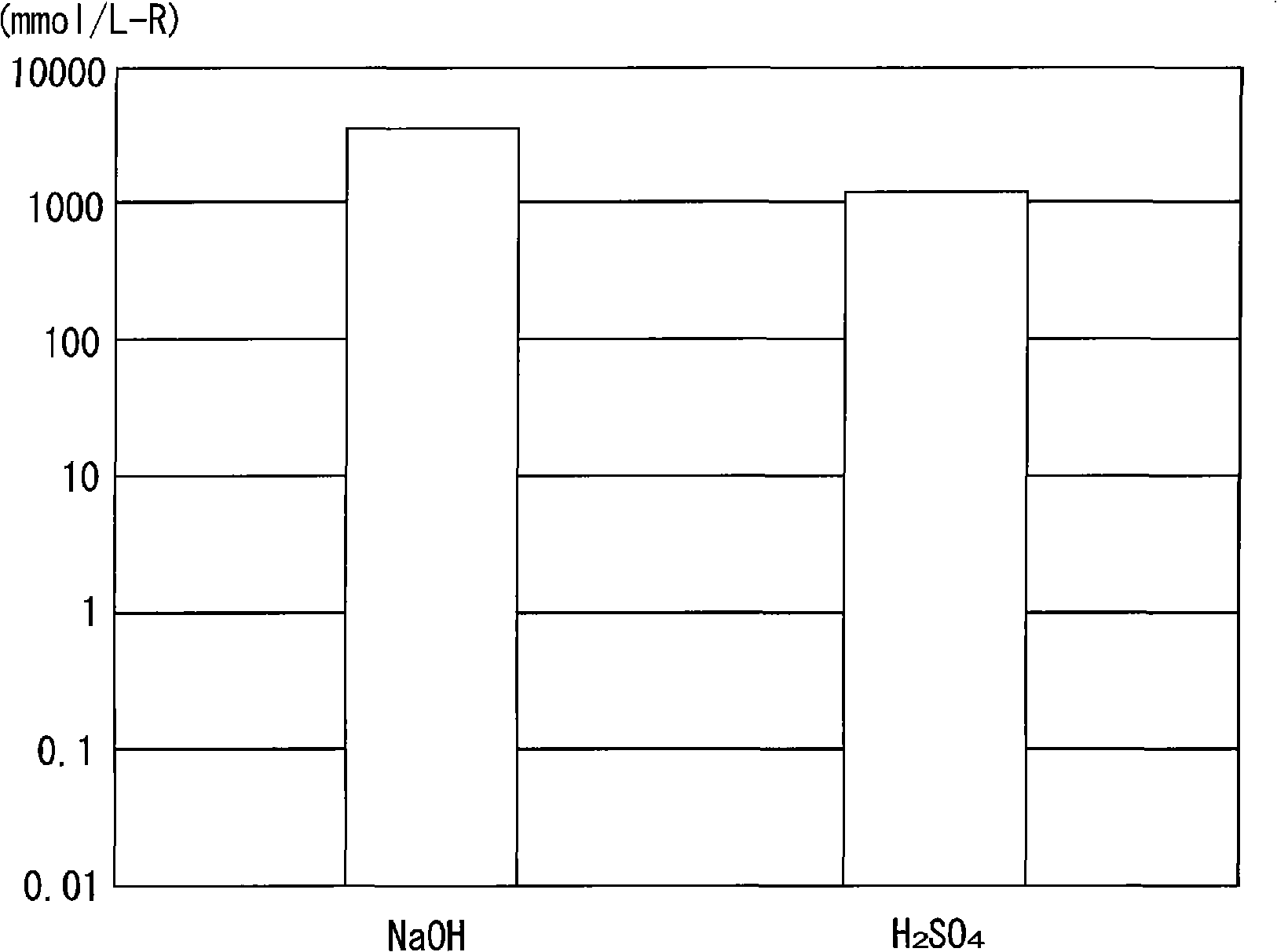

Hydrofluoric acid production apparatus and hydrofluoric acid production method

InactiveCN101277899AImprove production efficiencyInhibition decreasedWater contaminantsChemical industrySorbentDistillation

In the production of hydrofluoric acid by holding fluorine by adsorption from a drainage water or waste water containing fluorine with an inorganic ceramic adsorbent mainly composed of active alumina and silicon dioxide and producing hydrofluoric acid from the adsorbent provided after the adsorption, the object is to increase the efficiency of production of hydrofluoric acid and prevent the degradation of the adsorbent. A hydrofluoric acid production apparatus for producing hydrofluoric acid by holding a fluorine ion by adsorption from a fluorine compound or fluorine mixture which contains a fluorine ion with a ceramic adsorbent mainly composed of active alumina and silicon dioxide and producing hydrofluoric acid from the adsorbent provided after the adsorption, the apparatus comprising a distillation means for reacting the adsorbent with a strong alkali or strong acid and generating hexafluorosilicic acid gas by addition of crystalline silicon dioxide, and a cooling means for cooling and hydrolyzing the hexafluorosilicic acid gas produced in the distillation means to produce hydrofluoric acid.

