Hydrofluoric acid production apparatus and hydrofluoric acid production method

A generation device, hydrofluoric acid technology, applied in separation methods, chemical instruments and methods, fluorine, etc., can solve problems such as unusable, adsorbent deterioration, etc., to prevent concentration reduction, prevent distillate deterioration, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

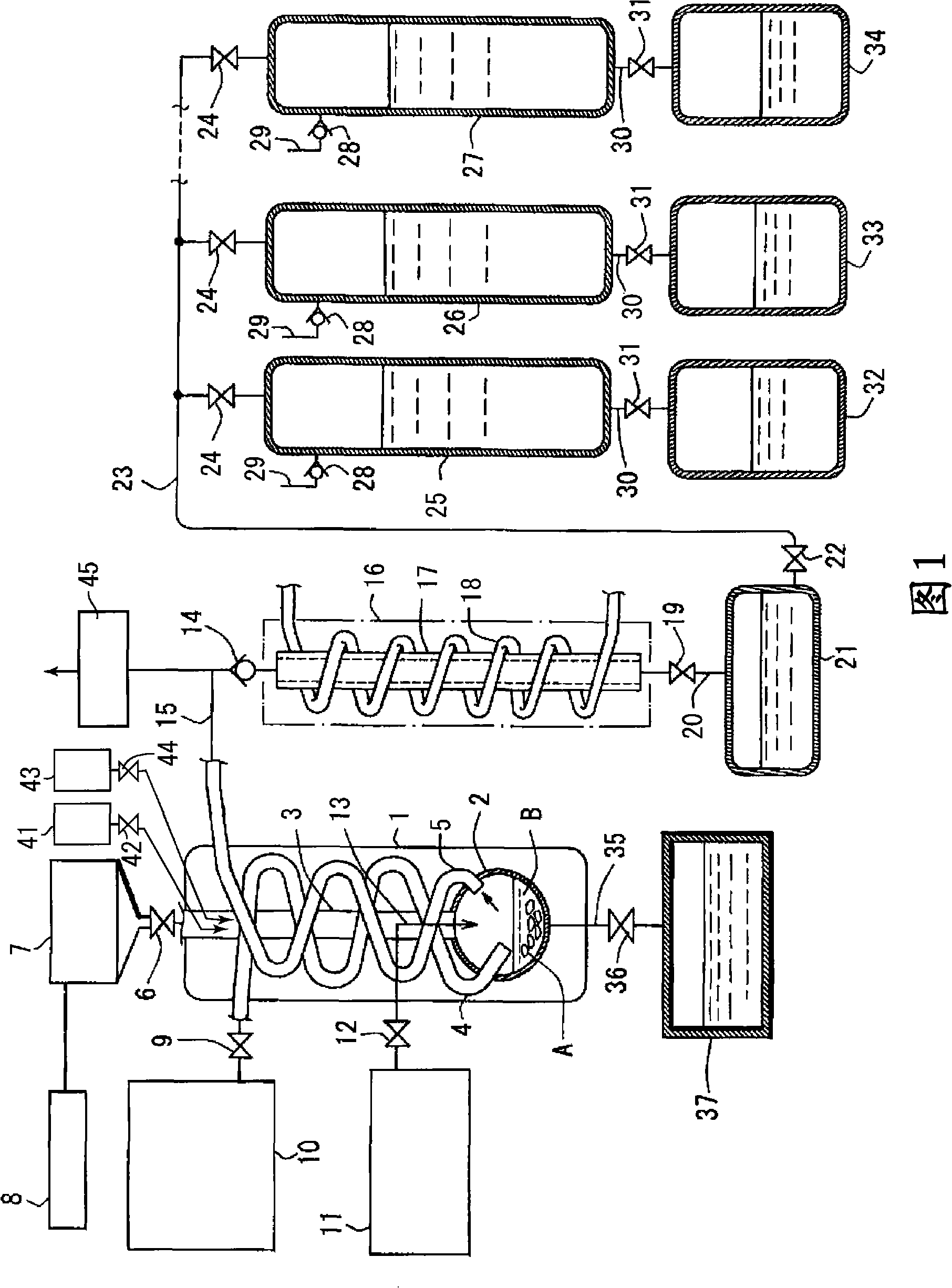

[0034] Embodiments of the present invention are described in detail according to the following drawings.

[0035] FIG. 1 shows a schematic diagram of a hydrofluoric acid generator of this embodiment. This hydrofluoric acid generating device is provided with a distillation tower 1 as a distillation mechanism. Inside the distillation tower 1, a heating furnace 2 and a raw material input passage 3 connected to the heating furnace 2 are provided, and a connection between the heating furnace 2 and the distillation tower 1 is provided. A spiral passage 4 for supplying water vapor on the upper side, and a spiral passage 5 for sending out hexafluorosilicic acid gas on the other upper side of the distillation column 1 that communicates the heating furnace 2 and the distillation column 1 .

[0036] In the raw material input channel 3, a raw material input port 8 is connected through the on-off valve 6 and the hopper 7, and further in the raw material input channel 3, a crystalline silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com