Patents

Literature

281results about How to "No further processing required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

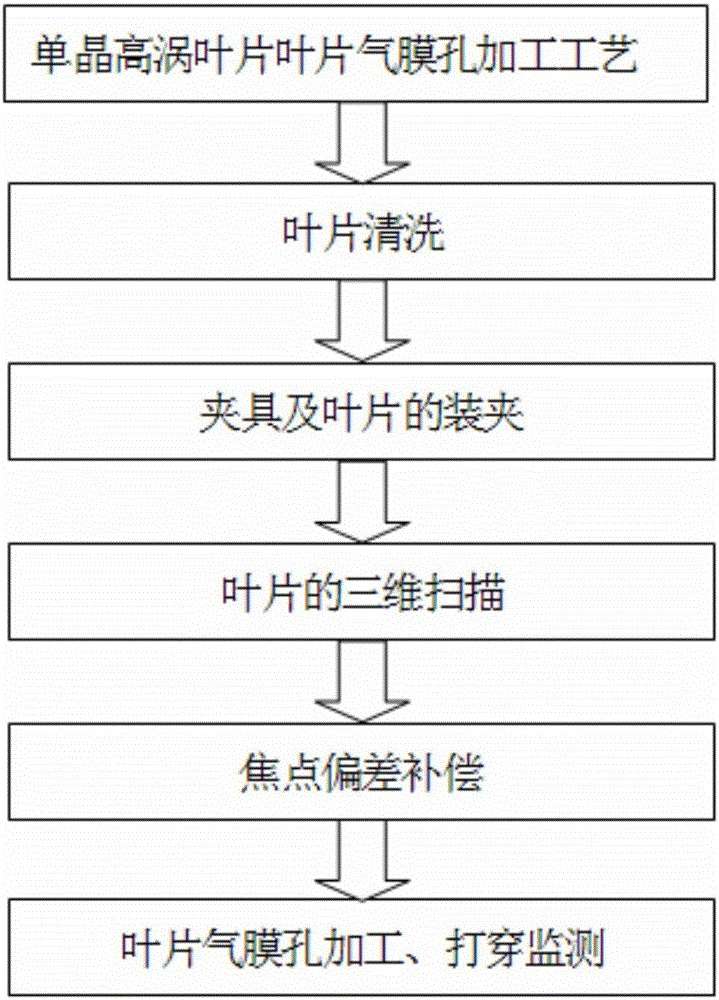

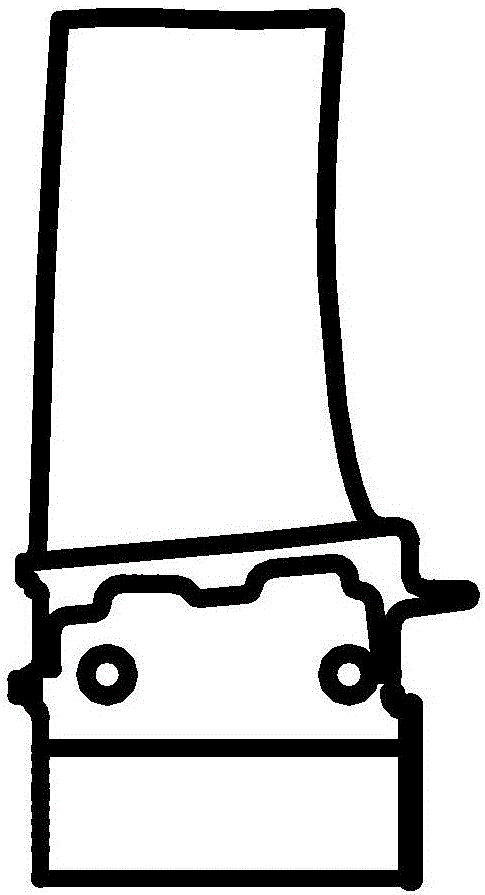

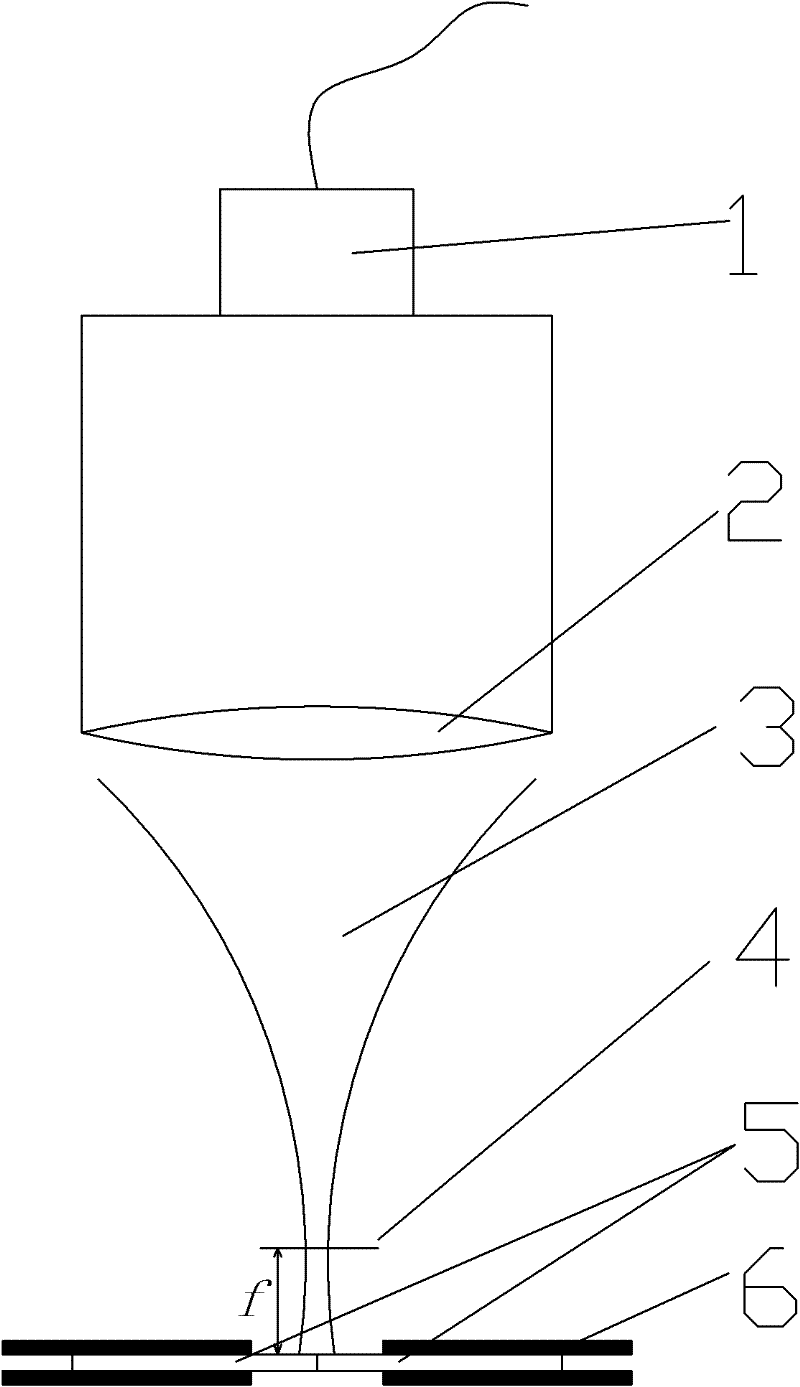

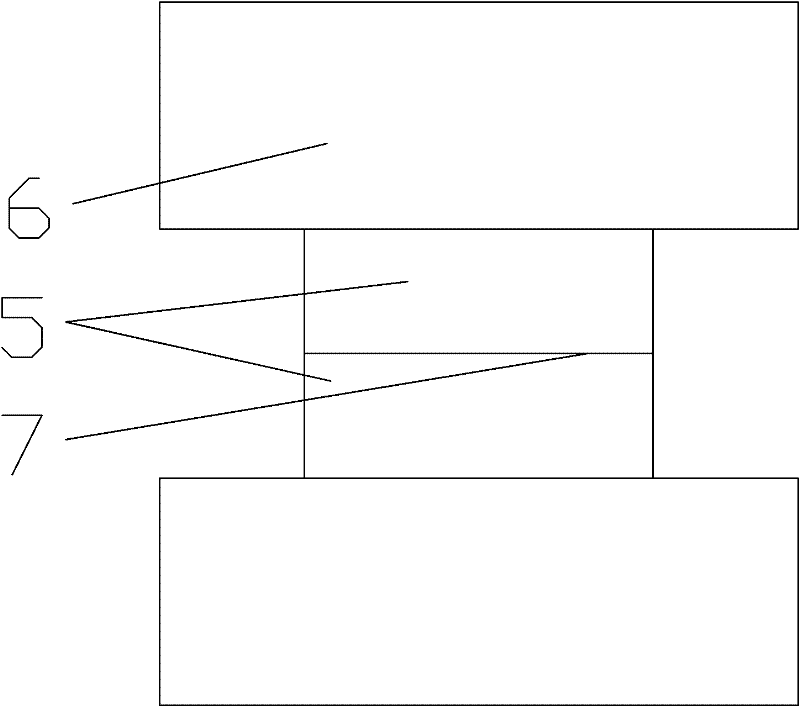

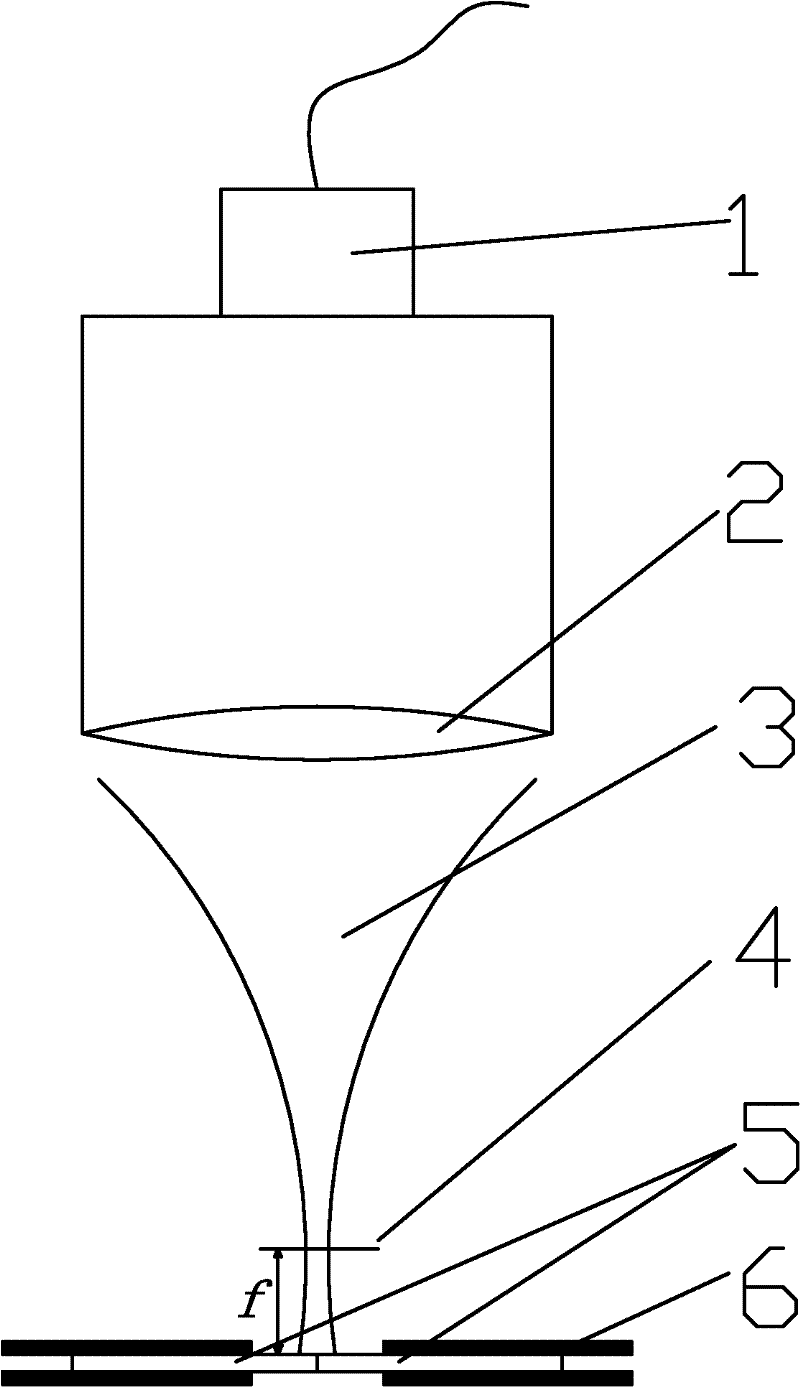

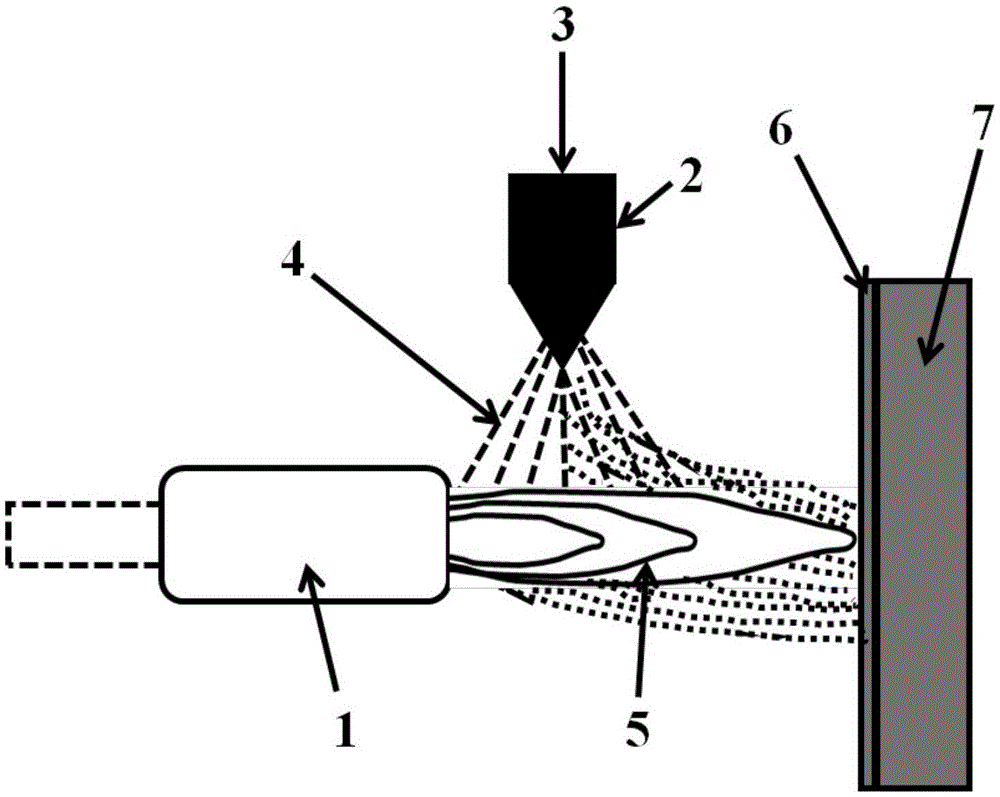

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

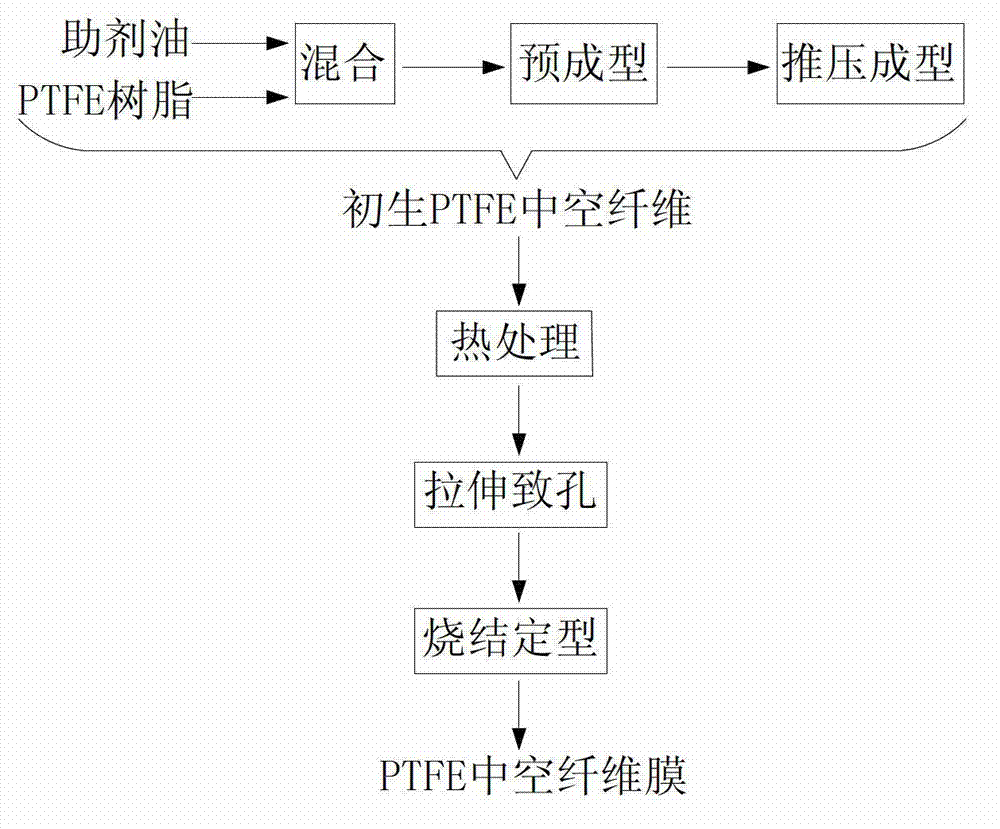

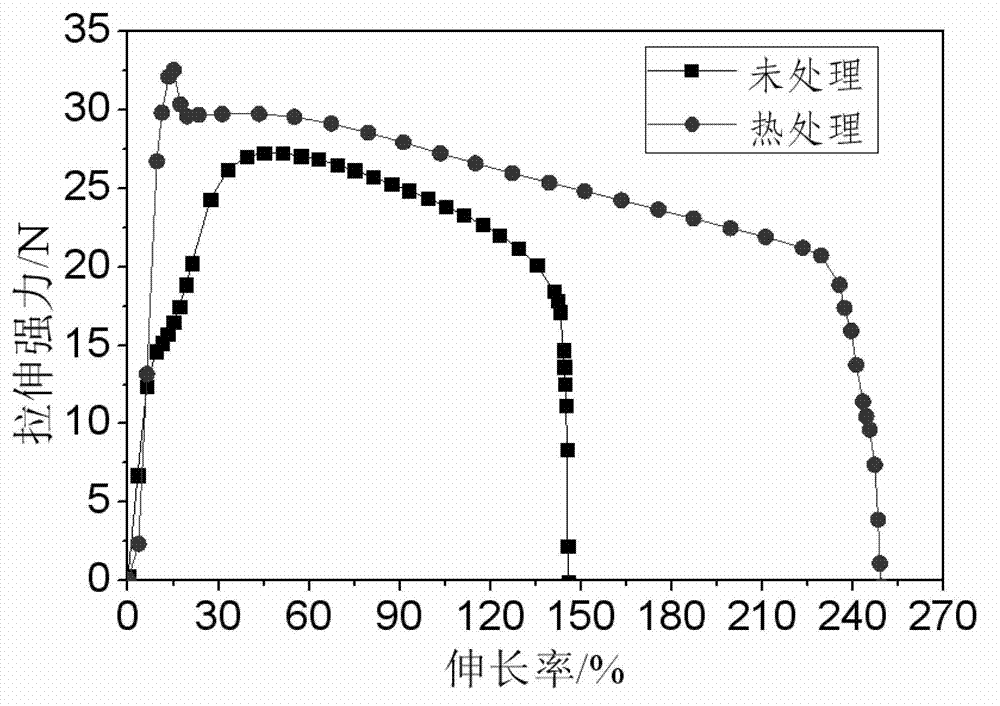

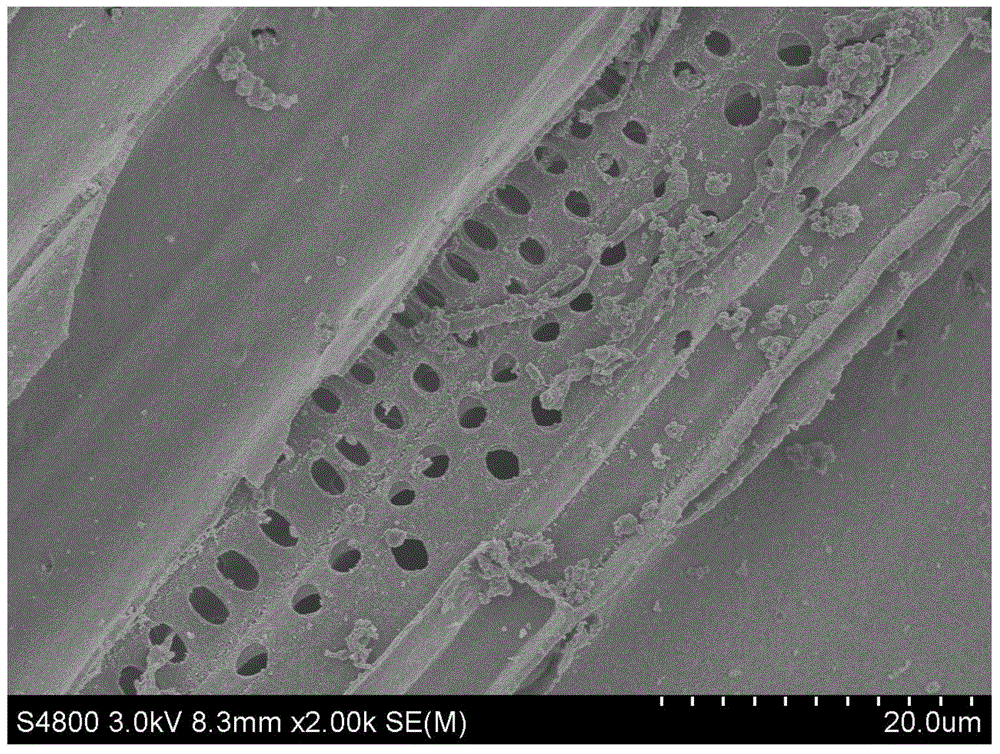

Polytetrafluoroethylene hollow fiber micro-porous film and preparation method thereof

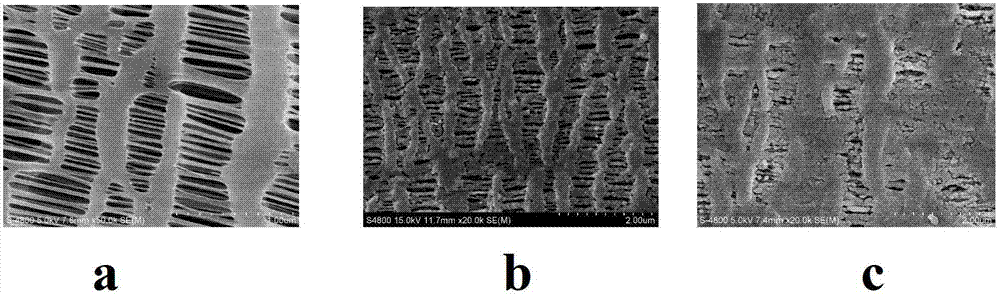

ActiveCN102961976AHigh mechanical strengthHigh porositySemi-permeable membranesPore diameterUltimate tensile strength

