Patents

Literature

94 results about "Low pressure molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Pressure Molding (LPM) with polyamide and polyolefin (hot-melt) materials is a process typically used to encapsulate and environmentally protect electronic components (such as circuit boards). The purpose is to protect electronics against moisture, dust dirt and vibration. Low Pressure Molding is also used for sealing connectors and molding grommets and strain reliefs.

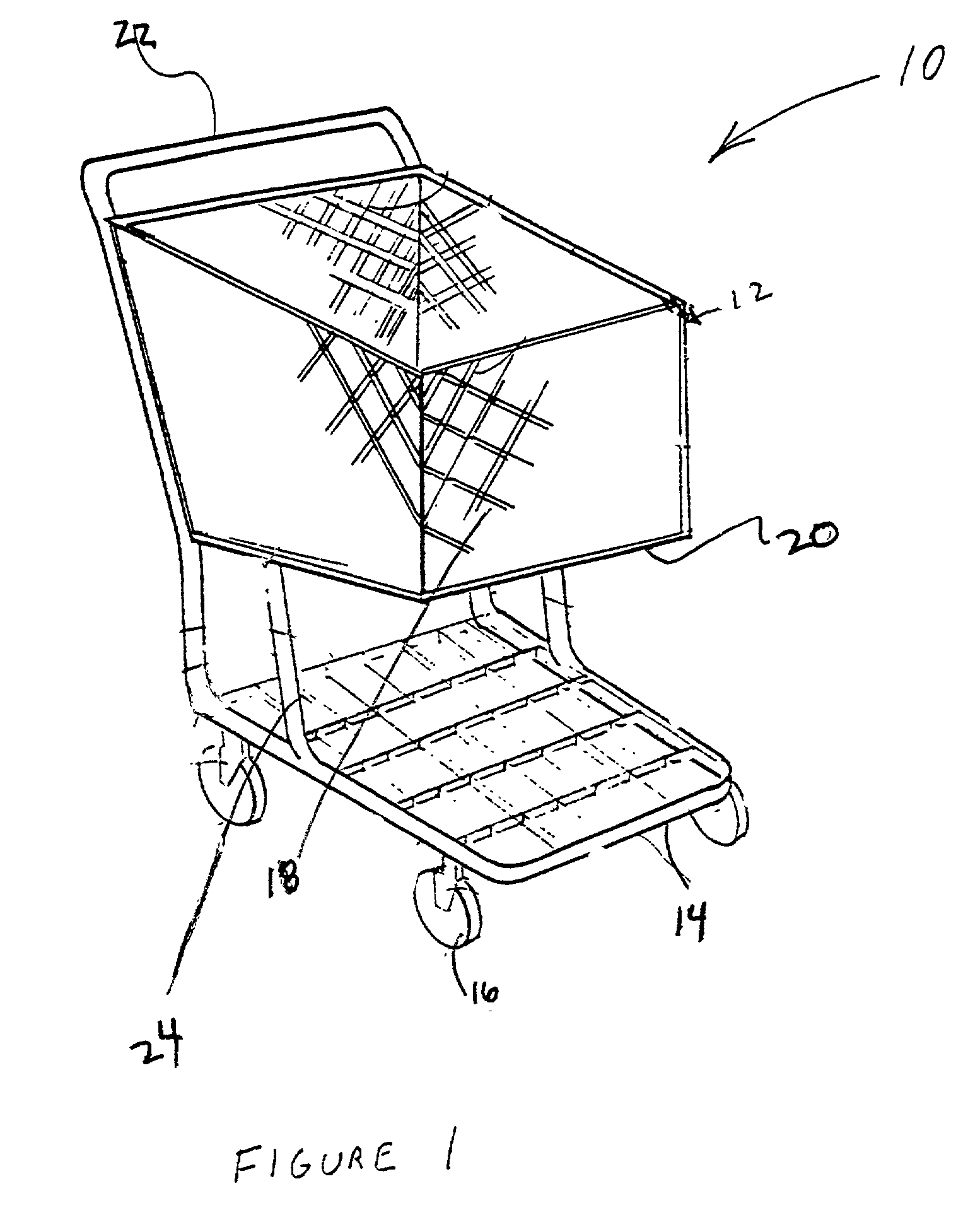

Method of molding a cart using molding processes

Owner:REHRIG INT INC +1

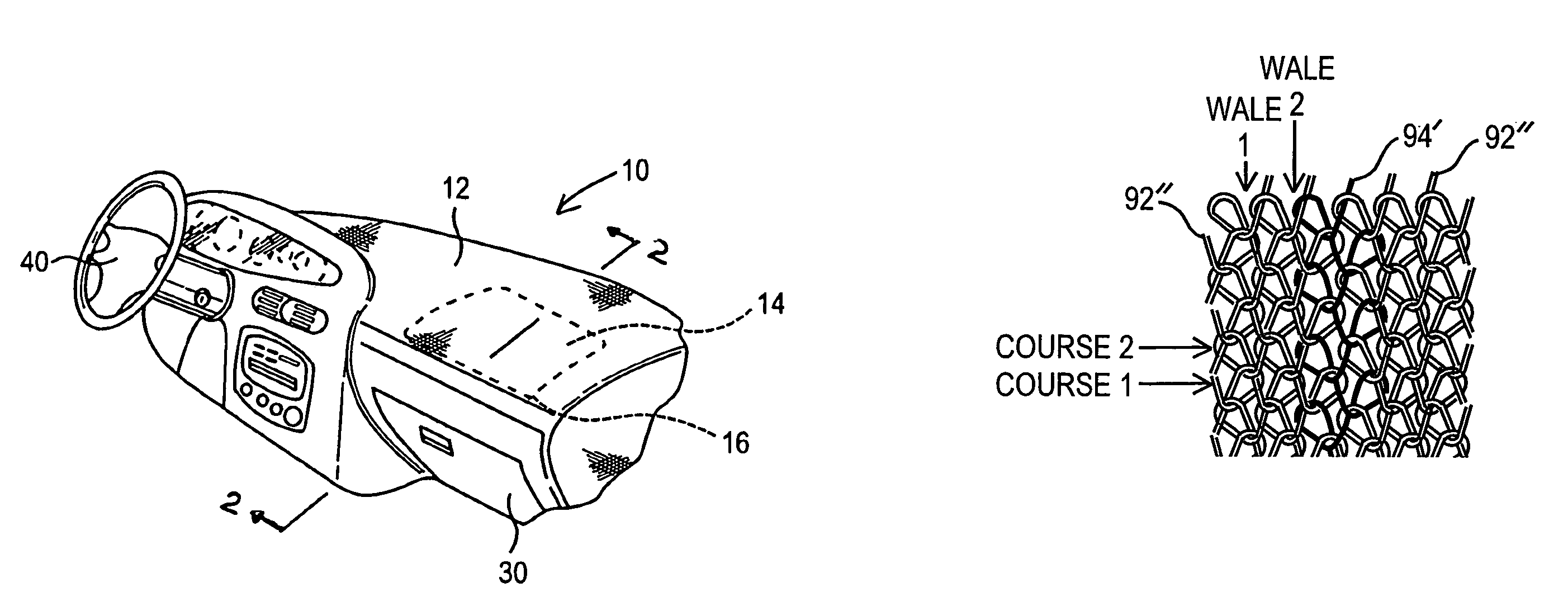

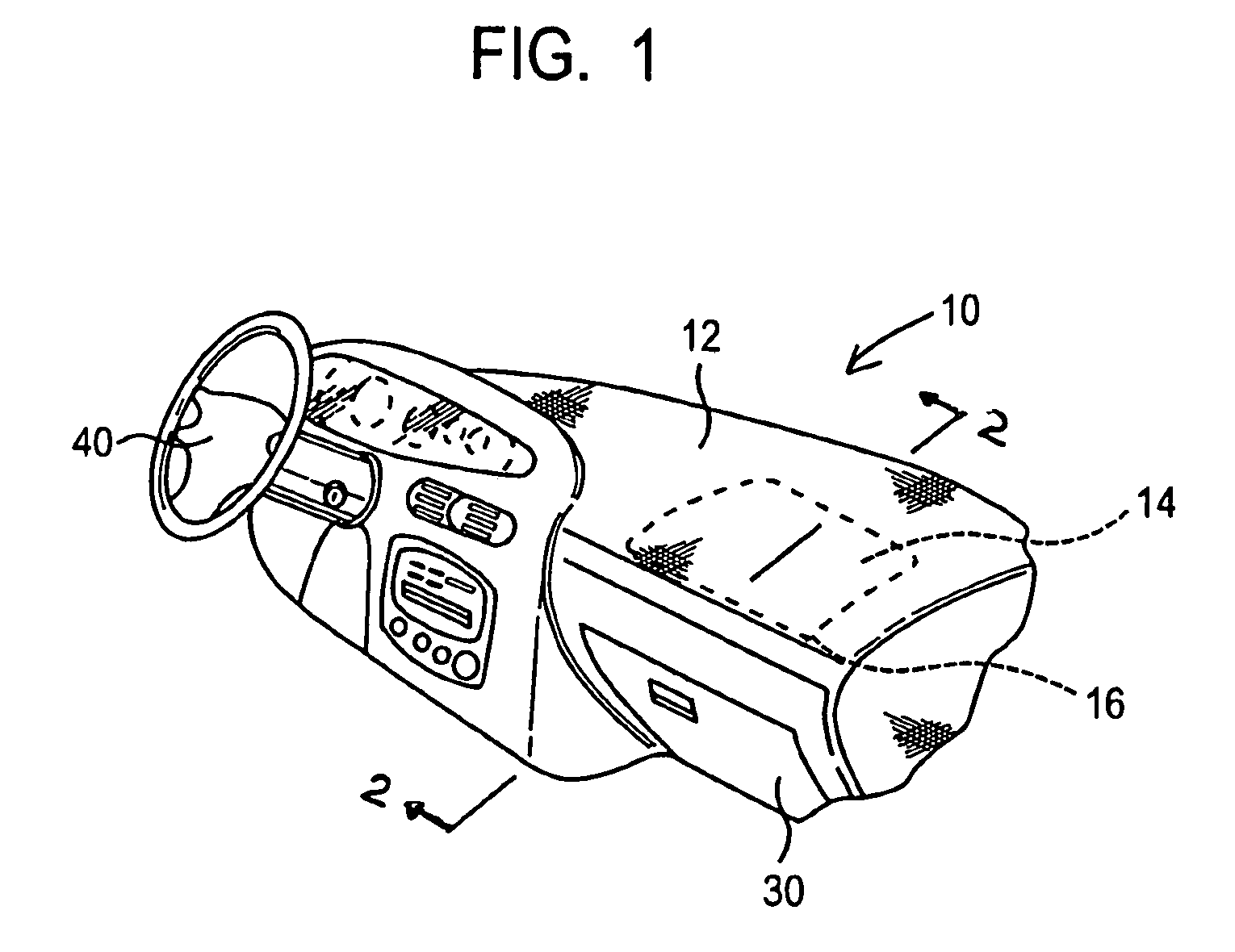

