Method for preparing nano microcapsule of shell-core structure from supercritical fluid

A nano-microcapsule and supercritical flow technology, which is applied in microcapsule preparation, microsphere preparation, bulk chemical production, etc., can solve the problems of complex operation process, wide particle size distribution range, large coating particle size, etc., and achieve simple operation. , Narrow particle size distribution, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

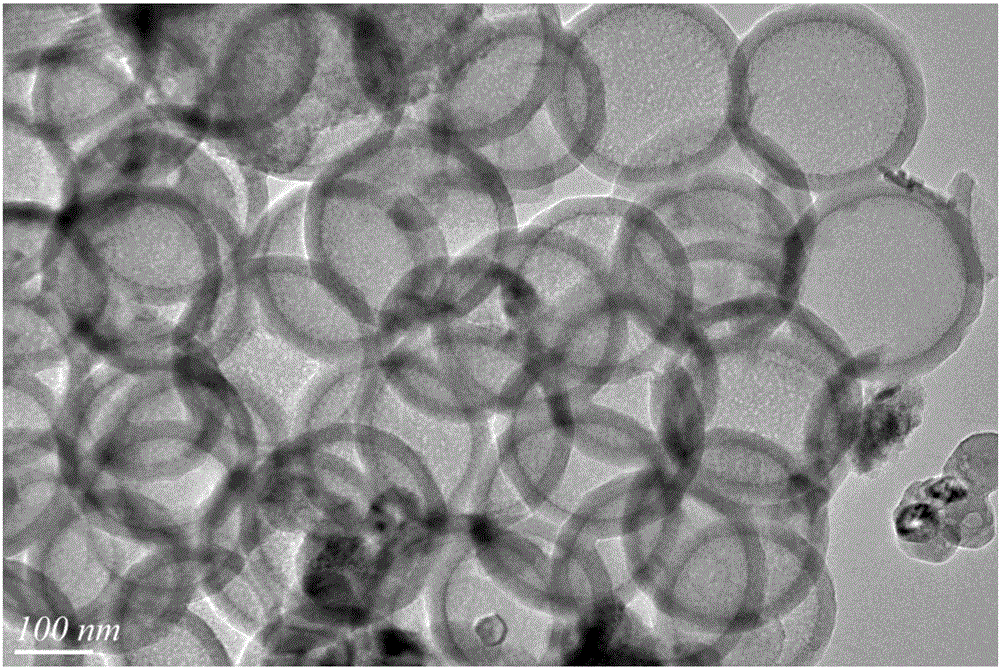

[0035] In this embodiment, a method for preparing nano-microcapsules with a "shell-core" structure with a supercritical fluid comprises the following steps:

[0036] 1) Combine 5g of RDX and Viton (F 26 ) 0.15g was added to dimethylformamide (DMF) 100mL and stirred until RDX was completely dissolved in DMF, F 26 Completely swell in DMF to form a solution, keep the temperature of the solution at 20°C;

[0037] 2) Turn on the temperature control switch of the supercritical atomization crystallization preparation system, set the temperature of the particle collection tank to 33°C, and set the initial supercritical CO 2 The temperature is 38 °C and preheated for 30 minutes.

[0038] 3) Set CO 2 The flow rate of the solution is 5kg / h, the flow rate of the solution is set at 2mL / min, and the working pressure of the particle collection tank is set at 8MPa.

[0039] 4) Turn on the CO 2 Cylinder valve, open CO 2 pump to make CO 2 Enter the supercritical atomization crystallizati...

