Ti-Nb-O high damping titanium alloy and powder metallurgy preparation method thereof

A technology of powder metallurgy and ti-nb-o, which is applied in the field of high damping titanium alloy and its preparation, can solve the problems of performance deterioration of other parts, engine performance deterioration, fuselage material damage, etc., so as to reduce production cost and be easy to realize , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

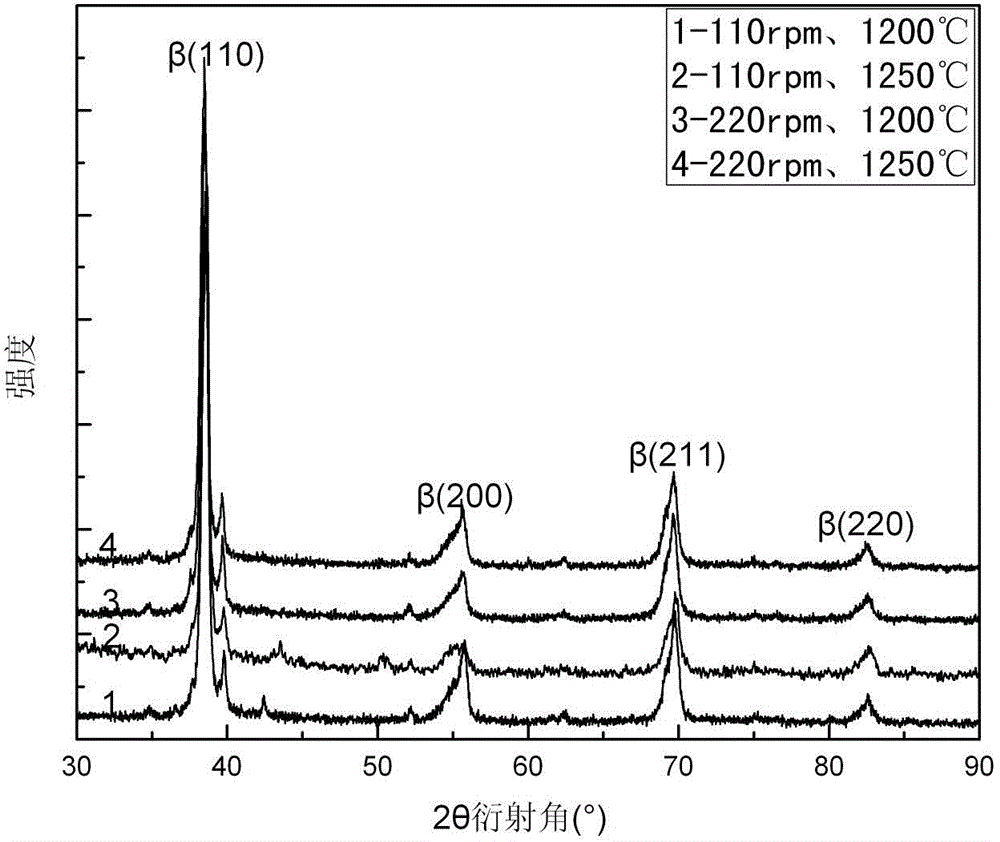

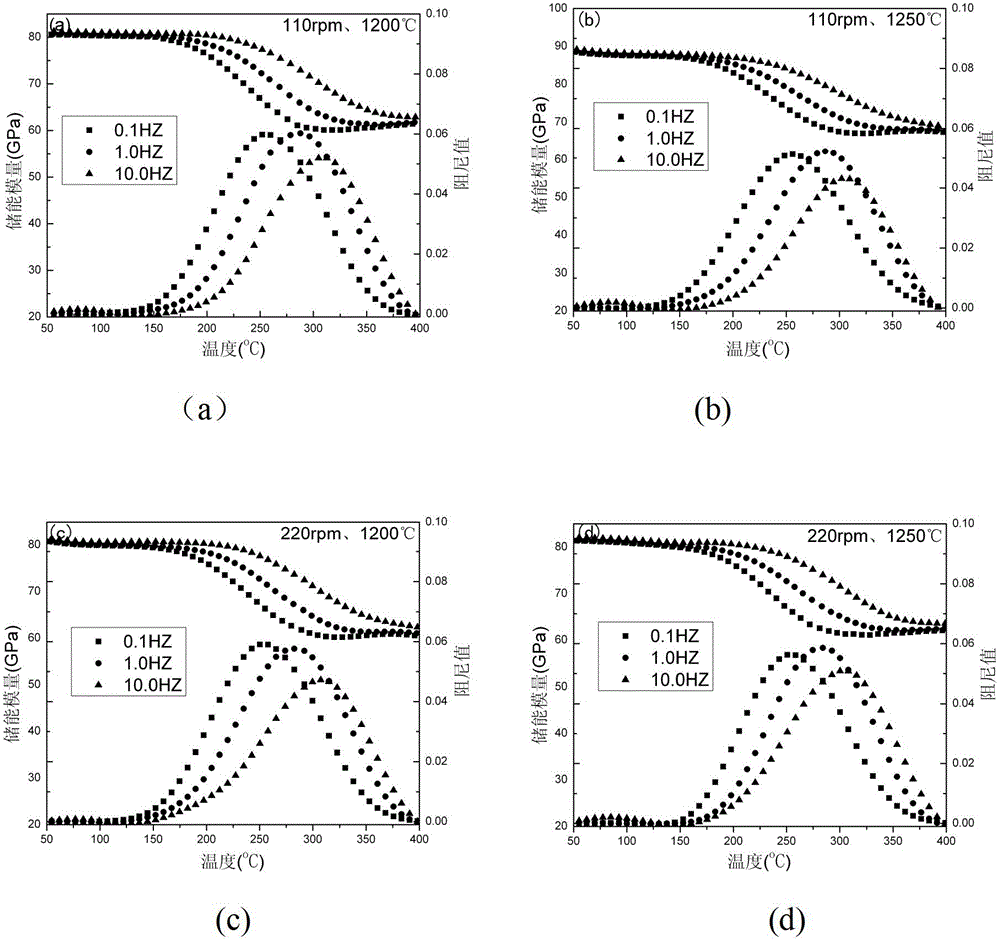

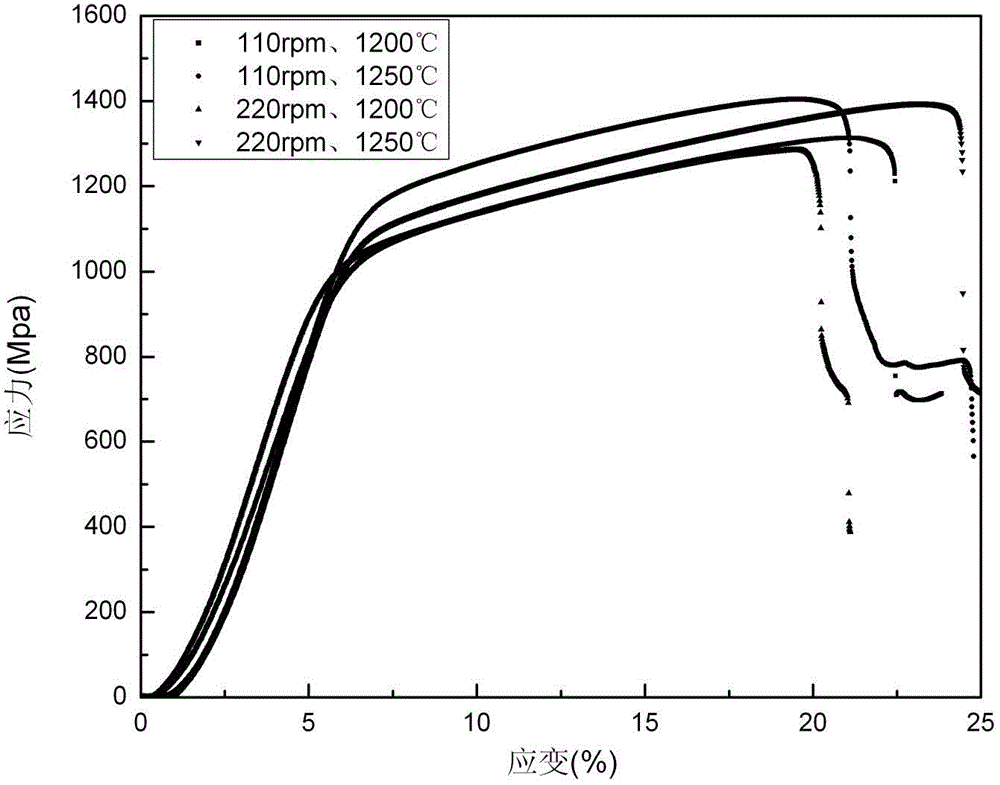

[0023] Ti-25Nb-1.5O(at%) alloy was prepared by powder metallurgy method.

[0024] 1. Weighing of raw materials, according to the ratio of Ti-25Nb-1.5O (at%), weigh high-purity Ti powder, high-purity Nb powder, high-purity TiO 2 pink;

[0025] 2. Use a ball mill to carry out ball milling and mixing of the weighed raw materials. The ball-to-material ratio is 2:1, the ball milling rate is 110rpm, and the ball milling time is 2h;

[0026] 3. The ball-milled powder is cold-pressed, and the cold-pressed forming pressure is 500 MPa, and the time is 5 minutes.

[0027] 4. Put the cold-pressed compact into a tube furnace for vacuum sintering, the sintering temperature is 1200°C-1250°C, and the sintering time is 5h.

