Multi-efficient high-molecular damping material

A technology of damping materials and polymers, applied in the field of damping materials, can solve problems affecting the use of water-based damping coatings, easy deformation of coating films, and small damping values, and achieve high cost performance, good environmental protection effects, and large damping values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

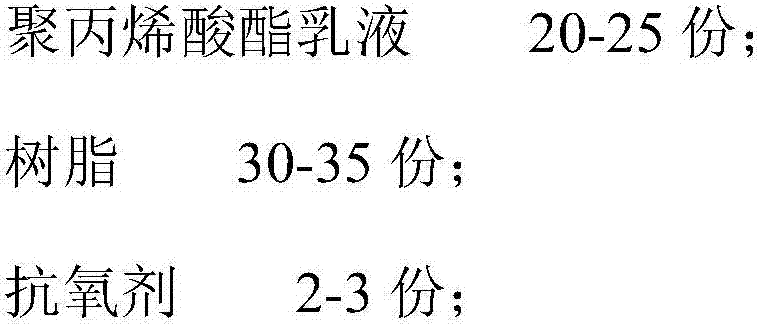

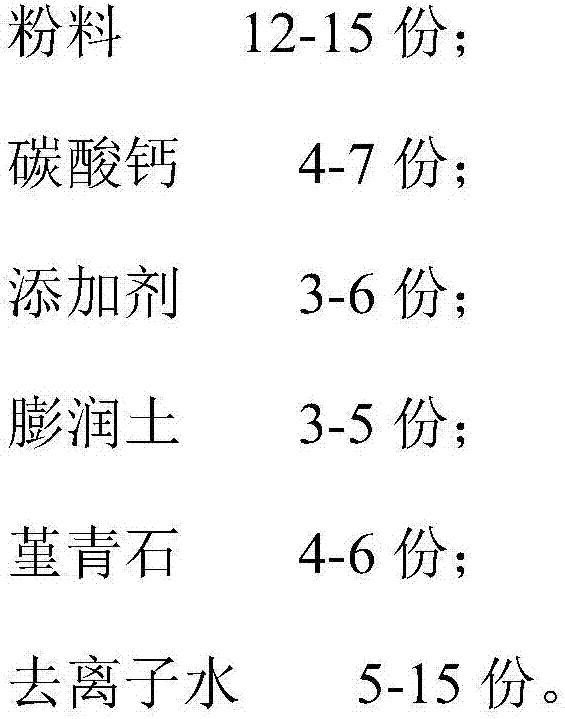

[0014] A multi-effect polymer damping material, comprising the following components by weight:

[0015]

[0016]

[0017] The powder includes activated carbon slag powder and white sand, and the weight ratio of activated carbon slag powder to white sand is 2:3.

[0018] The additives are cellulose, oxidized polyethylene wax and calcium stearate, and the weight ratio of cellulose, oxidized polyethylene wax and calcium stearate is 1:2:1.

Embodiment 2

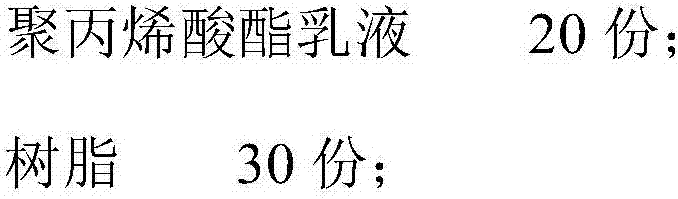

[0020] A multi-effect polymer damping material, comprising the following components by weight:

[0021]

[0022] The powder includes activated carbon slag powder and white sand, and the weight ratio of activated carbon slag powder to white sand is 2:3.

[0023] The additives are cellulose, oxidized polyethylene wax and calcium stearate, and the weight ratio of cellulose, oxidized polyethylene wax and calcium stearate is 1:2:1.

Embodiment 3

[0025] A multi-effect polymer damping material, comprising the following components by weight:

[0026]

[0027] The powder includes activated carbon slag powder and white sand, and the weight ratio of activated carbon slag powder to white sand is 2:3.

[0028] The additives are cellulose, oxidized polyethylene wax and calcium stearate, and the weight ratio of cellulose, oxidized polyethylene wax and calcium stearate is 1:2:1.

[0029] The beneficial effects of the present invention are: the use of bentonite and powder is safe and non-toxic, and has good environmental protection effect. At the same time, the damping material made of scientific proportioning with other raw materials has good cohesiveness during use, and is not easy to dry after being applied. Deformation, large damping value, high reliability, high cost performance, meeting the needs of the construction industry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com