Spinning solution, nuclear shell nanofiber as well as preparation method and application thereof

A nanofiber, spinning solution technology, applied in rayon manufacturing, fiber chemical characteristics, textiles and papermaking, etc., can solve problems such as high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

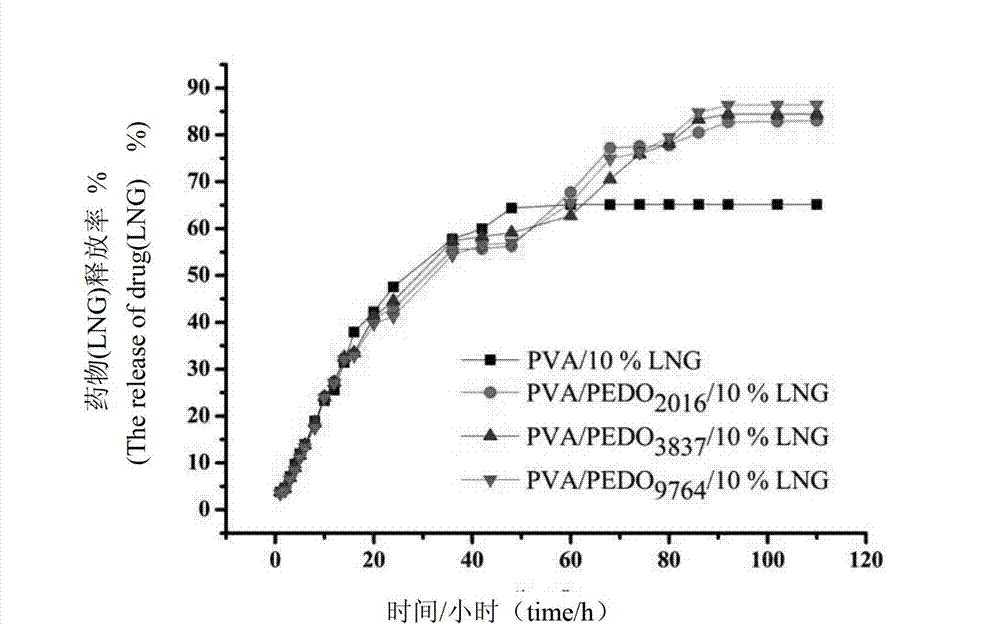

Embodiment 1

[0102] Weigh a certain amount of polyvinyl alcohol (PVA, average polymerization degree 1700, alcoholysis degree 88%) according to the formula and dissolve it in a certain volume of distilled water, the concentration of PVA is 4%wt / v (0.04g / ml), Heated and stirred at 80°C for 12h, and simultaneously weighed a certain amount of three different molecular weight polyethylene glycol-b-polydioxanone (PEG-b-PPDO, namely PEDO, its molecular structure is two blocks, The weight-average molecular weights were 9764, 3837 and 2716, respectively, and the mass ratios of the hydrophilic block PEG to the lipophilic block PPDO were 1:4, 1:0.9, and 1:0.7) were dissolved in a certain volume of distilled water in order to obtain three A PEDO solution and the concentrations of the three PEDO solutions are 1%wt / v (ie 0.01g / ml), heated and stirred at 30°C for 2h, and then the above PVA solution and each PEDO solution (ie PVA solution and three Any PEDO solution in the PEDO solution) the two are mixed...

