Method for modifying surface of polypropylene separation membrane

A surface modification and separation membrane technology, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of easy-to-pollution modification process, poor hydrophilicity, and small flux, so as to improve anti-pollution ability, improved surface performance, and increased rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: The PP membrane was washed successively with nitric acid solution (mass concentration 20%), sodium hydroxide solution (1mol / L), acetone, and deionized water for 10 minutes, 8 minutes, 7 minutes, and 9 minutes respectively, and dried at 50°C for 1 hour.

[0028] Titanium tetrachloride (TiCl 4 ), deionized water (H 2 O) as the precursor, high-purity nitrogen (N 2 ) as carrier and sweep gas. The pulse time of the two precursors was 0.3s and 0.015s respectively, the exposure time of the precursor was 0s, the cleaning time was 5s, and the flow rate of the carrier gas was 20sccm. Heat the temperature of the reaction chamber to 80°C, keep the membrane at the set temperature of the reaction chamber for 20 minutes, and prepare modified membranes with 100, 200, 300, 500, 800, and 1000 cycles respectively.

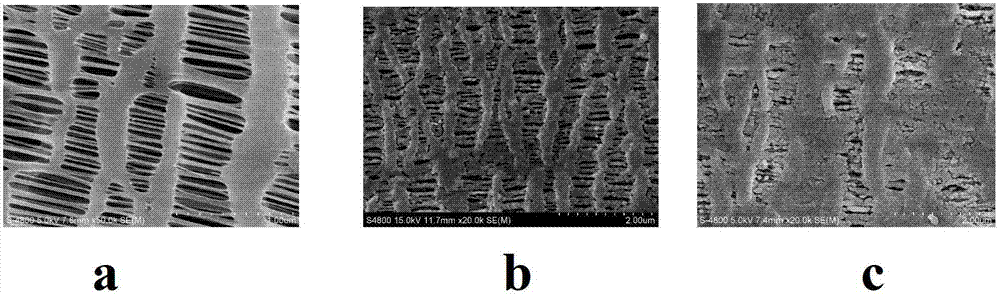

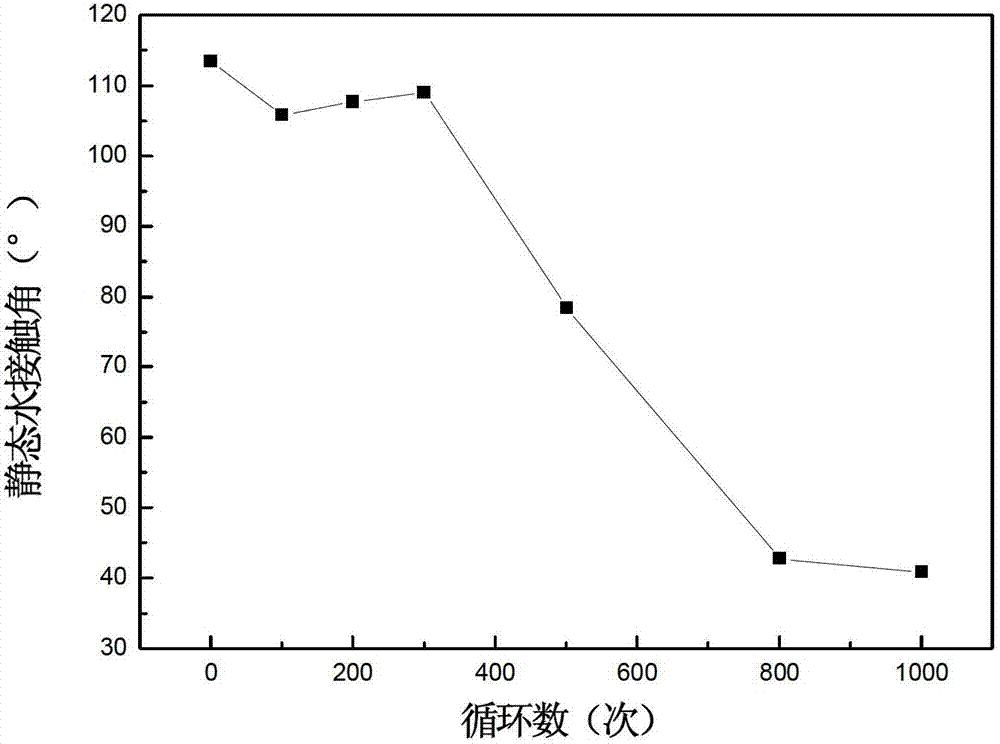

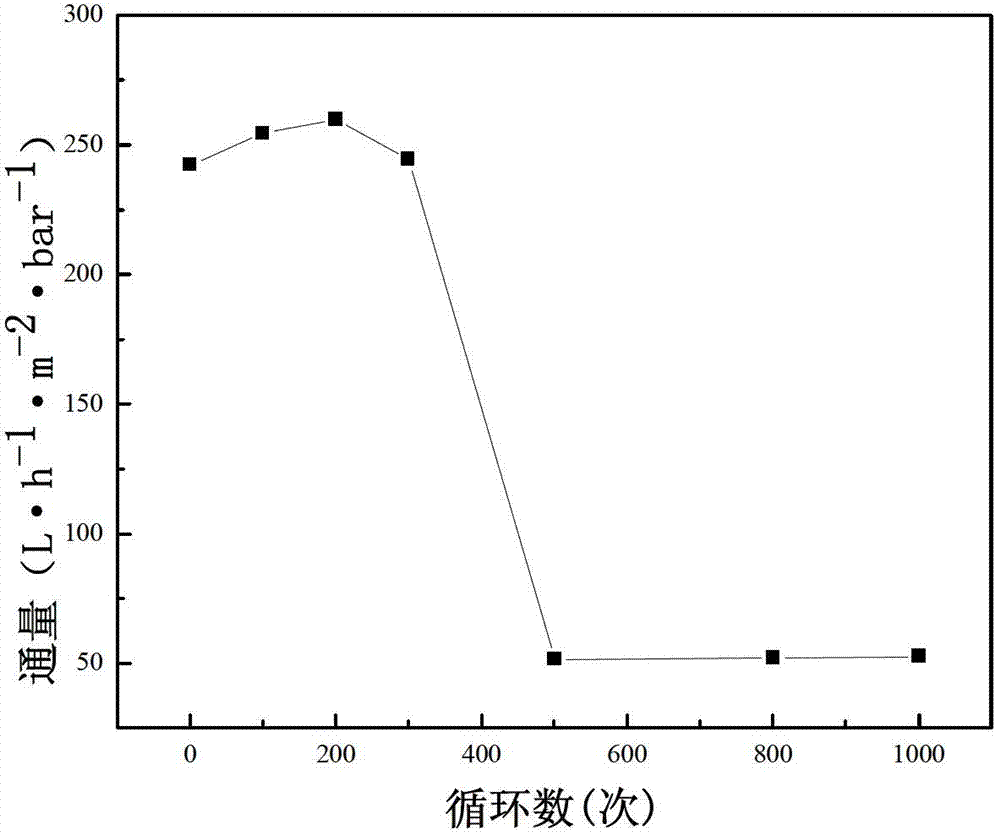

[0029] Depend on figure 1 It can be seen that with the increase of the deposition times, the titanium oxide particles in the membrane channels and on the surfac...

Embodiment 2

[0033] Example 2: The PP membrane was washed with nitric acid solution (25%), potassium hydroxide solution (1.5mol / L), dichloromethane, and deionized water for 5 minutes, 7 minutes, 9 minutes, and 10 minutes respectively, and dried at 30°C for 2 hours.

