Catalyst for polyester synthesis and its preparation method and application

A catalyst and polyester technology, applied in the field of polyester synthesis catalyst and its preparation, can solve the problems of affecting the quality uniformity of polyester products, high surface energy of catalyst powder, difficult to achieve ultra-fineness, etc., and achieve excellent humidity and heat resistance. Aging performance, easy industrial application, the effect of inhibiting the formation of cyclic oligomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

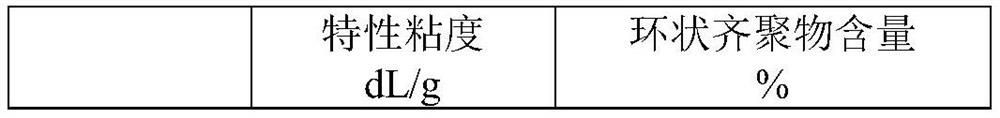

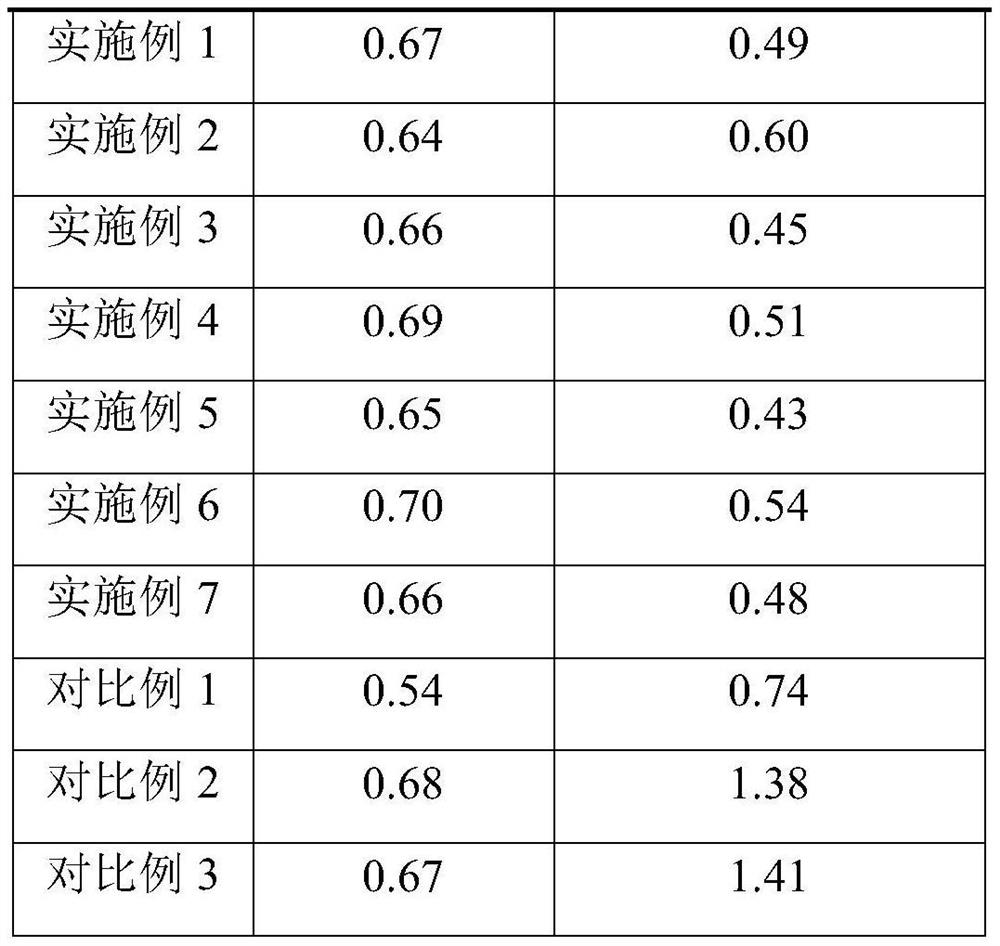

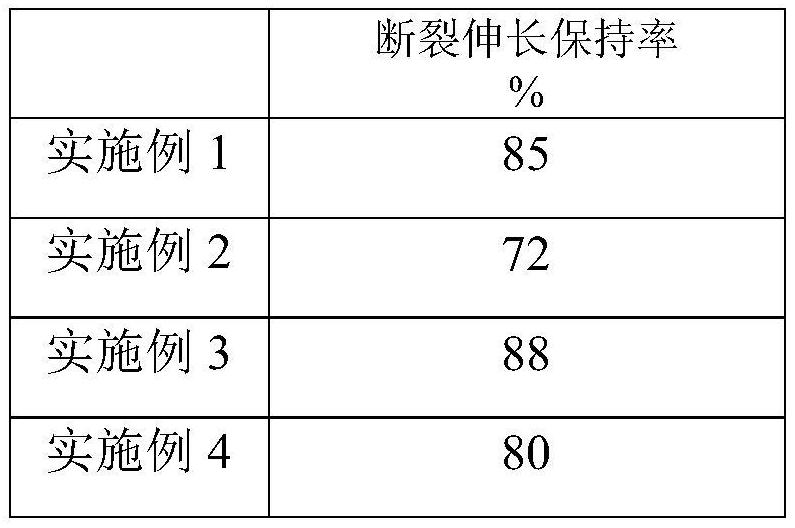

Examples

Embodiment 1

[0046] (1) Add 40 grams of aluminum isopropoxide into 160 grams of isopropanol and heat to reflux for 1 hour to obtain an isopropanol solution with a concentration of aluminum isopropoxide of 20%.

[0047] (2) The isopropanol solution of aluminum isopropoxide is slowly added to the ultrasonic reactor equipped with polyethylene glycol concentration of 1wt%, potassium dihydrogen phosphate concentration of 0.5% in the ultrasonic reactor of 800 grams of aqueous solution, the molecular weight of polyethylene glycol is 1000, the temperature of the ultrasonic reactor is 90 °C, and the reaction time is 1 h, and a water-based γ-AlOOH suspension is obtained.

[0048] (3) Add 400 grams of ethylene glycol to the water-based γ-AlOOH suspension, then distill under reduced pressure at 90° C. to remove water and low-boiling alcohols to obtain an ethylene glycol-based γ-AlOOH suspension.

[0049] (4) adding 20 grams of lanthanum acetylacetonate into 380 grams of isopropanol and heating to refl...

Embodiment 2

[0053] (1) Add 40 grams of aluminum ethoxide to 360 grams of isopropanol and heat to reflux for 1 hour to obtain an isopropanol solution with a concentration of aluminum ethoxide of 10%.