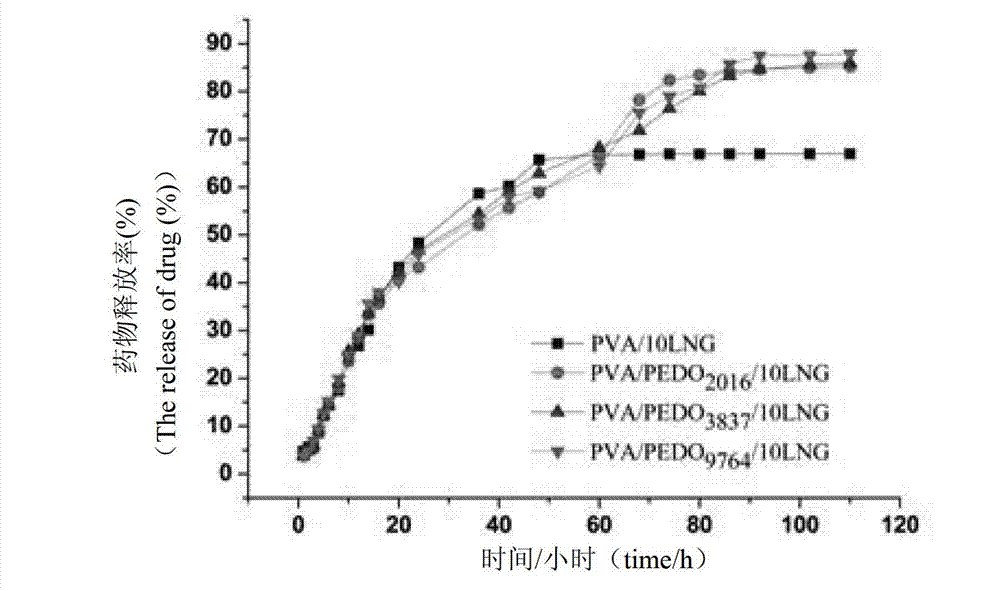

Embodiment 2

[0104] Weigh a certain amount of polyvinyl alcohol (PVA, average polymerization degree 1700, alcoholysis degree 88%) according to the formula and dissolve it in a certain volume of distilled water, the concentration of PVA is 4%wt / v (0.04g / ml), Heated and stirred at 80°C for 12 hours, and at the same time weighed a certain amount of three different molecular structures of polyethylene glycol-b-polydioxanone (PEG-b-PPDO, PEDO, the molecular structures were diblock, Tri-block and multi-block, the weight-average molecular weights are 3837, 5670 and 15000, respectively, and the mass ratio of the hydrophilic block PEG to the lipophilic block PPDO is 1:0.9, 1:1.8 and 1:6.5 respectively) dissolved in A certain volume of distilled water in order to obtain three PEDO solutions and the concentration of the three PEDO solutions is 5%wt / v (ie 0.05g / ml), heated and stirred at 30°C for 2h, and then the above PVA solution was mixed with each PEDO solution (that is, PVA solution and any PEDO ...

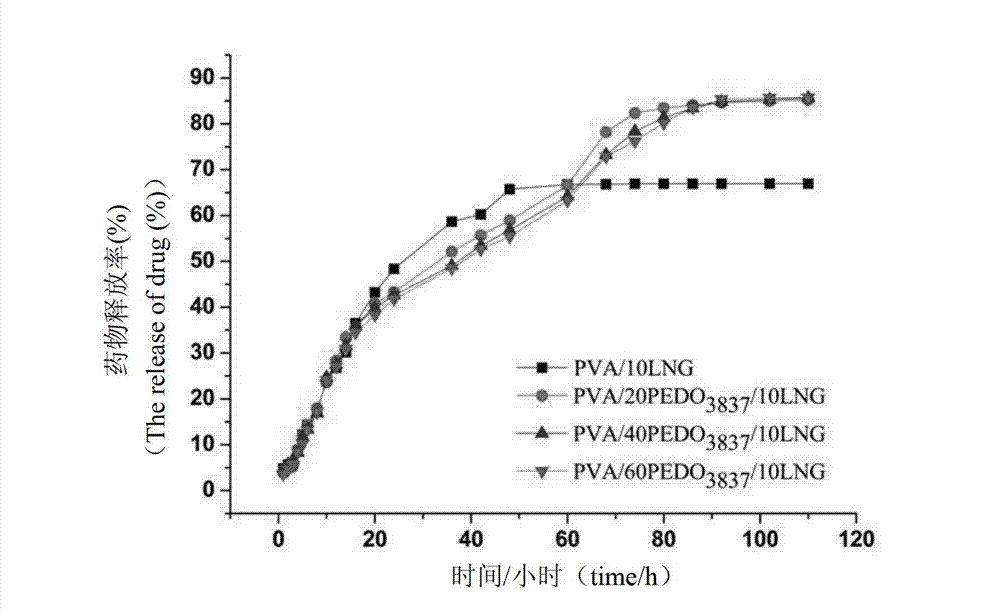

Embodiment 3

[0106] Weigh a certain amount of polyvinyl alcohol (PVA, average degree of polymerization 1700, degree of alcoholysis 66%) according to the formula and dissolve it in a certain volume of distilled water, the concentration of PVA is 4%wt / v (ie 0.04g / ml), Heated and stirred at 80°C for 12h, and simultaneously weighed a certain amount of three different molecular weight polyethylene glycol-b-polydioxanone (PEG-b-PPDO, namely PEDO, its molecular structure is two blocks, The weight-average molecular weights were 9764, 3837 and 2716, respectively, and the mass ratios of the hydrophilic block PEG to the lipophilic block PPDO were 1:3.8, 1:0.9, and 1:0.35 respectively) were dissolved in a certain volume of distilled water in order to obtain three A PEDO solution and the concentrations of the three PEDO solutions are all 10%wt / v (ie 0.1g / ml), heated and stirred at 30°C for 2h, and then the above PVA solution and each PEDO solution (ie PVA solution and three Any PEDO solution in the PED...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com