High-performance rubber damping material and preparation method thereof

A damping material and high-performance technology, applied in the field of damping materials, can solve the problems of large creep, high heat generation, short working life, etc., and achieve the effect of high tensile strength and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

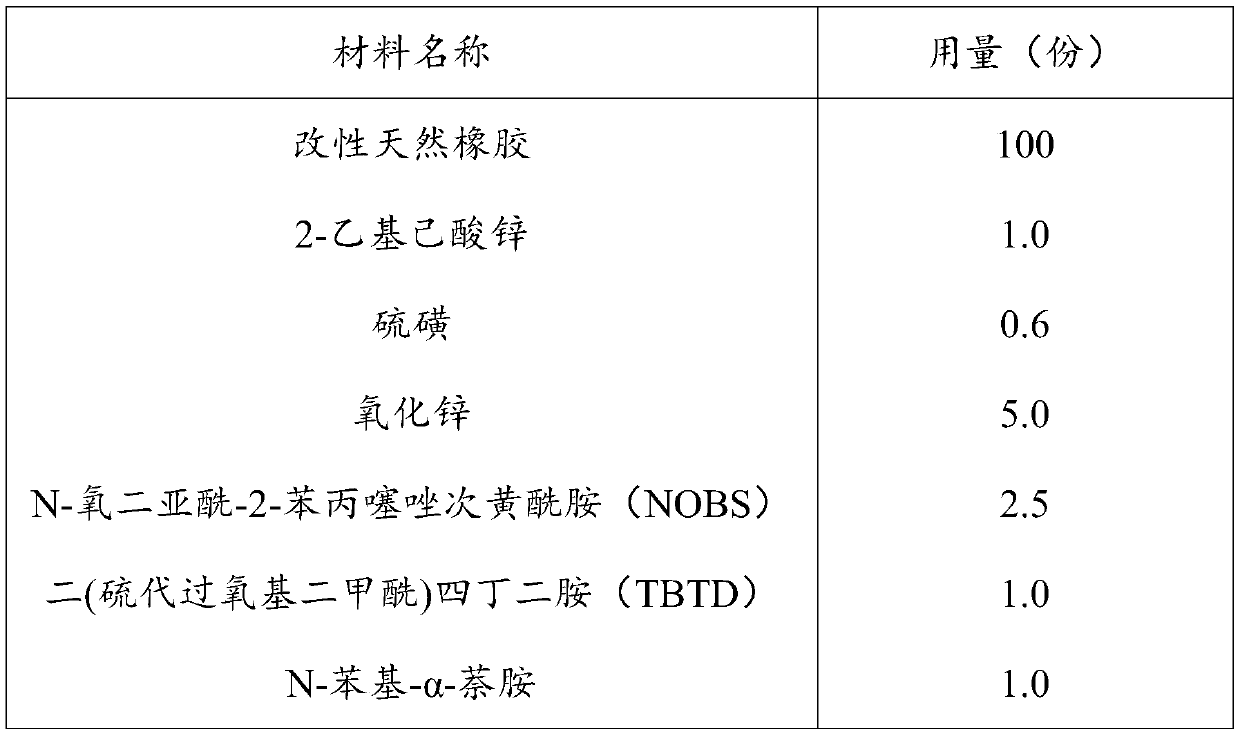

[0032] Embodiments of the present invention provide a method for preparing a high-performance rubber damping material, comprising: grafting hydroxyethyl methacrylate and lignin onto the rubber molecular chain of natural latex by graft copolymerization to obtain high-performance Rubber damping material.

[0033] It should be noted that this method uses natural latex as the base material, and grafts hydroxyethyl methacrylate and lignin onto the rubber molecular chains of natural latex through graft copolymerization to form a semi-interpenetrating network structure. Among them, hydroxyethyl methacrylate is mainly used for the modification of resins and coatings. It has a higher damping temperature range, which can endow the prepared rubber damping material with the advantages of wide temperature range and high damping. At the same time, lignin is a biopolymer with a three-dimensional network structure formed by three kinds of phenylpropane units connected to each other through et...

