A kind of preparation method of nano-modified bisphenol A type epoxy resin

A technology of epoxy resin and nano-modification, which is applied in the field of preparation of nano-in-situ modification, and can solve problems such as inability to mass-produce, different interface properties, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

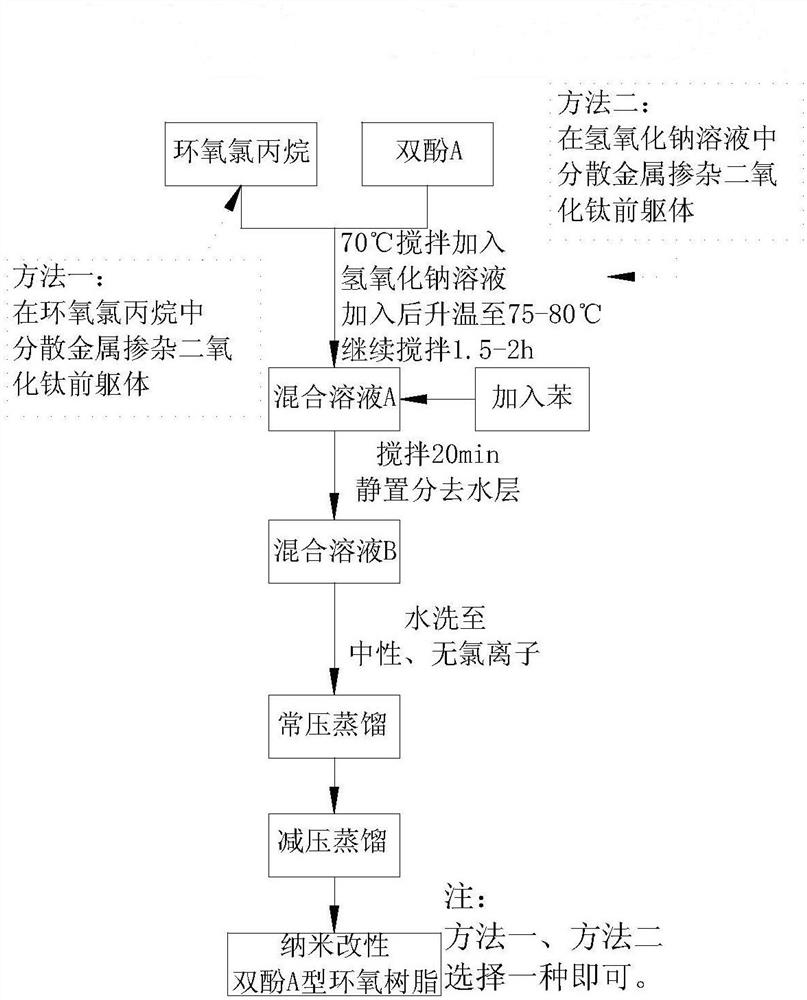

Method used

Image

Examples

Embodiment 1

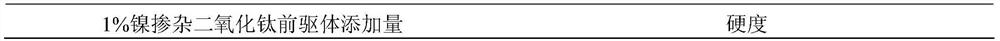

[0017] Preparation of 1% Nickel Doped Modified Bisphenol A Epoxy Resin

[0018] Add 0.05 g of 1% nickel-doped modified titanium dioxide precursor powder prepared by organic homogeneous deposition method, 28.02 g of epichlorohydrin solution, and 22 g of bisphenol A particles into a 250 ml container equipped with a stirrer, a dropping funnel, and a thermometer in sequence. In a three-necked flask; heat with a water bath, raise the temperature to 70°C, and stir the solution to fully dissolve the bisphenol A particles and 1% nickel-doped modified titanium dioxide precursor powder, and disperse them in the epichlorohydrin solution. At 70°C, Keep the temperature constant, add 40ml of 20% sodium hydroxide solution dropwise, control the dropping speed for 30min, then continue to heat up to 75-80°C and continue the reaction for 1.5-2h, stop heating, cool to room temperature, add 60ml of benzene solution, stir After the solution is fully dissolved, move it into a separatory funnel. Afte...

Embodiment 2

[0020] Preparation of 1% Nickel Doped Modified Bisphenol A Epoxy Resin

[0021] 0.05 g of the 1% nickel-doped modified titanium dioxide precursor powder prepared by the organic homogeneous deposition method was stirred and dispersed in 40 ml of 20% sodium hydroxide solution, and the modified titanium dioxide precursor powder was suspended in the sodium hydroxide solution to Wait for the subsequent addition; then add 28.02g of epichlorohydrin solution and 22g of bisphenol A particles into a 250ml three-necked flask equipped with a stirrer, dropping funnel and thermometer; Fully dissolve bisphenol A particles and 1% nickel-doped modified titanium dioxide precursor powder, disperse in epichlorohydrin solution, keep the temperature constant at 70°C, add 40ml of 1% nickel-doped modified titanium dioxide dropwise Precursor powder, sodium hydroxide solution with a concentration of 20%, control the dropping speed for 30 minutes, then continue to heat up to 75-80°C and continue to reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com