[0028] 5. Sample processing: Cut the alloy ingot with a wire electric discharge machine to obtain an XRD sample, a DMA test sample of 20.0mm×5.0mm×1.0mm and a compression sample of φ6mm×10mm.

[0029] 6. Sample processing and testing: Choose water sandpaper with differe...

Embodiment 2

[0035] Ti-25Nb-1.5O(at%) alloy was prepared by powder metallurgy method.

[0036] 1. Weighing of raw materials, according to the ratio of Ti-25Nb-1.5O (at%), weigh high-purity Ti powder, high-purity Nb powder, high-purity TiO 2 pink;

[0037] 2. Use a ball mill to carry out ball milling and mixing of the weighed raw materials. The ball-to-material ratio is 2:1, the ball milling rate is 220rpm, and the ball milling time is 2h;

[0038] 3. The ball-milled powder is cold-pressed, and the cold-pressed forming pressure is 500 MPa, and the time is 5 minutes.

[0039] 4. Put the cold-pressed compact into a tube furnace for vacuum sintering, the sintering temperature is 1200°C-1250°C, and the sintering time is 5h.

[0040] 5. Sample processing: Cut the alloy ingot with a wire electric discharge machine to obtain an XRD sample, a DMA test sample of 20.0mm×5.0mm×1.0mm and a compression sample of φ6mm×10mm.

[0041] 6. Sample processing and testing: Choose water sandpaper with differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| damping ratio | aaaaa | aaaaa |

| damping ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com