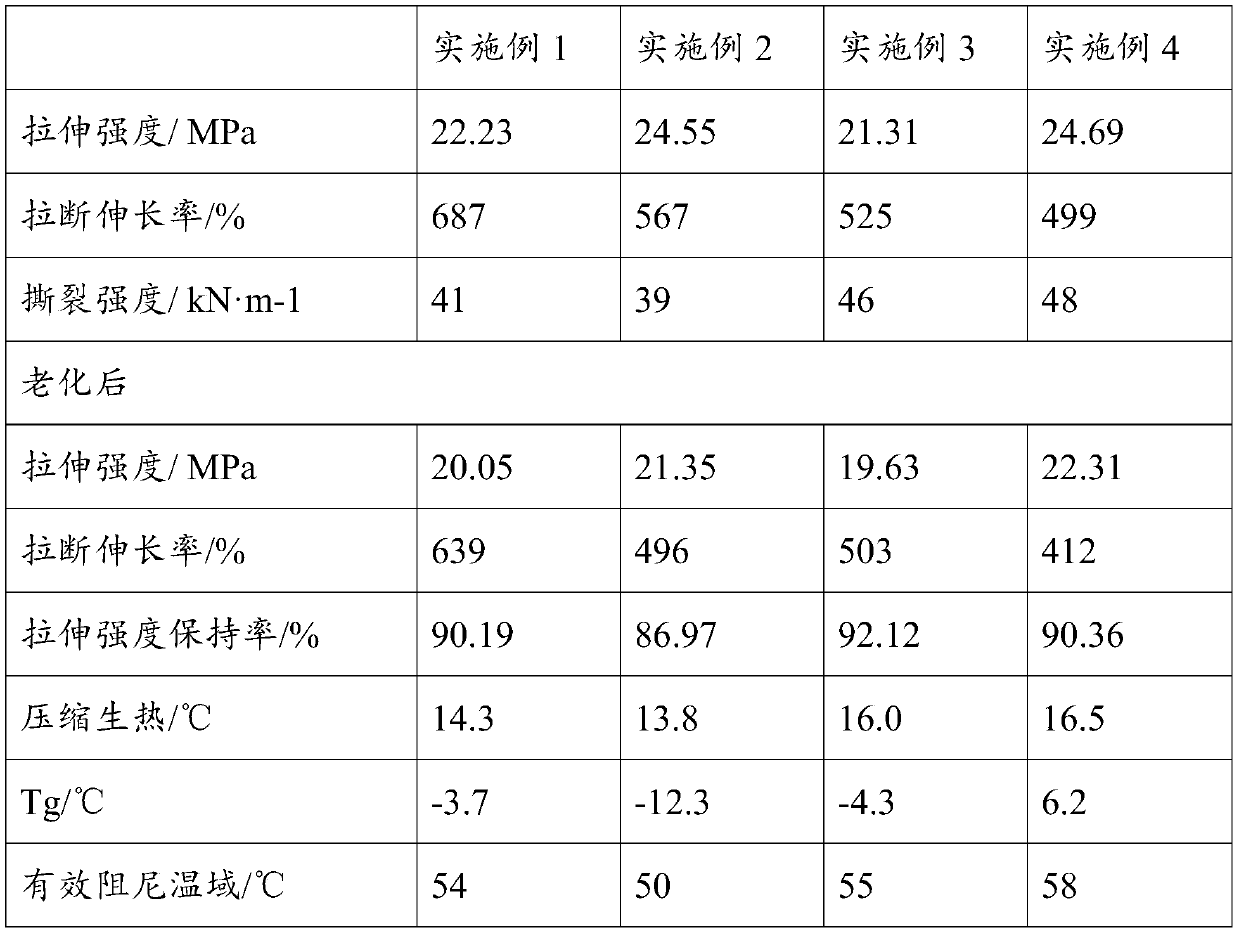

Embodiment 1

[0048] This embodiment provides a high-performance rubber damping material, which is prepared by the following method:

[0049] S1: Weigh 100 parts of concentrated natural rubber latex by dry rubber, add 4 parts of polyoxyethylene fatty alcohol ether (prepared as a 15% aqueous solution before adding), stir well; and, add 10 parts of dry rubber under slow stirring Hydroxyethyl methacrylate and 5 parts of lignin (prepared into a 50% aqueous dispersion in advance), drop 0.1 part of initiator and 0.08 part of crosslinking agent;

[0050] S2: Stand still at 25° C. for 20 hours under nitrogen protection condition. After standing still, add 0.08 part of activator, and add 280 parts of distilled water, so that the total solid content is about 20%. Branched modified natural rubber latex;

[0051] S3: The modified natural rubber latex is subjected to conventional rubber processing techniques such as coagulation, tableting, washing, and drying to obtain hydroxyethyl methacrylate-lignin...

Embodiment 2

[0054] This embodiment provides a high-performance rubber damping material, which is prepared by the following method:

[0055] S1: Weigh 100 parts of concentrated natural rubber latex calculated as dry rubber, add 4 parts of polyoxyethylene fatty alcohol ether (prepared as a 15% aqueous solution before adding), and stir evenly. Then, under slow stirring, add 5 parts of hydroxyethyl methacrylate and 10 parts of lignin (prepared into an aqueous dispersion with a concentration of 50% in advance), and add dropwise 0.1 part of initiator and 0.08 part of crosslinking agent;

[0056] S2: Stand still at 25° C. for 20 hours under nitrogen protection condition. After standing still, add 0.08 part of activator, and add 280 parts of distilled water, so that the total solid content is about 20%. Branched modified natural rubber latex;

[0057] S3: The modified natural rubber latex is subjected to conventional rubber processing techniques such as coagulation, tableting, washing, and dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com