The invention discloses a polytetrafluoroethylene hollow fiber micro-porous film and a preparation method thereof. The preparation method comprises the preparation steps of: preparing a primary PTFE (Polytetrafluoroethylene) hollow fiber, carrying out heat treatment, stretching to form a hole, sintering and sizing. According to the polytetrafluoroethylene hollow fiber micro-porous film and the preparation method thereof, a pushing-pressing molding PTFE fiber pipe preparation technology is organically combined with a stretching-method micro-porous film preparation technology; an un-sintered PTFE fiber pipe prepared by a pushing-pressing molding method is a primary hollow fiber and the film is prepared by a stretching method, so as to realize the effective control of a pore diameter structure, and a PTFE hollow fiber film with needed hole diameter, higher porosity and large mechanical strength is obtained; furthermore, the polytetrafluoroethylene hollow fiber micro-porous film has a simple process, has no pollution to an environment, is easy to operate and does not need subsequent treatment; and therefore, the technical problems that the primary PTFE hollow fiber is more fragile and is easy to damage under the effect of external force, a process of stretching to form the hole is difficult, the hole diameter and the porosity are difficult to control are solved.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

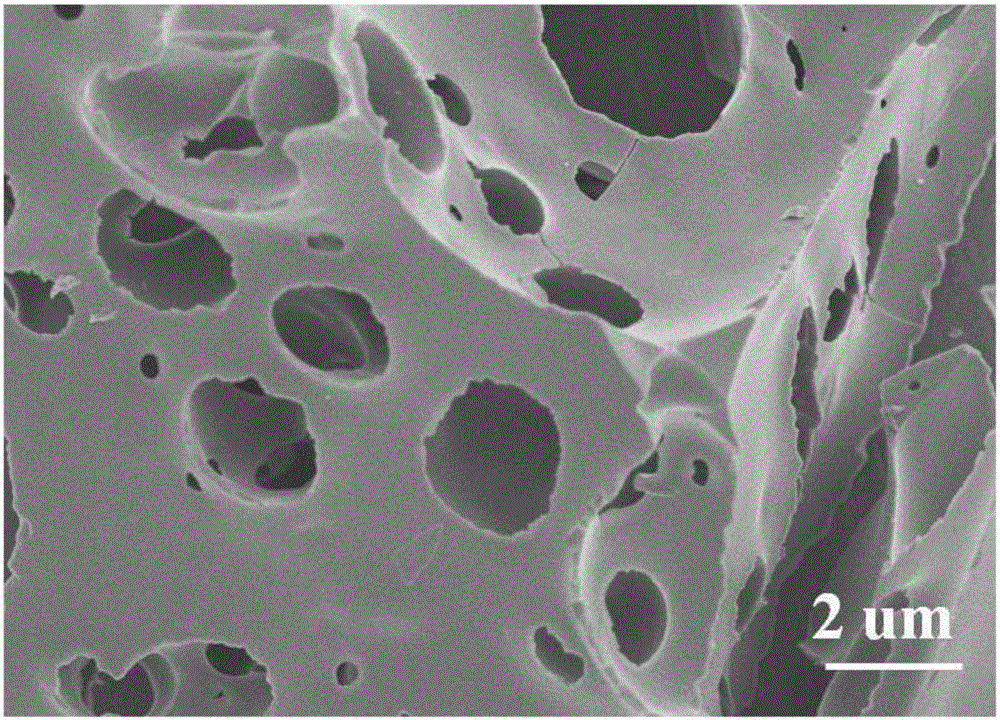

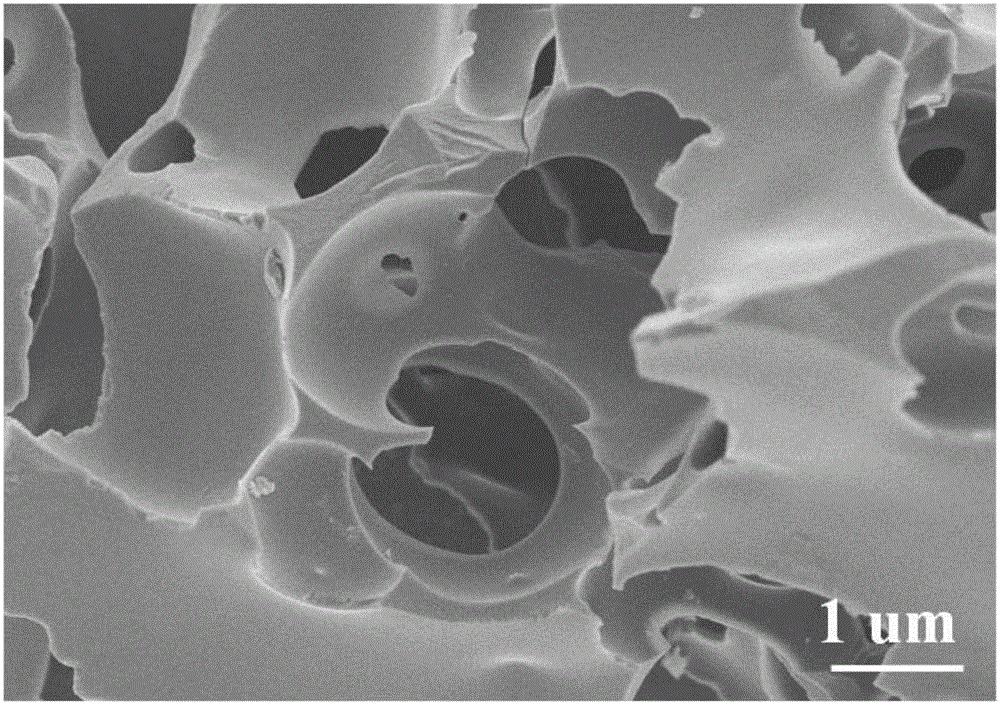

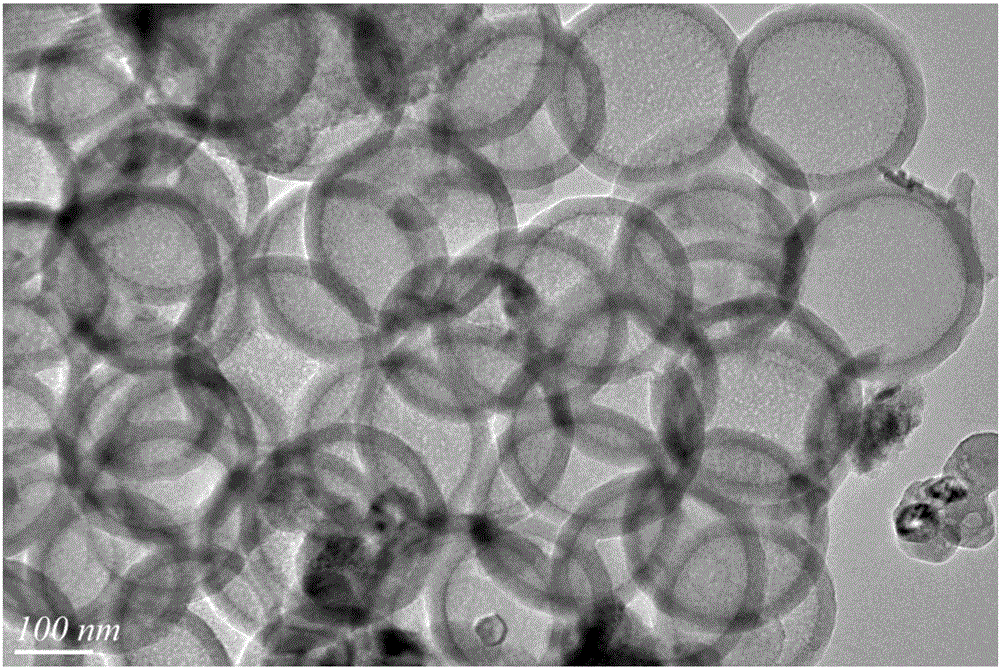

Method for preparing three-dimensional carbon nanomaterial by activating shaddock peel with strong base

InactiveCN106219510AReduce pollutionLarge specific surface areaCell electrodesSecondary cellsFiltrationFreeze-drying

The invention discloses a method for preparing a three-dimensional carbon nanomaterial by activating shaddock peel with a strong base. The method comprises the steps that the shaddock peel is washed to be clean and then subjected to freeze drying, a sulfuric acid solution is added for a hydrothermal reaction, and a biomass precursor is obtained; the biomass precursor is subjected to washing, suction filtration and drying and then mixed with the strong base to be subjected to carbonization in a tubular atmosphere furnace, and a carbonization product is obtained; the carbonization product is subjected to washing and suction filtration and then dried, and the three-dimensional carbon nanomaterial, namely, a carbon negative electrode material used for sodium-ion batteries is obtained. The strong base activated shaddock peel negative electrode material prepared through the method has a three-dimensional porous connected nantostructure, the specific surface area is large, more attachment sites are provided for sodium ions, micropores can be beneficial for entering of electrolyte to increase the contact area with the electrode material, a condition is provided for rapid transmission of the sodium ions, and the capacity of the material is increased.

Owner:SHAANXI UNIV OF SCI & TECH

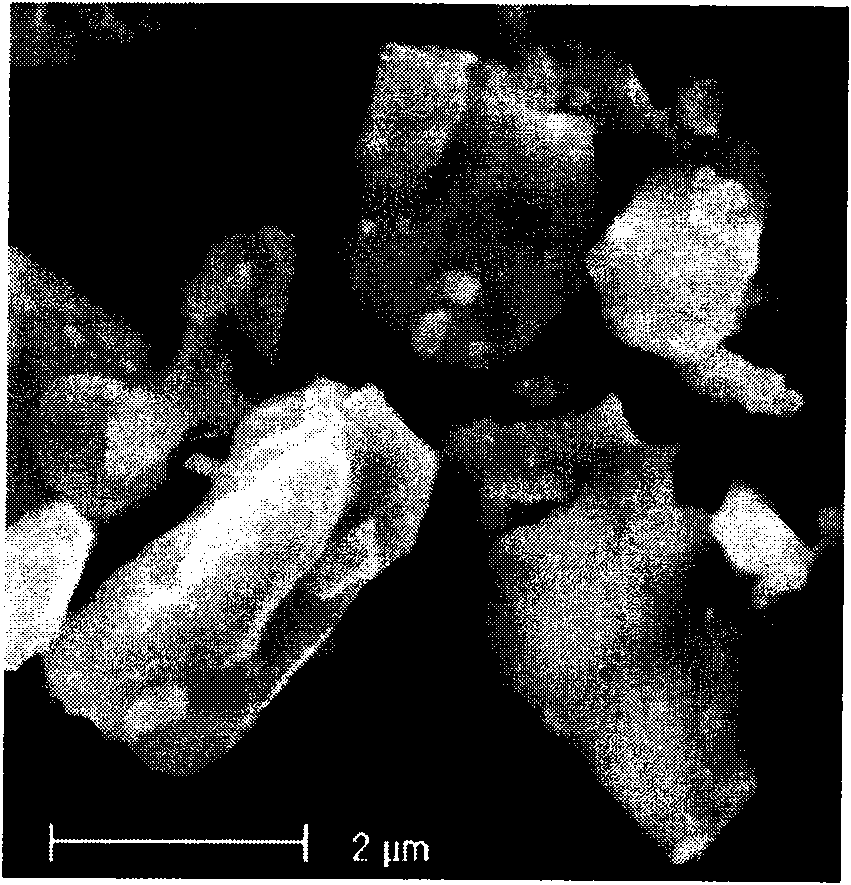

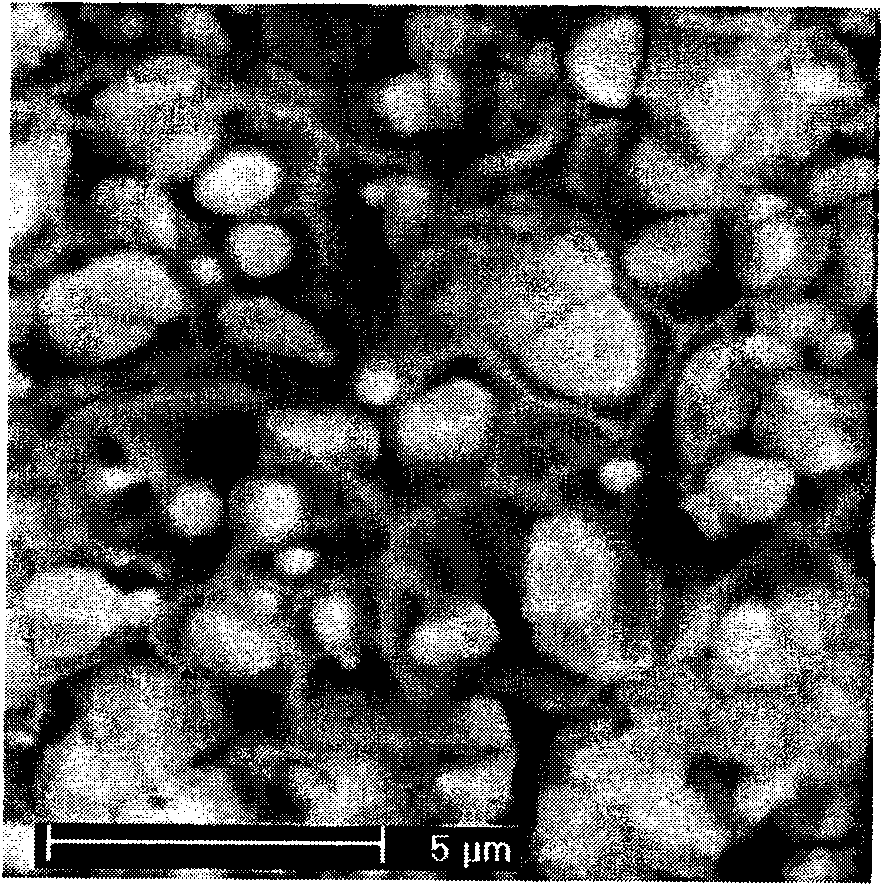

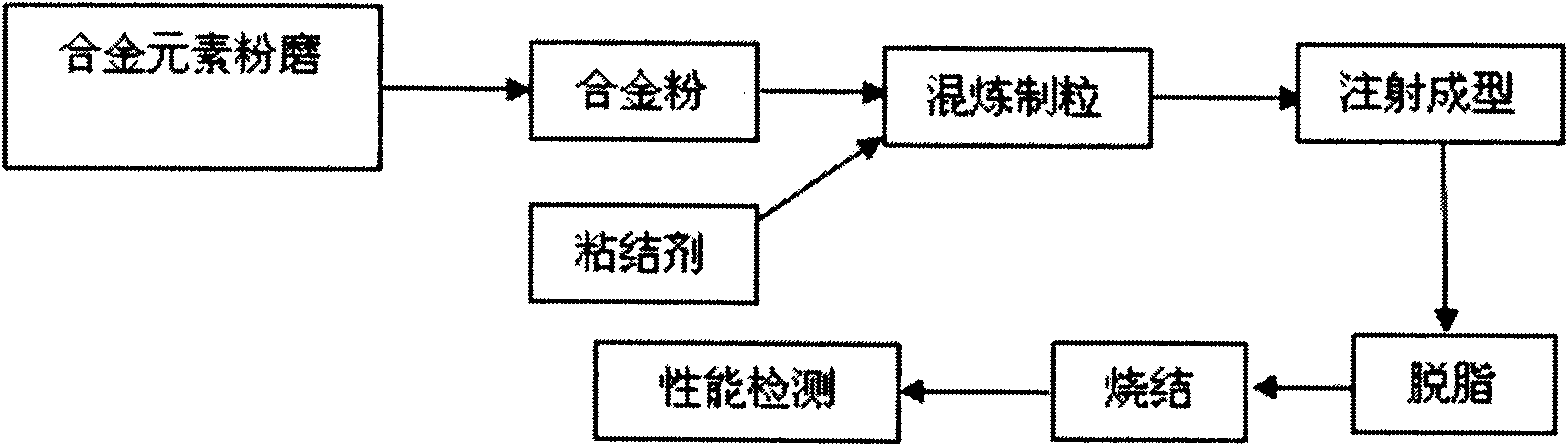

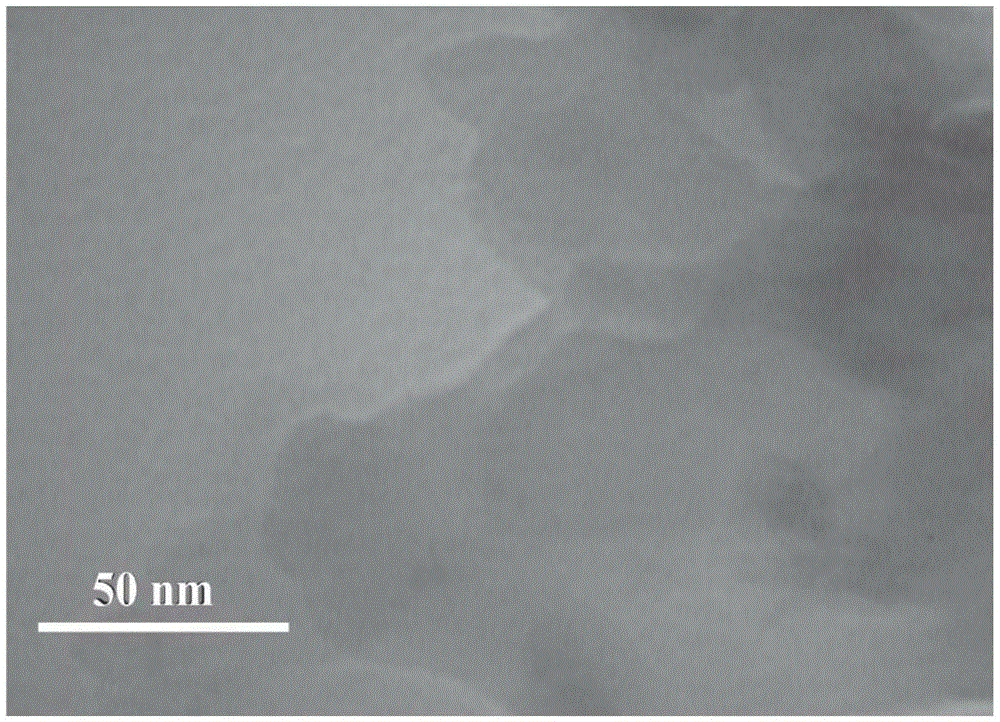

Preparation method of W-Cu electrical contact

InactiveCN101667498ANo further processing requiredLow costElectric switchesManufacturing cost reductionAlloy

The invention relates to a preparation method of a tungsten-copper electrical contact which adopts the injection moulding process. The method comprises the following steps: placing tungsten powder, copper powder and trace element Ni, Co, Mn and Mo according to a certain ratio in a ball mill to perform ball milling, mixing the prepared alloy powders and binder to smelt, injecting to prepare the green body with an injection machine, defating and finally sintering to obtain the electrical contact. The consistency (relative theoretical density) of the contact which is sintered through the liquid phase sintering is more than 98%. The tungsten-copper electrical contact of the invention has the advantage that the contact has high conductivity, low contact resistance and good fusion welding resistance, electric arc burning loss resistance and thermal stability, the electrical contact with a complicated shape can be prepared through one-step forming process, no subsequent machining is needed, the continuous production can be realized, and the production cost can be greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH

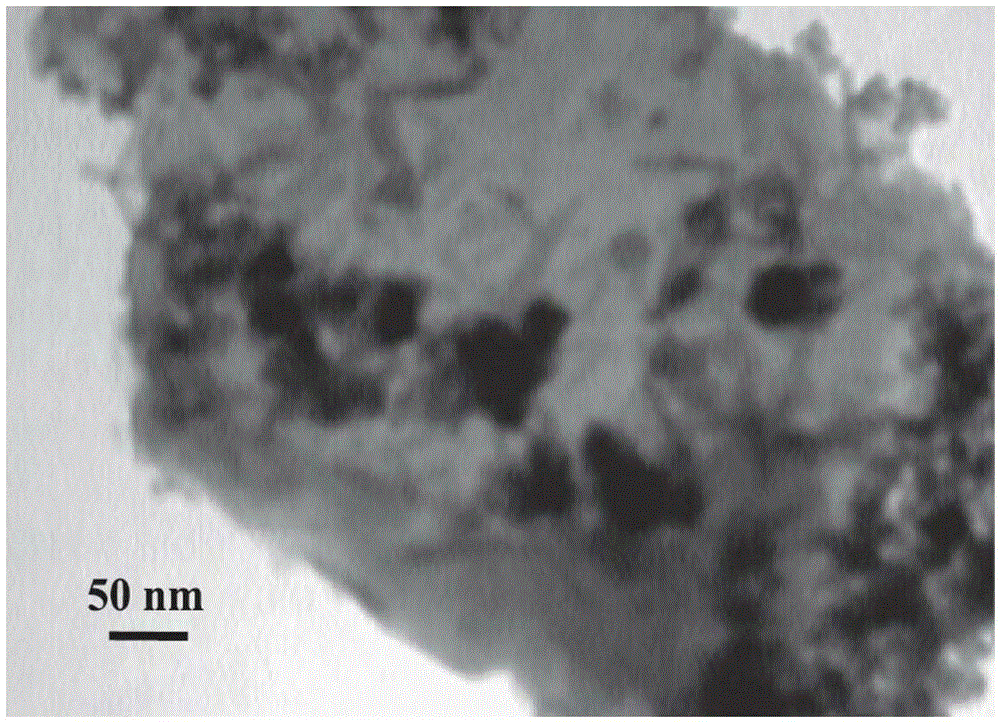

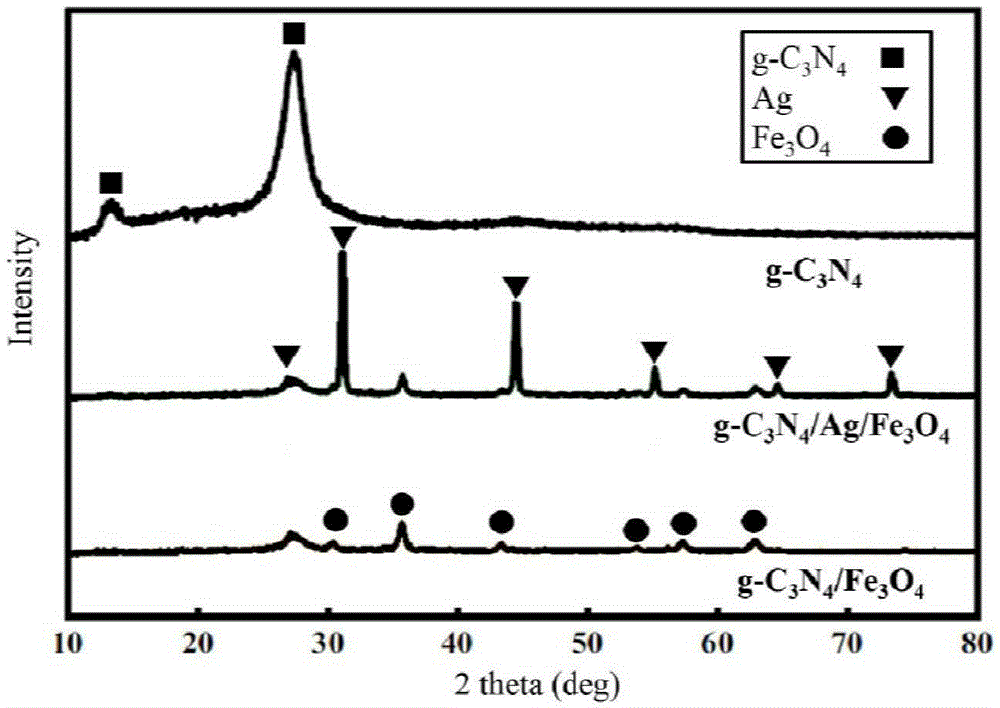

Magnetic nanometer composite photocatalysis material, and preparation method thereof

InactiveCN105233850AEasy to prepareStrong repeatabilityPhysical/chemical process catalystsPollutantPhoto catalysis

The invention discloses a magnetic separable g-C3N4 / Ag / Fe3O4 nanometer composite photocatalysis material and a preparation method thereof. The preparation method comprises the following steps: with melamine as a precursor, preparing g-C3N4 by using a pyrolysis method; then preparing g-C3N4 / Fe3O4 by using an in-situ precipitation method; and adding a silver salt solution and carrying out reduction by NaBH4 to complete modification of silver nanoparticles so as to prepare the g-C3N4 / Ag / Fe3O4 nanometer composite photocatalysis material. The preparation method is simple and easily practicable, has good repeatability, can realize large-scale production and does not need a template and subsequent treatment; and the prepared photocatalysis material has high visible light catalysis efficiency, can realize magnetic separation of degraded pollutants, can be well recycled and shows wide application prospects in degradation of pollutants in a water body.