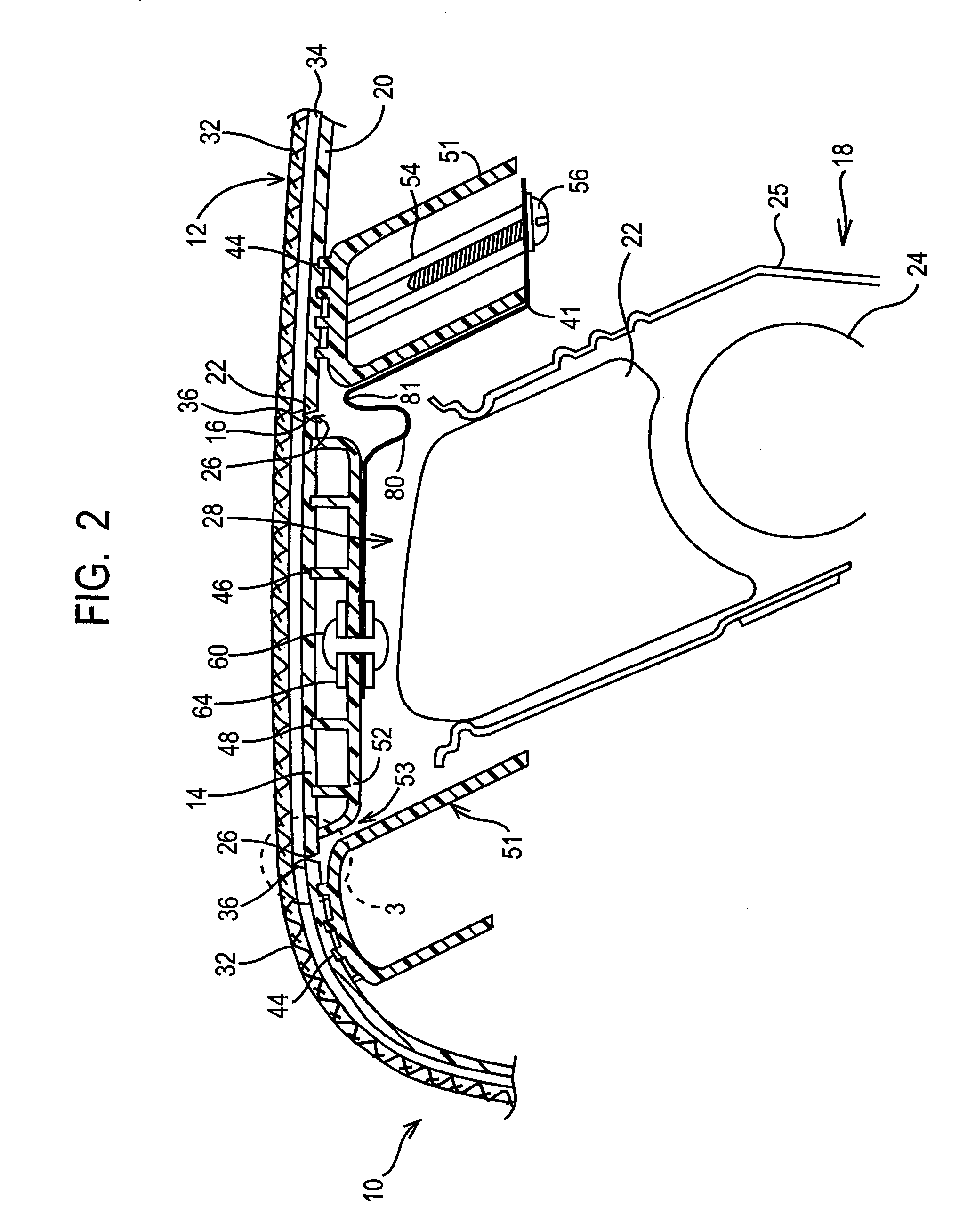

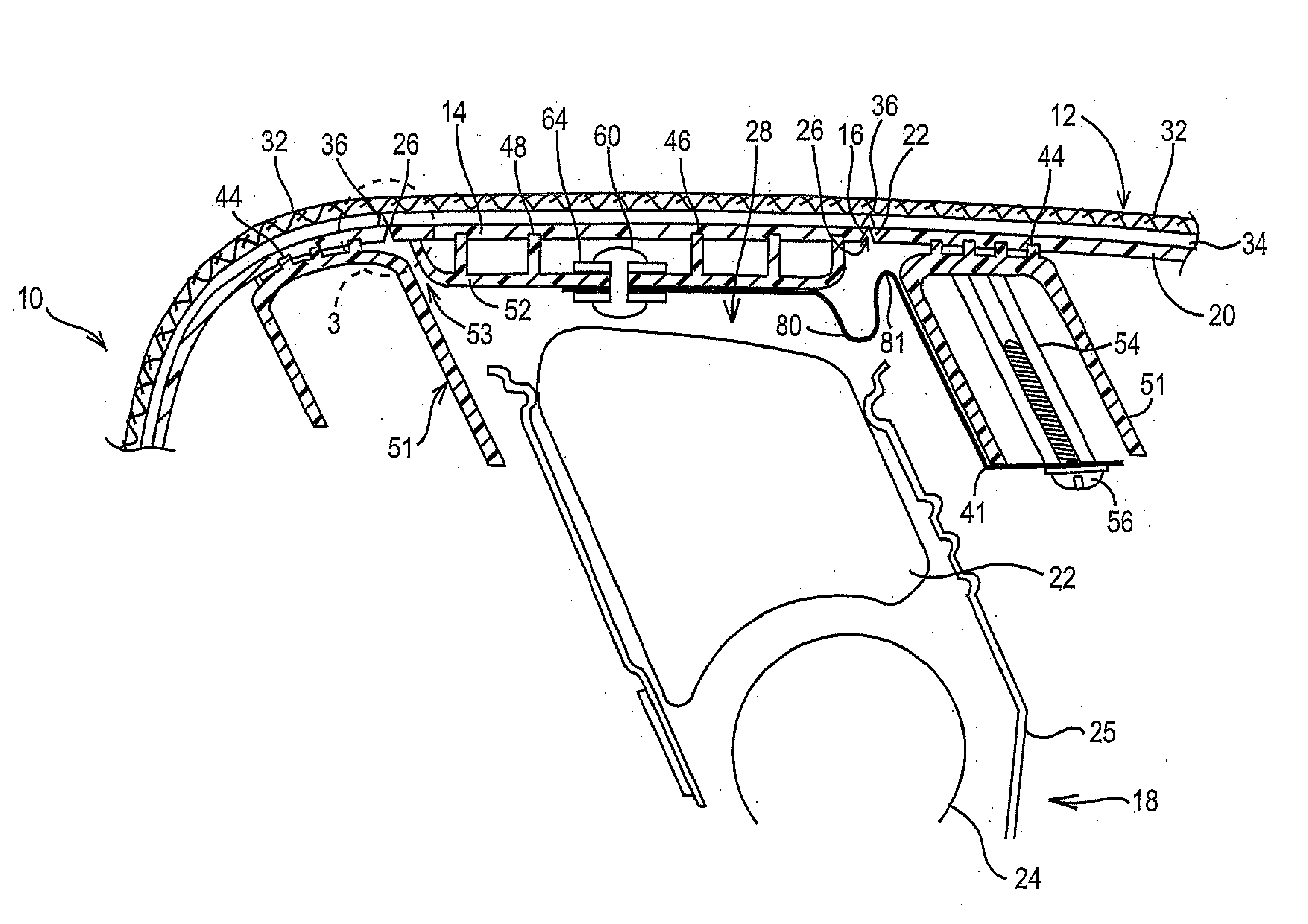

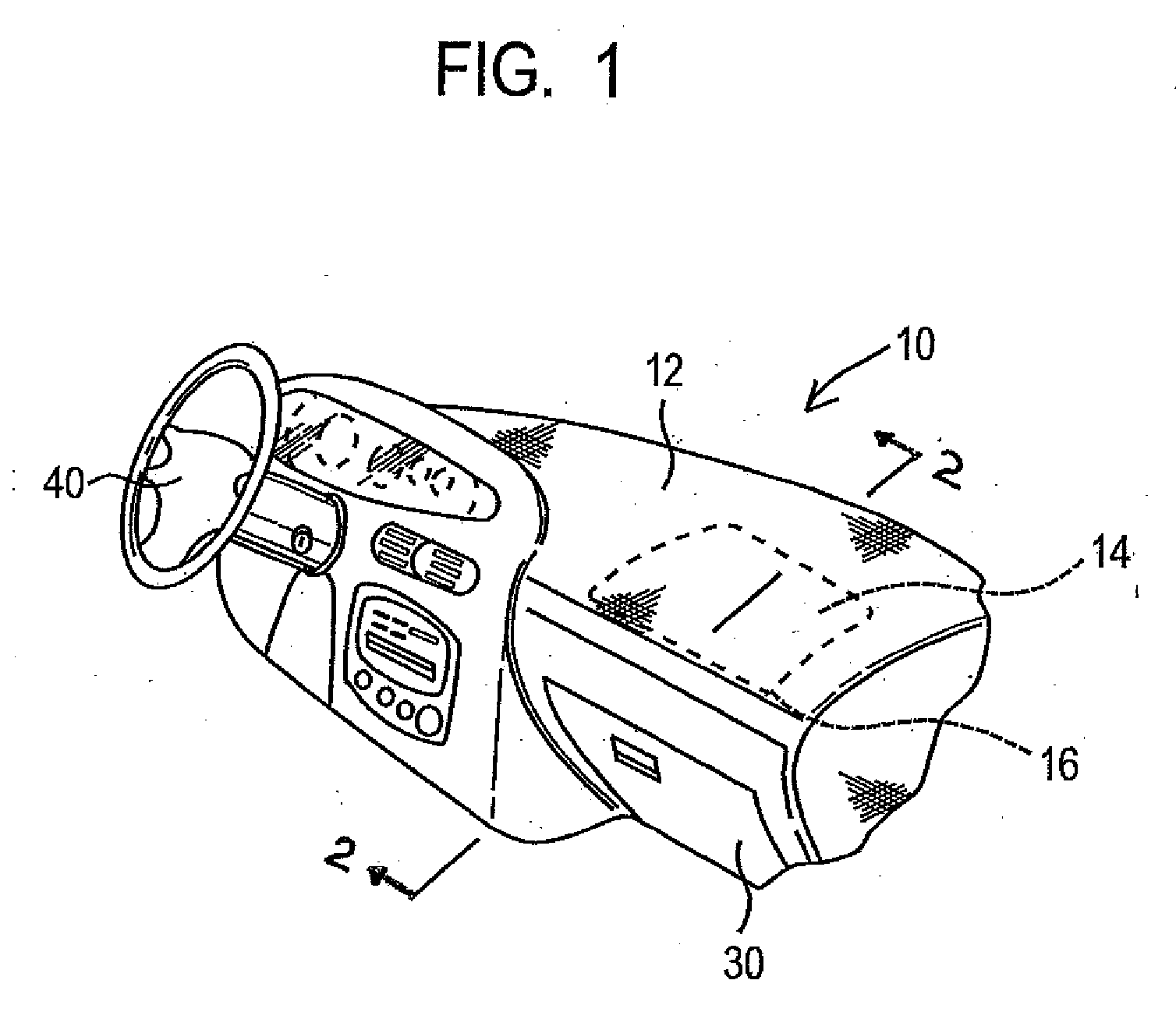

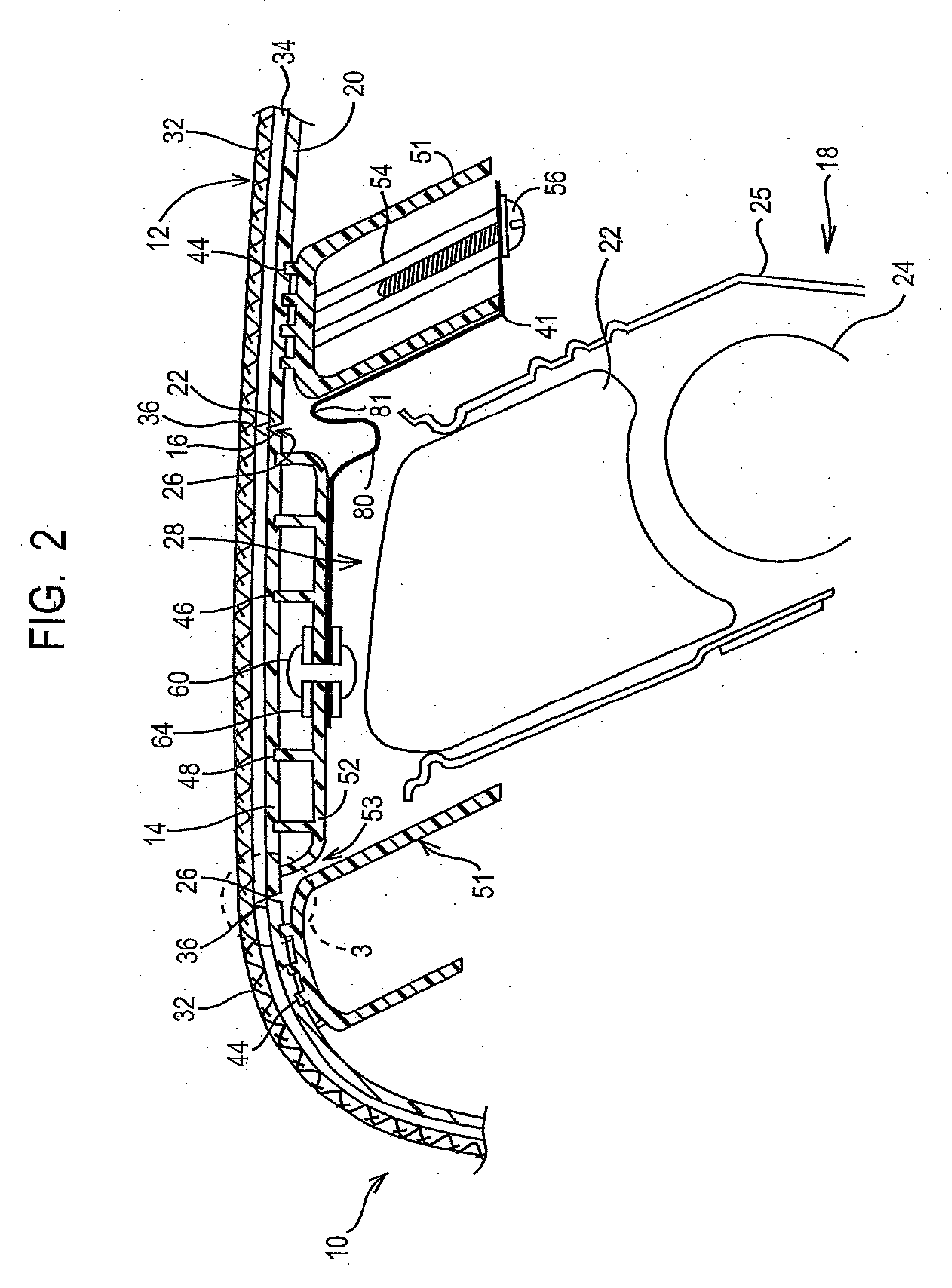

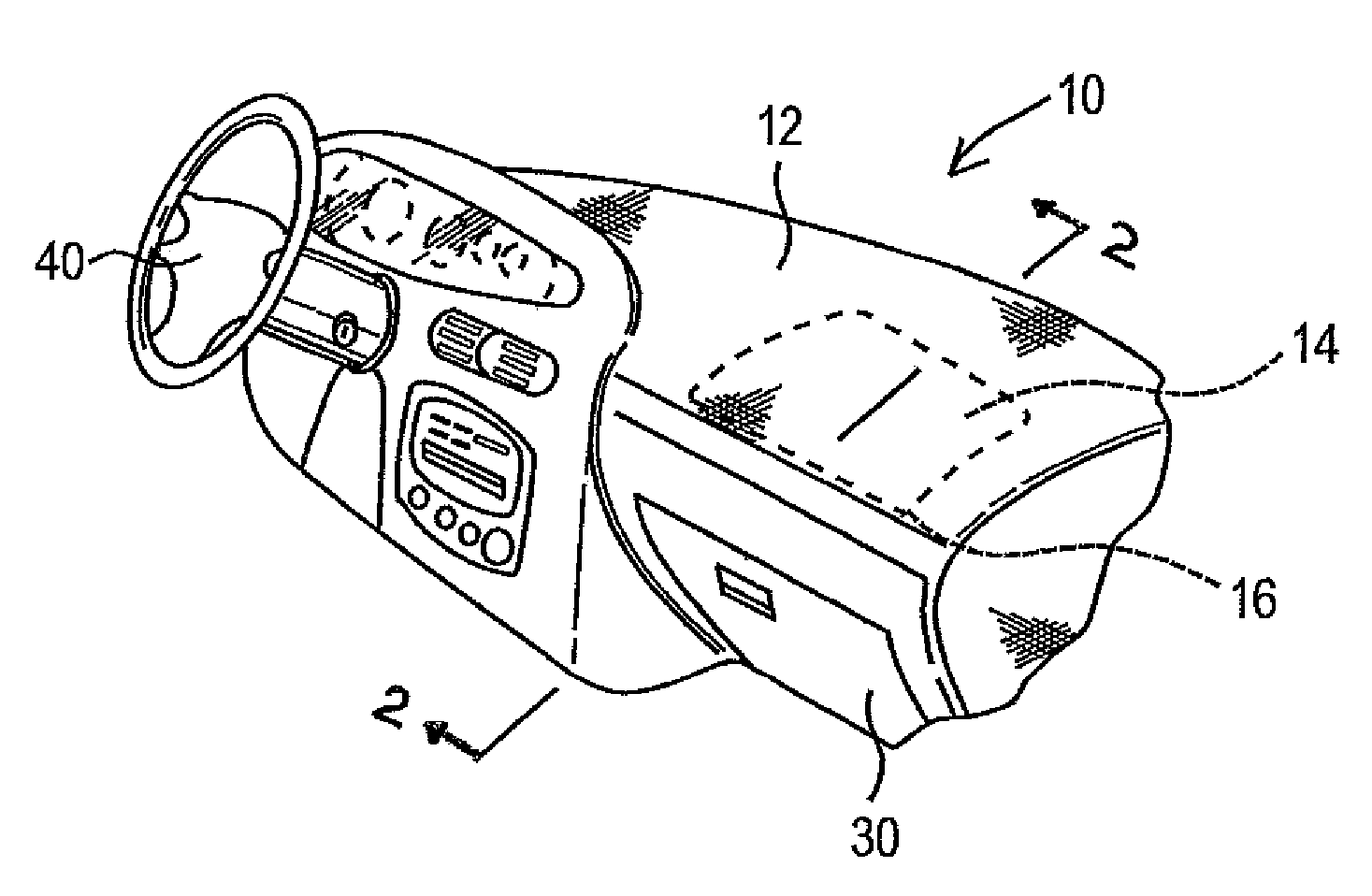

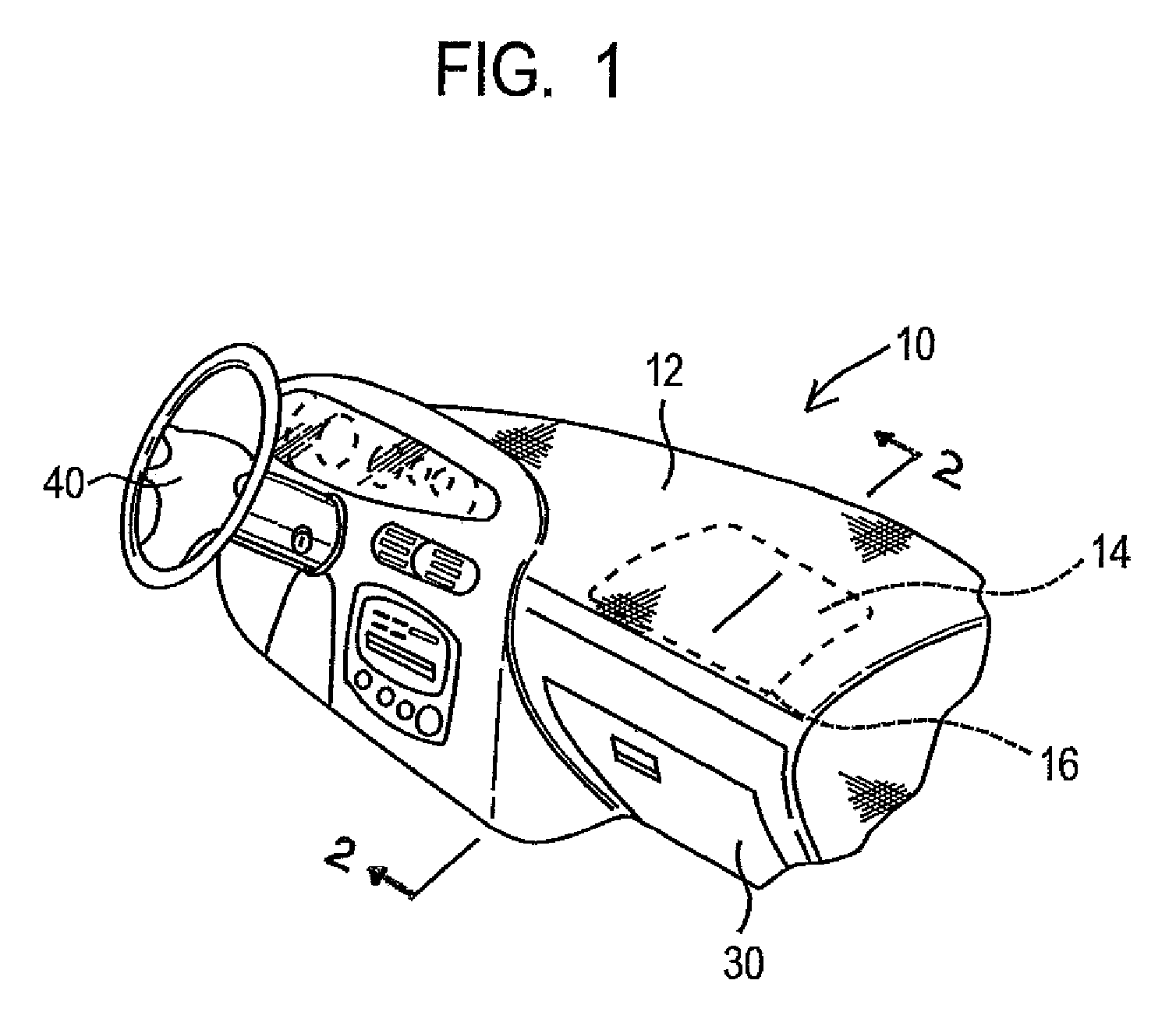

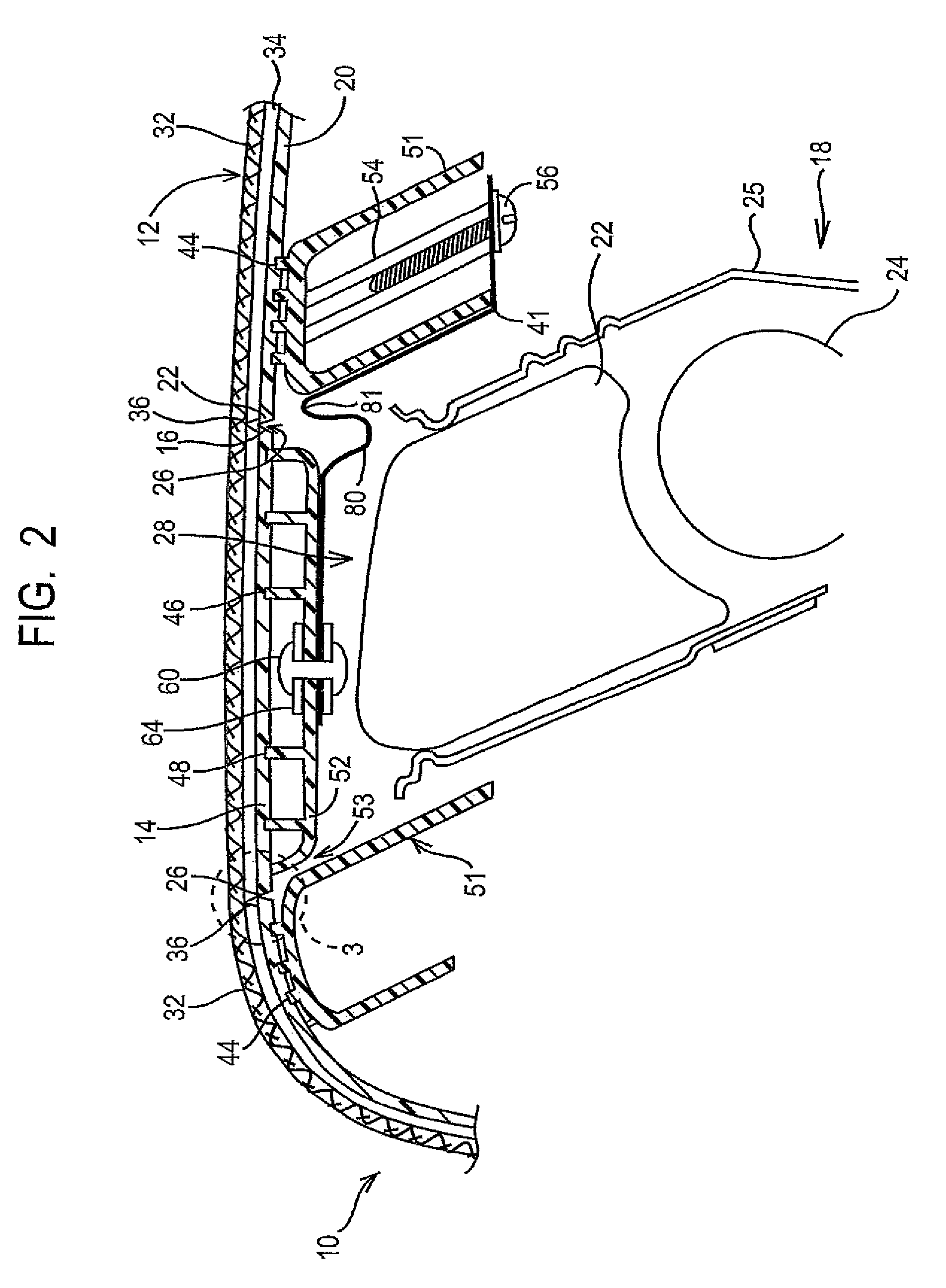

Pre-weakening of fabric covered airbag doors

