A kind of magnesium hydroxide/graphene flake composite flame retardant and preparation method thereof

A technology of graphene flakes and composite flame retardants, which is applied in the field of flame retardants and their preparation, can solve the problems of complex process, low thermal stability and flame retardant performance, difficulty in controlling magnesium hydroxide, etc., and achieve simple process, Improve compatibility and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

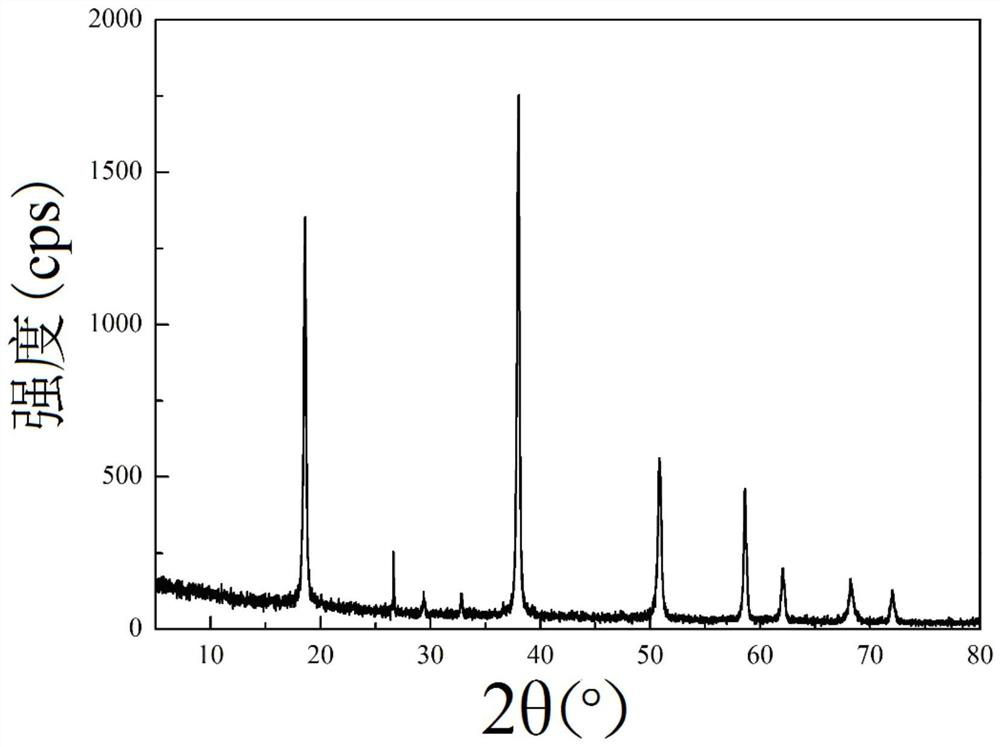

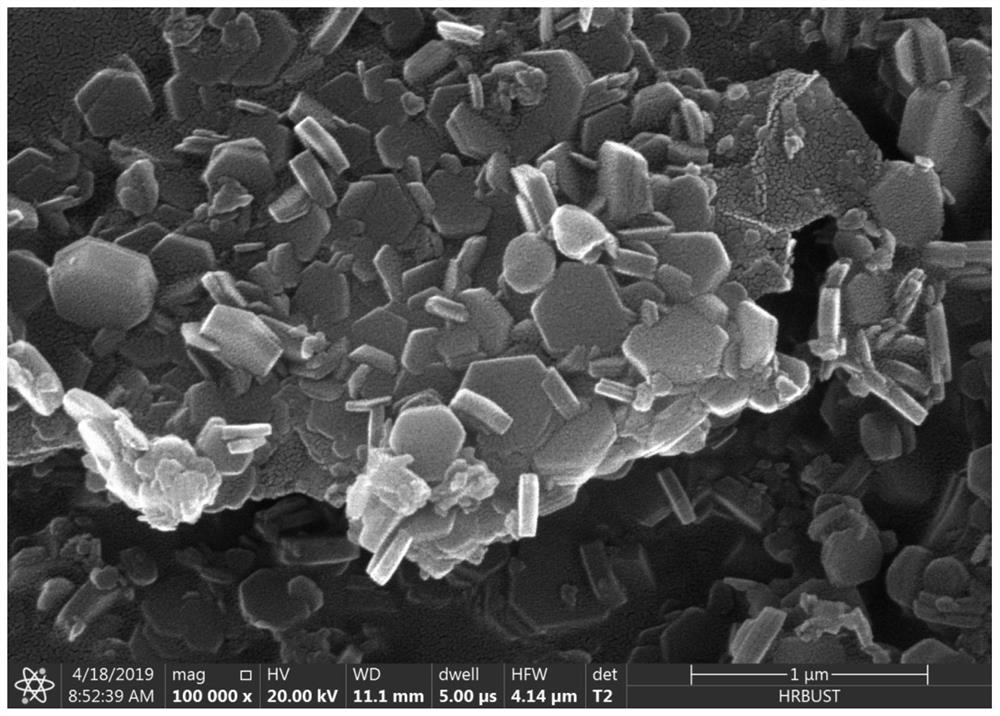

[0030] Embodiment 1: This embodiment is a magnesium hydroxide / graphene flake composite flame retardant that is a magnesium hydroxide-coated graphene flake with a hexagonal flake structure, and the size of the magnesium hydroxide with the hexagonal flake structure is 100nm to 800nm.

specific Embodiment approach 2

[0031] Specific embodiment two: present embodiment is a kind of preparation method of magnesium hydroxide / graphene flake composite flame retardant and is finished according to the following steps:

[0032] 1. Preparation of graphene flake dispersion:

[0033] Mixing the graphene flakes, dispersant and deionized water, and then transferring to a grinding device for grinding to obtain a graphene flake dispersion;

[0034] The mass ratio of graphene flake described in step 1 and dispersant is 1:(0.5~10);

[0035] The mass ratio of graphene sheet described in step 1 and deionized water is (0.001~0.05):(1~20);

[0036] 2. Add light-burned magnesium powder to the grinding equipment equipped with graphene flake dispersion, and then grind to obtain magnesium hydroxide / graphene flake composite slurry;

[0037] The mass ratio of lightly burned magnesium powder and graphene flakes described in step 2 is 1:(0.001~0.01);

[0038] 3. Add modifier to the grinding equipment equipped with m...

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the mass ratio of graphene flakes and deionized water described in step one is (0.001~0.05):(8~10). Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com