Vaporizing separator for liquid medium and the like

A technology of liquid medium and separation device, which is applied in the direction of distillation separation, separation method, fractionation, etc., which can solve the problems of reduced accuracy of liquid level detection, difficulty in measuring changing liquid level, failure to meet requirements, etc., and achieve reliability and safety High, corresponding to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

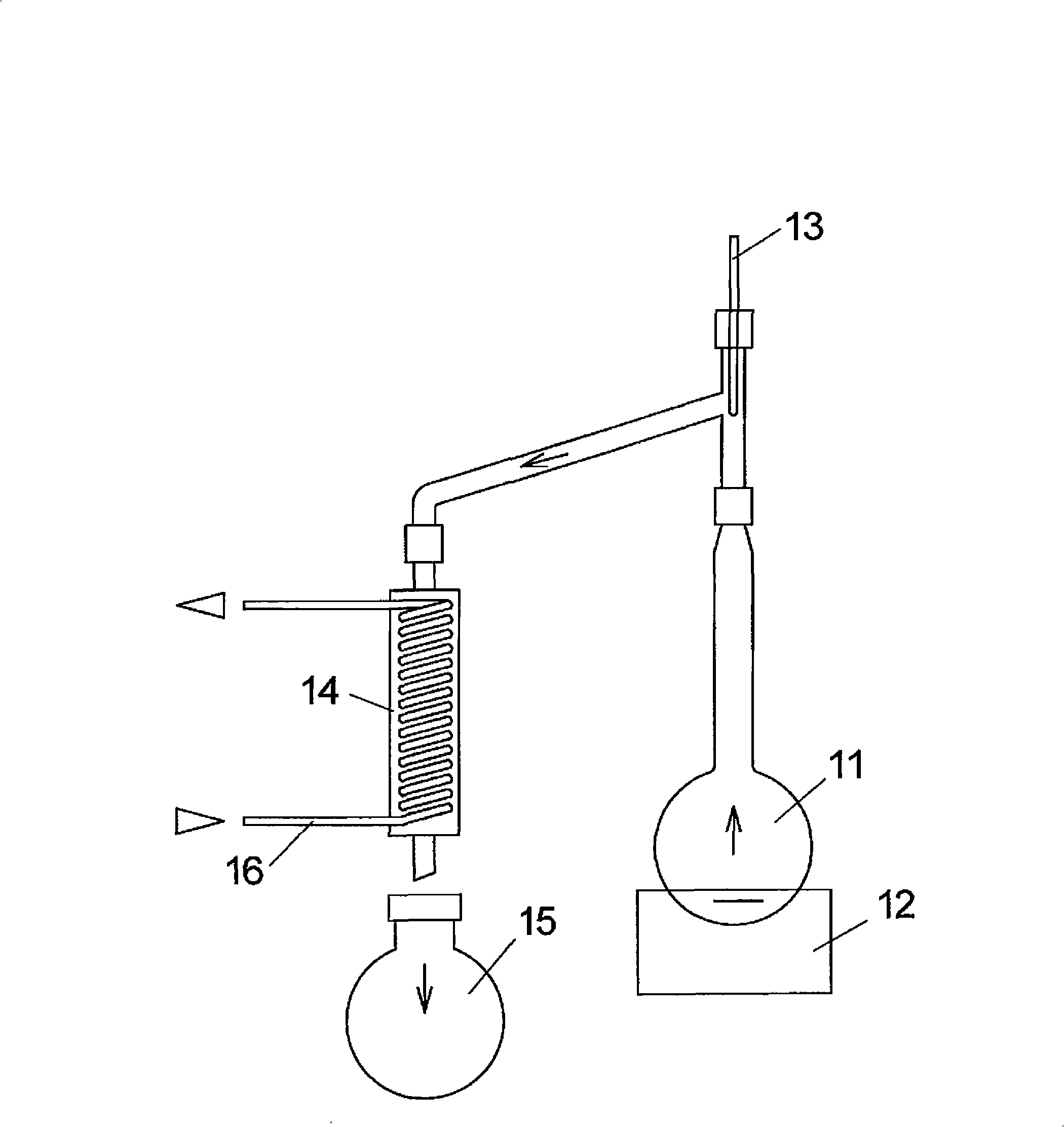

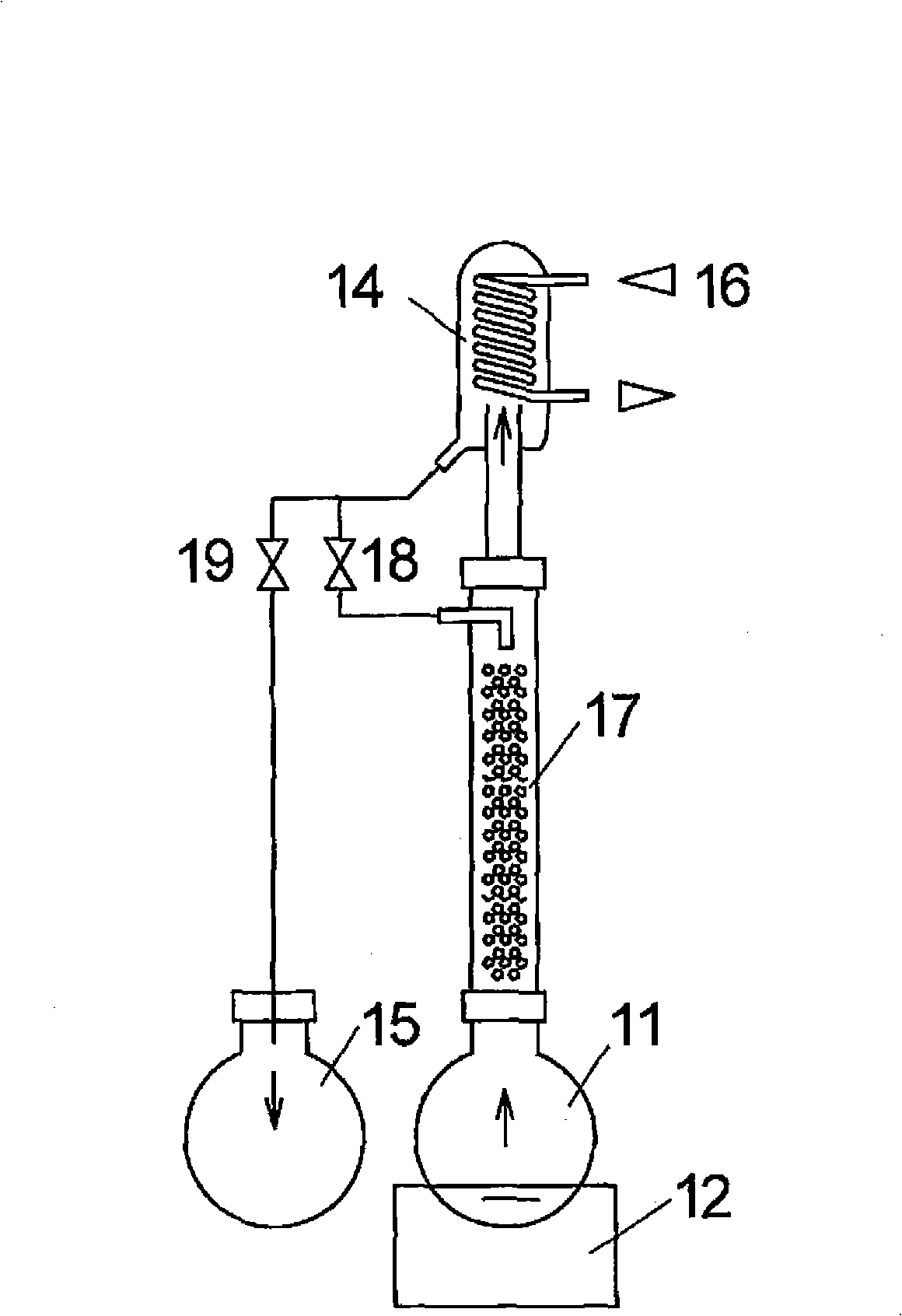

Embodiment 1

[0202] In the liquid medium and mixed liquid vaporization separation device 10 of the present invention, first, the container 110 (flask type 10 L capacity) is heated to 35° C. with a hot water bath, and a refrigerant (-10 L) is supplied to the cooling condenser 140 for condensation. °C), and then the rotation (stirring) of the container 110 was started using a large-scale rotary evaporator for solvent evaporation, and detection control for operation preparation was performed.

[0203] Next, the pump 200 was operated for about 5 minutes to discharge the remaining volatile substances in the pump.

[0204] Next, reduce the pressure inside the device (vaporization separation device 10) to the setting value A-1 (-80.0 kPa) of the composite pressure gauge S2. Next, the methanol solution is injected from the unrefined stock solution tank 156 .