Owner:HOHAI UNIV

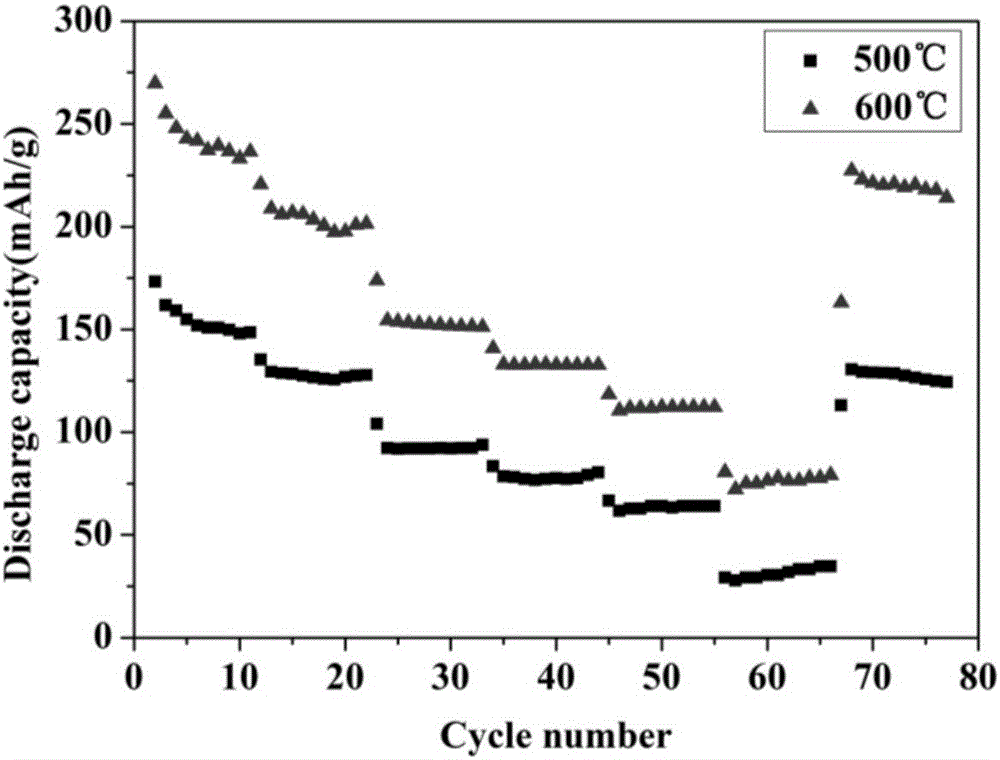

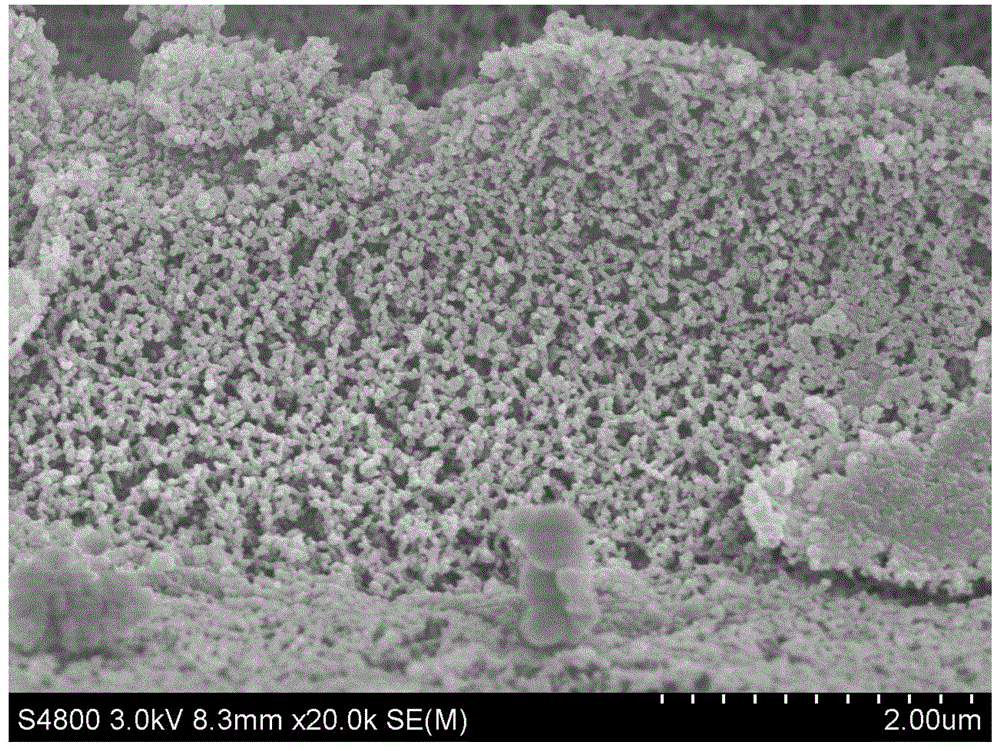

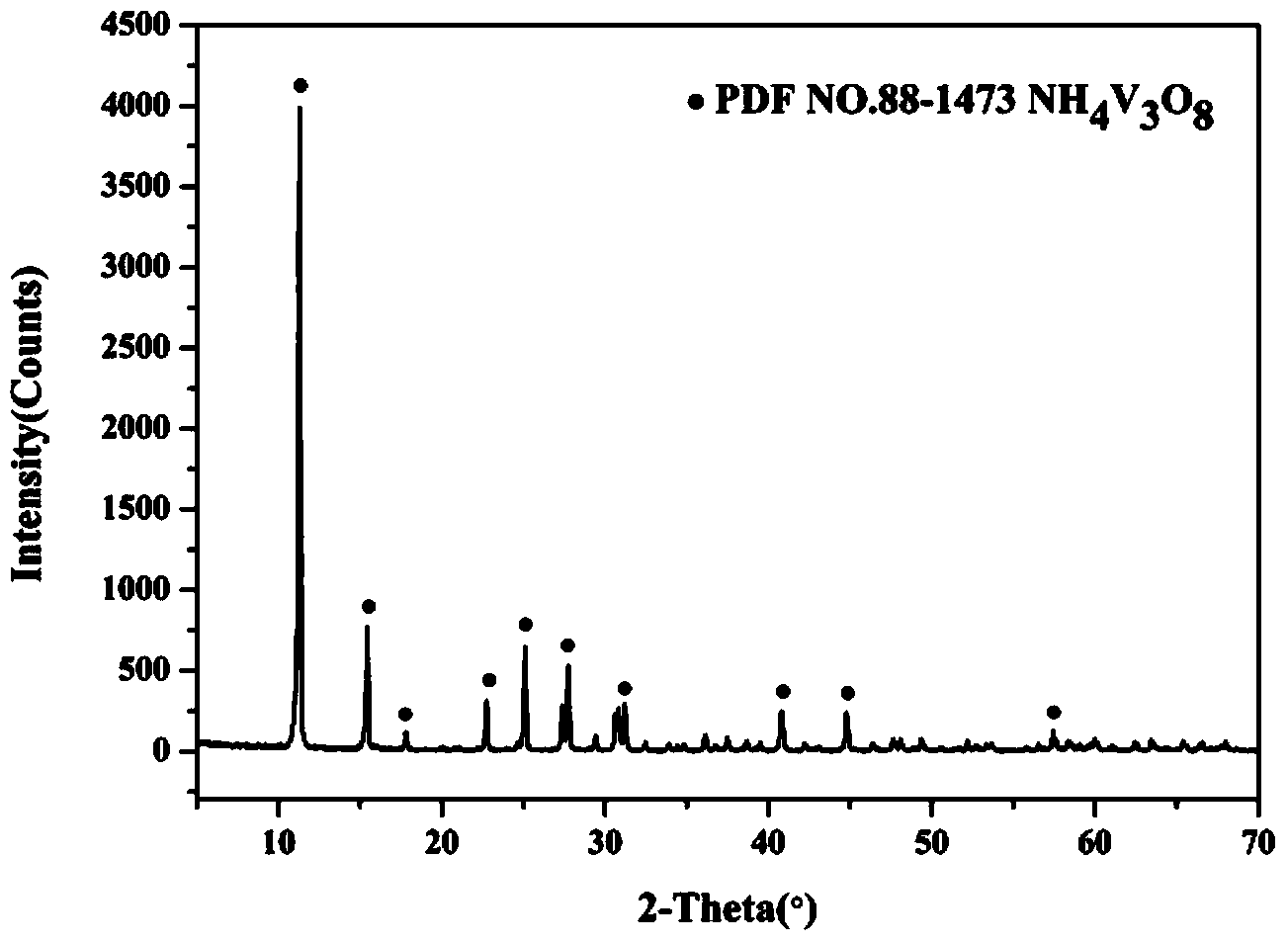

Method for preparing biochar/ammonium vanadate lithium ion cell cathode material

The invention discloses a method for preparing a biochar / ammonium vanadate lithium ion cell cathode material. The method comprises the steps of cleaning and cutting a biomass preformed body into pieces, drying the biomass preformed body, and adding concentrated nitric acid for homogeneous reaction, so that a reaction product is obtained; conducting suction filtration and drying on the reaction product, and carbonizing the reaction product in a tubular atmosphere oven, so that a carbonized product is obtained; conducting washing and suction filtration on the carbonized product, and drying the carbonized product, so that porous biochar is obtained; finally, adding biochar into a NH4VO3 solution obtained from deionized water by means of ammonium metavanadate, and placing the mixture in a hydrothermal induction heater, so that the biochar / ammonium vanadate lithium ion cell cathode material is obtained. The obtained biochar / ammonium vanadate composite material has excellent conductivity, and specific capacity and stability are also improved remarkably. The preparing method is simple, reaction temperature is low, reaction time is short, subsequent processing is not needed, environmental friendliness is realized, and large-scale production can be achieved with the method.

Owner:珠海东杰科技有限公司

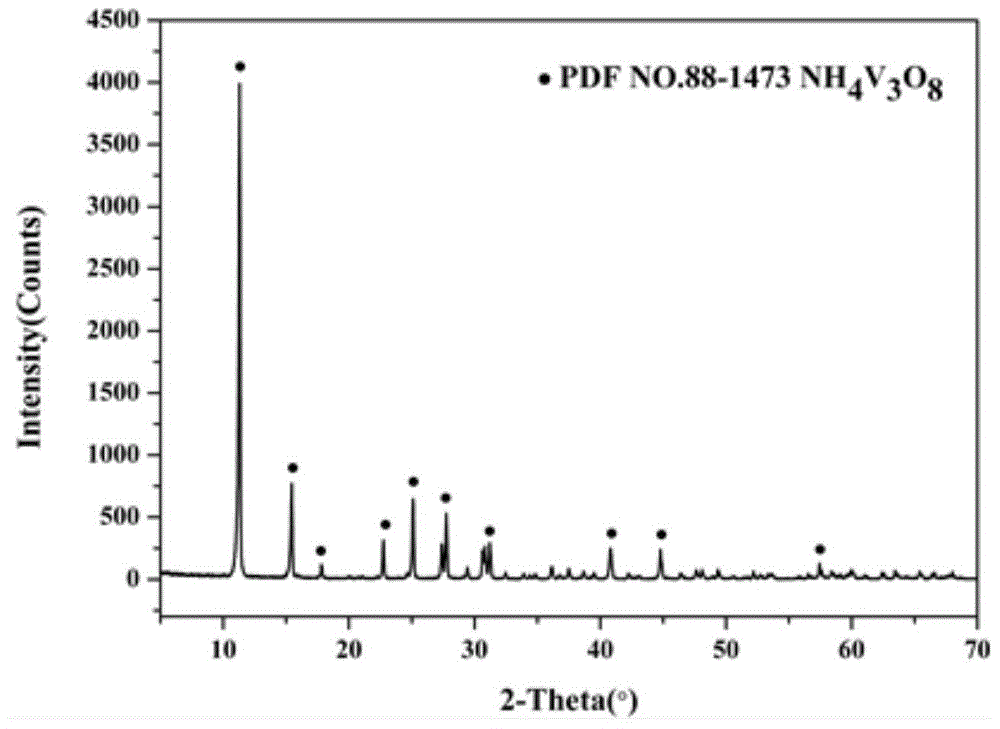

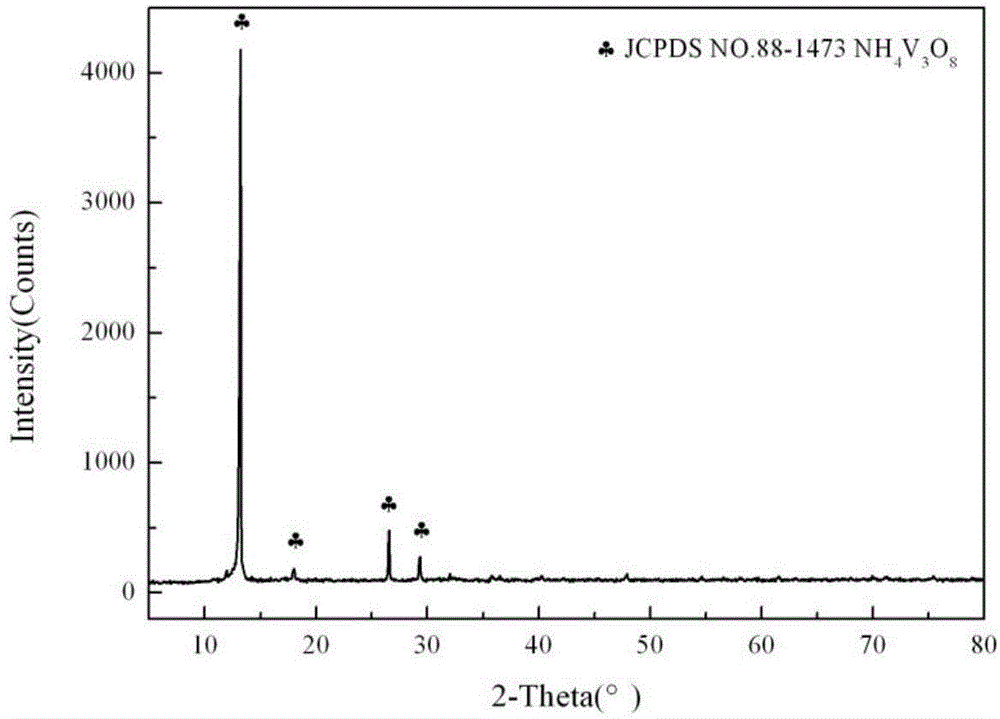

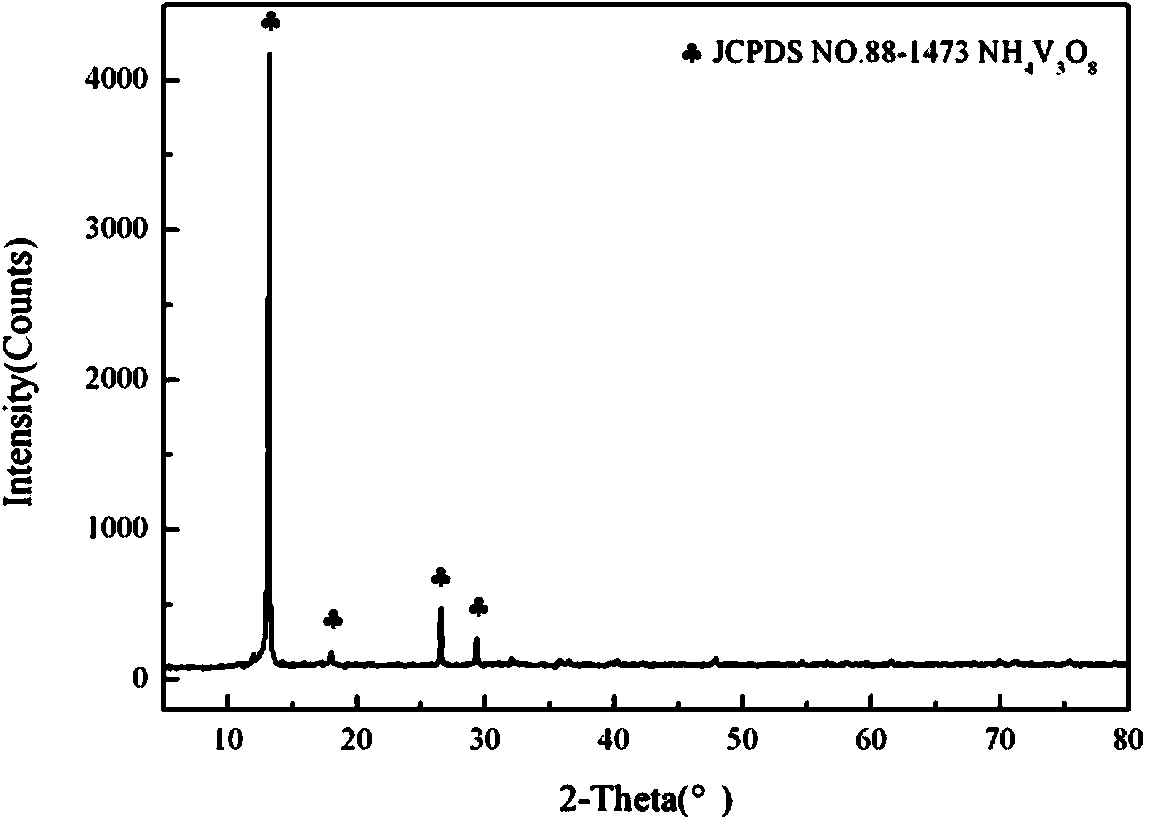

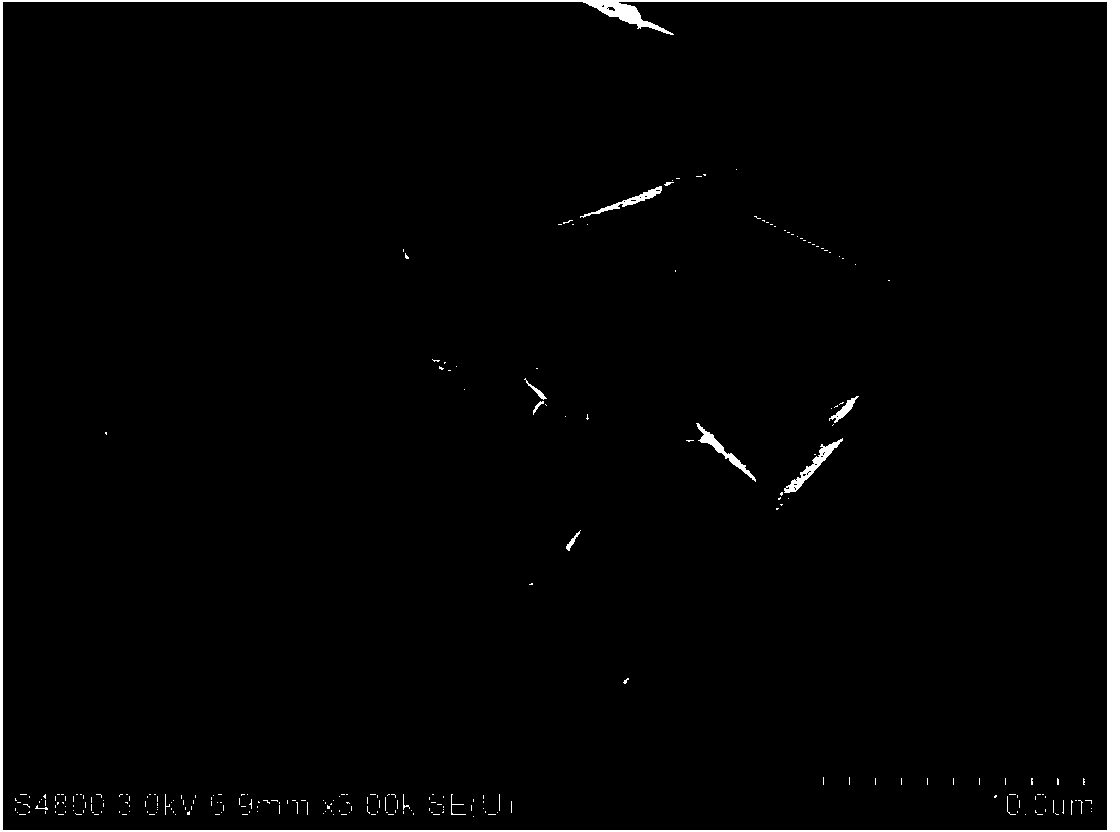

Method for preparing NH4V3O8 anode material for lithium ion battery

ActiveCN104701517APromote absorptionIncrease profitCell electrodesVanadium compoundsFiberCarbon fibers

The invention discloses a method for preparing an NH4V3O8 anode material for a lithium ion battery. The method comprises the steps that ammonium metavanadate is dissolved in deionized water, an NH4VO3 solution is prepared, pre-oxidization short carbon fibers of 1 mm to 3 mm are added, the NH4VO3 solution is transferred into a reaction still after the pH value is adjusted, forced mixing is carried out, after the reaction still is sealed, the reaction still is placed in a water and heat induction heater, and suspension liquid is obtained after a heating reaction; centrifugal separation is carried out on the suspension liquid to obtain a powder product, the powder product is soaked in the deionized water and the absolute ethyl alcohol, repeated washing is carried out, and then drying and grinding are carried out. The NH4V3O8 microcrystal prepared through the method is uniform in chemical component, high in purity and uniform in form, and the electrochemical performance of the material can be effectively improved. The preparation method is simple, low in reaction temperature, short in reaction period, high in productivity, free of any subsequent treatment, environmentally friendly and capable of being suitable for large-scale production.

Owner:安徽翰邦科技咨询有限公司

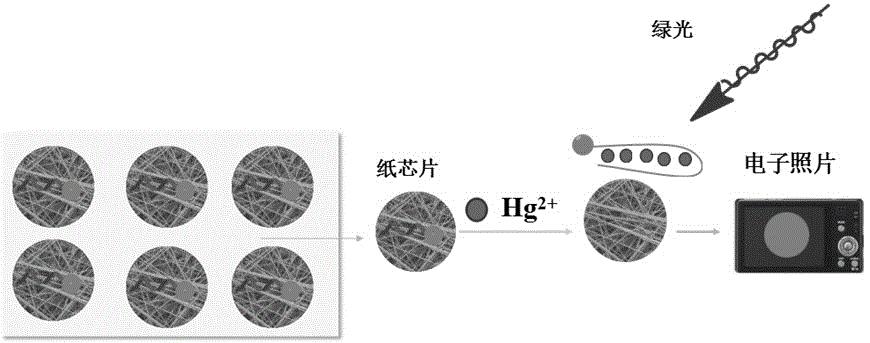

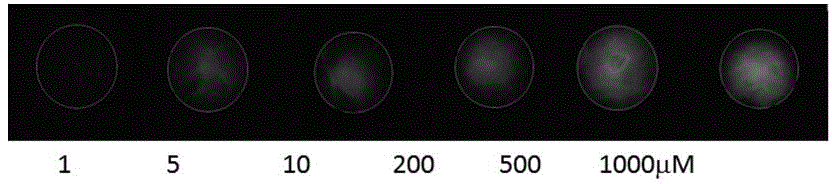

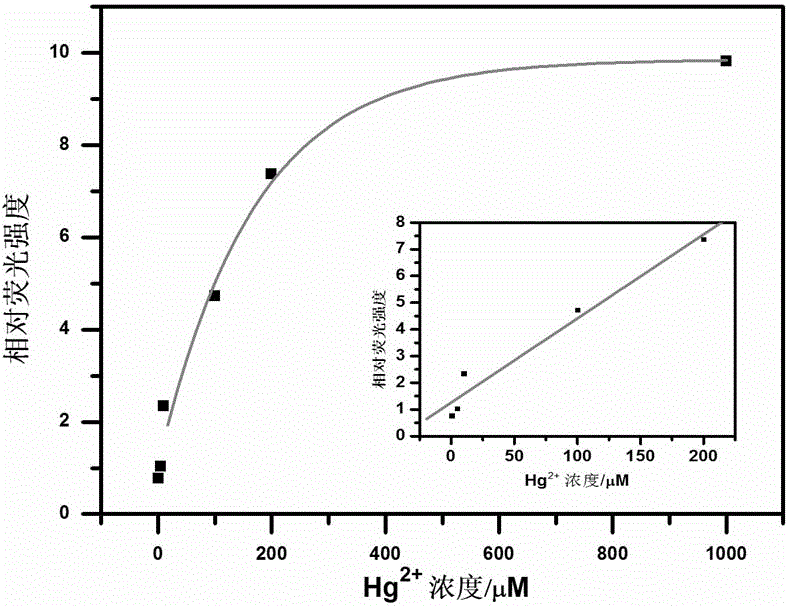

Method for detecting mercury ion on basis of fluorescence resonance energy transfer of paper chip

InactiveCN105527266ANo further processing requiredSimple methodFluorescence/phosphorescenceMicro fluidicFörster resonance energy transfer

The invention belongs to the technical field of paper chip micro fluidics, and particularly discloses a method for detecting a mercury ion on the basis of fluorescence resonance energy transfer of a paper chip. According to the method disclosed by the invention, the mercury ion of heavy metal is detected by taking a glass fiber chip as a carrier and by utilizing a method of the fluorescence resonance energy transfer. According to property that a Cy3 fluorescence dye labeled Hg<2+> aptamer (Cy3-Hg<2+>-aptamer) can be specifically bound with Hg<2+> to form a T-Hg<2+>-T structure, by taking the Cy3-Hg<2+>-aptamer as a fluorescence reporter molecule and graphene oxide as a fluorescence quenching agent, Hg<2+> is rapidly detected directly at low cost. The paper chip is designed and cut by a common household cutting machine, and does not need to be further modified or activated; according to the method disclosed by the invention, a fluorescence inverse microscope is also served as an excitation light source to provide excitation light for acquisition of a fluorescence picture, and finally, the acquired fluorescence picture is recorded by a digital camera, therefore a potential requirement is provided for disease diagnosis and biological analysis.

