Reflux condenser

A reflux condenser and condenser technology, which can be used in reflux condensation, vapor condensation, tubular distiller, etc., can solve problems such as relative excess and yield loss of purified substances.

Active Publication Date: 2010-12-22

DOW TECH INVESTMENTS

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, in this process, if the overhead stream contains low formaldehyde concentrations, the relative amount of ethylene oxide therein may be in excess, resulting in a loss of yield of the desired purified material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0076]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

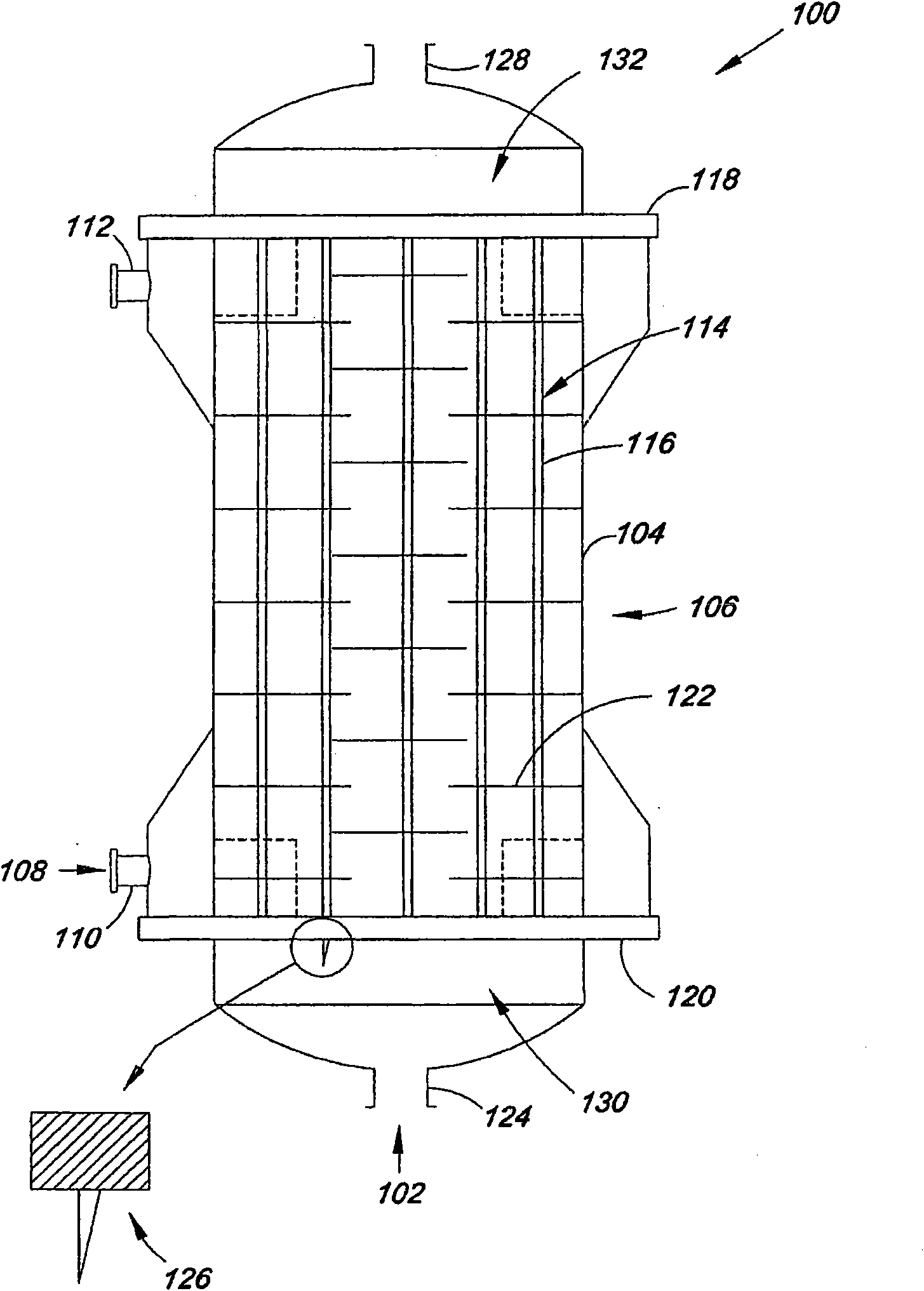

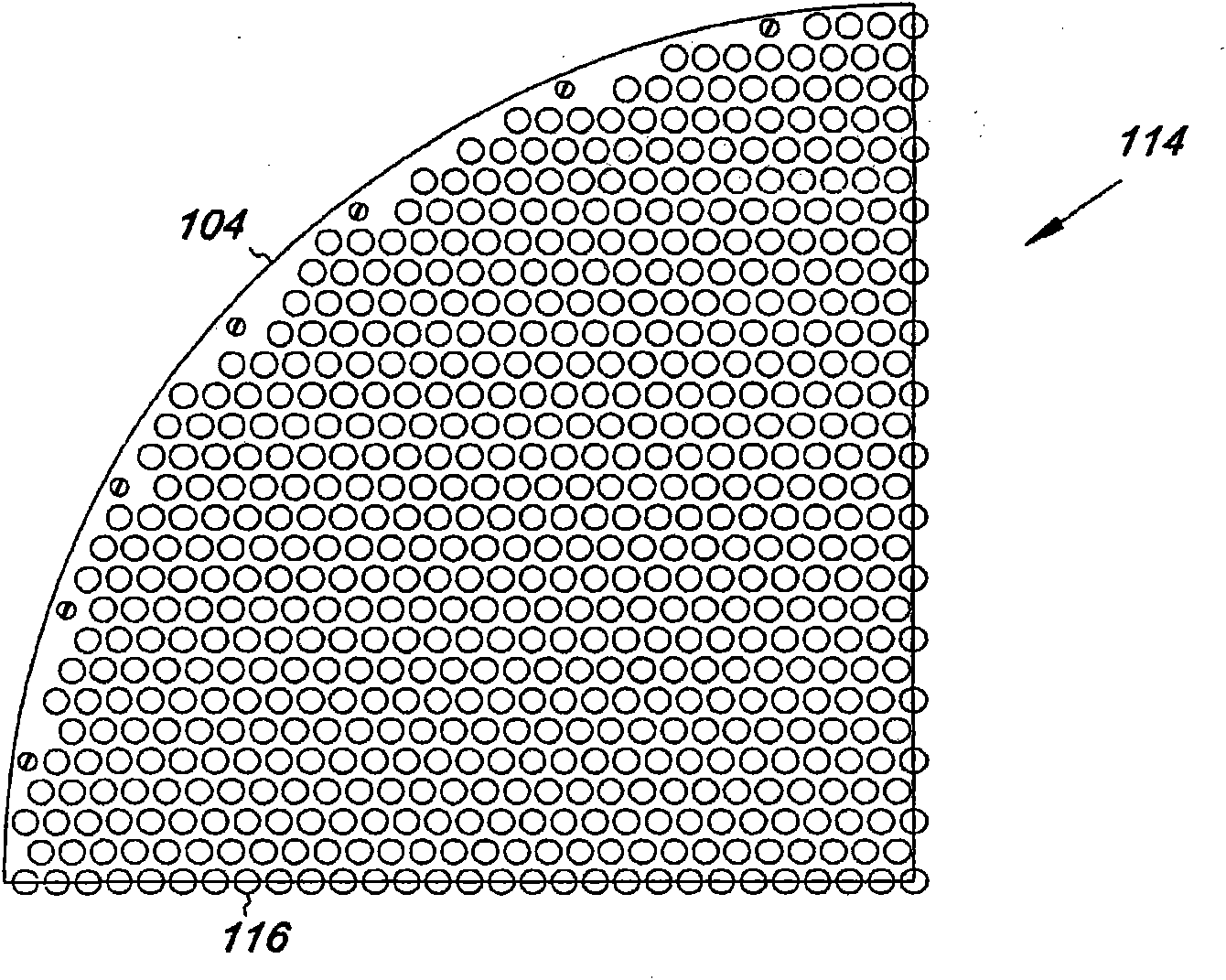

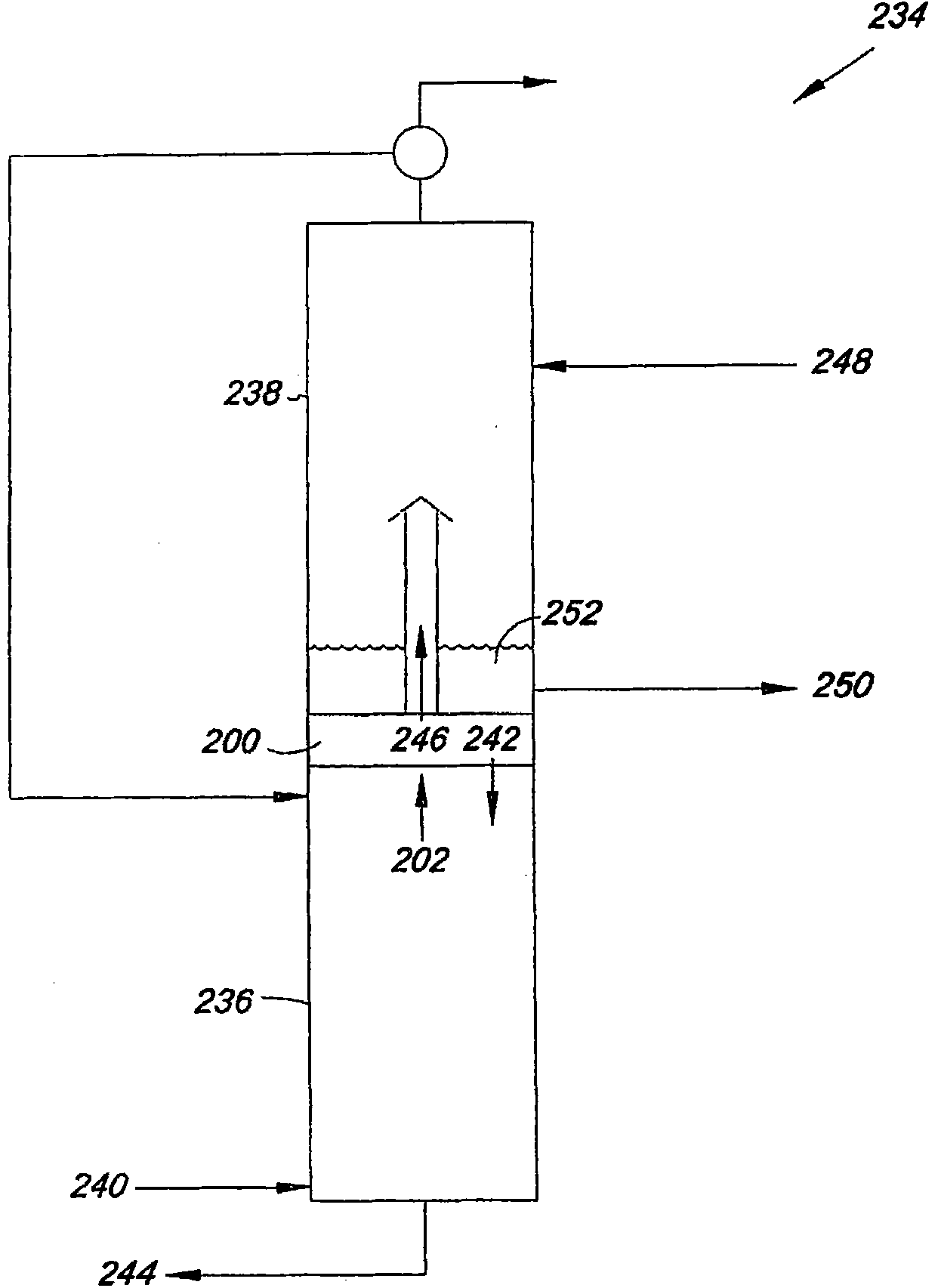

Methods, apparatus, and processes are provided for a condenser including flowing a vapor stream including formaldehyde into a tube bundle in a vertical upflow reflux condenser, where