Self-adhesive and environment-friendly damping rubber plate and preparation method therefor

A damping rubber sheet, self-adhesive technology, applied in the field of damping materials, can solve the problems of insufficient strength and fragile materials, and achieve the effect of good flame retardant performance and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

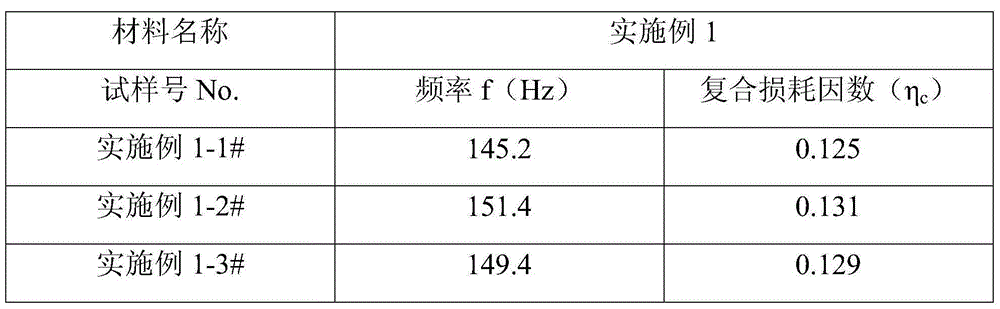

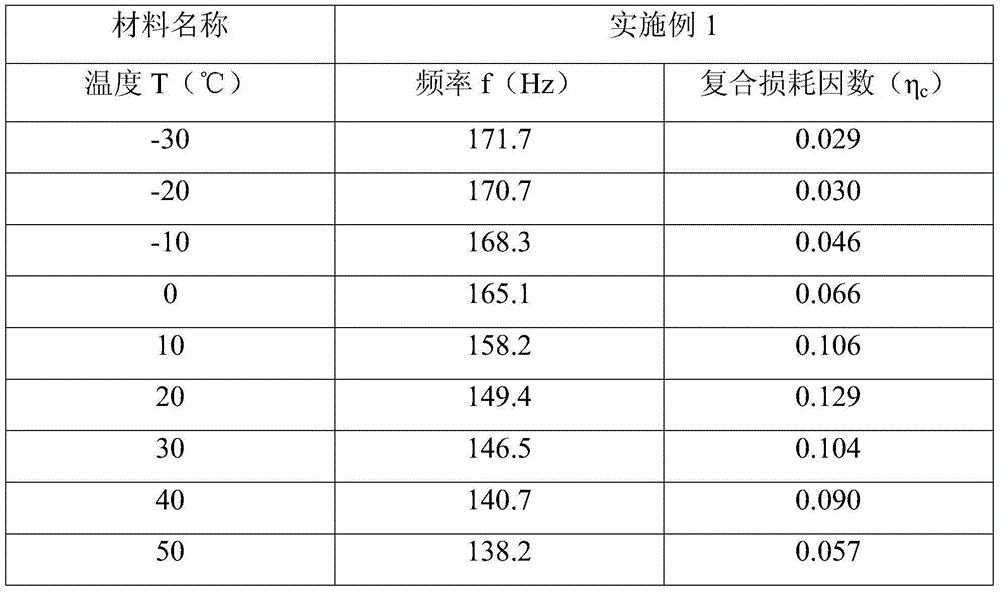

Embodiment 1

[0028] A self-adhesive environmentally friendly damping rubber sheet and a preparation method thereof. The damping rubber sheet is composed of thin aluminum foil, damping glue, reinforcing ribs and isolation paper. The damping rubber is composed of the following parts by mass: 45 parts of modified rubber with a softening point of 90℃, 1 part of iron oxide pigment, 20 parts of flame retardant, 5 parts of aluminum hydroxide, 9 parts of heavy calcium carbonate, mica powder 10 parts, 10 parts quartz powder.

[0029] The damping rubber sheet is prepared according to the following method: Step 1: Heat the modified rubber to a molten state in a closed environment, add pigments, flame retardants, and damping fillers in proportions, and stir evenly to obtain damping rubber; Step 2: : Apply a layer of damping glue on the aluminum foil with a coater, the thickness of the aluminum foil is 0.1mm, and the thickness of the damping glue is 1.0mm; the third step: put in the tic-shaped stiffeners,...

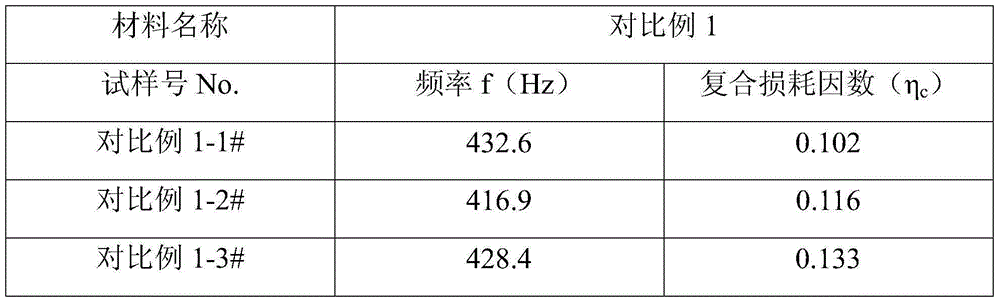

Embodiment 2

[0034] A self-adhesive environmentally friendly damping rubber sheet and a preparation method thereof. The damping rubber sheet is composed of thick aluminum foil, damping glue, reinforcing ribs and isolation paper. The damping rubber is composed of the following parts by mass: 35 parts of modified rubber with a softening point of 105℃, 3 parts of rutile titanium dioxide pigment, 25 parts of flame retardant, 10 parts of aluminum hydroxide, 7 parts of heavy calcium carbonate, sulfuric acid 10 parts of barium and 10 parts of mica powder.

[0035] The damping rubber sheet is prepared according to the following method: Step 1: Heat the modified rubber to a molten state in a closed environment, add pigments, flame retardants, and damping fillers in proportions, and stir evenly to obtain damping rubber; Step 2: : Coat a layer of damping glue on the aluminum foil with a coater, the thickness of the aluminum foil is 0.25mm, and the thickness of the damping glue is 1.0mm; the third step: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com