Owner:FUDAN UNIV

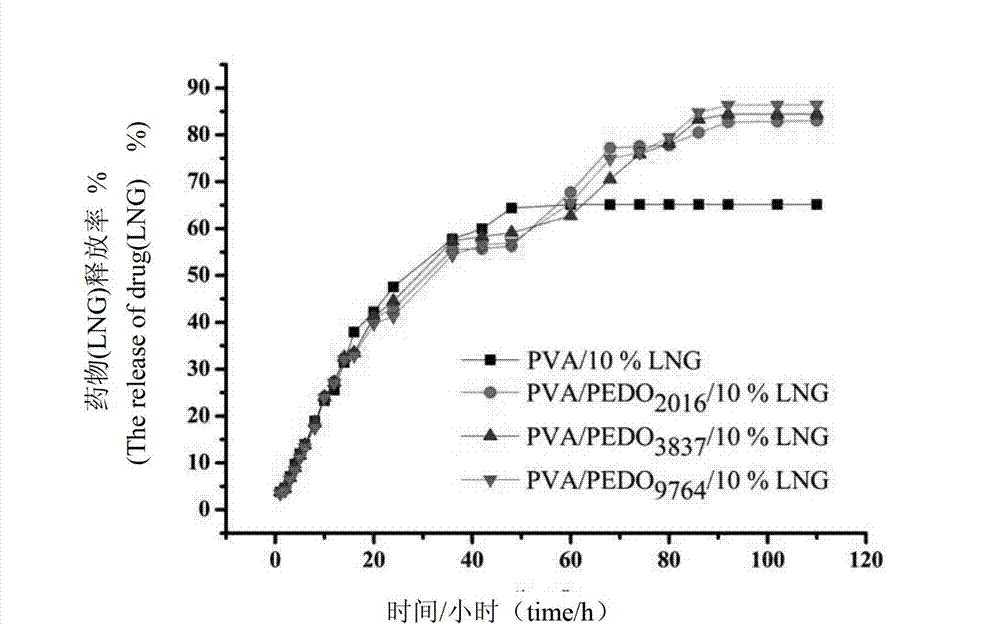

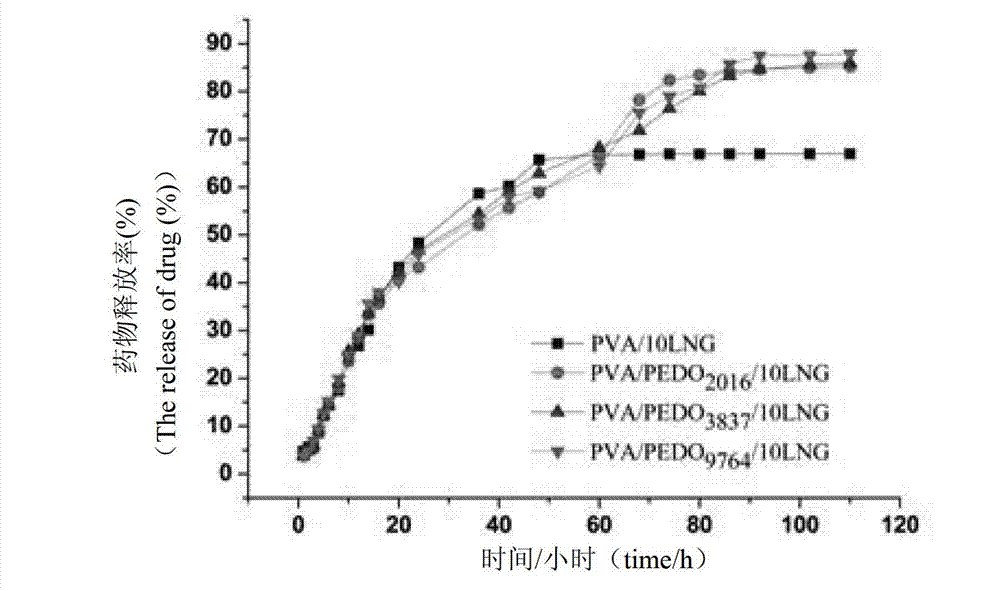

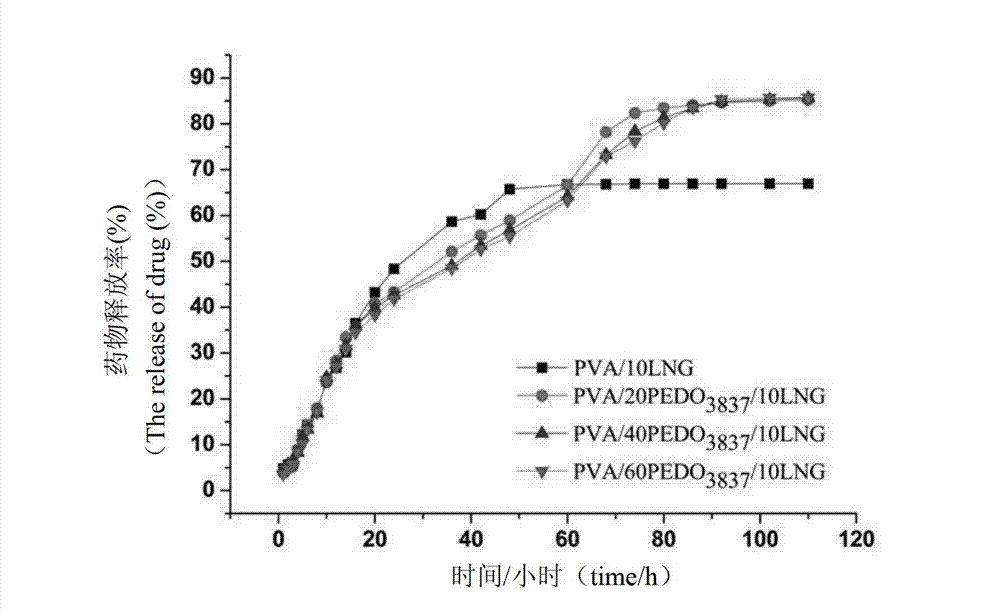

Spinning solution, nuclear shell nanofiber as well as preparation method and application thereof

InactiveCN103046158AAchieving shape controlEasy to preparePharmaceutical non-active ingredientsConjugated synthetic polymer artificial filamentsP-dioxanoneFiber

The invention discloses a spinning solution, nuclear shell nanofiber as well as a preparation method and application thereof. A hydrophobic drug and polyvinyl alcohol (PVA) / polyethylene glycol-b-poly(p-dioxanone) (PEG-b-PPDO) are blended to obtain a spinning solution system, and the nuclear shell nanofiber is directly formed by utilizing a single-axis spinneret under a high-voltage electrostatic effect. The preparation method disclosed by the invention has the advantages of simple equipment, mild conditions, simple flow and low energy consumption, can be used for achieving the aims of high-efficiency embedding of the hydrophobic drug, controllable drug release speed and long sustained release time, and is very suitable for industrial production.

Owner:SICHUAN UNIV

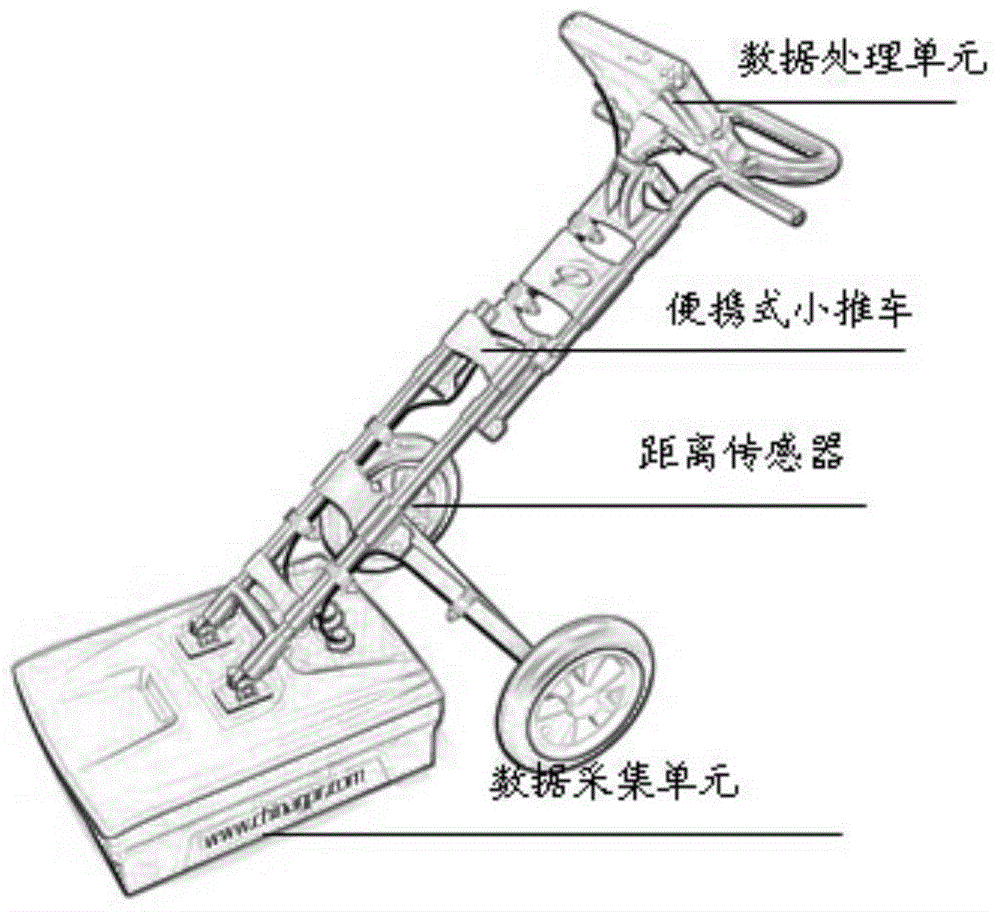

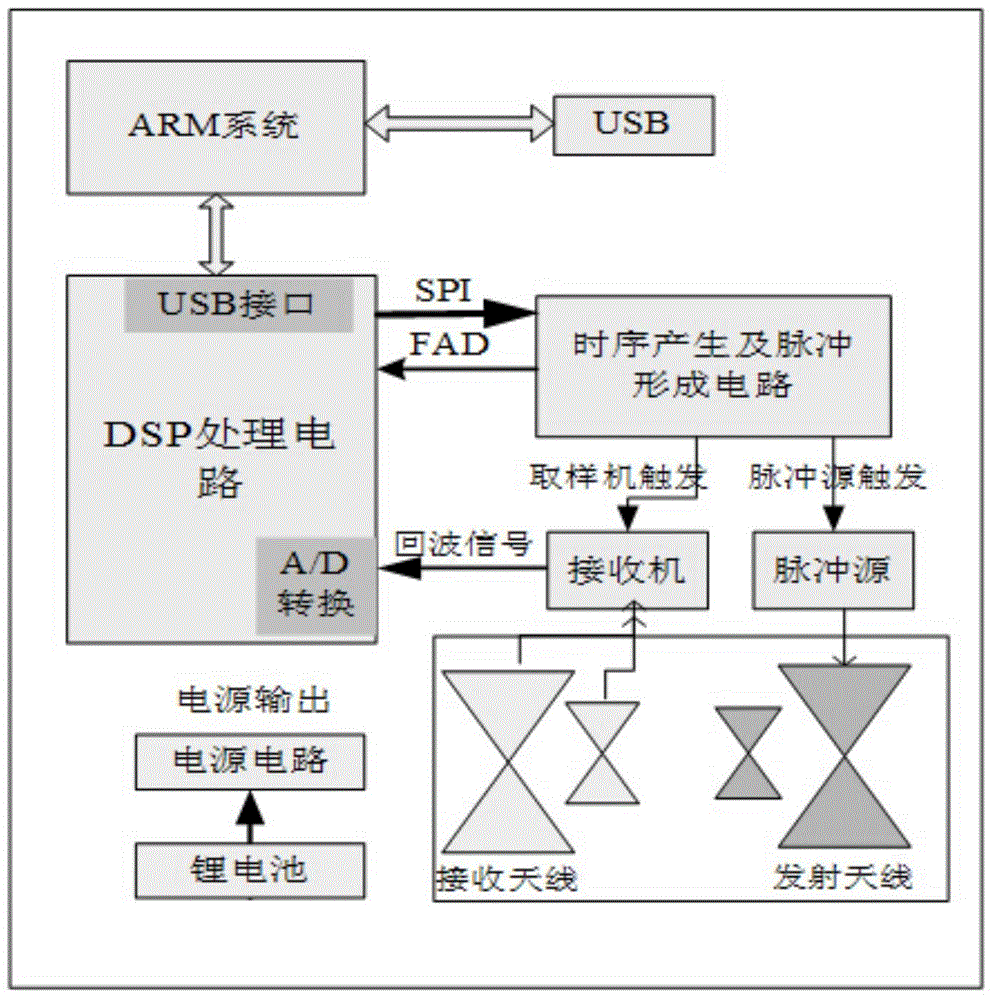

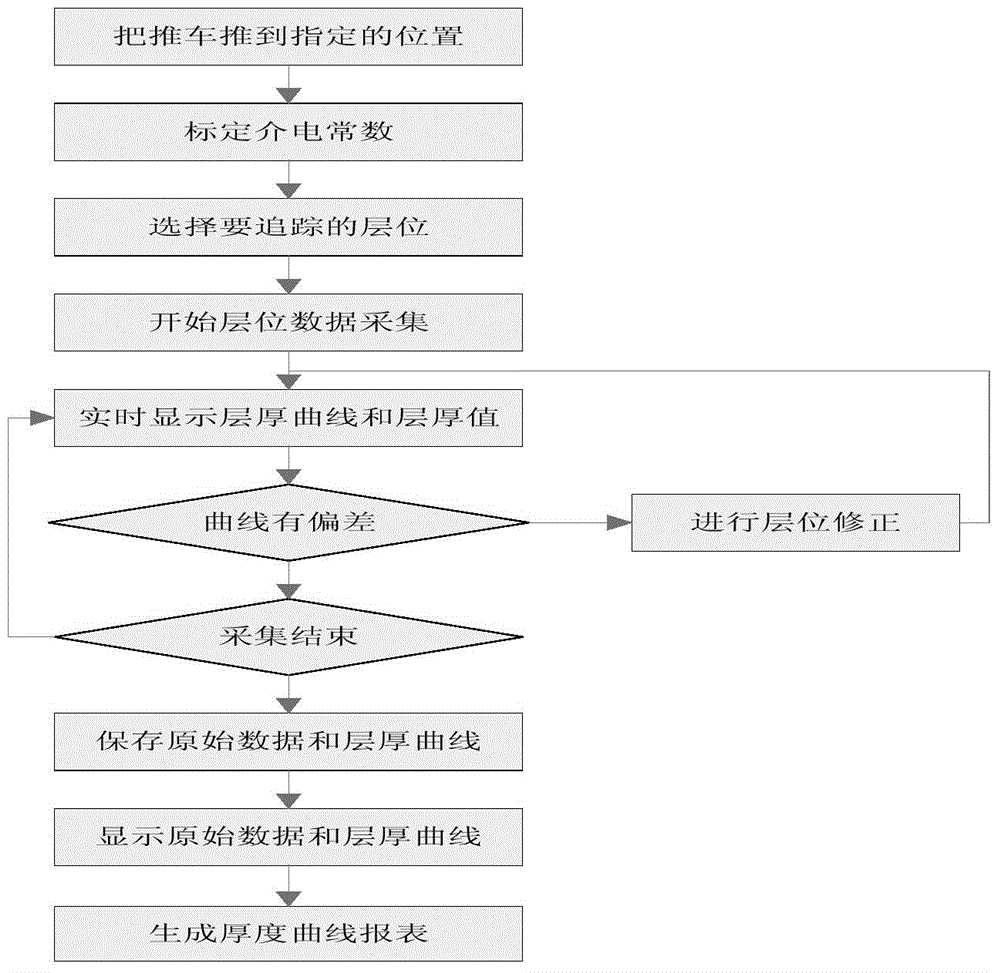

Radar device and method used for real-time detection of road structure layer thickness

InactiveCN104133212AImprove general performanceEasy to carryRadio wave reradiation/reflectionRadarLayer thickness

The invention discloses a radar device used for real-time detection of a road structure layer thickness. The device includes a trolley. A data acquisition unit, a data processing unit and a distance sensor are installed on the trolley, wherein the data acquisition unit is controlled by the data processing unit; and the data acquisition unit includes a radar control module, a wireless module and a power supply module. The invention also discloses a method used for real-time detection of the road structure layer thickness. The radar device is high in universality, convenient to carry and capable of offering layer thickness data in a real-time manner without follow-up processing. The method not only has a plurality of advantages of high distinguishing capability, high detection precision, high detection depth and convenient operation and the like, but also realizes change from manual explanation to software automatic explanation, and from postprocessing to real-time processing of radar data through special-purpose real-time road structure layer thickness detection software.

Owner:THE 22ND RES INST OF CHINA ELECTRONICS TECH GROUP CORP

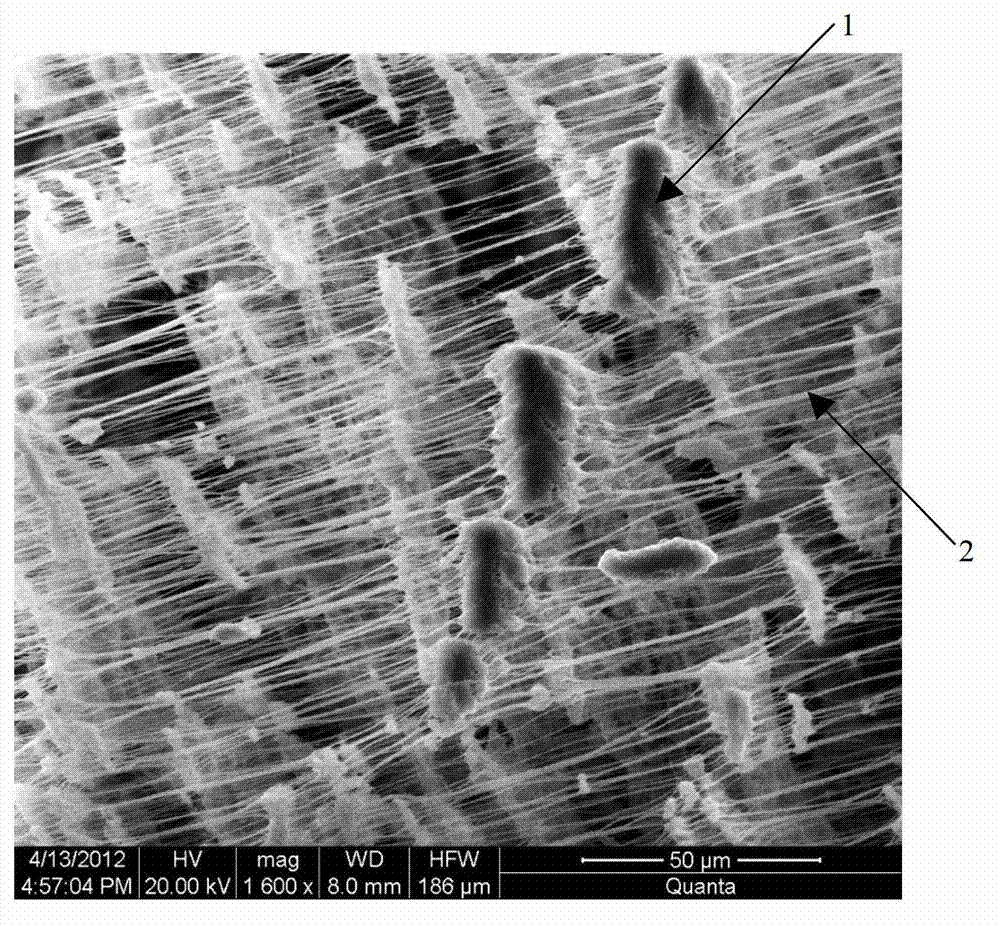

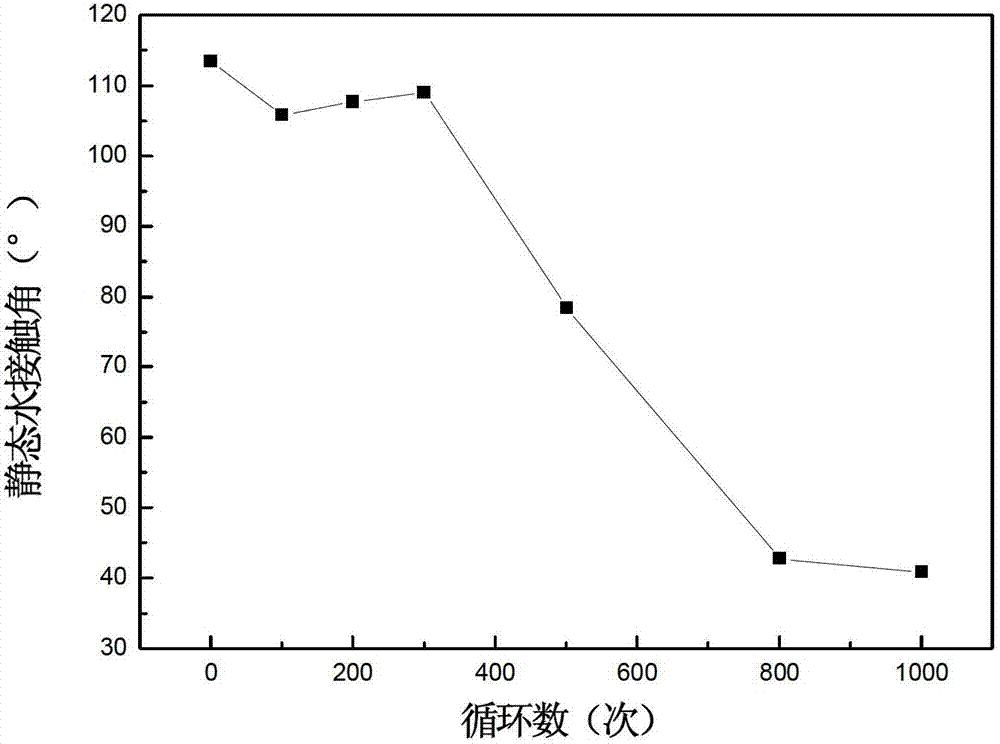

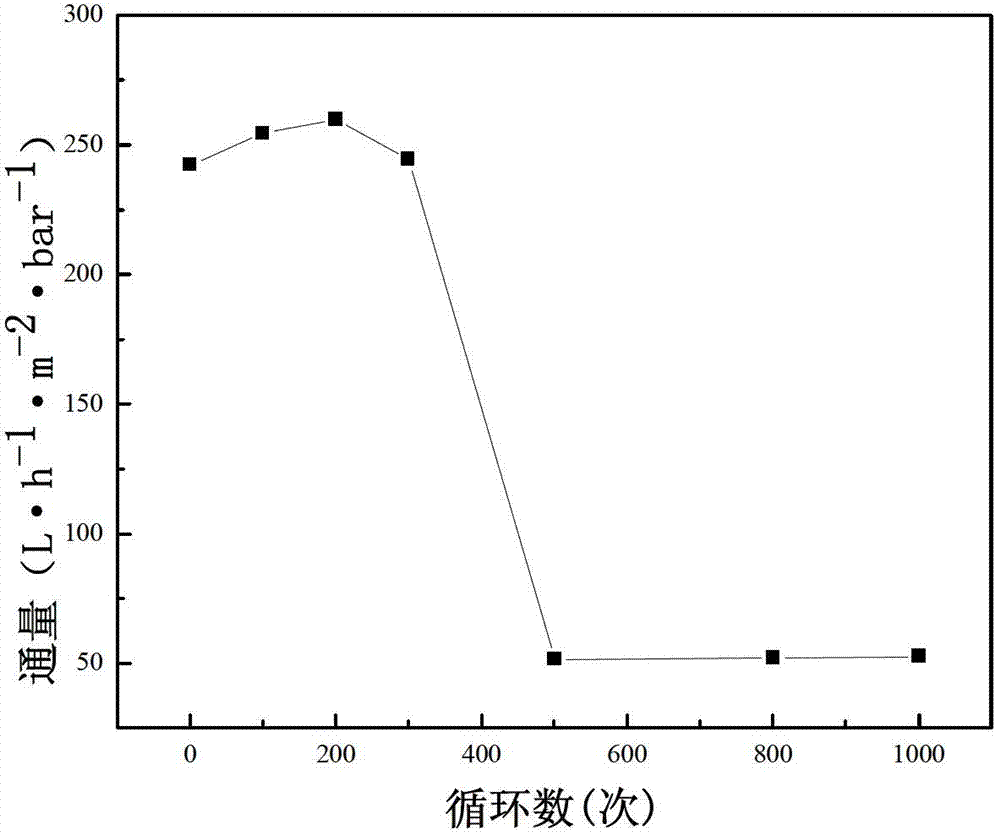

Method for modifying surface of polypropylene separation membrane

ActiveCN102728238AImprove surface propertiesImprove hydrophilicitySemi-permeable membranesPolypropyleneAtomic layer deposition