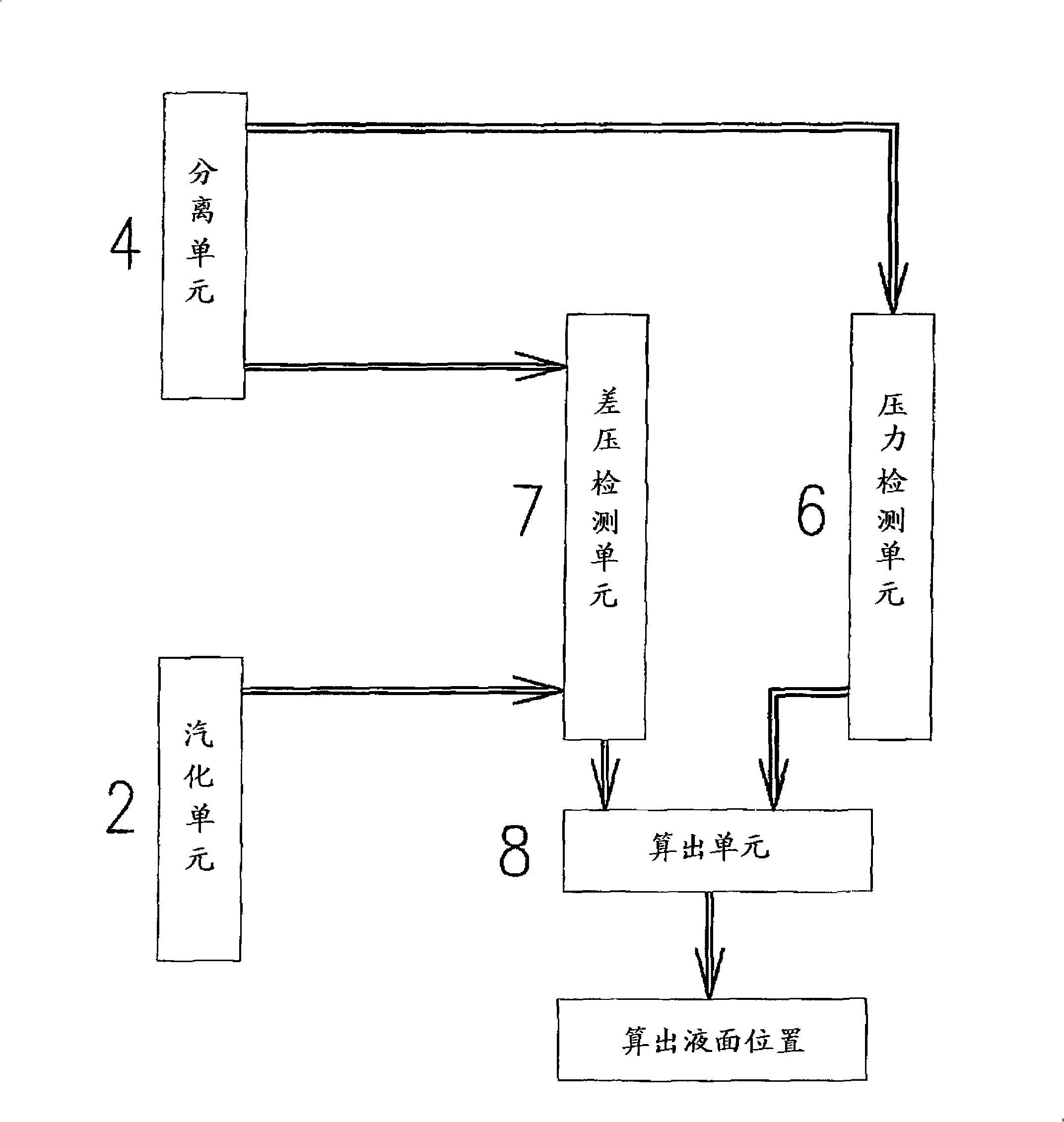

[0205] Next, the liquid level position in the container is measured. That is, comparison with the set value B-1 (0.5 kPa) of the differen...

Embodiment 2~9

[0210] The same procedure as in Example 1 was performed except that the type of recovery solvent and the heating bath were shown in Table 2.

[0211] Table 2 shows the results of Examples 1-9.

[0212] Table 2 Recovery of solvent under reduced pressure

[0213]

[0214] Solvent Recovery at Atmospheric Pressure

Embodiment 10

[0216] In the apparatus of the present invention, the same procedure as in "Example 1" was carried out up to the detection and control of the discharge of residual volatile substances due to the detection and control of the initial operation preparation and the detection and control of the liquid supply from the stock solution tank before refining. , so that the temperature of the heating bath is 65°C.

[0217] Then, the gas was flowed in until it reached the setting value F-2 (-1.0 kPa) of the composite pressure gauge, and the pressure of the gas was brought to atmospheric pressure.

[0218] Next, transfer to vaporization separation control. In this control, the diaphragm pump is operated to maintain the set value C-2 (approximately -5 kPa) of the composite pressure gauge S2 while supplying gas into the vaporization container. At the same time, the detection and recovery of the liquid level position are carried out. When it reaches the set value E-2 (0.2kPa) of the differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com