[0054] (2) The isopropanol solution of aluminum ethylate is slowly added to the ultrasonic reactor equipped with polyethylene glycol concentration of 3 wt%, sodium dihydrogen phosphate concentration of 0.17% in the ultrasonic reactor of 800 grams of aqueous solution, the molecular weight of polyethylene glycol is 400 , the temperature of the ultrasonic reactor was 80 °C, and the reaction time was 1 h to obtain a water-based γ-AlOOH suspension.

[0055] (3) Add 400 grams of ethylene glycol to the water-based γ-AlOOH suspension, then distill under reduced pressure at 80° C. to remove water and low-boiling alcohols to obtain an ethylene glycol-based γ-AlOOH suspension.

[0056] (4) adding 10.8 grams of lanthanum acetylacetonate into 529.2 grams of isopropanol and heating to reflux for 1 h to ob...

Embodiment 3

[0060] (1) Add 24.6 grams of aluminum sec-butoxide into 467.4 grams of isopropanol and heat to reflux for 1 hour to obtain an isopropanol solution with a concentration of aluminum isopropoxide of 5%.

[0061] (2) The isopropanol solution of aluminum sec-butoxide is slowly added to the ultrasonic reactor equipped with polyethylene glycol concentration of 10wt%, sodium hypophosphite concentration of 1.1% in the ultrasonic reactor of 400 grams of aqueous solution, the molecular weight of polyethylene glycol 400, the temperature of the ultrasonic reactor was 100 °C, and the reaction time was 1 h to obtain a water-based γ-AlOOH suspension.

[0062] (3) Add 800 grams of ethylene glycol to the water-based γ-AlOOH suspension, then distill under reduced pressure at 100° C. to remove water and low-boiling alcohols to obtain an ethylene glycol-based γ-AlOOH suspension.

[0063] (4) adding 57.5 grams of hafnium acetylacetonate into 1092.5 grams of isopropanol and heating to reflux for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com