The invention relates to a method for modifying the surface of a polypropylene separation membrane, belonging to the field of membrane material. According to the method, the problems that the polypropylene separation membrane is poor in hydrophily, small in flux and easy to pollute can be solved; when the modified separation membrane is used as a lithium battery membrane, the performance and the safety of the lithium battery can be improved. According to the method, an oxide thin layer is continuously deposited on the channel surface of the PP separation membrane by using the atomic layer deposition, and the accuracy regulation of the aperture and the surface performance of the separation membrane are realized. The specific steps are as follows: (1) using acid, alkali, organic solvent and water to wash the PP (Propene Polymer) membrane, drying the PP membrane; (2) putting the PP membrane to a reaction chamber of an ALD (atomic layer deposition) instrument; vacuumizing and heating up to the deposition temperature; and maintaining temperature of the membrane for a certain time at set temperature; (3) pulsing metal source titanium tetrachloride or isopropyl titanate, cleaning air, water and cleaning air to the reaction chamber in sequence; and (4) preparing the modified membrane with needed performance by changing cycle indexes. According to the method, not only can the hydrophily, pure water flux and pollution resistance of the PP separation membrane be improved, but also the process is simple; and therefore, the batch production is realized easily.

Owner:NANJING UNIV OF TECH

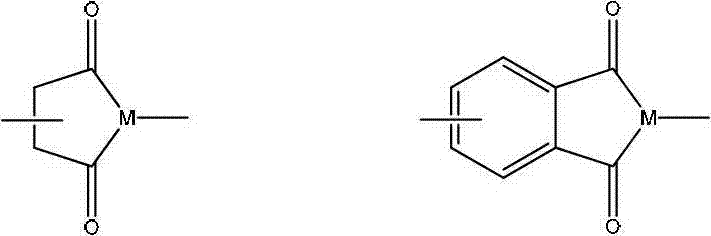

Method for preparing polyimide in supercritical carbon dioxide

ActiveCN102766260ANo pollution in the processSimple methodBulk chemical productionOrganic solventAniline

The invention relates to a method for preparing polyimide by performing polymerization reaction in supercritical carbon dioxide, belongs to the technical field of synthesis of polyimide polymer, and solves the technical problems that an organic solvent is needed and subsequent treatment difficulty is high in the synthesis reaction process of the polyimide in the prior art. According to the method, the polyimide is synthesized by taking acid anhydride or aniline as a blocking agent and the supercritical carbon dioxide as a medium. The method comprises the following steps of: adding dianhydride, a diamine monomer, a catalyst and the blocking agent into a reaction kettle at one time or in batches, introducing carbon dioxide, and gradually raising temperature and pressure to ensure that a system is in a supercritical state; and polymerizing at certain temperature and pressure to obtain a polyimide product with a good shape and high performance. The organic solvent is not used, the product is pure, subsequent treatment is not needed, the reaction medium is non-toxic and pollution-free, and the method is an economic, practical and environment-friendly process method for synthesizing and preparing the polyimide.

Owner:HANGZHOU SURMOUNT SCI & TECH +2

Method for preparing nano microcapsule of shell-core structure from supercritical fluid

InactiveCN106563399ANarrow particle size distributionEasy to operateNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsMicroballoon preparationChemistryNucleation

The invention relates to a preparation method of a nano microcapsule of an energetic material by using supercritical CO2 as an anti-solvent, an atomizing medium and a drying medium. A series of problems that the cladding is not uniform, cladding particle sizes are too large, the distribution range of the particle sizes is wide, the process operation is complicated, the application is limited, the environment is polluted, and the like, and which exist in an existing technical method in which the micronization is carried out first and then the cladding is carried out are mainly solved. According to the method, by using the supercritical CO2 as the anti-solvent, the atomizing medium and the drying medium, and based on the supercritical principle that the atomization is carried out first and then the crystallization is carried out, after a solution is atomized through a spray nozzle, a crystal nucleus is formed and grows inside a fog drop; a molecular chain of a cladding material collapses towards the interior of the fog drop; as the sum of the nucleation and growth times of a crystal is less than the collapsing time of the molecular chain, the crystalline particle of the energetic material is tightly enwrapped by the cladding material; and the nano microcapsule of the shell-core structure is formed. By using the method, a micronization technique and a cladding technique are integrated; a preparation process is accomplished at one fling; the subsequent treatment is not needed; the production efficiency is high; the preparation quality of the microcapsule is good; and the sphericity of the particle is good.

Owner:ZHONGBEI UNIV

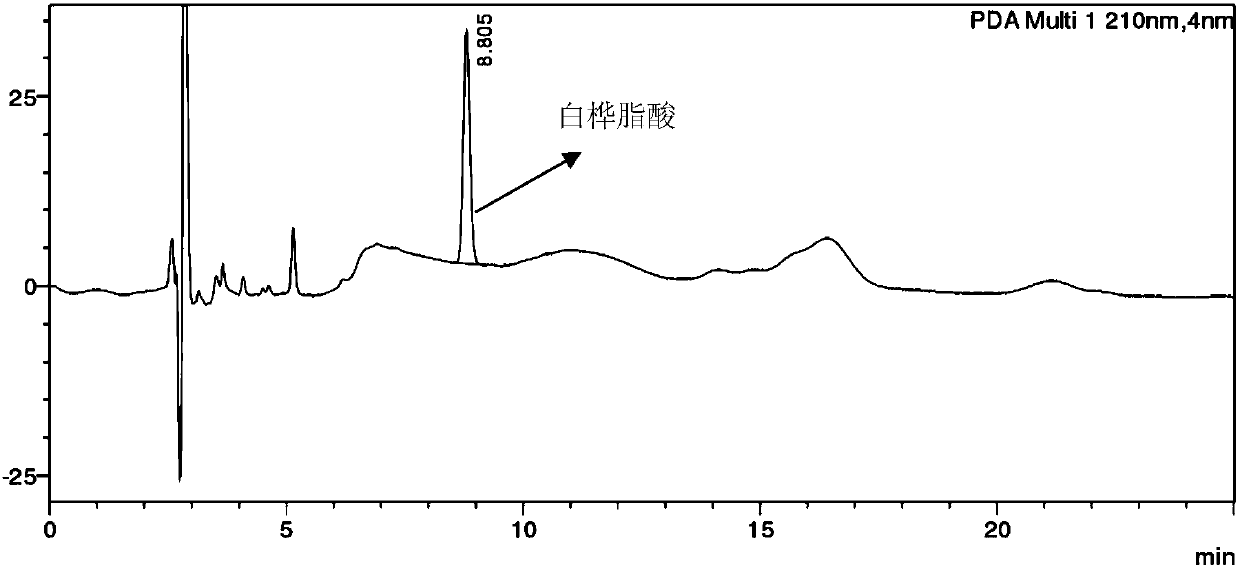

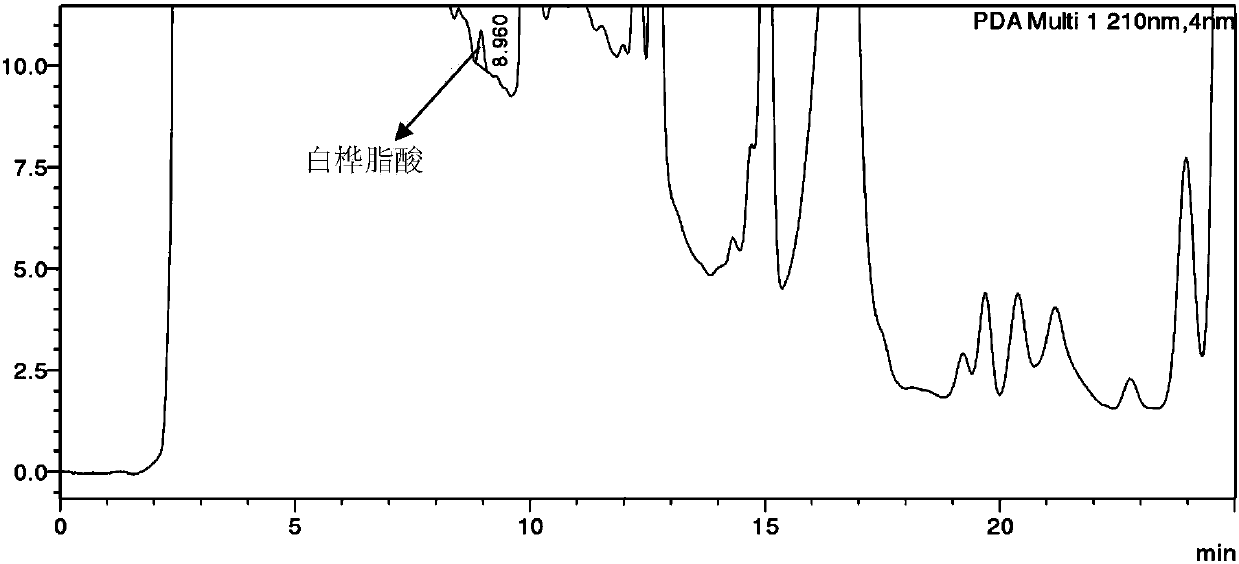

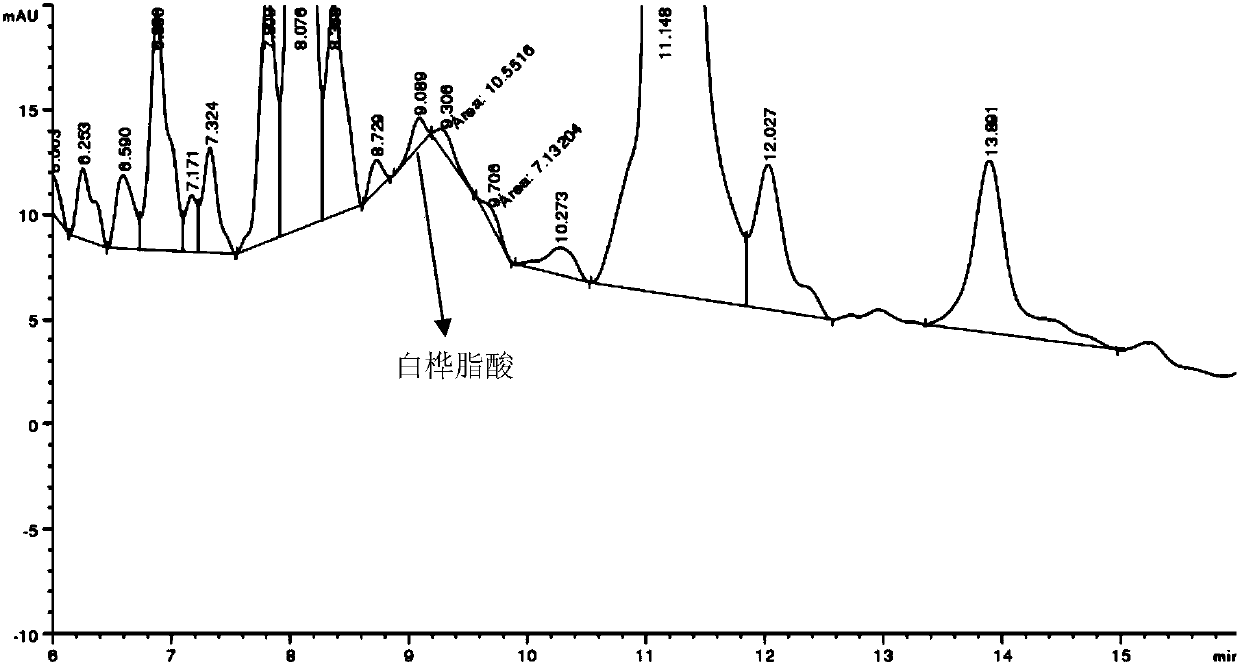

Method for extracting triterpene substances from inonotus obliquus by use of quorum sensing molecules induction

InactiveCN107841523AIncrease productionBiologically activeFungiMicroorganism based processesLiquid mediumTriterpenoid

The invention discloses a method for extracting triterpene substances from inonotus obliquus by use of quorum sensing molecules induction, wherein the method comprises the following steps: adding activated inonotus obliquus CFCC 83414 into a liquid medium, and performing fermentation culture for 8-14 days at 24-26 DEG C; adding quorum sensing molecules in the 5th-8th days of the fermentation; after the fermentation, separating thalli and fermentation liquid; performing aftertreatment to separate and purify triterpene substances from the thalli and fermentation liquid. According to the method disclosed by the invention, quorum sensing molecules are added in the fermentation metaphase to stimulate growth of inonotus obliquus; the method does not need introduction of a gene engineering strainor additional enzyme, is simple in aftertreatment, and can effectively increase the yield of triterpene substances in inonotus obliquus.

Owner:ZHEJIANG UNIV

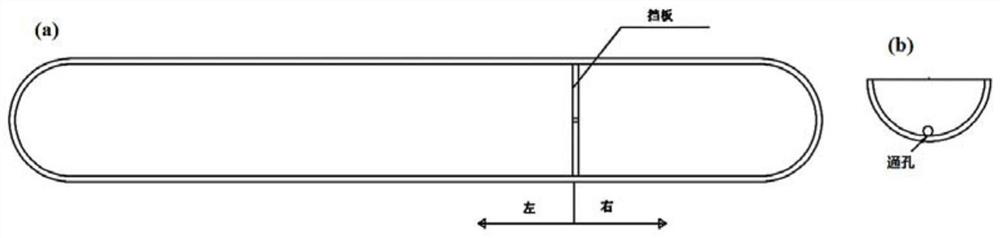

Preparation method of ultra-pure tellurium

PendingCN111924811AImprove purification efficiencyUltra High Purity Tellurium Bright SurfacePolycrystalline material growthBy zone-melting liquidsPhysical chemistryMetallic materials

The invention discloses a preparation method of ultrahigh-purity tellurium, and belongs to the field of high-purity metal materials. The method comprises the following steps: putting raw material tellurium into a container in which a baffle plate is arranged, positioning the raw material tellurium on one side of the baffle plate; heating the raw material tellurium under the protection of shieldinggas until tellurium is completely molten; and controlling the liquid level of the tellurium melt on the side where the raw material tellurium is located to be above the through hole of the baffle plate so that impurities (carbon powder and oxide) in the raw material tellurium are intercepted on one side of the baffle plate. The impurity content of the tellurium melt flowing to the other side through the through hole is reduced, the part of tellurium melt is condensed and then used for preparing the ultra-pure tellurium, the purification efficiency is improved, and the obtained ultra-pure tellurium is bright in surface, free of oxide and free of subsequent treatment.

