Novel bifunctional electrochemical efficient catalyst composite material and preparation method thereof

A composite material, dual-function technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of reducing volume capacity and mass capacity, low energy density, etc. problems, to achieve the effect of improving performance, increasing specific surface area, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

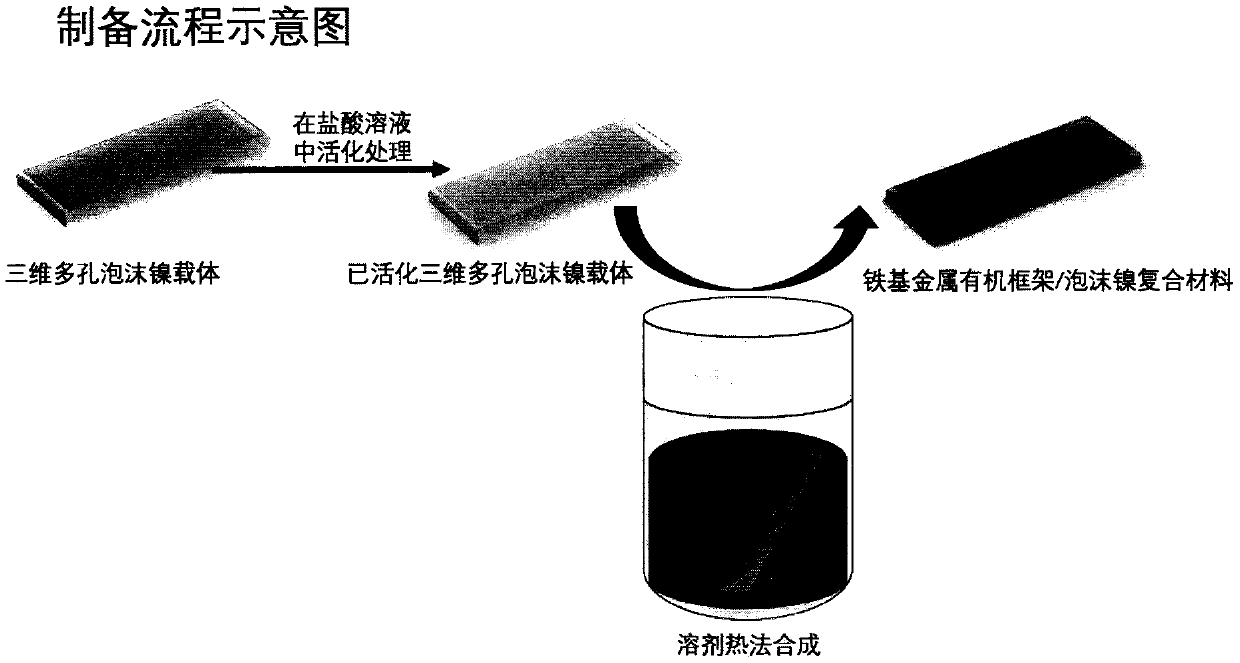

[0043] The present invention provides a method for preparing an iron-based metal organic frame / nickel foam composite material, which includes the following procedures and steps:

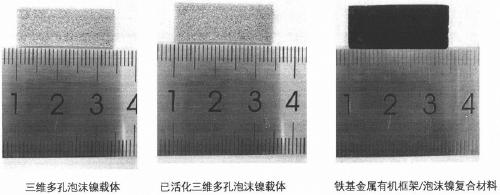

[0044] Process (1): Take commercially available foamed three-dimensional porous nickel foam material, composition: nickel content 99.8%; specification size: 250mm*200mm*1mm; surface density: 320g / m 2 ±20

[0045] Step (2): Preparation of activated three-dimensional porous nickel foam material carrier:

[0046] Activating solution formula: HCL, concentration 1~10mol / L

[0047] Activation process: temperature 25~60℃, time 1~45min.

[0048] According to the above formula and process, the three-dimensional porous nickel foam material is activated to remove the oxide scale on the surface of the three-dimensional porous nickel foam material, and then taken out and dried to obtain an activated three-dimensional porous nickel foam material carrier.

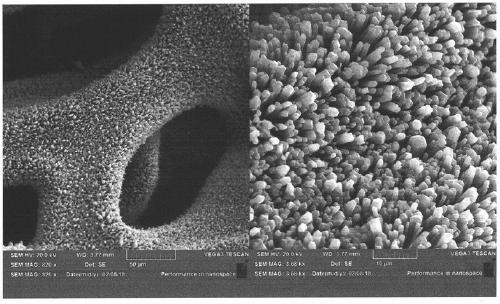

[0049] Process (3): Preparation of iron-based metal organic frame / nic...

Embodiment 1

[0059] In the above specific embodiment,

[0060] Step (1): Prepare the foam three-dimensional porous nickel foam material according to the above "specific implementation method"

[0061] Step (2): Preparation of activated three-dimensional porous nickel foam material carrier:

[0062] HCL, concentration 1mol / L, temperature 60℃, time 45min.

[0063] Process (3): Preparation of iron-based metal organic frame / nickel foam composite material:

[0064] Step 1: Ferrous chloride tetrahydrate: 60mg, 2,5-dihydroxyterephthalic acid: 100mg; DMF: 20Ml, deionized water: 1.5ml, absolute ethanol: 1.5ml

[0065] Step 2: Prepare the autoclave according to the above "specific implementation method".

[0066] Step 3: Prepare MOF material according to the above "specific implementation method":

[0067] Electrochemical test results:

[0068] Use the prepared MOF material as the working electrode of HER linear cyclic voltammetry test, reaching 300mA / cm 2 The current density. This reflects the excellent hydroge...

Embodiment 2

[0071] In the above specific embodiment,

[0072] Step (1): Prepare the foam three-dimensional porous nickel foam material according to the above "specific implementation method"

[0073] Step (2): Preparation of activated three-dimensional porous nickel foam material carrier:

[0074] HCL, concentration 3mol / L, temperature 60℃, time 30min.

[0075] Process (3): Preparation of iron-based metal organic frame / nickel foam composite material:

[0076] Step 1: Ferrous chloride tetrahydrate: 136.7mg, 2,5-dihydroxyterephthalic acid: 60mg; DMF: 20ml, deionized water: 1.5ml, absolute ethanol: 1.5ml

[0077] Step 2: Prepare the autoclave according to the above "specific implementation method".

[0078] Step 3: Prepare MOF material according to the above "specific implementation method":

[0079] Using the prepared MOF material as the working electrode of HER linear cyclic voltammetry test, 320mA / cm is achieved 2 The current density. This reflects the excellent hydrogen evolution performance of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com