Owner:日本顶点株式会社 +1

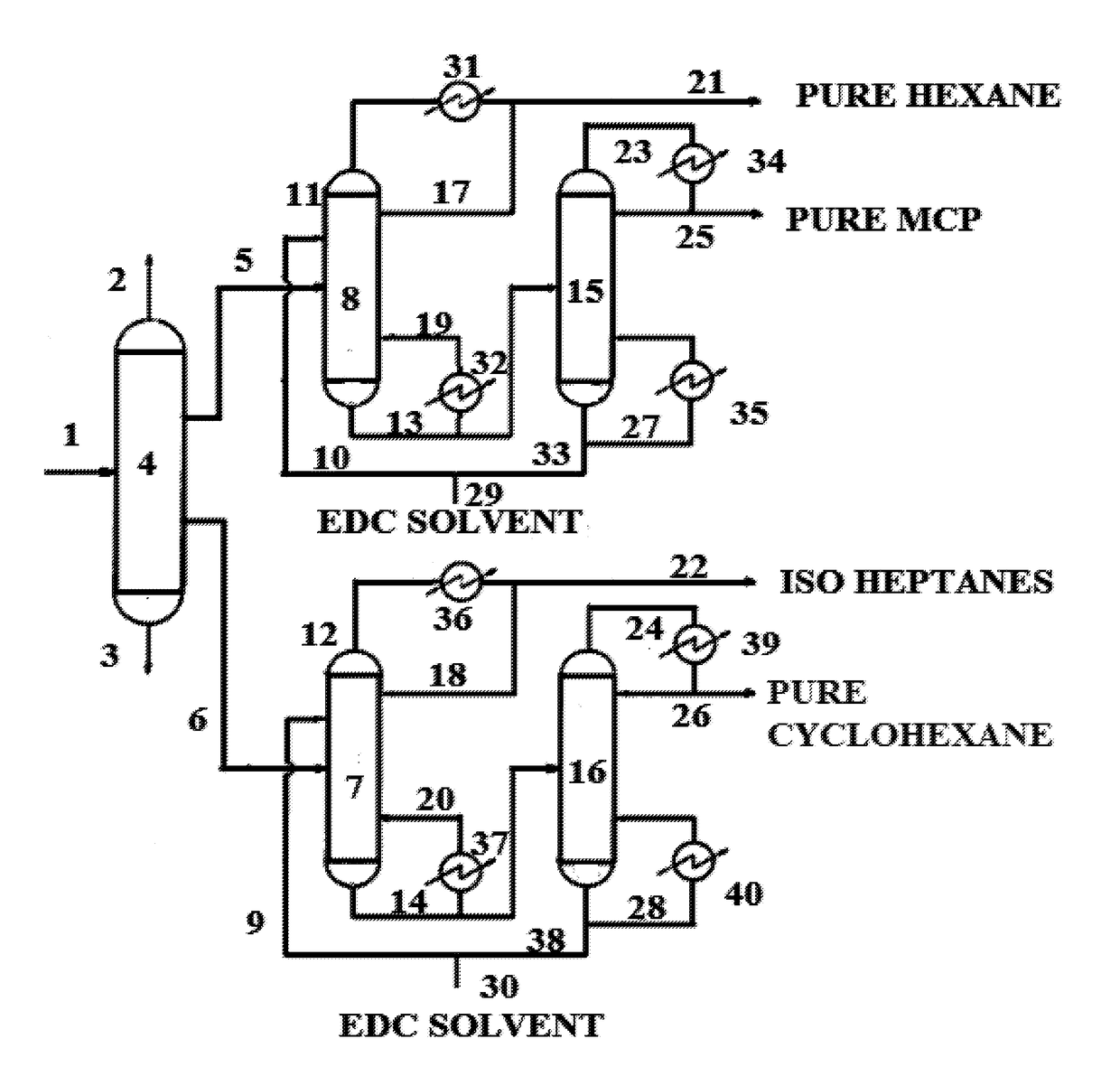

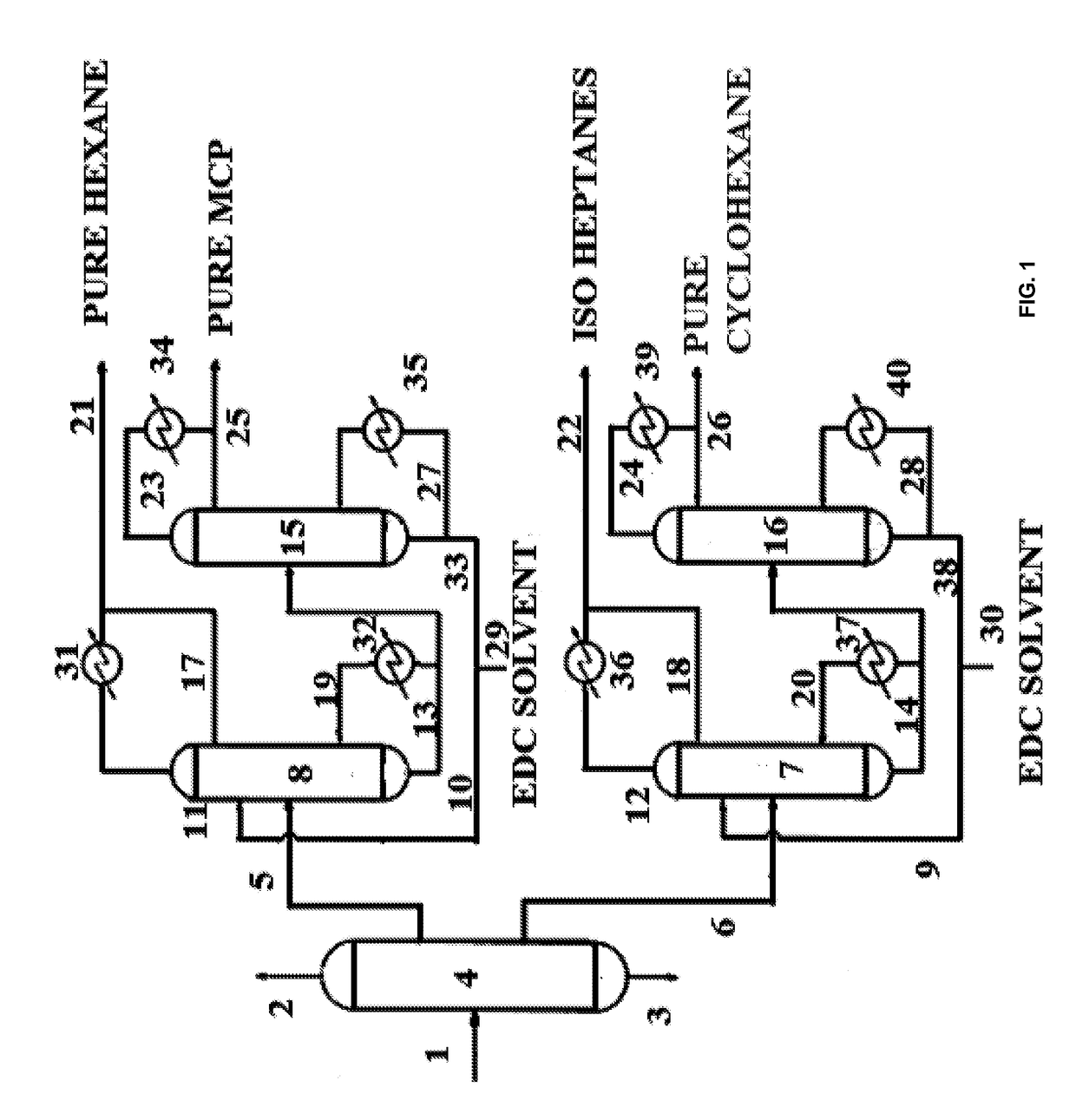

Process for high purity hexane and production thereof

ActiveUS20170203231A1Distillation purification/separationFractional condensation purification/separationBenzeneOrganic solvent

The invention relates to the production of High purity n-hexane from low value stream such as raffinate from benzene extraction unit in crude oil refineries employing extractive distillation. The present invention further related to an extractive distillation employing an organic solvent having comparable or same Hansen dispersive force parameter (δd) of that of the key component of to be separated through extractive distillation. The present invention is useful for separating and isolating pure cyclohexane, pure methylcyclopentane and pure iso-heptane along with the pure n-hexane.