Owner:清远先导材料有限公司

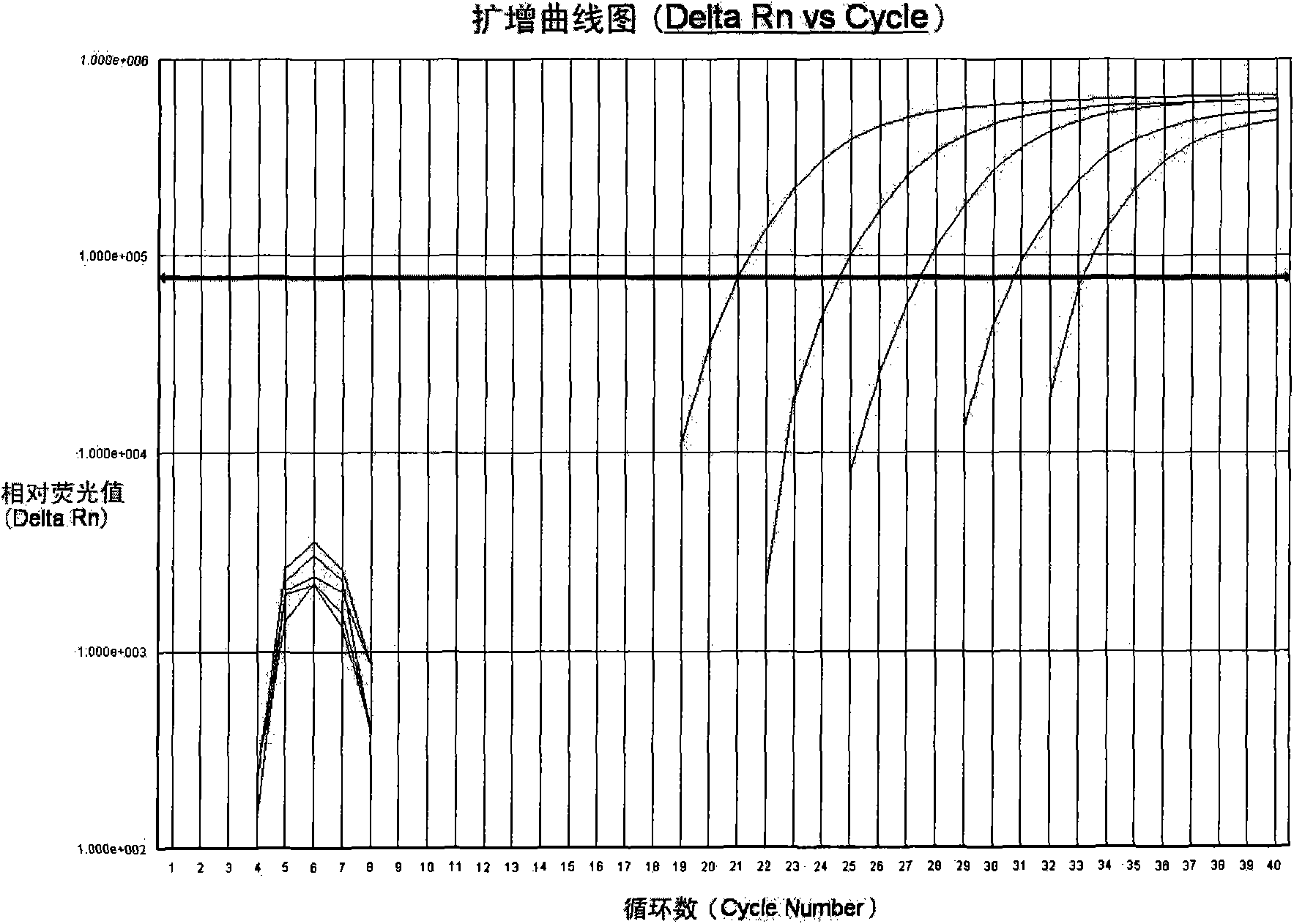

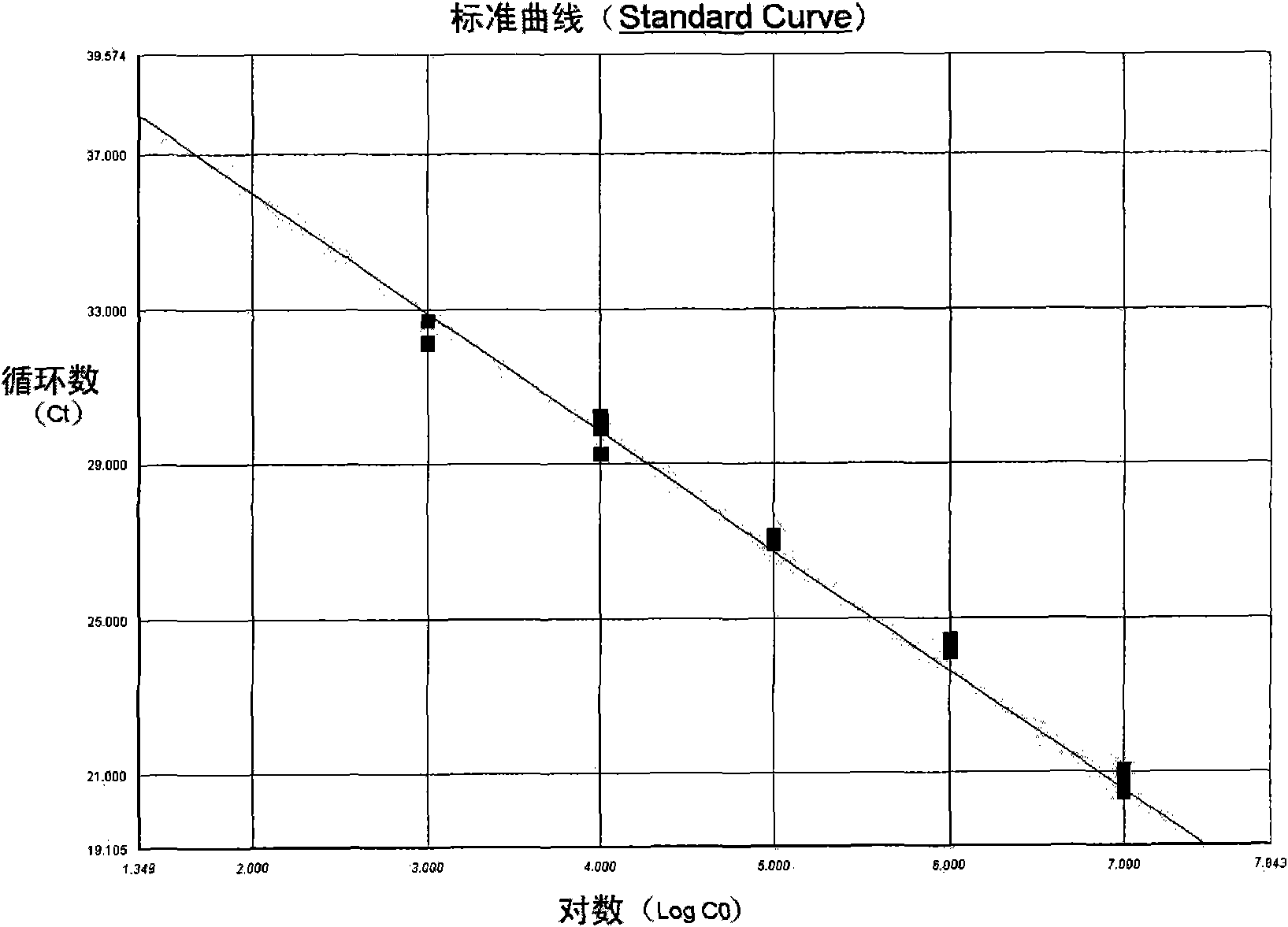

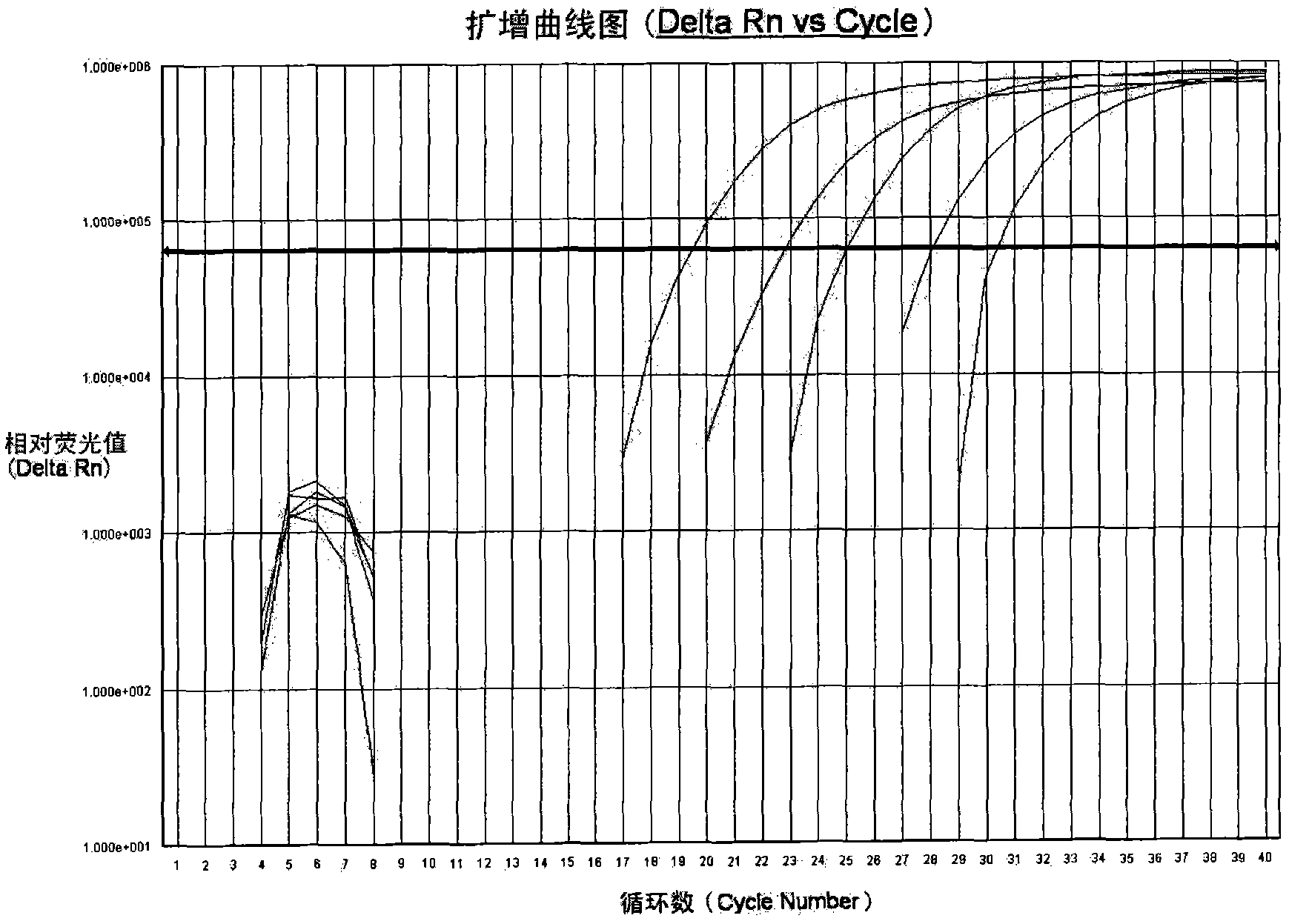

Fluorescent PCR (Polymerase Chain Reaction) kit for quantitively detecting HPV16/18 type infection

InactiveCN101781686AIncreased sensitivityReduce the risk of contaminationMicrobiological testing/measurementMicroorganism based processesFluorescenceControl substances

The invention discloses a fluorescent PCR (polymerase chain reaction) kit for quantitatively detecting human papilloma virus (HPV) 16 / 18 type infection, belonging to the field of in vitro nucleic acid diagnosis kits. The kit comprises a quantitive reference substance, a negative reference control substance, a positive reference substance, a critical positive reference substance, a fluorescent polymerase chain reaction solution, PCR serotype specific primers, a specific fluorescent probe and a DNA extraction solution. The kit comprises a multi-PCR system based on a fluorescent PCR technology, which consists of the positive and reverse primers and the fluorescent probe which aim at 16 type HPV and 18 type HPV and can simultaneously detect the DNA of the 16 type HPV and the 18 type HPV in a reaction tube under appropriate PCR conditions. The kit can simply, conveniently and rapidly detect the HPV infection in a clinical sample and has high specificity and great clinical value on early prevention and treatment of cervical carcinoma.

Owner:道可名康医学发展(上海)有限公司

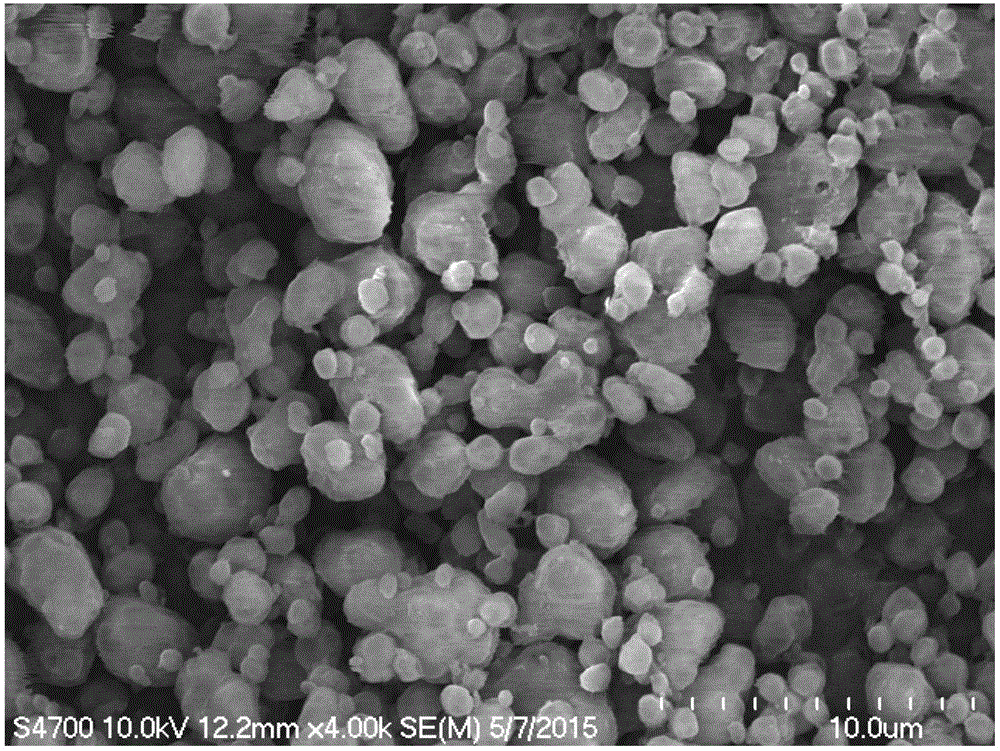

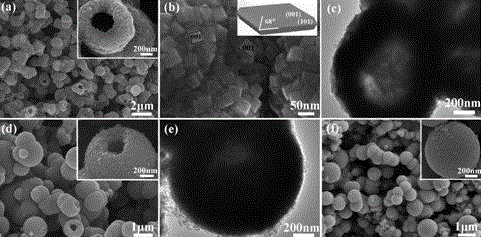

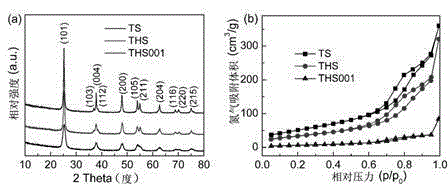

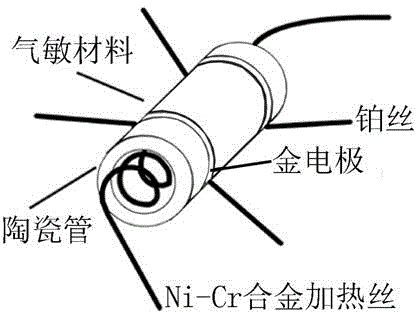

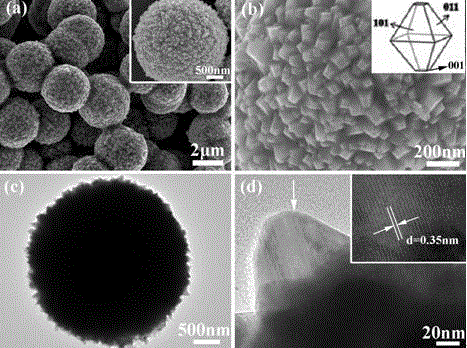

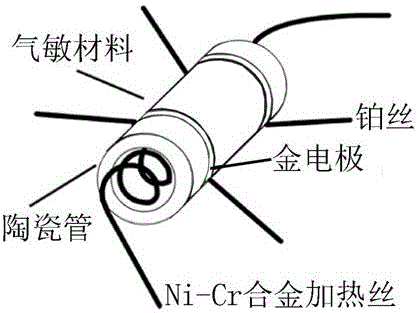

Acetone gas sensor and preparation method thereof

ActiveCN104965008AEasy to prepareSimple processMaterial resistanceAnatase titanium dioxideOperating temperature range

The invention discloses an acetone gas sensor and a preparation method thereof. The preparation method comprises the following steps: firstly, controlling hydrolysis, nucleation and crystallization processes of titanium source titanium sulfate by utilizing ammonium fluoride, and carrying out one-step quick hydrothermal reaction to obtain a three-dimensional hierarchical TiO2 hollow sphere material with anatase-phase high-energy {001} crystal face exposure; and then, adopting a heater-type gas sensor to carry out gas-sensitive material coating, welding and ageing to prepare a semiconductor type gas-sensitive device by a normal process. According to the gas-sensitive property test results, the device can detect acetone within different working temperature ranges, so that structure-enhanced gas-sensitive properties are shown. According to the invention, the construction for the gas sensor based on the three-dimensional hierarchical TiO2 hollow sphere material with anatase-phase high-energy {001} crystal face exposure is firstly realized, so that the research thought of the semiconductor type gas sensor is expanded.

Owner:JIANGXI NORMAL UNIVERSITY

Preparation method of porous structure ammonium vanadate material

ActiveCN103715407AHeating evenlyImprove efficiencyCell electrodesSecondary cellsChemical reactionReaction temperature

The invention provides a preparation method of a porous structure ammonium vanadate material. The preparation method comprises the following steps: dissolving ammonium metavanadate in deionized water so as to obtain a NH4VO3 solution A; adjusting the pH value of the solution A to 1.5-3.0, and then carrying out phonochemistry reaction so as to obtain a solution B; pouring the solution B into a reactor, enabling microwaves and an ultraviolet lamp to simultaneously act on the solution B, heating to 60-90 DEG C, preserving heat, and then naturally cooling to a room temperature; and carrying out centrifugal separation on suspension liquid in the reactor so as to obtain a powder product, washing and drying, thus obtaining the porous structure ammonium vanadate material. The NH4V3O8 microcrystal prepared by the method is uniform in chemical composition and relatively high in purity, is a special porous structure and has good electrochemistry performance when serving as an anode material for a lithium ion battery; the specific area of the material can be effectively enlarged. The preparation method is simple, low in reaction temperature, short in reaction time, environmentally-friendly and suitable for large-scale production; the follow-up treatment is not needed.

Owner:盐城大数据资产经营管理有限公司

Peat absorbent and method thereof for processing soil polluted by spilled oil

ActiveCN101711974AWide range of applicationsAvoid volatilization and leakageOther chemical processesContaminated soil reclamationEnvironmental standardPetroleum

The invention discloses a peat absorbent and a method thereof for processing soil polluted by spilled oil. The peat absorbent is prepared by mixing meadow peat, sphagnum peat and a nitrogenous fertilizer which are proportioned in a way that: in the total weight of 100, the weight percentage of the meadow peat is 25 to 33, the weight percentage of the sphagnum peat is 20 to 33 and the weight percentage of the nitrogenous fertilizer is 25 to 50. The method for processing the soil polluted by the spilled oil is implemented orderly through the following steps: spraying the absorbent into the polluted soil in a shortest time after the soil is polluted by the spilled oil, wherein the input amount of the absorbent is 0.1 to 0.17 times as great as oil spillage; adding quicklime into the soil polluted by the spilled oil, wherein the input amount of the quicklime is 0.1 to 0.3 times as great as the oil spillage; ploughing up the polluted soil sprayed with the absorbent and added with the quicklime, wherein the depth of ploughing is determined according to the penetration depth of the oil; irrigating the polluted soil in a way that the moisture of the soil reaches 80 to 85 percent; and monitoring the content of petroleum hydrocarbon in the polluted soil until the soil meets environmental standards for reuse.

Owner:PIPECHINA SOUTH CHINA CO

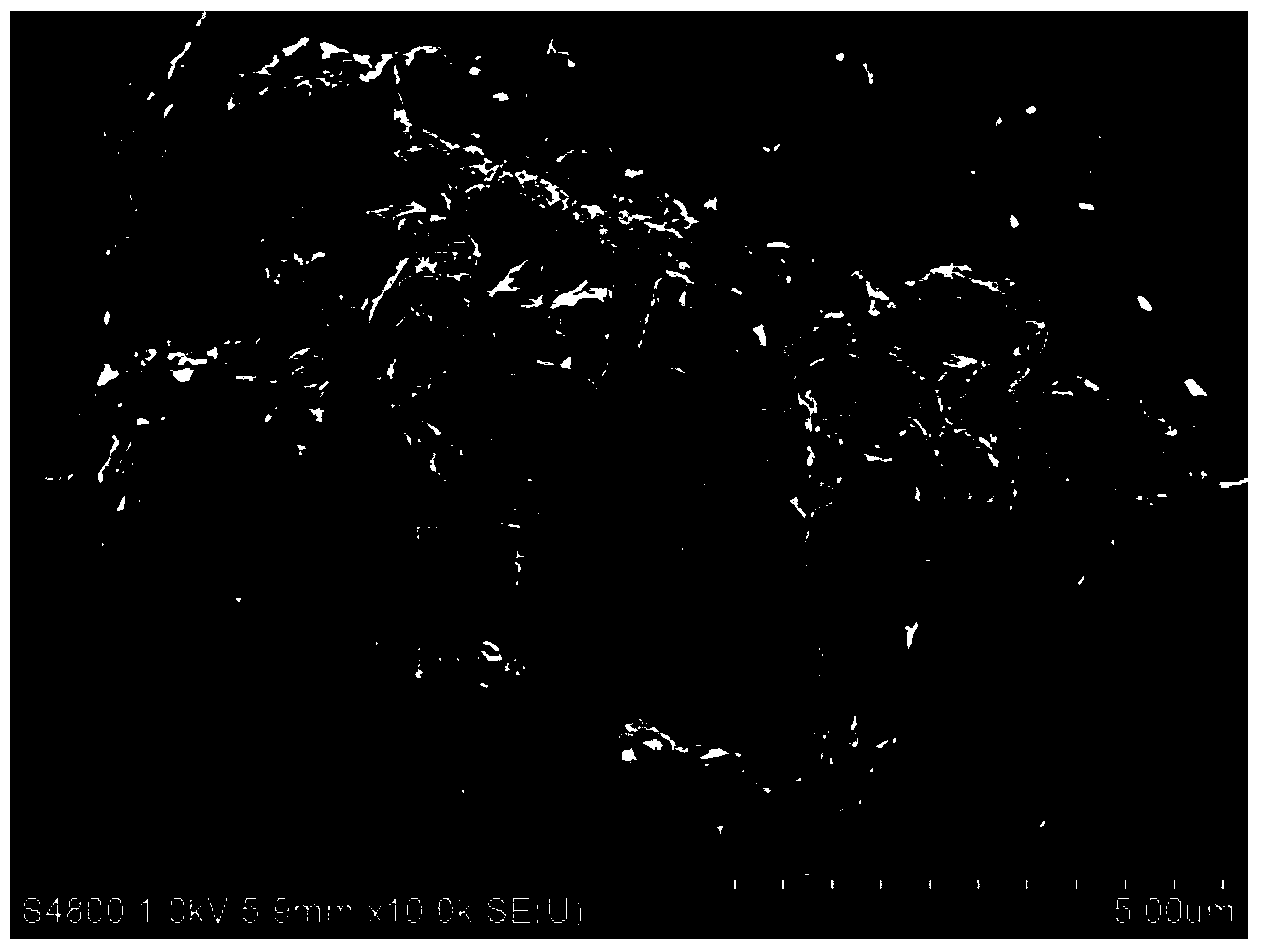

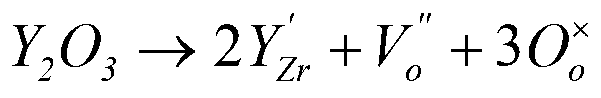

Graphene-ceramic composite material and preparation method thereof

The invention discloses a preparation method of a graphene-ceramic composite material. The preparation method comprises the following steps of: (1), penetrating cerate (or zircon salt), auxiliaries and graphene oxide through alcohol dissolving auxiliaries, ultrasonically dispersing the materials uniformly for co-decomposing into metal oxides to obtain a composite material; (2), adding organic adhesive solvent to the graphene-metal oxide composite material for sufficiently mixing and grinding; pressing the mixture into a strip-shaped composite sample by adopting a dry-press process, placing the composite sample in a vacuum tube furnace; and controlling the sintering condition by ventilating a gas mixture of a certain proportion, cooling to the room temperature to obtain the graphene-ceramic composite material. The preparation method of the graphene-ceramic composite material disclosed by the invention can be used for improving the dispersibility and cycling stability of ceramic oxide particles, increasing a three-phase interface among the ceramic oxide particles and improving the electrochemical activity of the composite material, so that the ceramic material has the advantages of being low in density, high in strength, excellent in oxidation resistance, thermal scouring resistance, corrosion resistance and the like.

Owner:SHAANXI COAL & CHEM TECH INST

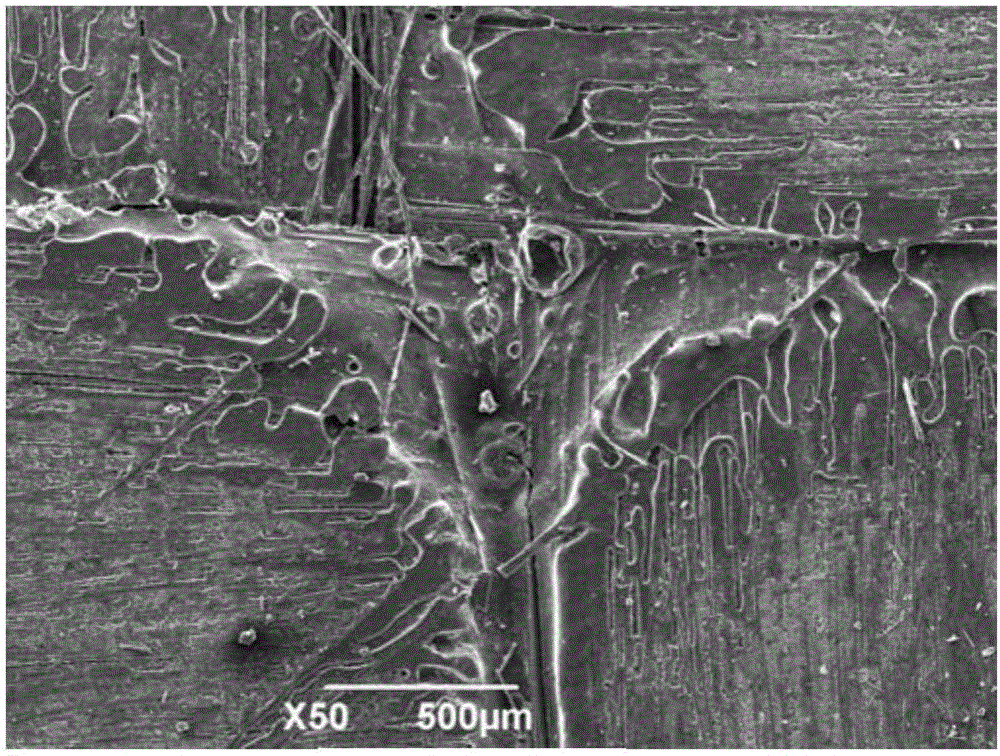

Welding forming method of thin invar alloy

InactiveCN102240851AAchieve weldingContinuously adjustable widthLaser beam welding apparatusInvar alloyShielding gas

The invention discloses a welding forming method of a thin invar alloy. The welding is carried out by adopting an Nd: YAG laser device. The welding forming method comprises the steps of: fixing the invar alloy in a fixture and then installing the invar alloy on a workbench; adjusting the pulse width and the pulse frequency of the Nd: YAG laser device, relative position of the laser and the thin invar alloy and the pressure of a side-blown protective gas; determining proper laser average line energy density; and carrying out forming welding on the thin invar alloy. The welding of the invar alloy is realized directly by using the laser, so that extra welding wires are not needed while welding. The pulse width, the pulse frequency and the defocusing amount of the laser device are continuously adjustable, so that the invar alloy of 0.5-2 mm in thickness can be formed by autogenous welding. And the pulse laser line energy density of the Nd: YAG laser device in the invention is between 100-900 J / mm, therefore, the welding line without obvious positive and negative weld reinforcements and pores and cracks can be realized, and follow-up processes to the welding line are not needed.