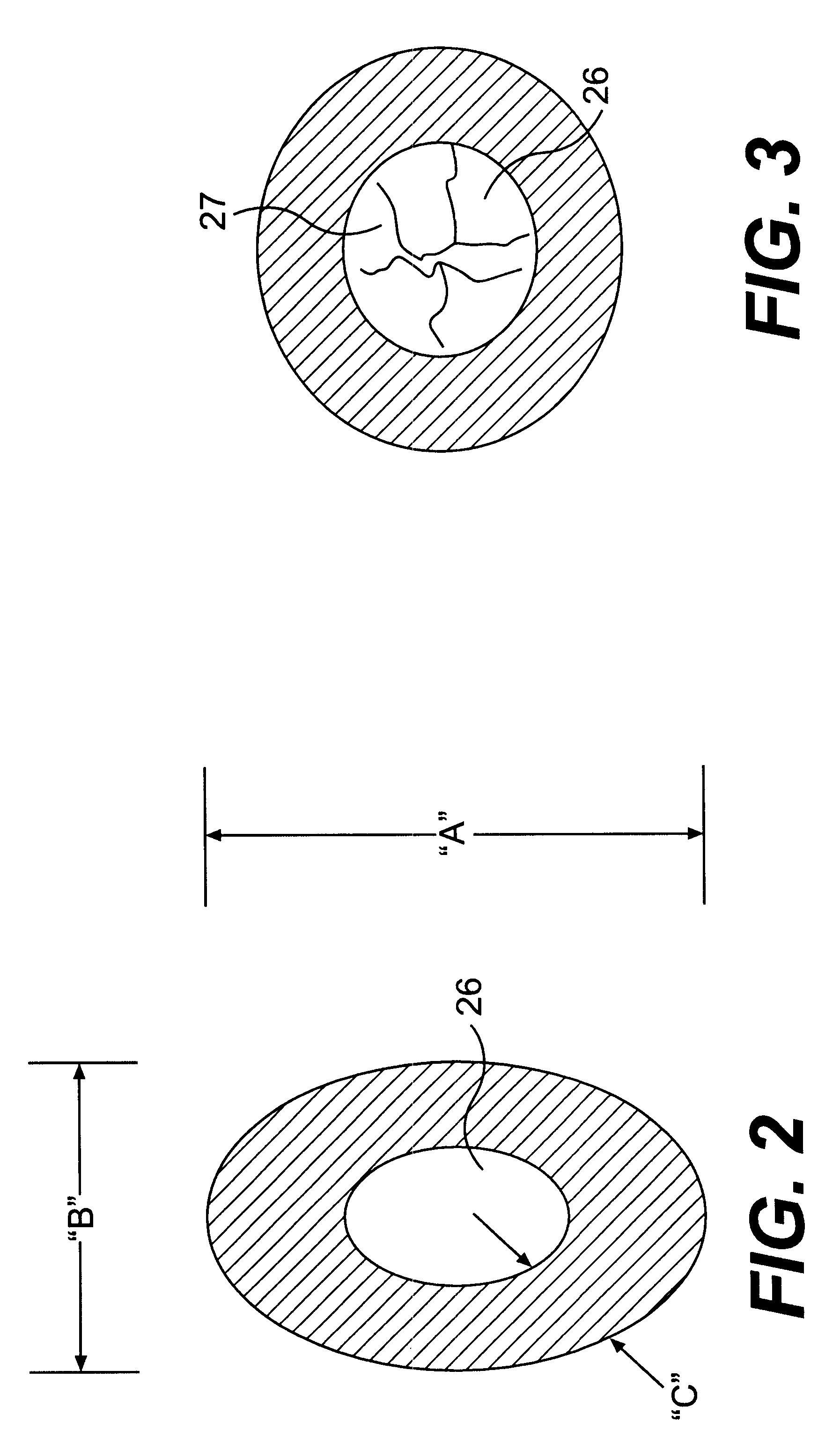

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

Pre-Weakening Of Fabric Covered Airbag Doors

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

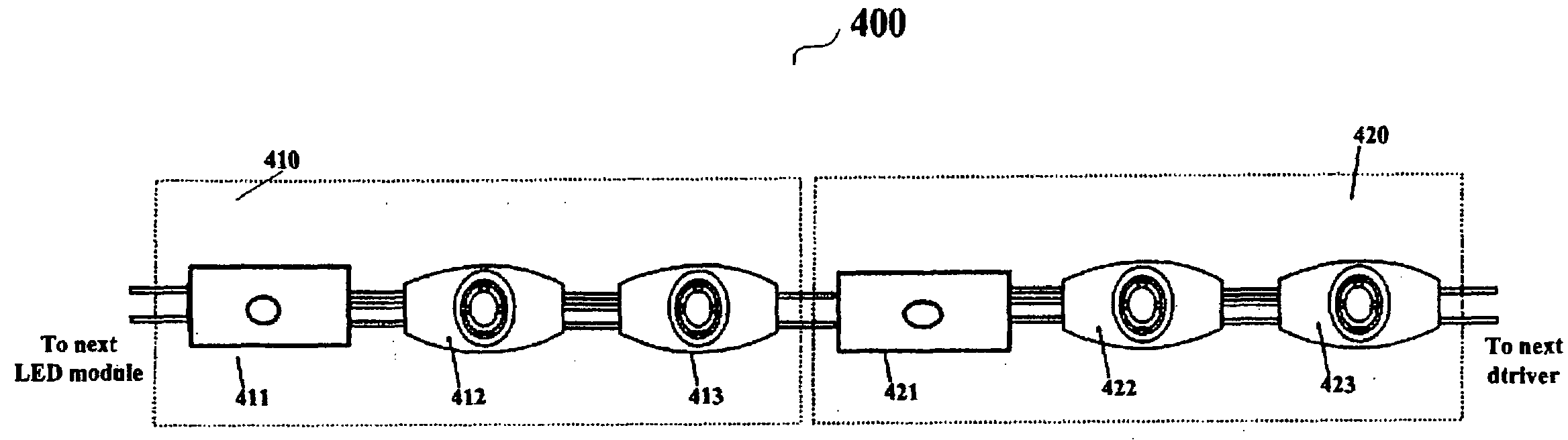

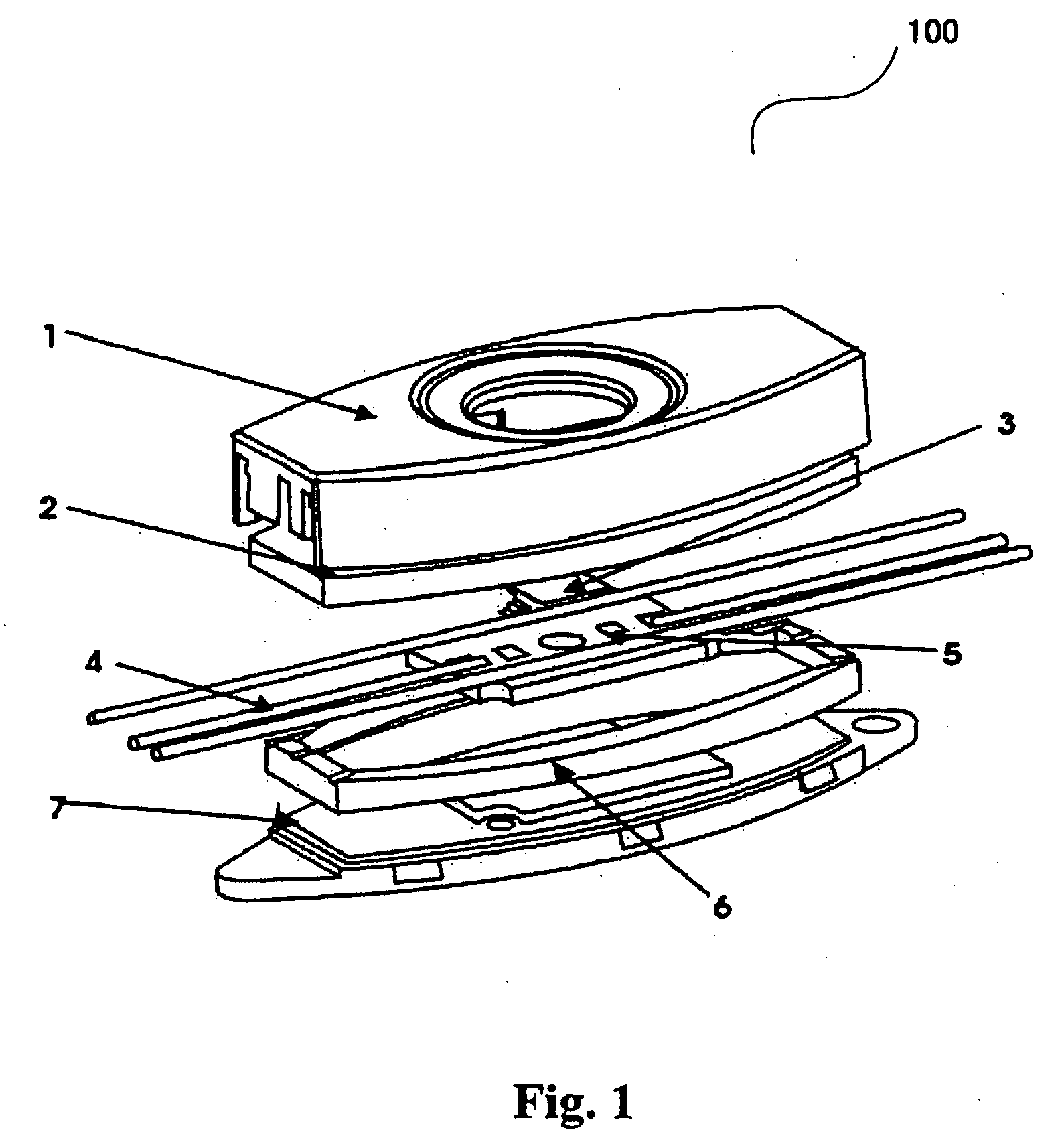

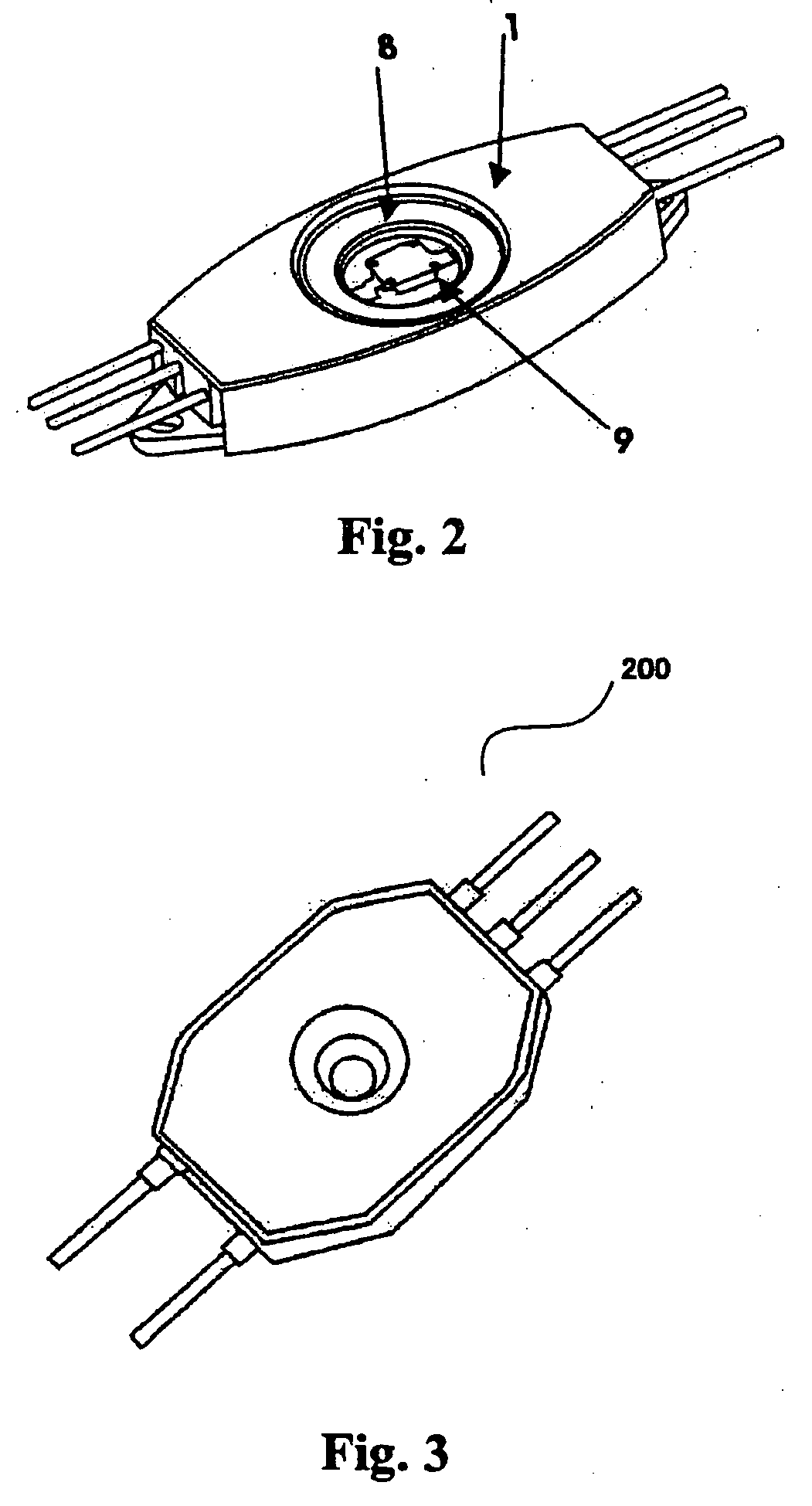