Owner:INDIAN OIL CORPORATION

Re-direction of vapor flow across tubular condensers

InactiveUS20170307300A1Reduces and even eliminatesHeat exhanger conduitsSteam/vapor condensersVapor liquidDistillation

Vapor flow-diverting devices that re-direct upwardly flowing vapor, for example, in a downward direction across condenser tubes disposed in the upper or top section of a vapor-liquid contacting apparatus, are described. These devices are particularly beneficial in tubular condensers within distillation columns and may be used in combination with other associated equipment (e.g., a deflector plate and divider plate) as well as in combination with the tube surface enhancements to improve the heat transfer coefficient.

Owner:UOP LLC

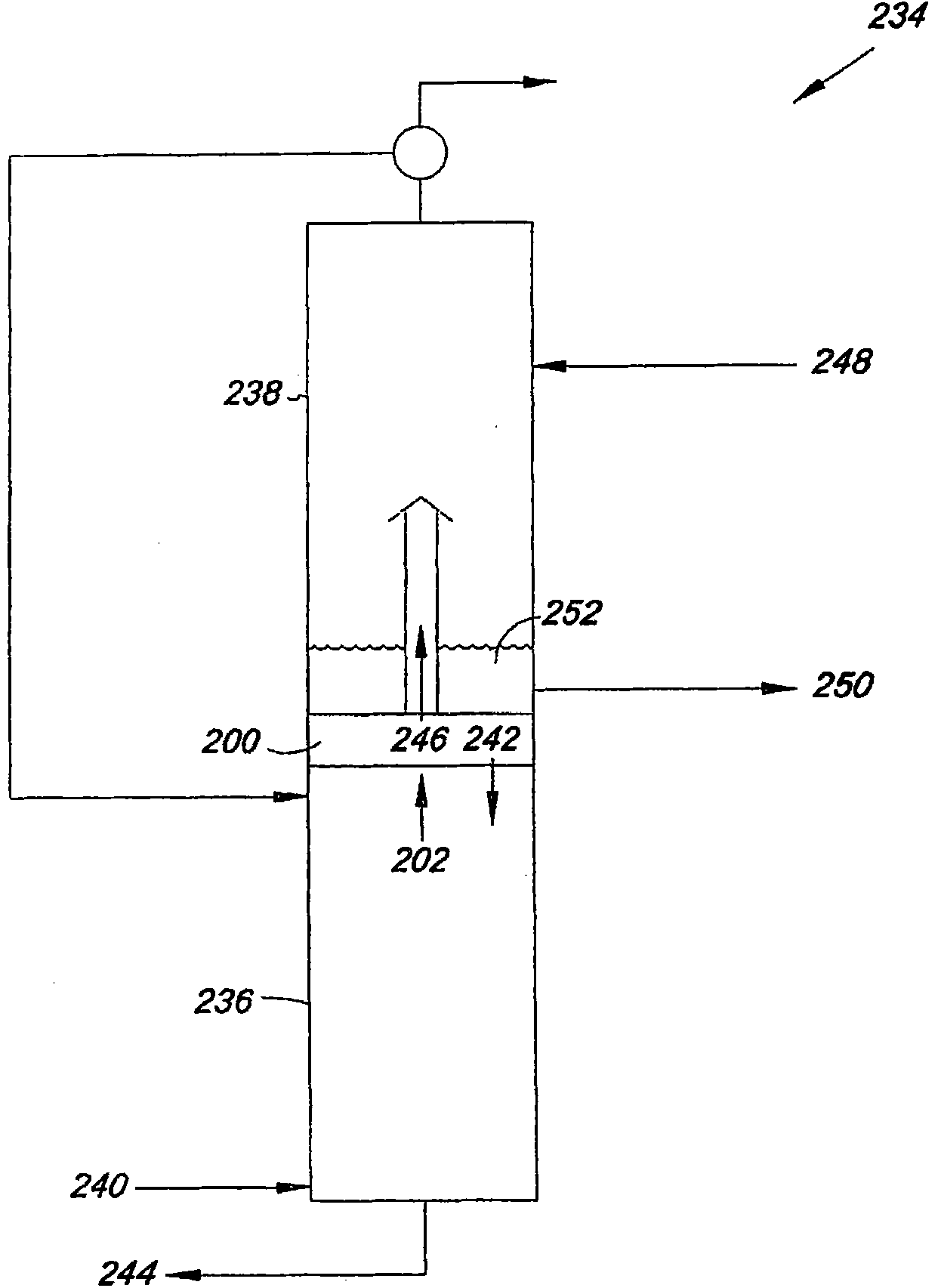

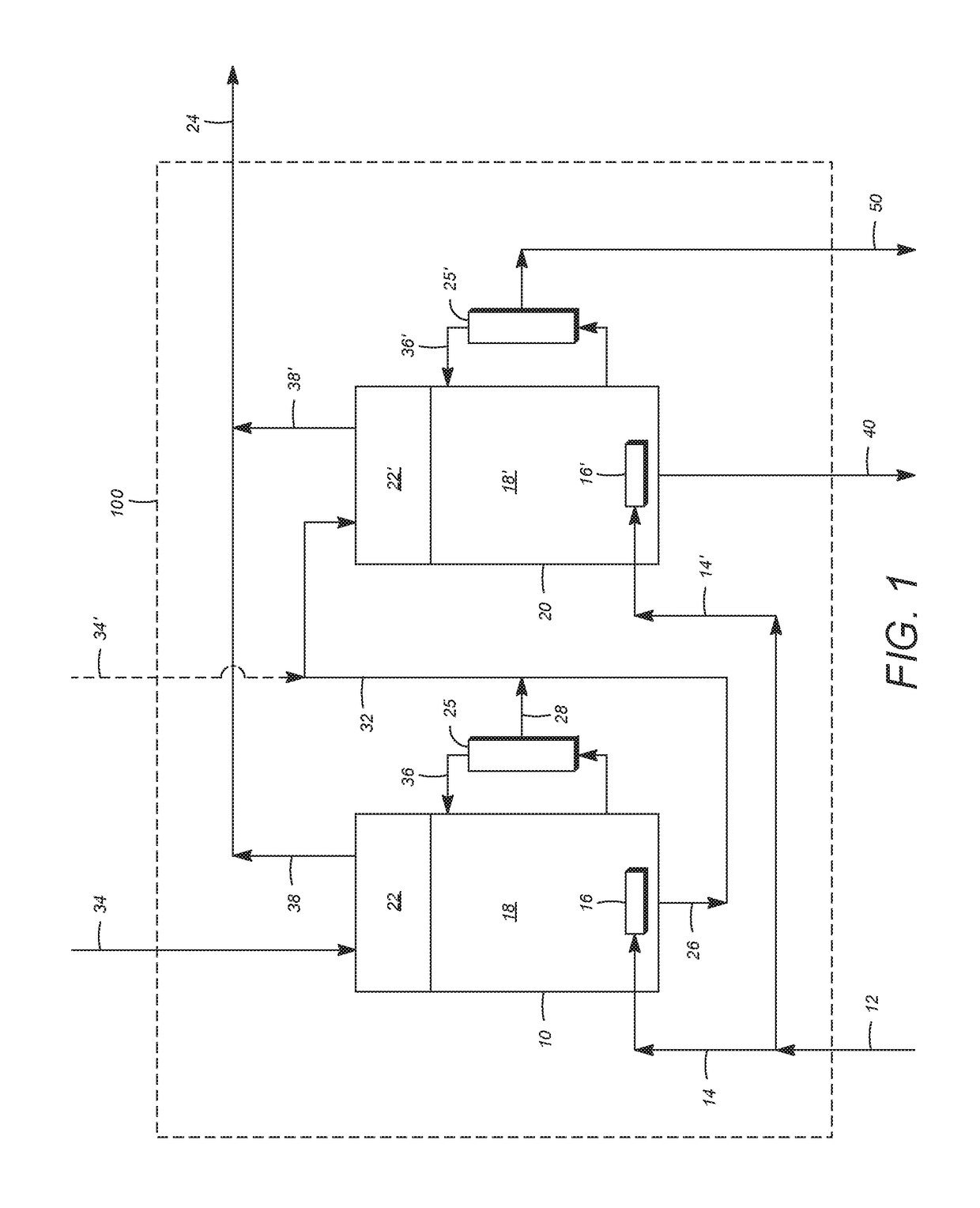

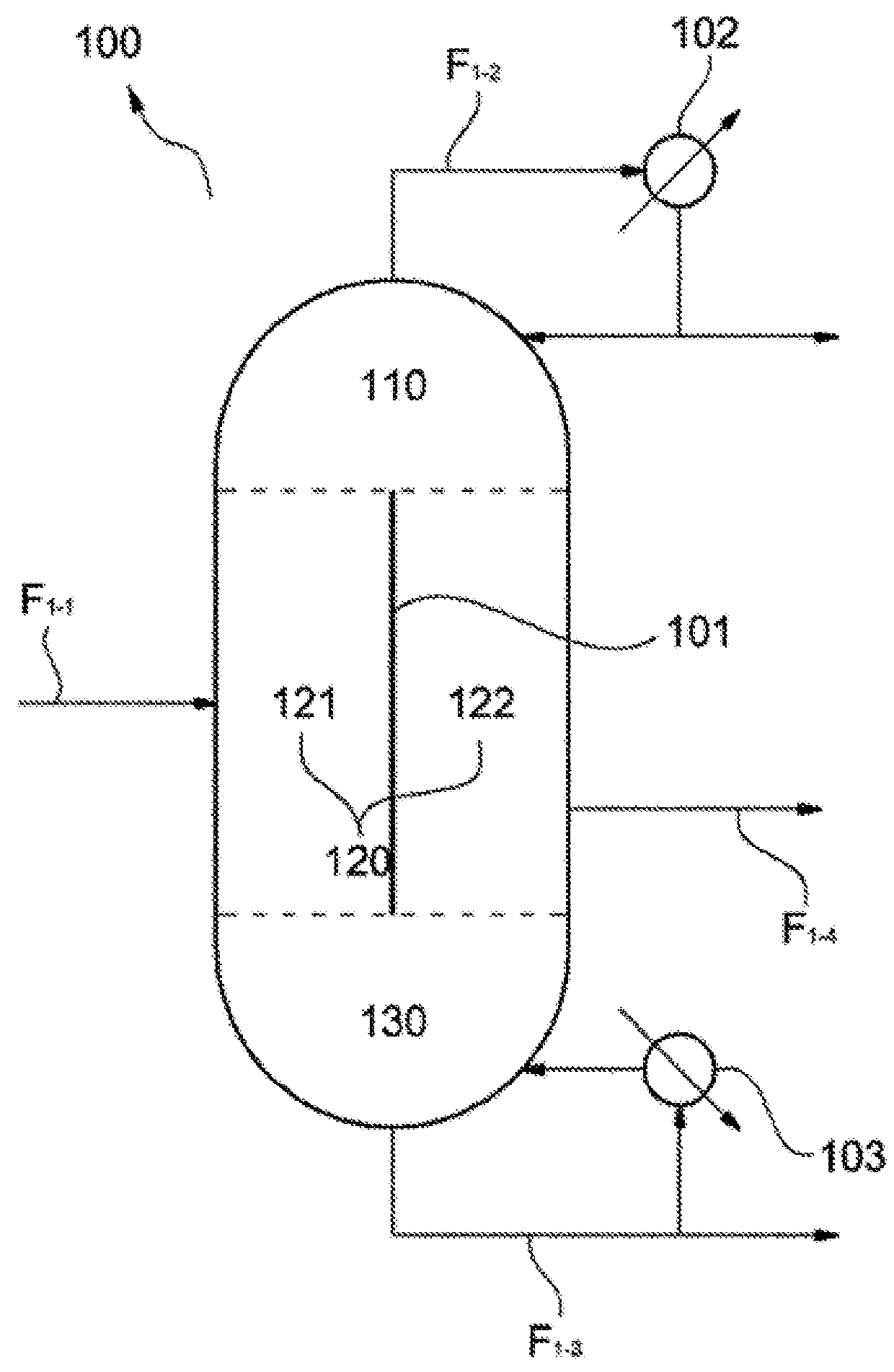

Low pressure separator having an internal divider and uses therefor

ActiveUS10010807B2Easy to keepHigh degree of controlFermented solutions distillation/rectificationBacteriaExhaust fumesEnvironmental engineering