Owner:DALIAN UNIV OF TECH

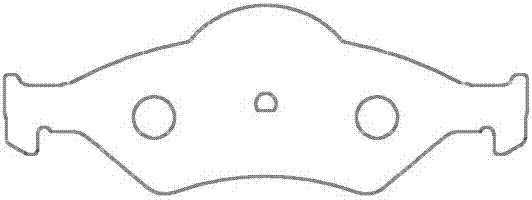

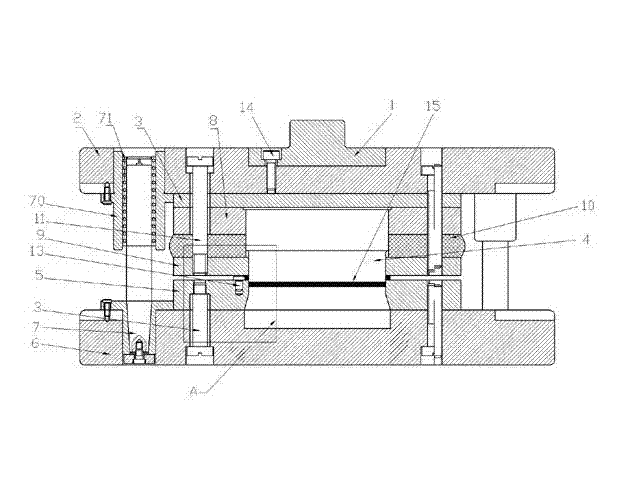

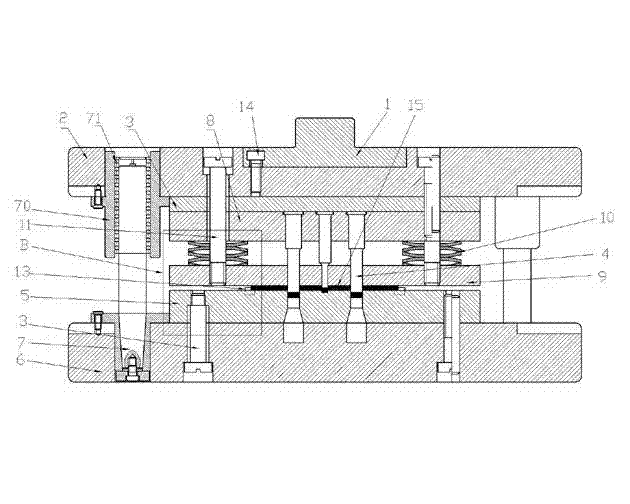

Fine stamping die and fine stamping method of automobile disc brake pad steel back

The invention discloses and provides a fine stamping die and a fine stamping method of an automobile disc brake pad steel back. The fine stamping die of the automobile disc brake pad steel back comprises a die handle (1), a punch set (2), an upper base plate (3), a core die (4), a cavity die (5) and a die set(6), wherein the die handle (1) is arranged on the punch set (2) and the cavity die (5) is arranged on the die set(6); the fine stamping die of the automobile disc brake pad steel back comprises an elastic discharging device as well; the punch set (2), the upper base plate (3) and the elastic discharging device are sequentially connected through a screw (11), the core die (4) penetrates and is connected inside the elastic discharging device in a sliding mode, and the core die (4) and the elastic discharging device are both located above the cavity die (5). Based on the fine stamping die, the fine stamping method of the automobile disc brake pad steel back has the advantages of being high in efficiency, low in energy consumption, capable of effectively improving the quality of the product and low in production cost and being capable of effectively removing the defect caused by the normal stamping method.

Owner:ZHUHAI HUALI FRICTION MATERIAL

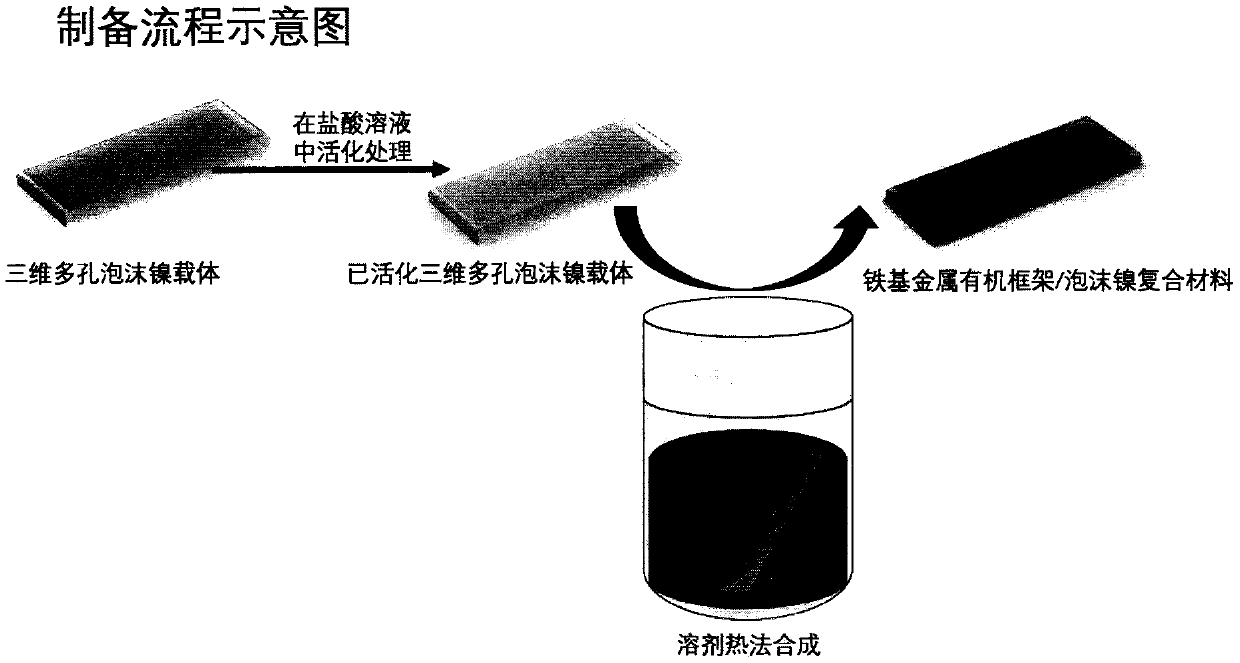

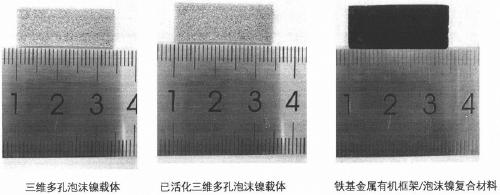

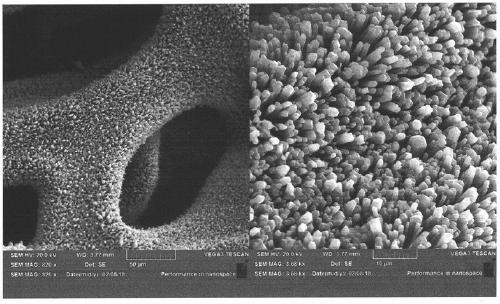

Novel bifunctional electrochemical efficient catalyst composite material and preparation method thereof

PendingCN111318306ALarge specific surface areaImproving the performance of electron transport and other aspectsOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesPtru catalystIron salts

The invention belongs to the technical field of new energy materials, and particularly relates to a novel bifunctional electrochemical efficient catalyst, in particular to a metal organic framework (MOF) array constructed by introducing ferrous ions and a preparation method thereof. The preparation method comprises the following steps: (1) putting nickel foam (NF) into a hydrochloric acid solutionto remove impurities such as nickel oxide on the surface, improving the adhesive force of reactants on the surface of nickel foam, taking out, washing, and drying water on the surface to obtain an activated nickel foam carrier; and (2) weighing iron salt according to a certain molar weight, taking a certain amount of ligand, dissolving iron salt and the ligand in a solvent, immersing the nickel foam carrier obtained in the step (1) into the solution, and carrying out a solvothermal reaction to obtain the iron-based metal organic framework composite material with a columnar structure. The prepared novel bifunctional electrochemical catalyst has a large current effect and super-stability under a high current density, and thus the novel bifunctional electrochemical catalyst has a more excellent electrochemical catalytic performance and higher stability.

Owner:HUBEI UNIV +1

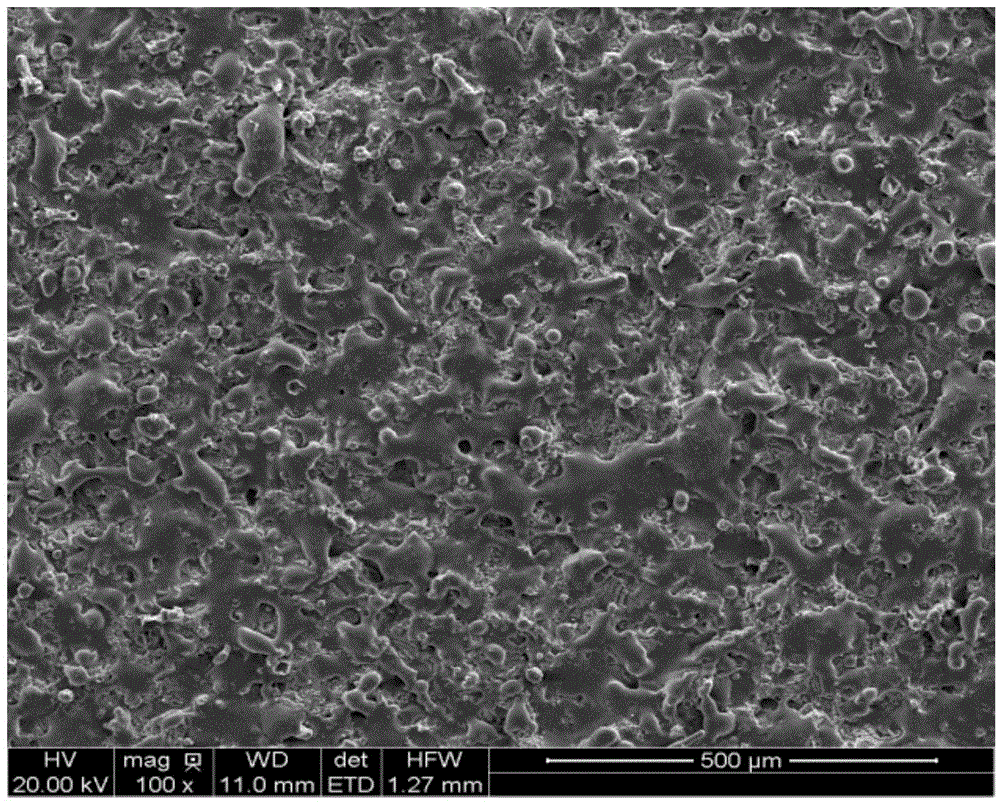

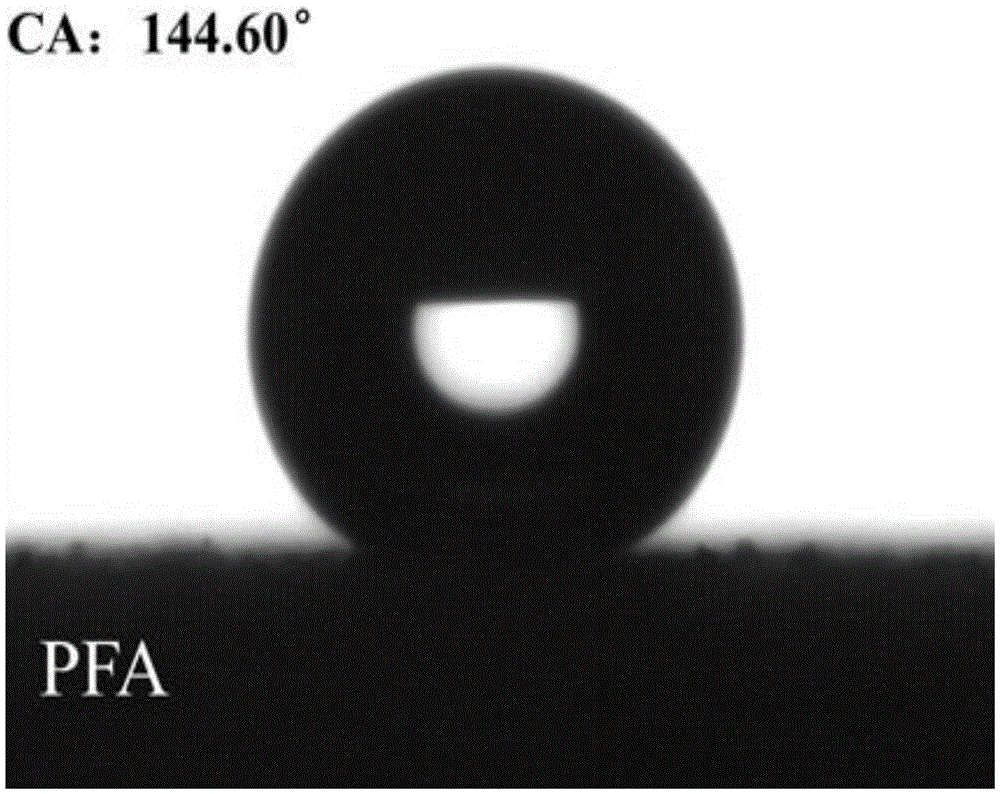

Method for preparing hydrophobic coating through liquid material thermal spraying

ActiveCN105478322ASimple processReduce equipment costsPretreated surfacesSpecial surfacesSolventMicrometer

The invention relates to a method for preparing a hydrophobic coating through liquid material thermal spraying. The method includes the following steps that fusible polytetrafluoroethylene particles are added into a solvent, and turbid liquid is obtained; the surface of a matrix is subjected to pretreatment oil removal and roughening; and the turbid liquid is sprayed to the pretreated surface of the matrix through liquid material thermal spraying, and the hydrophobic coating is prepared. The liquid material thermal spraying is liquid material flame spraying or liquid material plasma spraying. The mass percent of the fusible polytetrafluoroethylene particles in the solvent ranges from 10% to 50%, and the particle size of the fusible polytetrafluoroethylene particles ranges from 10 micrometers to 100 micrometers. The method for preparing the hydrophobic coating has the advantages of being simple, low in cost, flexible in process, free of following processing and suitable for industrial production, achieving one-time forming and the like; and the method has wide application prospects and economic benefits in the field of coating preparation.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

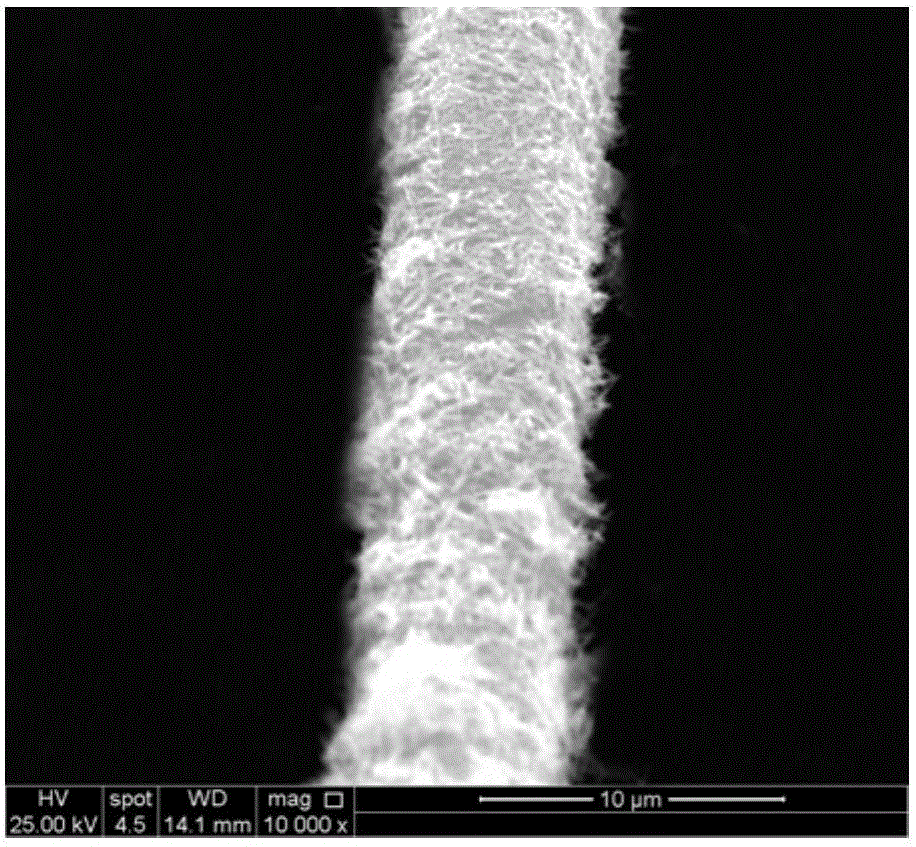

Preparation method and application of carbon-fiber-reinforced macromolecule-based composite

ActiveCN105690802AShort preparation cycleThe process is simple and easy to controlCoatingsFiberCarbon fibers

The invention discloses a preparation method and application of a carbon-fiber-reinforced macromolecule-based composite. A saline solution required by an inorganic compound is put in a reaction kettle, a base material used for inducting an alternating magnetic field is put in the reaction kettle, the reaction kettle is sealed and then put into water-heat induction heating equipment, then the reaction kettle is cooled to the room temperature, and the base material loaded with the inorganic compound is taken out to be cleaned and dried; and finally, hot press molding is conducted on the base material, and the carbon-fiber-reinforced macromolecule-based composite is obtained. According to the method and application, the water-heat induction heating technology is applied to surface grafting of a carbon fiber, and the defect that the carbon fiber cannot be combined with other components easily due to surface inertia of the carbon fiber is overcome. In addition, under the action of the alternating magnetic field, multiple kinds of nanometer materials are promoted to grow on the surface of the carbon fiber due to the high temperature of the carbon fiber, more engaged position points are provided for bonding of the carbon fiber and resin, and interfacial bonding of the carbon fiber and the resin and the mechanical performance of the composite are improved.