[0034] Titanium isopropoxide (heated to 85°C), deionized water (H 2 O) as the precursor, high-purity nitrogen (N 2) as carrier and sweep gas. The pulse time of titanium isopropoxide and water is 0.2s, the exposure time of the precursor is 3s, the cleaning time is 15s, and the flow rate of the carrier gas is 10sccm. Heat the temperature of the reaction chamber to 100°C, keep the membrane at the set temperature of the reaction chamber for 10 minutes, and prepare modified membranes with 200, 400, and 600 cycles respectively.

[0035] After titanium oxide was deposited on the polypropylene film, the static water contact angle decreased with the increase of deposition times. For the modified film deposited 200, 400, and 600 times...

Embodiment 3

[0037] Example 3: The PP membrane was washed successively with nitric acid solution (23%), sodium hydroxide solution (1.3mol / L), acetone, and deionized water for 8 minutes, 6 minutes, 7 minutes, and 10 minutes, and dried at 40°C for 1.5 hours.

[0038] Titanium isopropoxide (heated to 82°C), deionized water (H 2 O) is the precursor, and high-purity argon (Ar) is used as the carrier gas and sweep gas. The pulse time of titanium isopropoxide is 1 s, the pulse time of water is 0.9 s, the exposure time of the precursor is 3 s, the cleaning time is 50 s, and the flow rate of the carrier gas is 15 sccm. Heat the temperature of the reaction chamber to 120° C., keep the film at the set temperature of the reaction chamber for 20 minutes, and deposit titanium oxide 200 times. The measured pure water flux of the modified membrane is 239.39 (L h -1 m -2 · bar -1 ), an increase of 9.9% compared to the original film, a static contact angle of 80.3°, and a rejection rate of 47.2% for BSA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com