Improvements in biological conversion processes and associated apparatuses are disclosed for the generation of useful end products such as ethanol, through metabolic pathways of C1-fixing bacteria that utilize, as a nutrient, a C1-carbon source from a C1-containing substrate such as an industrial waste gas. Particular aspects of the disclosure relate to the downstream recovery of ethanol and / or isopropanol from bleed and permeate streams and more particularly to performing such recovery with improved efficiency that can advantageously reduce capital (e.g., equipment) and / or operating (e.g., utility) costs. Particular aspects related to the downstream recovery of ethanol and / or isopropanol using a low pressure separator having an internal divider.

Owner:LANZATECH NZ INC

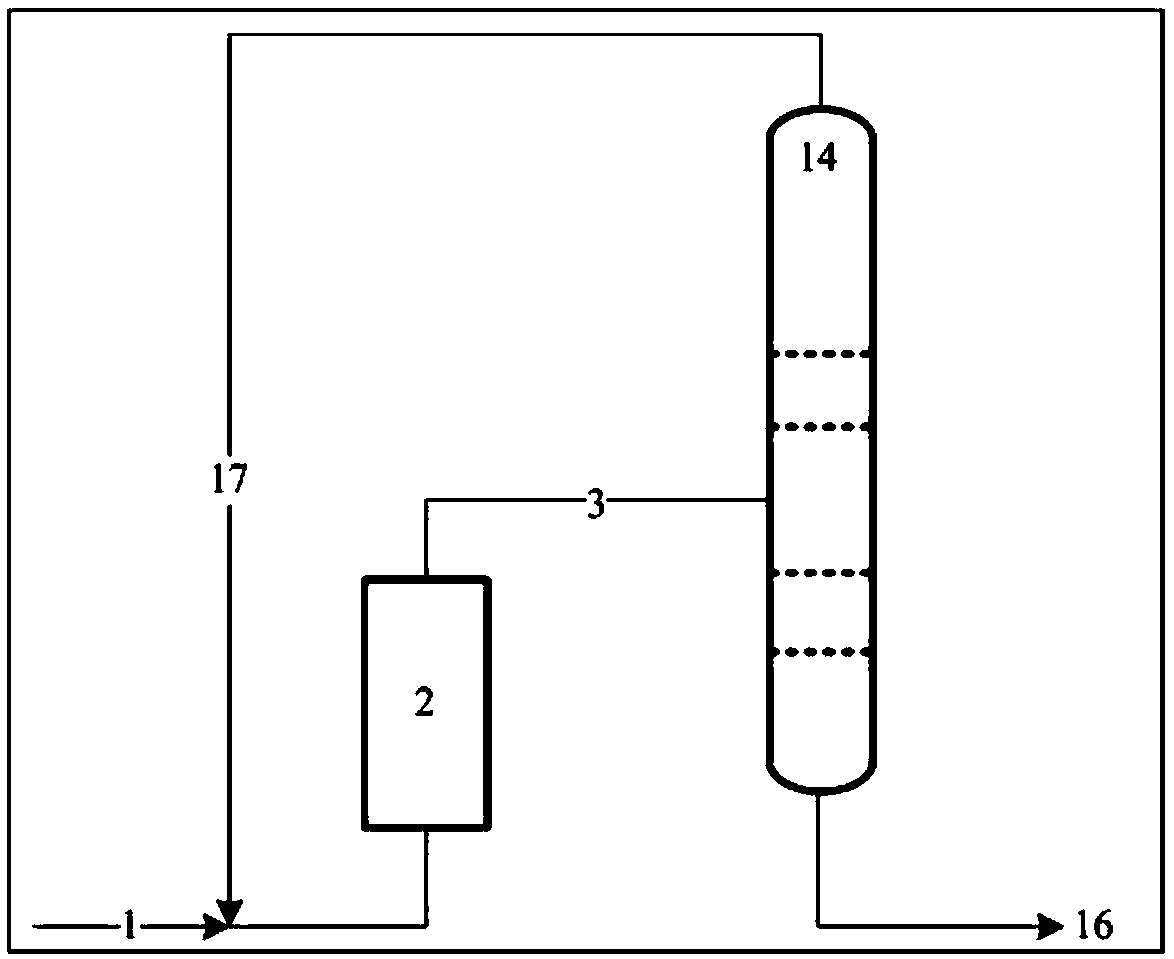

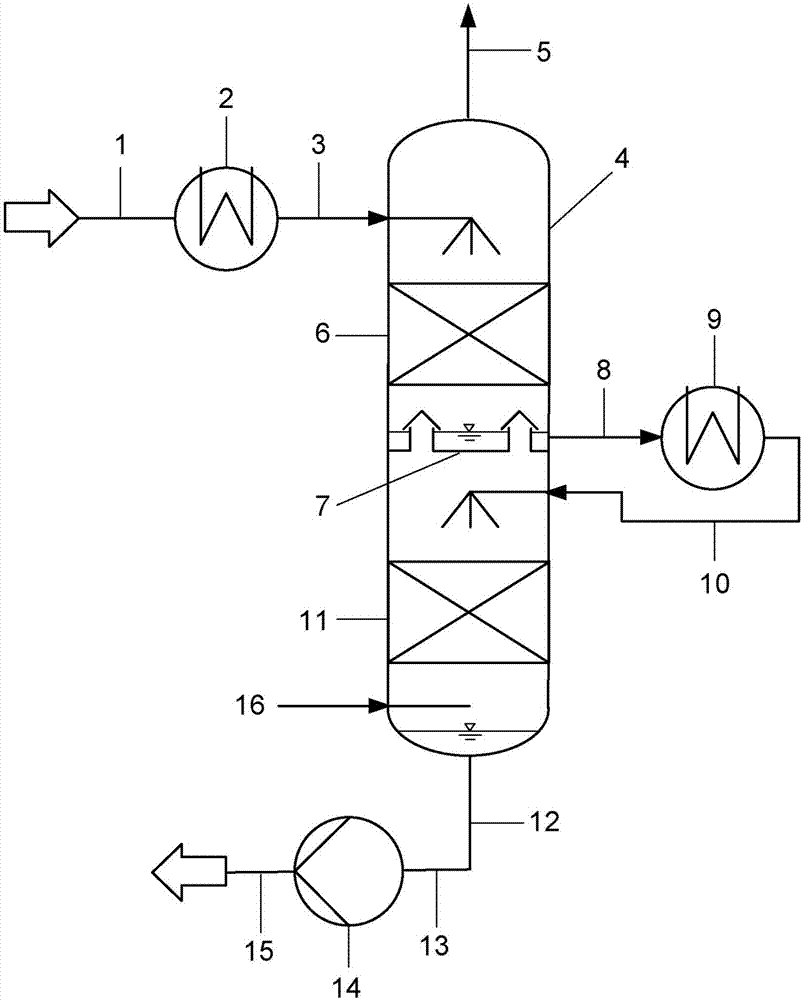

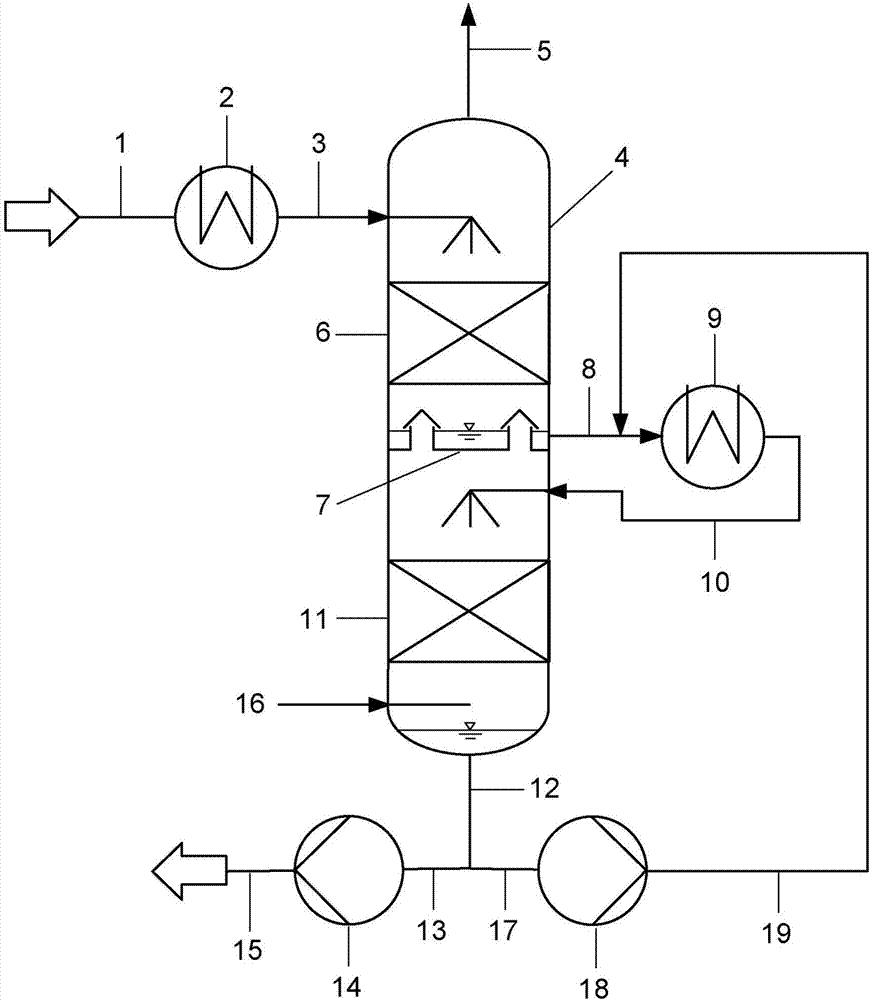

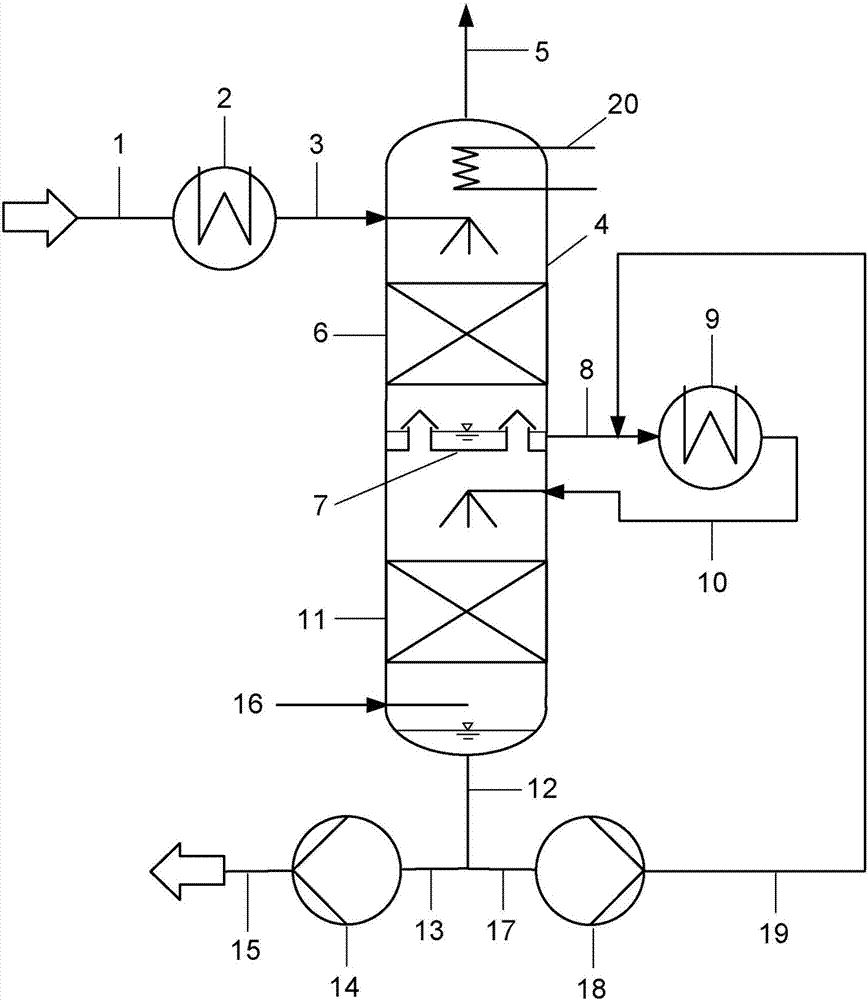

Washing apparatus for separation of methanol from gas

Provided a washing apparatus for separation of methanol from gas. According to the invention, a washing apparatus and process for the efficient separation and recovery of methanol from waste gases loaded with methanol are proposed, wherein the invention also can be used in an integrated flow chart for the production and processing of methanol. The methanol fractions separated from the waste gases are recovered within the already existing, distillative processing of the crude methanol to pure methanol, so that no separate apparatuses are required for the recovery of the methanol from the loaded scrubber waste waters. The valuable substance methanol is recovered and the impact on the environment is reduced. By particular aspects of the invention the total degree of methanol separation can be adapted according to the locally applicable emission limit values.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