Embodiment 2

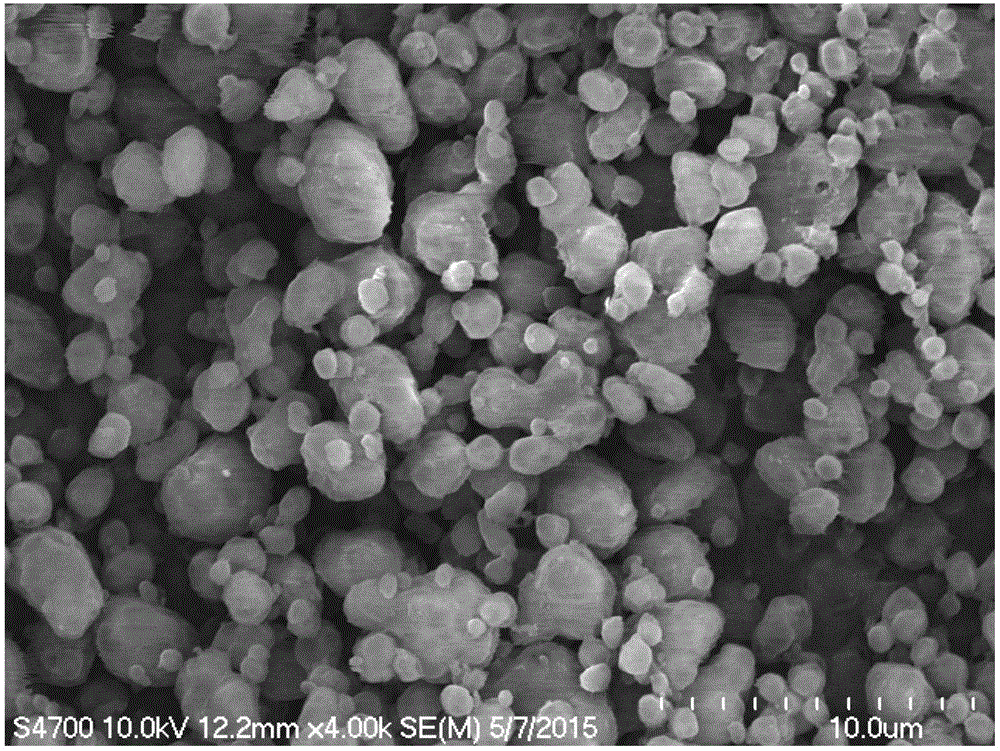

[0046] In this embodiment, a method for preparing nano-microcapsules with a "shell-core" structure with a supercritical fluid comprises the following steps:

[0047] 1) Mix RDX (RDX) 15g and fluororubber (F 26 ) 0.45g was added to dimethylformamide (DMF) 100mL and stirred until RDX was completely dissolved in DMF, F 26 Completely swell in DMF to form a solution, keep the temperature of the solution at 25°C;

[0048] 2) Turn on the temperature control switch of the supercritical atomization crystallization preparation system, set the temperature of the particle collection tank to 36°C, and set the initial supercritical CO 2 The temperature is 50°C and preheated for 30 minutes.

[0049] 3) Set CO 2 The flow rate of the solution is 10kg / h, the flow rate of the solution is set at 2mL / min, and the working pressure of the particle collection tank is set at 13MPa.

[0050] 4) Turn on the CO 2 Cylinder valve, open CO 2 pump to make CO 2 Enter the supercritical atomization cryst...

Embodiment 3

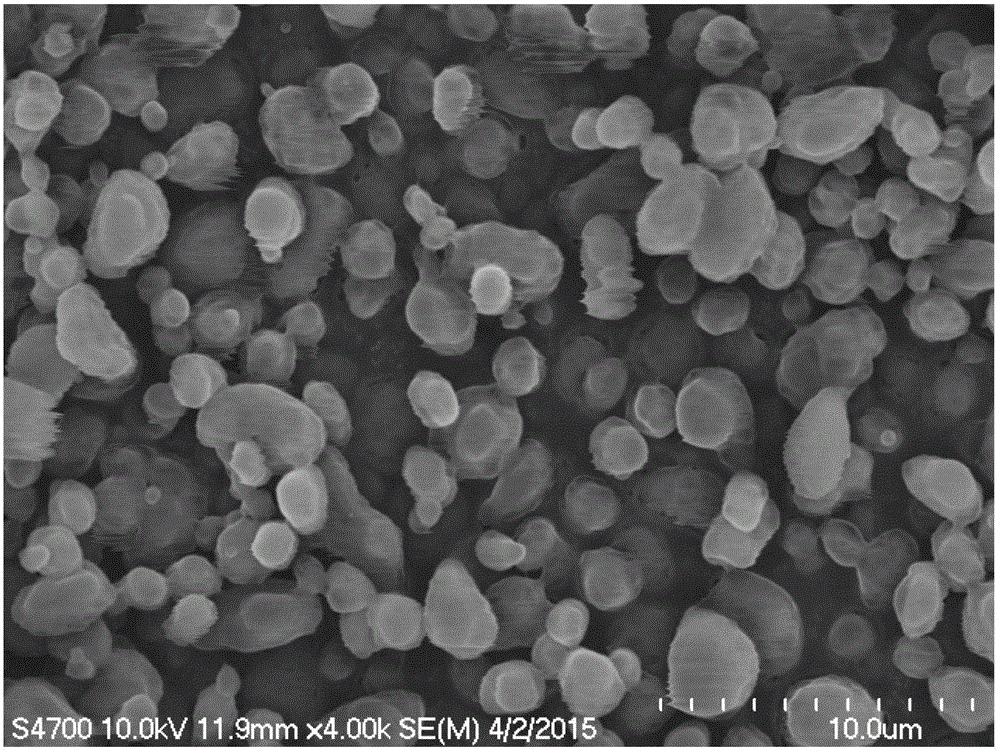

[0055] In this embodiment, a method for preparing nano-microcapsules with a "shell-core" structure with a supercritical fluid comprises the following steps:

[0056] 1) Mix RDX (RDX) 30g and fluororubber (F 26 ) 0.9g was added to dimethylformamide (DMF) 100mL and stirred until RDX was completely dissolved in DMF, F 26 Completely swell in DMF to form a solution, keep the temperature of the solution at 30°C;

[0057] 2) Turn on the temperature control switch of the supercritical atomization crystallization preparation system, set the temperature of the particle collection tank to 40°C, and set the initial supercritical CO 2 The temperature is 65°C and preheated for 30 minutes.

[0058] 3) Set CO 2 The flow rate of the solution is 20kg / h, the flow rate of the solution is set at 2mL / min, and the working pressure of the particle collection tank is set at 18MPa.

[0059] 4) Turn on the CO 2 Cylinder valve, open CO 2 pump to make CO 2 Enter the supercritical atomization crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com