TLMD vibration isolation system

A vibration damping system and mass block technology, applied in the direction of shock absorbers, shock absorber-spring combinations, shock absorbers, etc., can solve the problem that liquid cannot provide steady-state amplitude and phase difference vibration damping force, etc., to achieve increased The effect of sloshing liquid mass, enhancing vibration damping ability, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

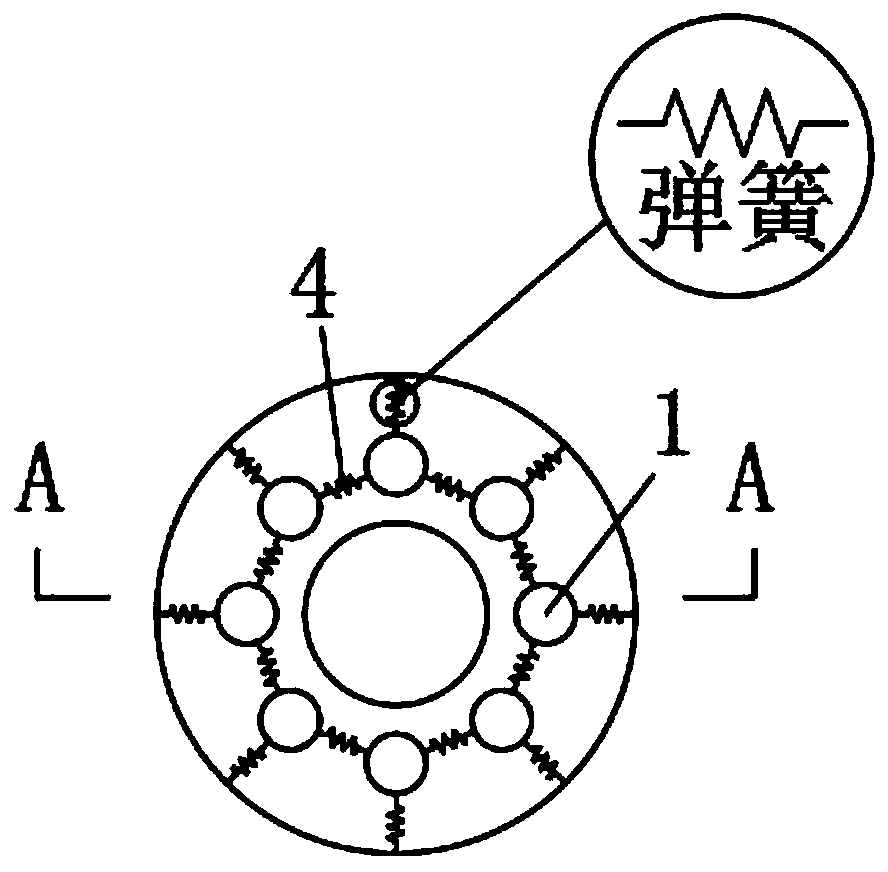

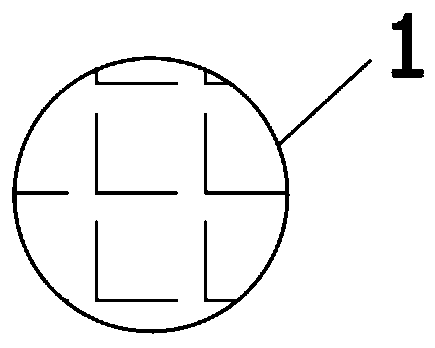

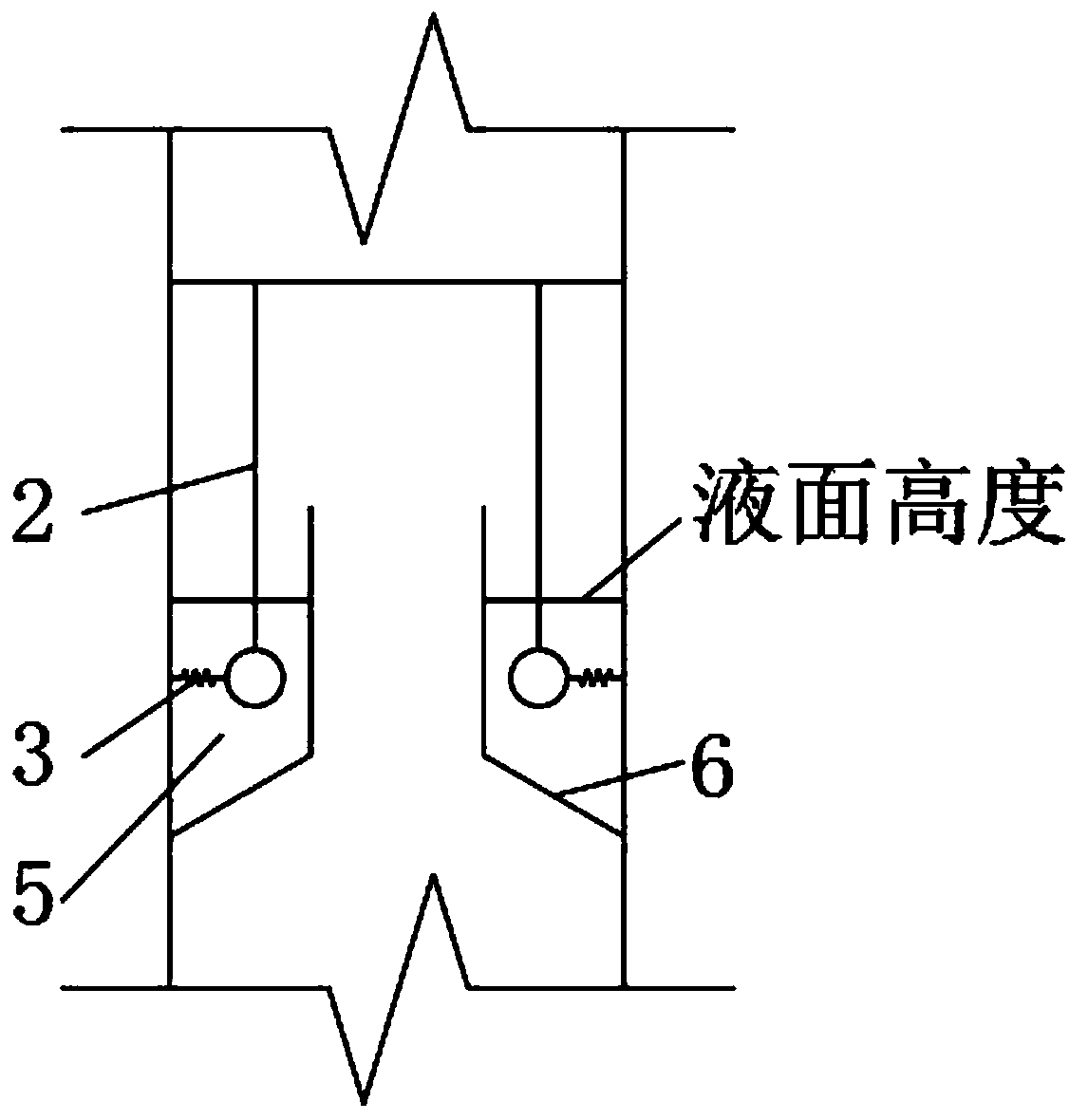

[0032] refer to Figure 1-4 , a TLMD damping system, including TLD and a plurality of TMD, TMD consists of mass 1, first and third spring 7, second spring 4, third spring 7 and liquid 5, TLD also includes liquid 5 and liquid storage Box 6.

[0033] The present invention arranges a plurality of tuned mass dampers (TMD), and the swing rod 2 is connected with the main structure through a universal hinge to ensure that the mass block 1 can swing along various directions, and the liquid storage tank 6 is welded on the two side walls of the main structure. The mass block 1 , the second spring 4 and the third spring 7 of the TMD are all immersed in the TLD liquid 5 .

[0034] Overall TMD tuning frequency passable Calculate, where L is the length of the pendulum 2, ∑K is the total equivalent stiffness, M is the mass of mass block 1, the number of TMD mass blocks and the frequency value can be selected according to the specific structure and vibration reduction requirements, each ma...

Embodiment 2

[0038] refer to Figure 1-4 , a TLMD damping system, including TLD and a plurality of TMD, TMD consists of mass block 1, first spring 3, second spring 4, third spring 7 and liquid 5, TLD also includes liquid 5 and liquid storage tank 6 .

[0039] The present invention arranges a plurality of tuned mass dampers (TMD), and the swing rod 2 is connected with the main structure through a universal hinge to ensure that the mass block 1 can swing along various directions, and the liquid storage tank 6 is welded on the two side walls of the main structure. The mass block 1 , the first spring 3 , the second spring 4 and the third spring 7 of the TMD are all immersed in the TLD liquid 5 .

[0040] Overall TMD tuning frequency pass-through combine Calculate, where L is the length of the pendulum 2, ∑K is the total equivalent stiffness, M is the mass of mass block 1, the number of TMD mass blocks and the frequency value can be selected according to the specific structure and vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com