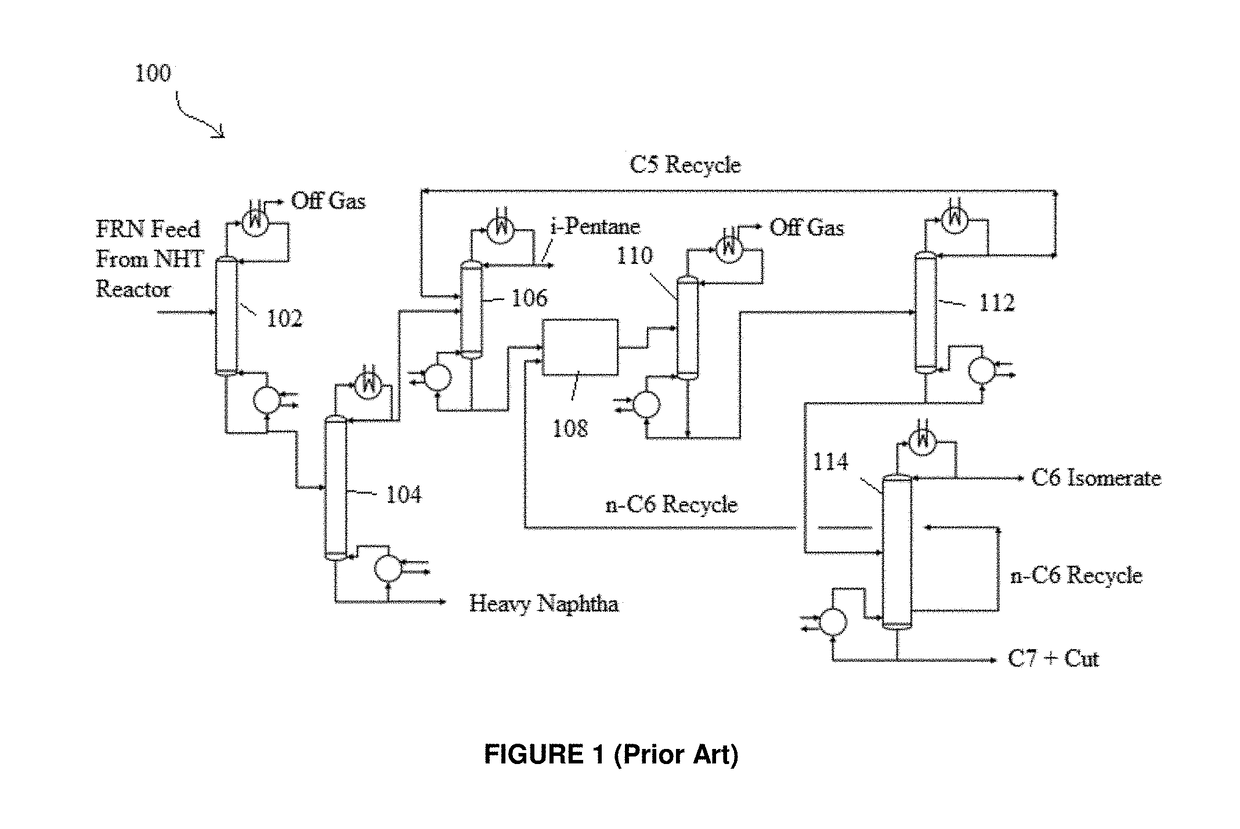

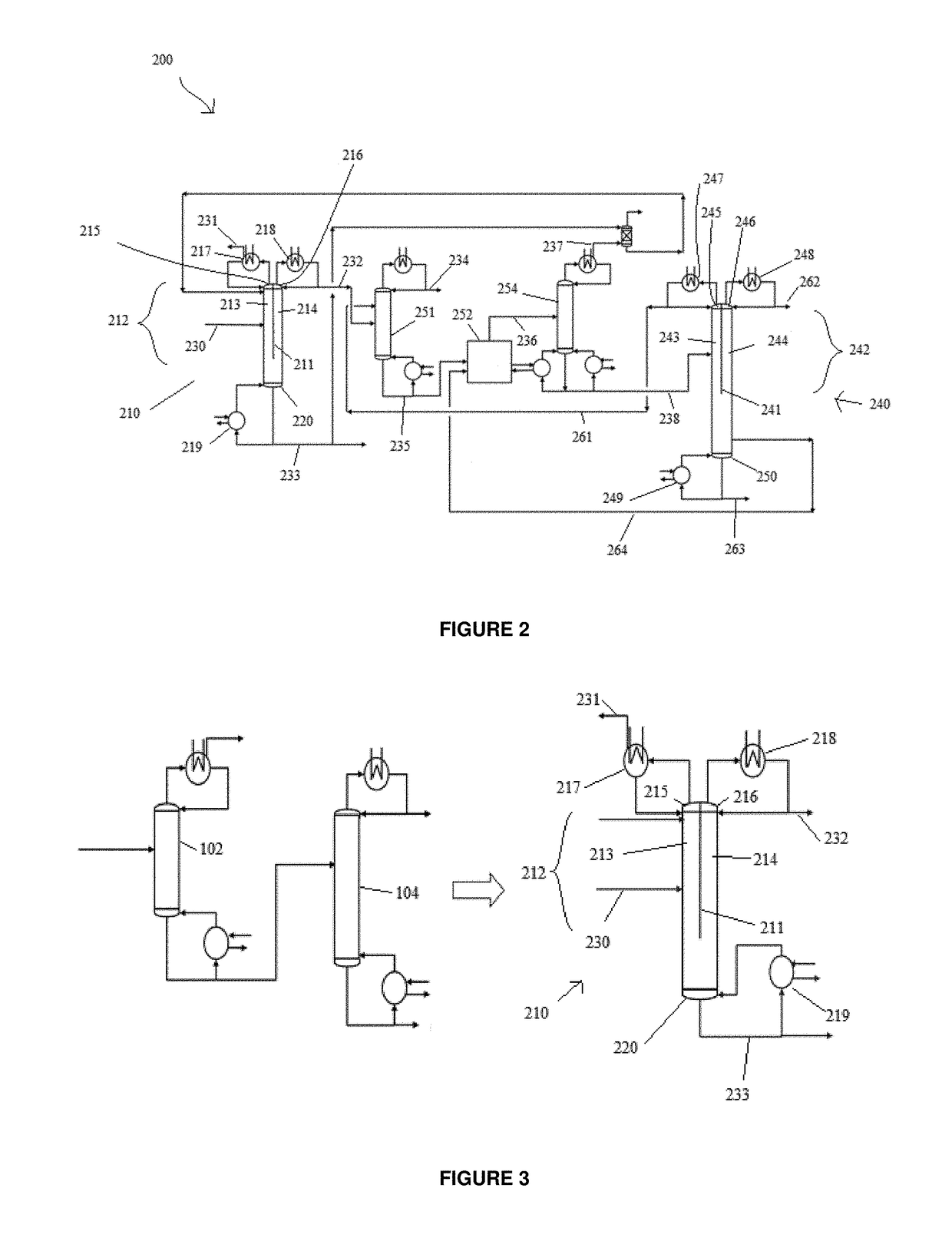

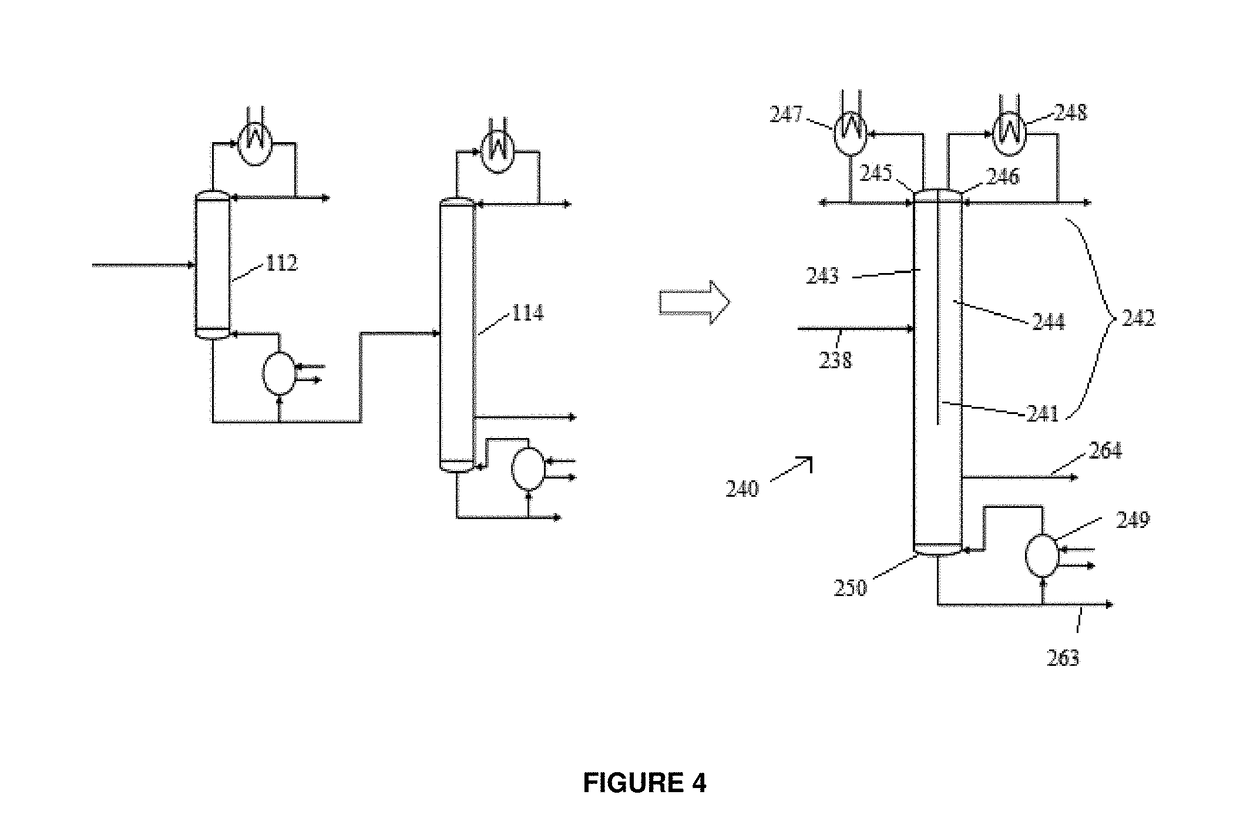

Use of top dividing wall in isomerization unit

ActiveUS20190083898A1Reduce use costImprovement to efficiency and costHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonNaphthaIsomerization

The invention is directed to a combined naphtha hydrotreating (NHT) and isomerization process scheme, which includes dividing wall columns (DWC) that replace multiple distillation columns and allow optimized heat integration within the system. The disclosed design provides reductions in both capital and energy costs compared to conventional schemes.

Owner:SULZER MANAGEMENT AG

Distillation device

ActiveUS20180178141A1Economic feasibility of processReduce installation costsDistillation in boilers/stillsSolid-state devicesResistDistillation

By using the distillation device of the present application, energy loss occurring in a purification process of a solution including a waste stripper and a stripped photoresist resin used in a stripping process of a photoresist can be minimized and the installation cost of the distillation device can be reduced compared to the case in which dual distillation columns are used, thereby increasing the economic feasibility of a process.

Owner:LG CHEM LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com