a tube in the tube bundle has a length to outside diameter ratio of greater than about 170:1, flowing a cooling fluid on a shell-side of the vertical upflow reflux condenser to condense at least a portion of the vapor stream, where the condensed portion of the vapor stream forms a wetted tube internal surface area on each tube in the generally upright tube bundle; and maintaining the vapor stream velocity at a rate that provides a liquid residence time where formaldehyde condensed on the wetted internal surface area of each tube can react with water to form methylene glycol, removing at least sixty percent (60%) of formaldehyde from the vapor stream fed to the condenser.

Description

technical field [0001] The present disclosure relates to a method and system for removing formaldehyde from a formaldehyde-containing vapor stream. More specifically, the present disclosure relates to an improved process for condensing a formaldehyde-containing vapor feed stream to remove formaldehyde from the vapor feed stream and recover a desired product. Background technique [0002] When ethylene oxide is produced by the silver-catalyzed vapor-phase partial oxidation of ethylene by molecular oxygen, a gaseous reaction effluent is obtained. This effluent can be extremely dilute relative to the desired ethylene oxide product, containing from about 0.3 mole percent to about 5 mole percent of the desired species. [0003] Since the ethylene oxide effluent is very dilute in the gaseous mixture produced by the oxidation reaction, this mixture is subsequently subjected to various treatments (absorption, distillation, flashing, etc.) to obtain pure ethylene oxide. However, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D3/04B01D5/00C07D301/32B01J19/24

CPCB01D5/0063B01D3/04C07D301/32B01D5/0012B01D5/0057C07C31/20

Inventor 克莱德·L·罗德斯Ⅱ约翰·F·苏尔佛瑞德·A·康尼维

Owner DOW TECH INVESTMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com