Washing apparatus for separation of methanol from gas

A technology for washing equipment and gas separation, which is applied in separation methods, gas treatment, and separation of dispersed particles, and can solve problems such as reducing separation efficiency and damaging methanol solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

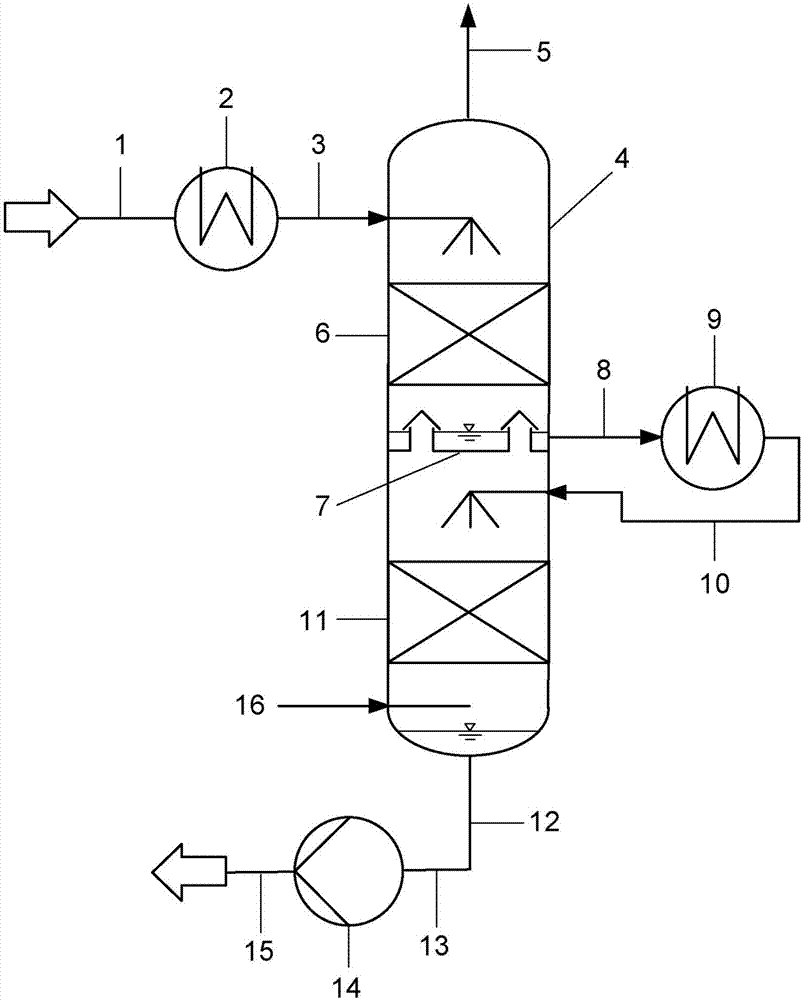

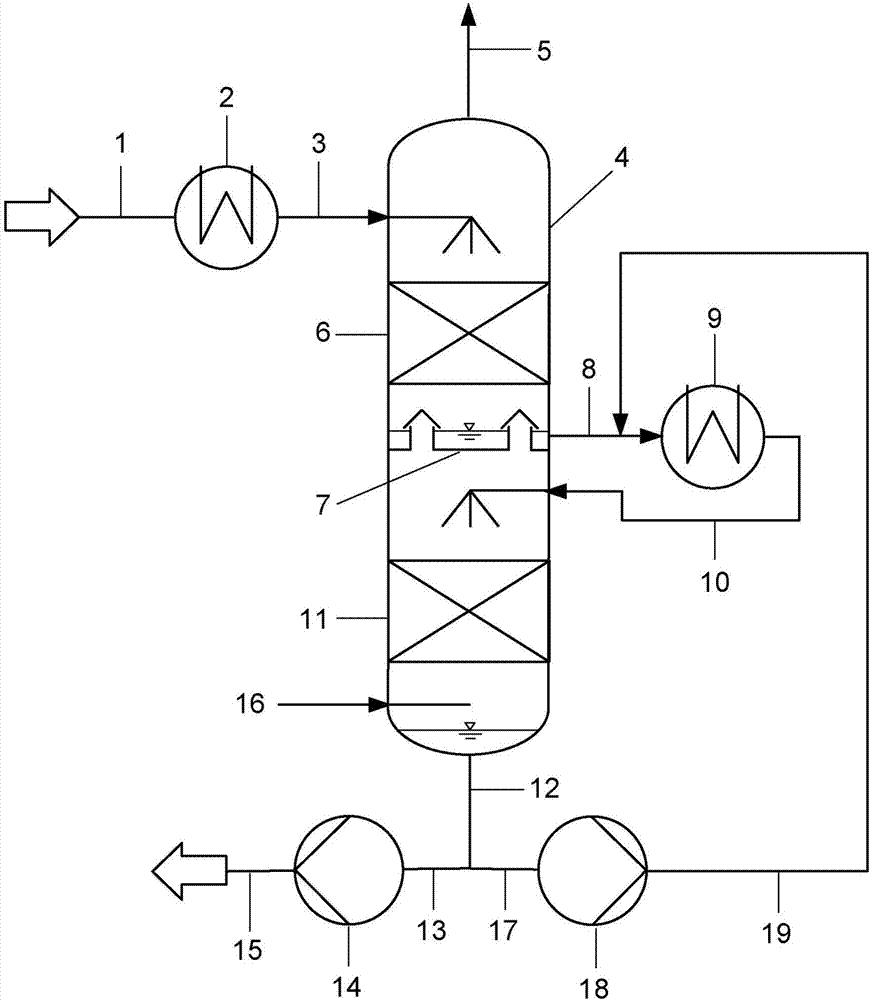

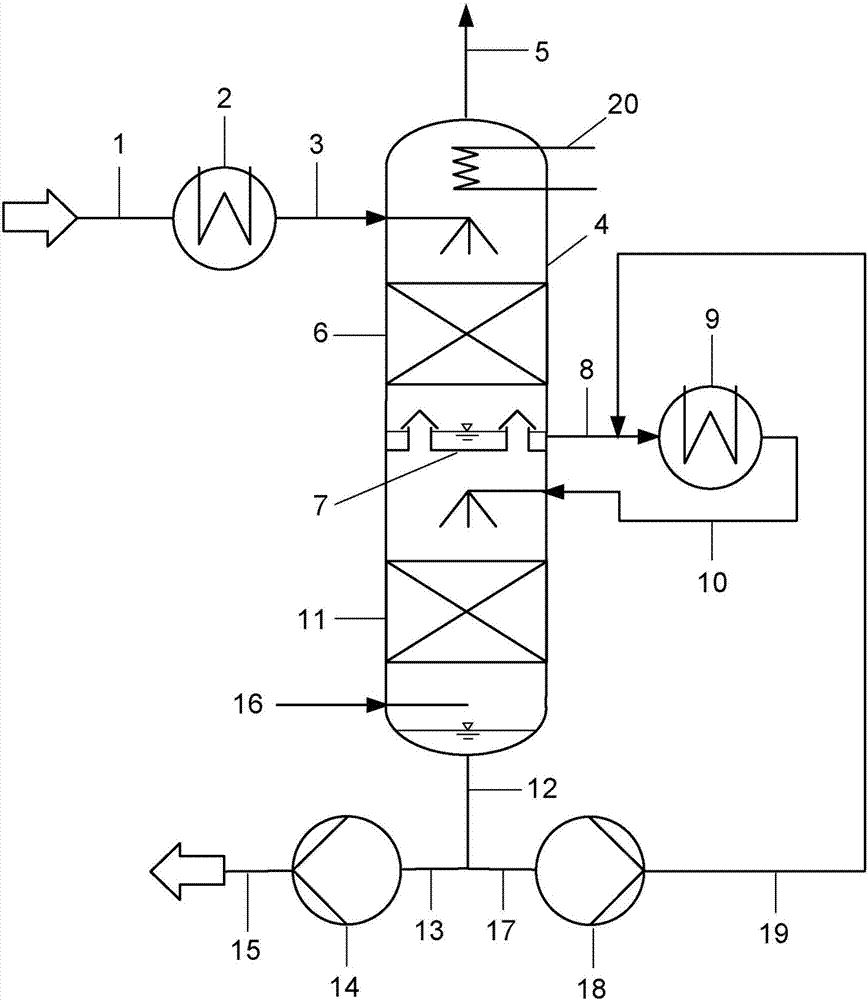

[0048] exist figure 1 The method of the invention according to the first aspect and the washing apparatus of the invention are explained in . Via pipe 1, demineralized water is led as washing agent to heat exchanger 2 and is thereby cooled by indirect heat exchange with cooling water. Via line 3 , the cooled detergent is led to a scrubber 4 and filled into this scrubber 4 by a distribution device shown schematically in the figure. By gravity, the detergent then flows through the mass transfer zone 6 which acts as a packed bed. In the mass transfer zone 6, an intensive contact between the scrubbing agent and the methanol-laden gas stream to be purified is achieved due to the high specific surface of the packed bed. During the absorption of methanol in the detergent, the enthalpy of dissolution is released and the detergent is heated accordingly.

[0049] After leaving the mass transfer area 6 , the scrubbing agent, now partially laden with methanol, reaches the separation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com