Owner:SHAANXI UNIV OF SCI & TECH

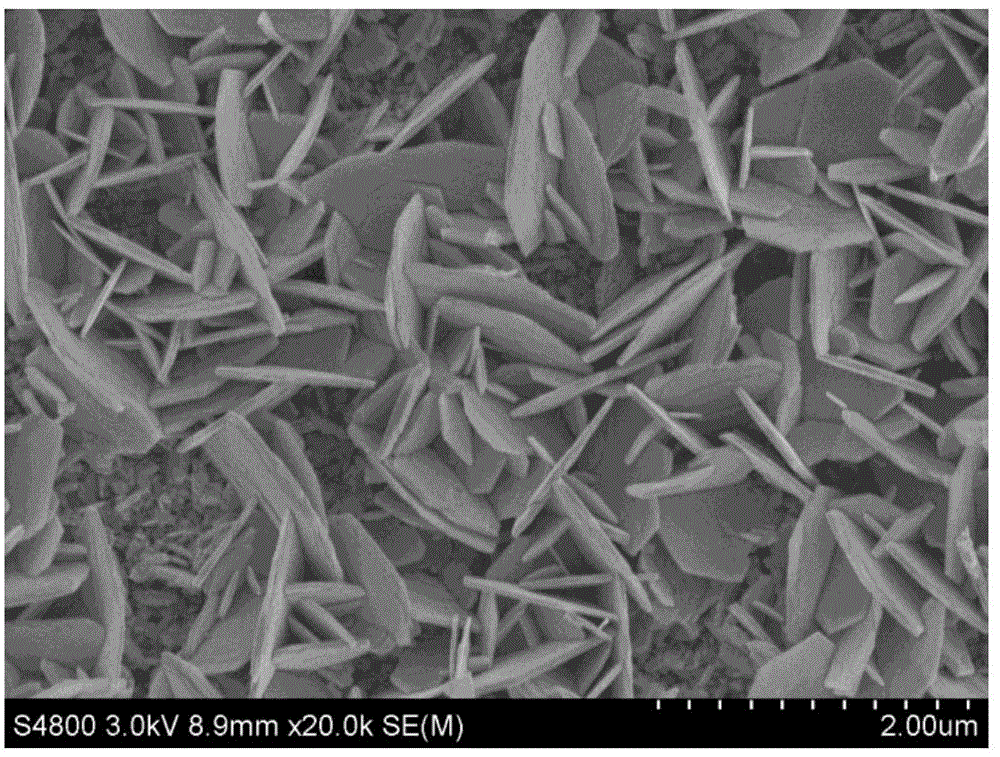

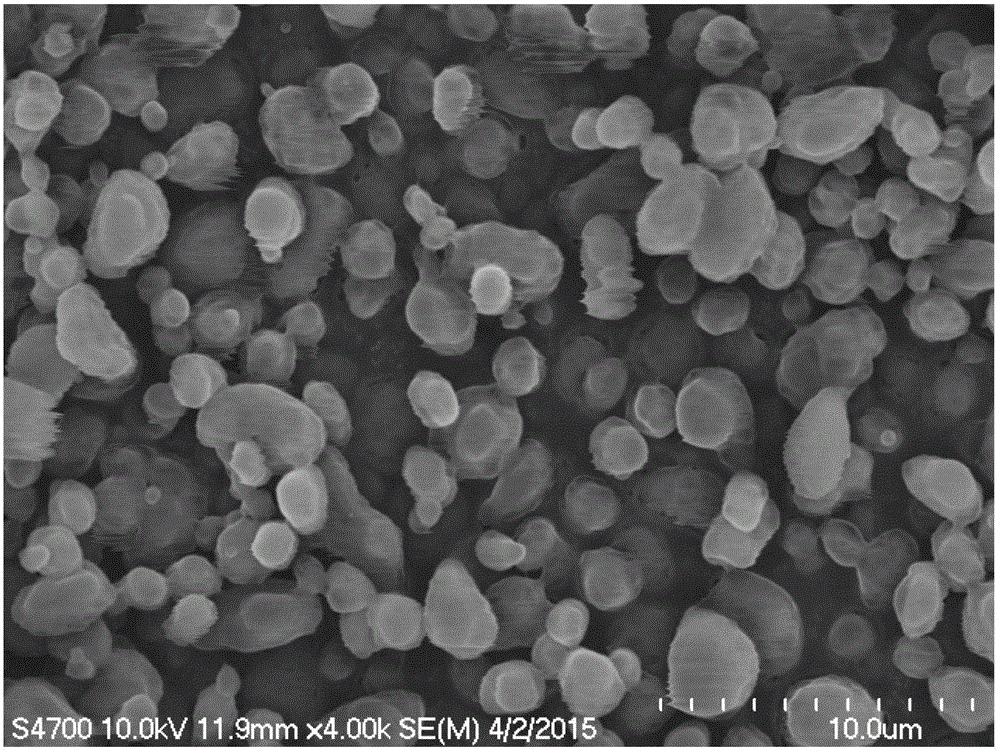

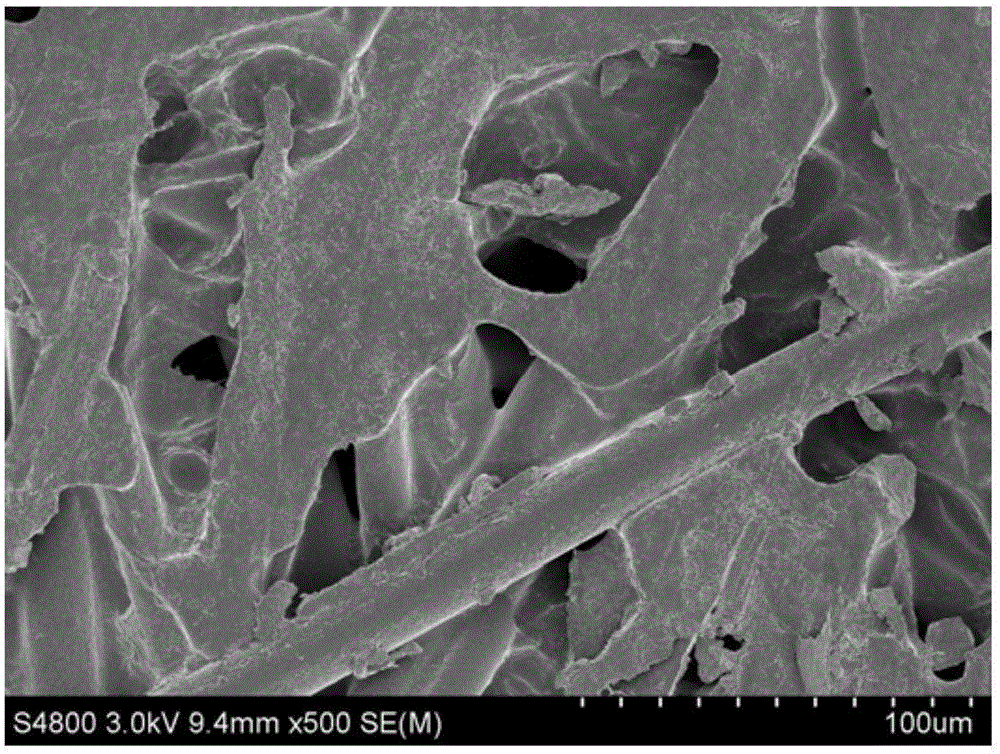

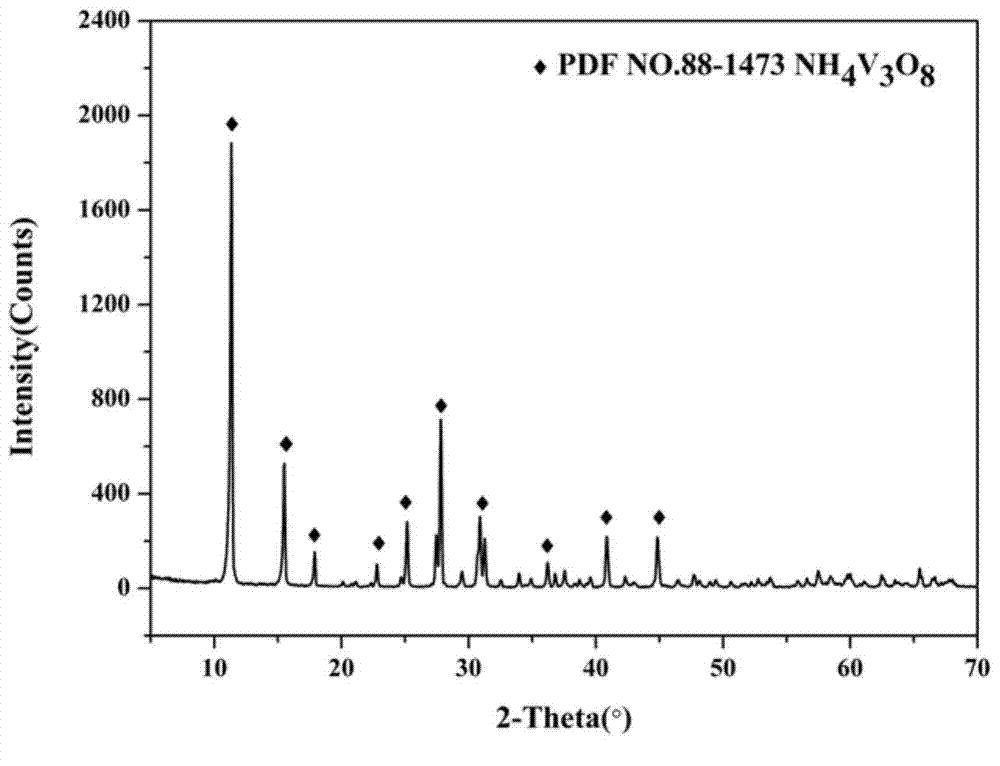

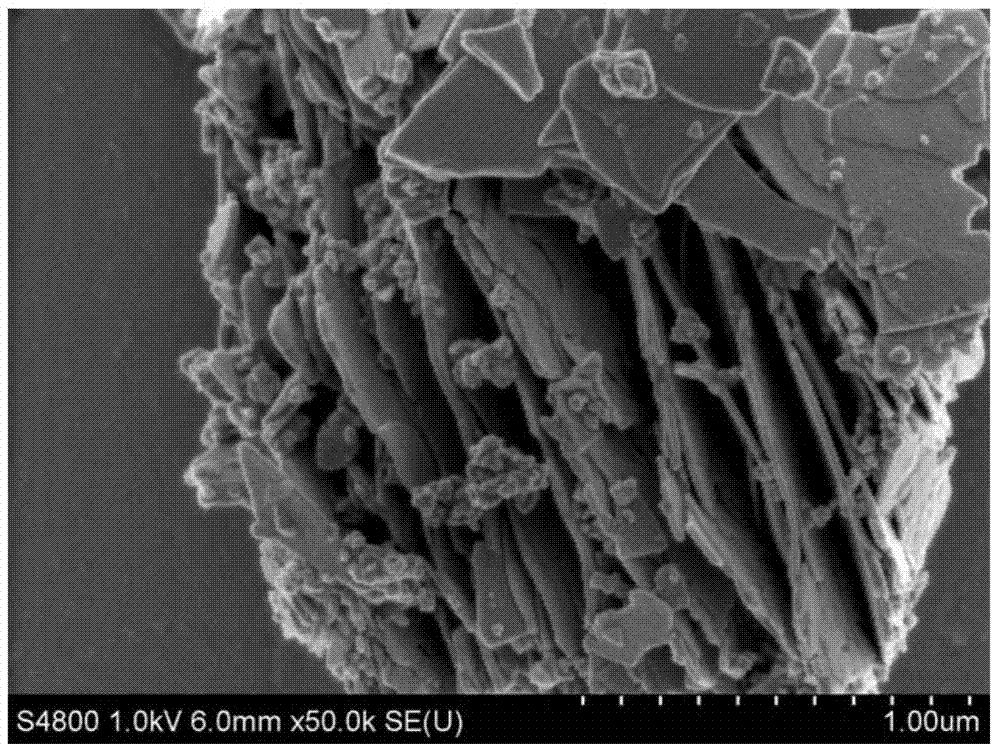

Preparation method for card-shaped NH4V308 micro crystal

ActiveCN103490065AUniform chemical reactionImprove efficiencyCell electrodesNanotechnologyMicrowaveChemical composition

Disclosed is a preparation method for a card-shaped NH4V308 micro crystal. Ammonium metavanadate is dissolved in deionized water to prepare an NH4VO3 solution with the concentration of NH4+ being 0.03-0.15mol / L, and then the pH of the solution is regulated to be 3.5-4.5 to obtain a solution B; microwaves and an ultraviolet lamp simultaneously act on the solution B in a microwave and ultraviolet combined mode, the temperature rises to be at 50-90 DEG C and then is kept, and suspension liquid is obtained; centrifugal separation is carried out on the suspension liquid to obtain powdery products, and then the products are dried. The NH4V308 micro crystal prepared in the method is uniform in chemical composition, is high in purity and is shaped like a card, the thickness of the NH4V308 micro crystal is about 200-500nm, and the NH4V308 micro crystal has good electric chemical performance when serving as anode materials for a lithium ion battery. The preparation method for the card-shaped NH4V308 micro crystal is simple, low in reaction temperature, short in reaction period, without subsequent processing, friendly to the environment, and suitable for large-scale production.

Owner:盐城抱璞文化传媒有限公司

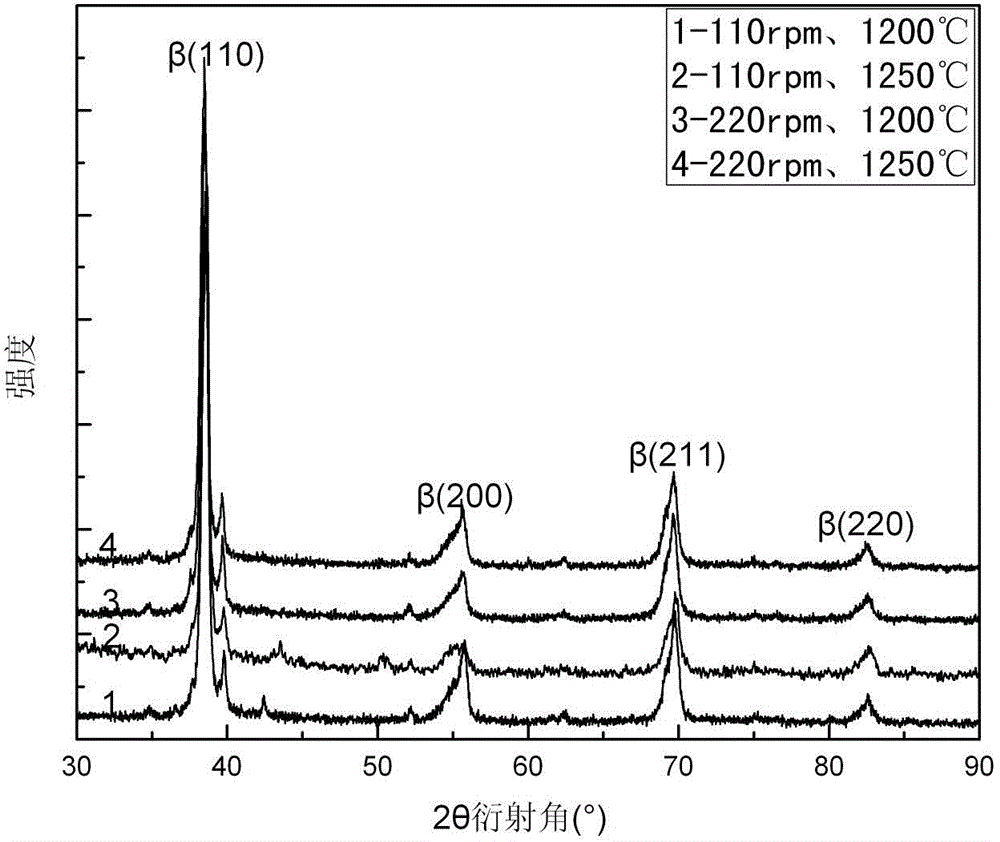

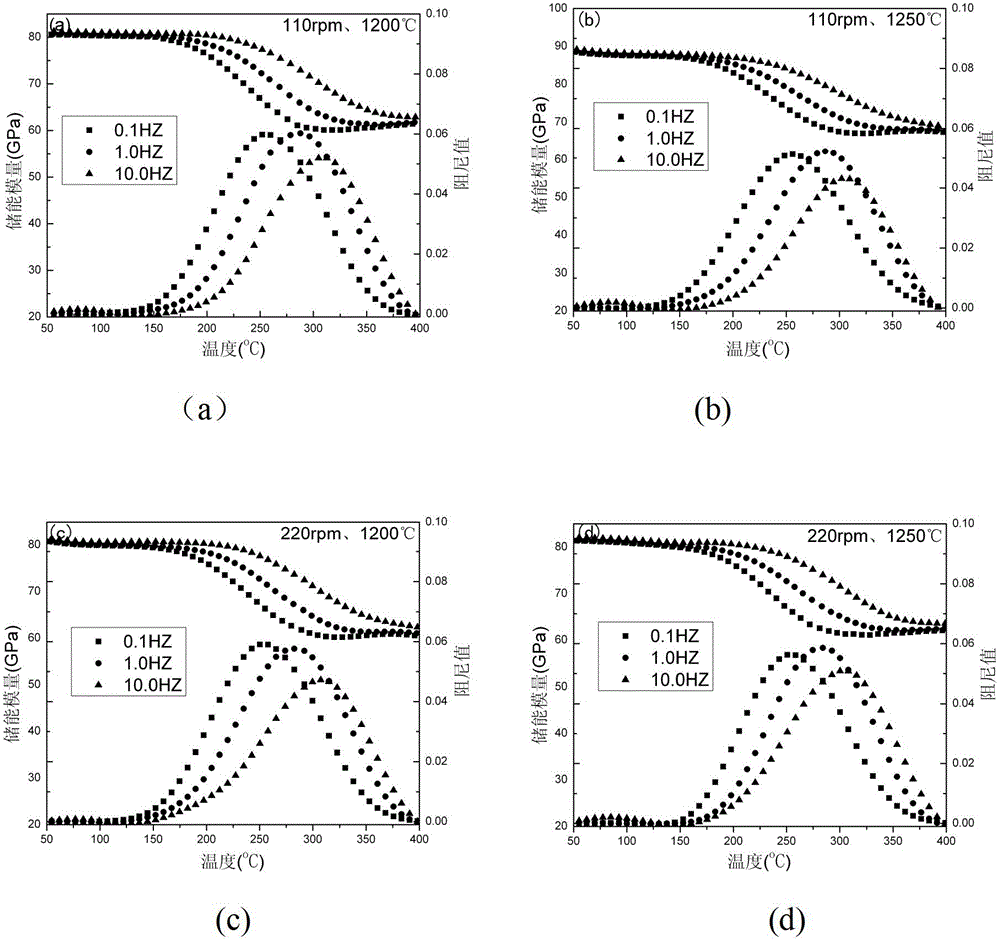

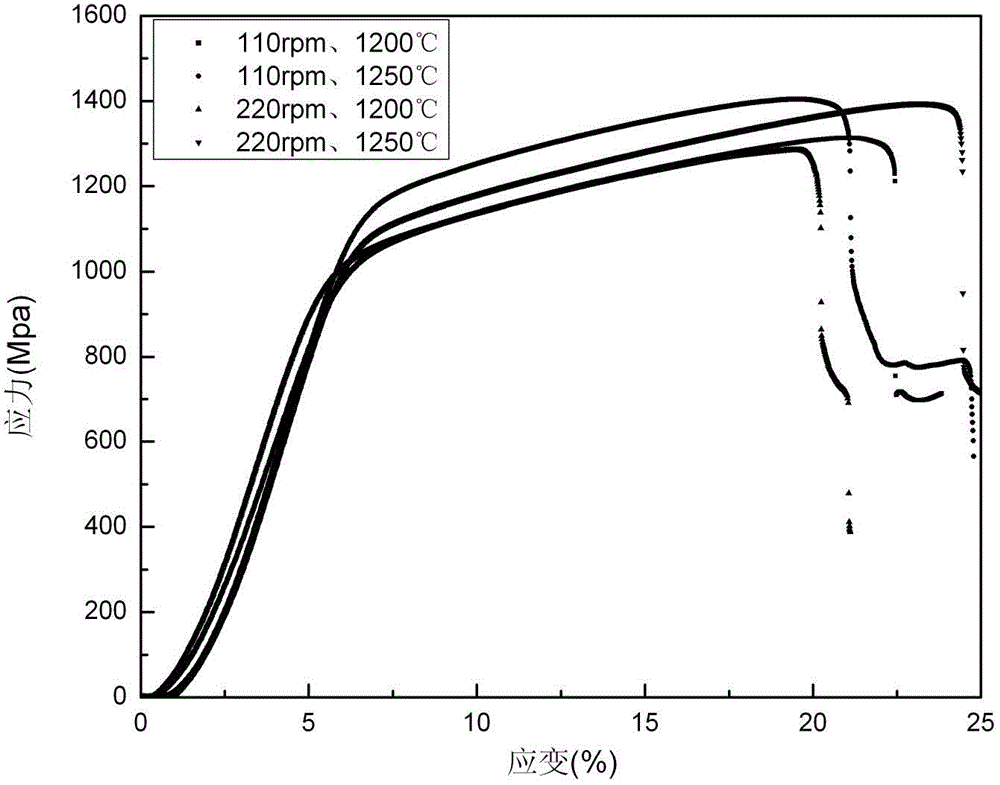

Ti-Nb-O high damping titanium alloy and powder metallurgy preparation method thereof

The invention discloses a Ti-Nb-O high damping titanium alloy and a powder metallurgy preparation method of the Ti-Nb-O high damping titanium alloy. The alloy comprises the following elements in percentage by atoms: 25 percent of Nb, 1.5 percent of O and the balance of Ti. The alloy is a metastable beta type high damping titanium alloy and is prepared by adopting the powder metallurgy method; and the high damping titanium alloy with excellent damping performance and mechanical property is obtained by adopting a ball milling, cold pressing and sintering method and regulating a powder metallurgy technology. The high damping titanium alloy can be used at the temperature between 200 and 350 DEG C, has the advantages of high damping value, high mechanical property and the like, and can be developed and used in a method for preparing high damping materials.

Owner:TIANJIN UNIV

Preparation method of sandwiched-layer-shaped NH4V3O8 nanocrystalline

ActiveCN103700824AUniform processFast processMaterial nanotechnologyCell electrodesNanoparticleReaction temperature

The invention discloses a preparation method of a sandwiched-layer-shaped NH4V3O8 nanocrystalline. The preparation method of the sandwiched-layer-shaped NH4V3O8 nanocrystalline comprises the following steps: dissolving ammonium metavanadate into deionized water, thereby obtaining a NH4VO3 solution, and labeling as a solution A; adjusting the pH value of the solution A as 4.5-6.0, thereby obtaining a solution B; pouring the solution B into a reactor so as to enable microwaves to be functioned on the solution B, and warming to 60-90 DEG C and preserving heat at the microwave power of 400-600W; carrying out centrifugal separation on suspension in the reactor so as to obtain powder body products, then washing, and drying. The preparation method disclosed by the invention is simple in process, low in reaction temperature, short in reaction cycle without subsequent treatment, protects the environment, and can be suitable for large scale production. The NH4V3O8 nanocrystalline prepared by the preparation method disclosed by the invention is homogenous in chemical constitution, is relatively high in purity, is of special sandwiched-shaped morphology, is formed by automatically assembling thin sheets with the thicknesses of 30nm and nano particles among the sheets, and has favorable electrochemical performance as the lithium ion battery cathode material.

Owner:盐城大数据资产经营管理有限公司

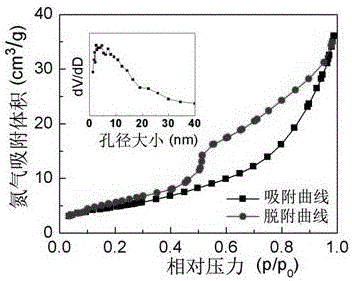

Porous carbon material taking polyvinylidene fluoride as precursor and preparation method

InactiveCN105293473AAdjustable porous structureUniform pore size distributionWatch glassTube furnace

The invention relates to a porous carbon material taking polyvinylidene fluoride as a precursor and a preparation method, belonging to the technical field of porous carbon material production. The method specifically comprises the steps of sufficiently dissolving polyvinylidene fluoride raw powder and an additive in a solvent according to a mass ratio under a certain temperature, flow-casting obtained solution on clean watch glass to form a thin layer, drying at 40 DEG C to obtain a polyvinylidene fluoride slice, and heating the polyvinylidene fluoride precursor to 500 to 1000 DEG C under nitrogen protection in a tube furnace for carbonization, thus obtaining the porous carbon material. The method is simple and convenient in operation process and free of complex production equipment, the product can be obtained only by the process of dissolving, curing and high temperature carbonization without subsequent treatment; the obtained carbon material has an adjustable porous structure, the pore size distribution is uniform and is 2 to 5nm, and a specific surface area range is 700 to 1200m<2> / g.

Owner:TIANJIN POLYTECHNIC UNIV

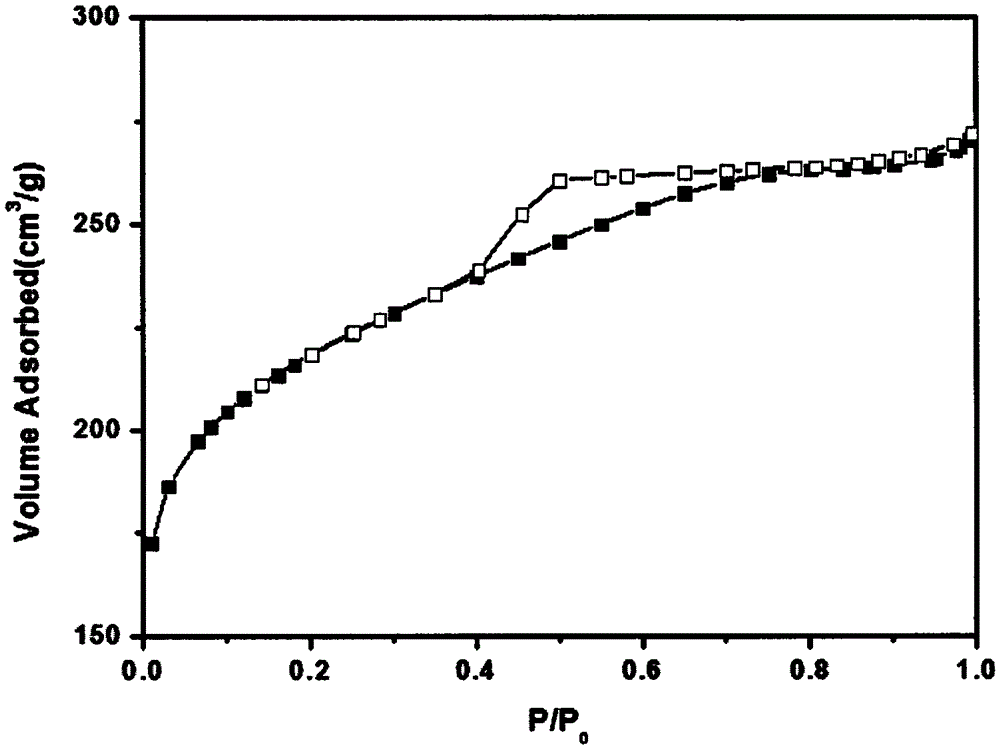

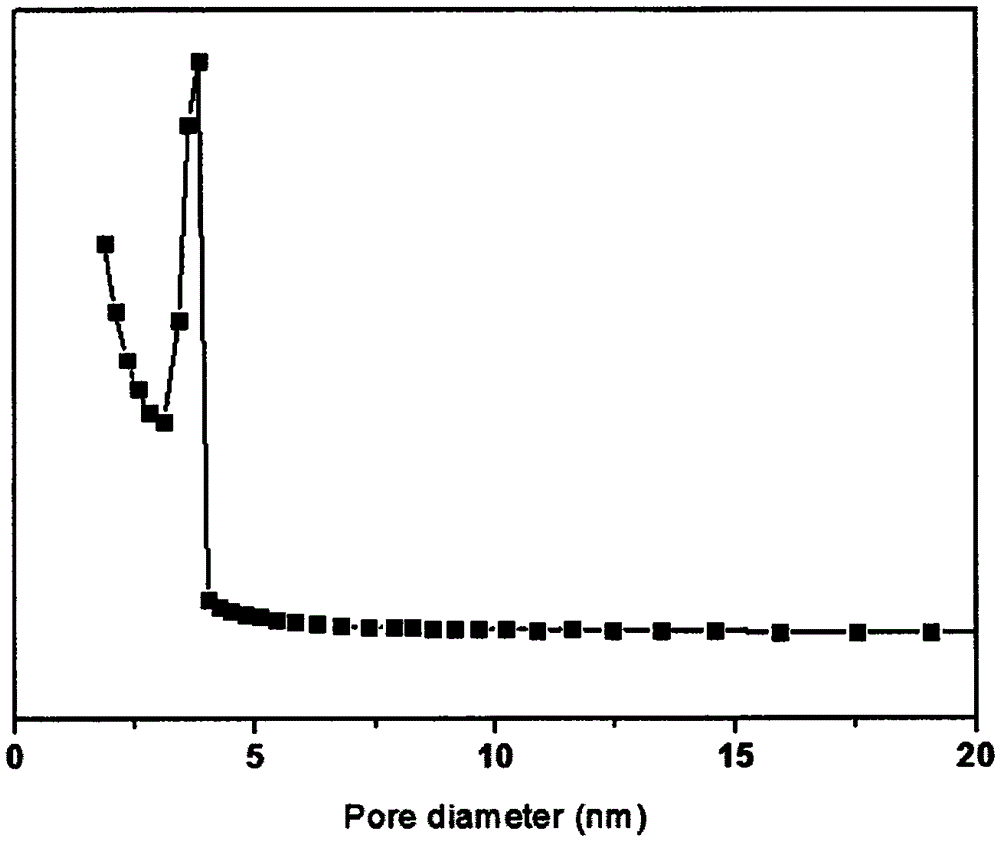

Graduated porous titanium dioxide microsphere, and preparation method and applications thereof

ActiveCN105000594AEasy to prepareDevelop research ideasTitanium dioxideMaterial resistanceHigh energyMicrosphere

The invention discloses a graduated porous titanium dioxide microsphere, and a preparation method and applications thereof. According to the preparation method, preparation is completed via one-step hydrothermal reaction; the preparation method is simple and convenient; yield is high; large-scale production can be realized easily; the graduated porous titanium dioxide microsphere possesses a microspheric structure; microsphere diameter ranges from 2 to 5<mu>m; the graduated porous titanium dioxide microsphere is obtained via assembling of truncated-octahedral nanocrystals; the particle size of the truncated-octahedral nanocrystals ranges from 50 to 100nm; anatase phase high-energy (001) crystal faces are exposed; the graduated porous titanium dioxide microsphere possesses a graduated porous structure; pore size ranges from 5 to 20nm. Indirectly-heated gas sensor technology can be adopted for coating, welding, and aging of the graduated porous titanium dioxide microsphere material so as to prepare semi-conductive type gas sensors. It is shown by gas sensitive property testing results that the semi-conductive type gas sensors possesses structural enhanced gas-sensitive property on acetone, and research approach of resistance-type semiconductor gas sensors is widened.

Owner:JIANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com