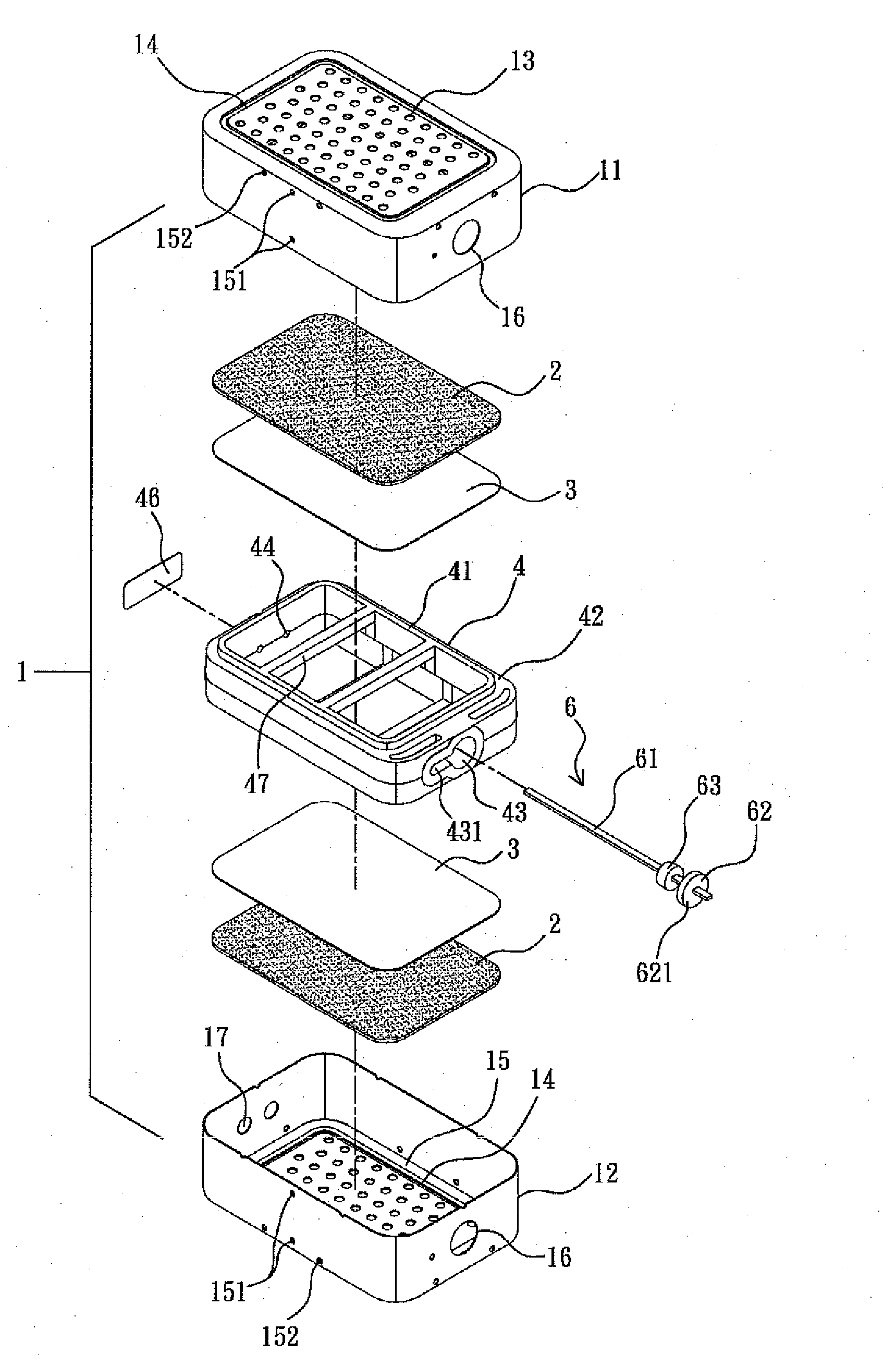

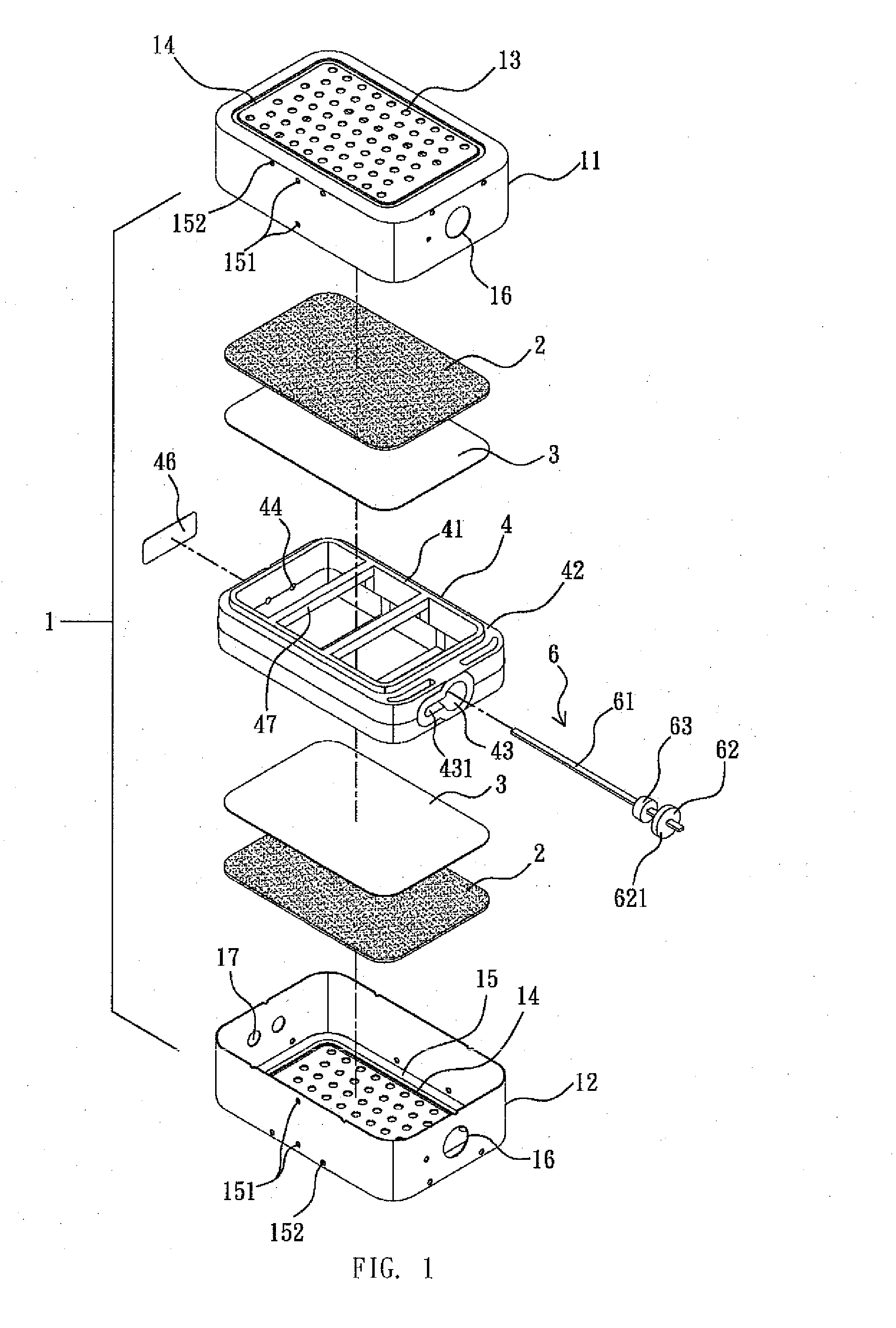

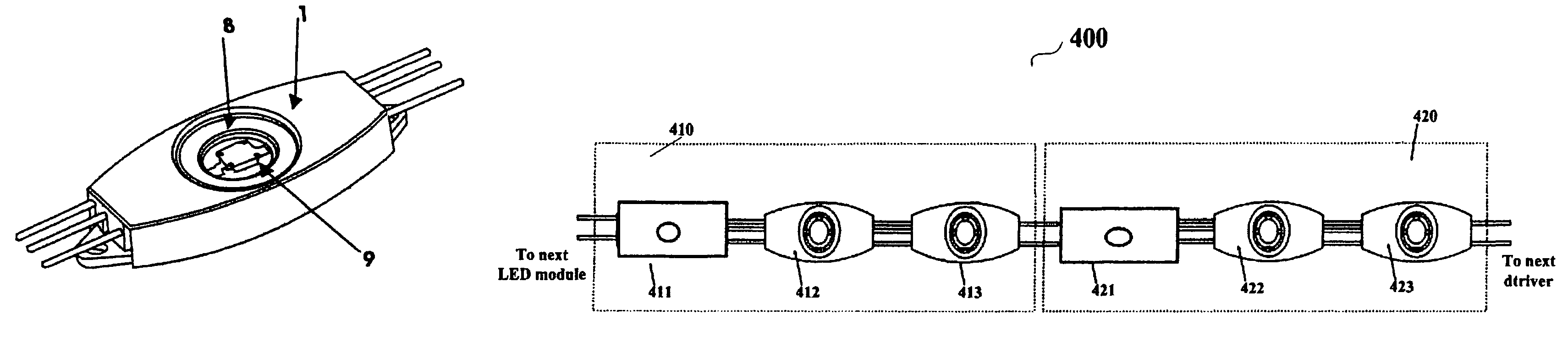

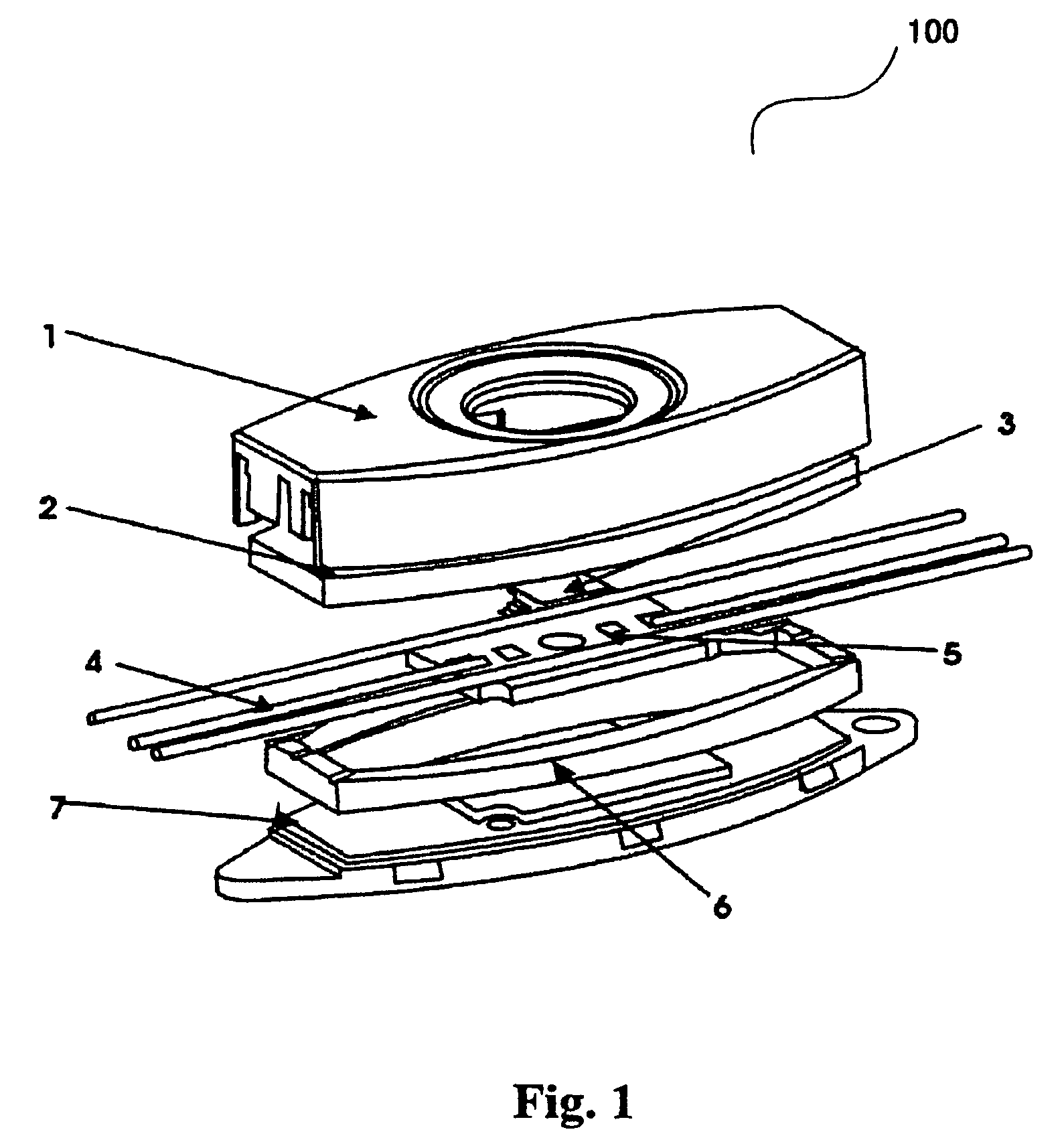

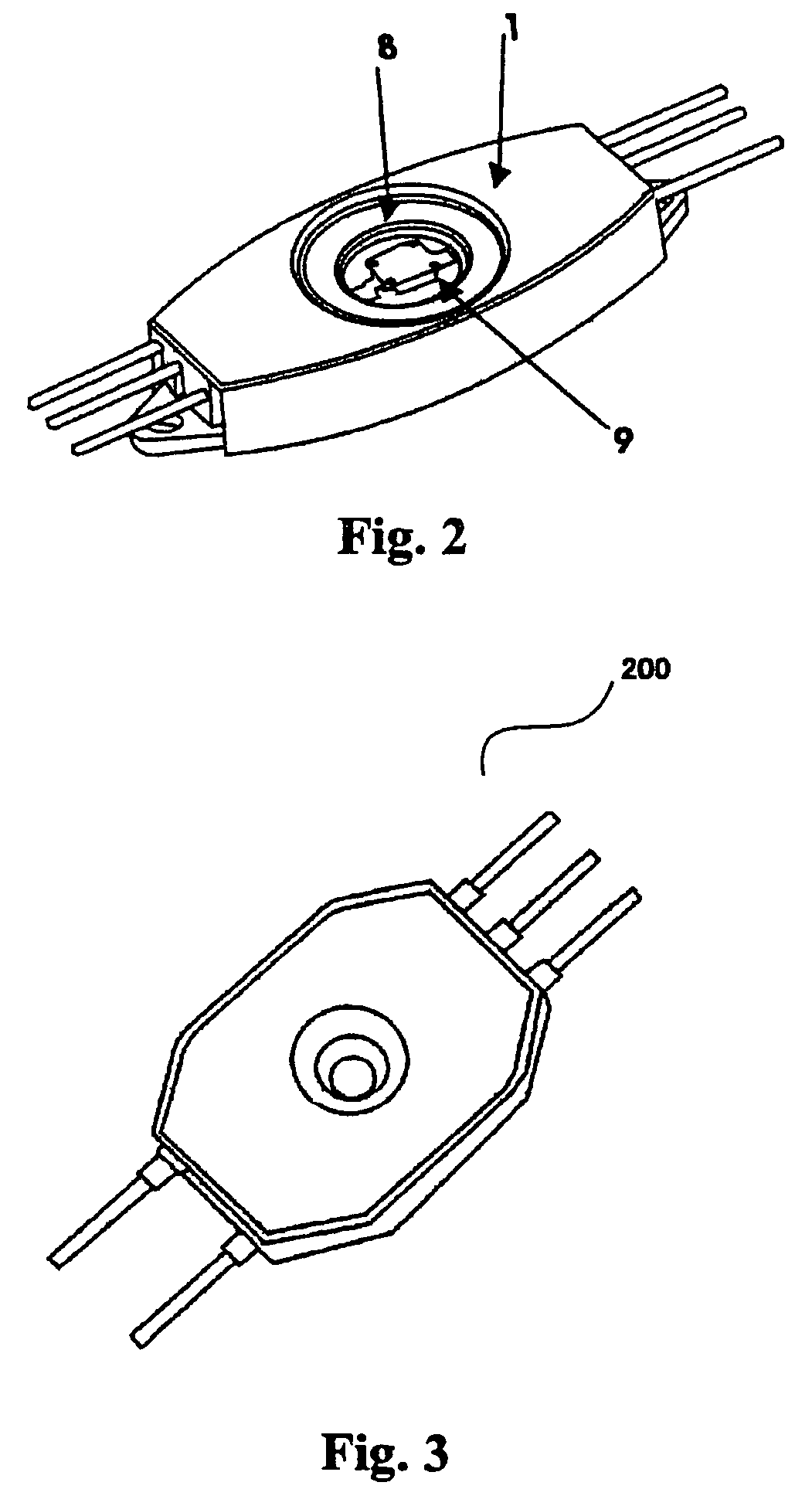

LED module, and LED chain containing the same

ActiveUS20090272986A1Improve thermal conductivityPoint-like light sourceSemiconductor/solid-state device detailsEngineeringLow pressure molding

The present invention discloses an LED module comprising: a waterproof enclosure; an LED accommodated in the waterproof enclosure; a wire for coupling the LED module with other LED modules and a driver; and a radiating unit set in the bottom of the waterproof enclosure and exposed to the external environment. The invention further provides an LED chain comprising the above said LED module and a driver coupled with the LED module. The LED chain according to the invention may have a high waterproof level, for example, IP65. The heat generated during the operation of the high power LED module may be transmitted to the external environment in time via a heat sink set on the LED module, thereby effective thermal management for the LED module and a long service life of the LED module may be obtained. Moreover, the finish surface of the driver may be made handsome by encapsulating the driver through the low pressure molding.

Owner:OPTOTRONIC GMBH

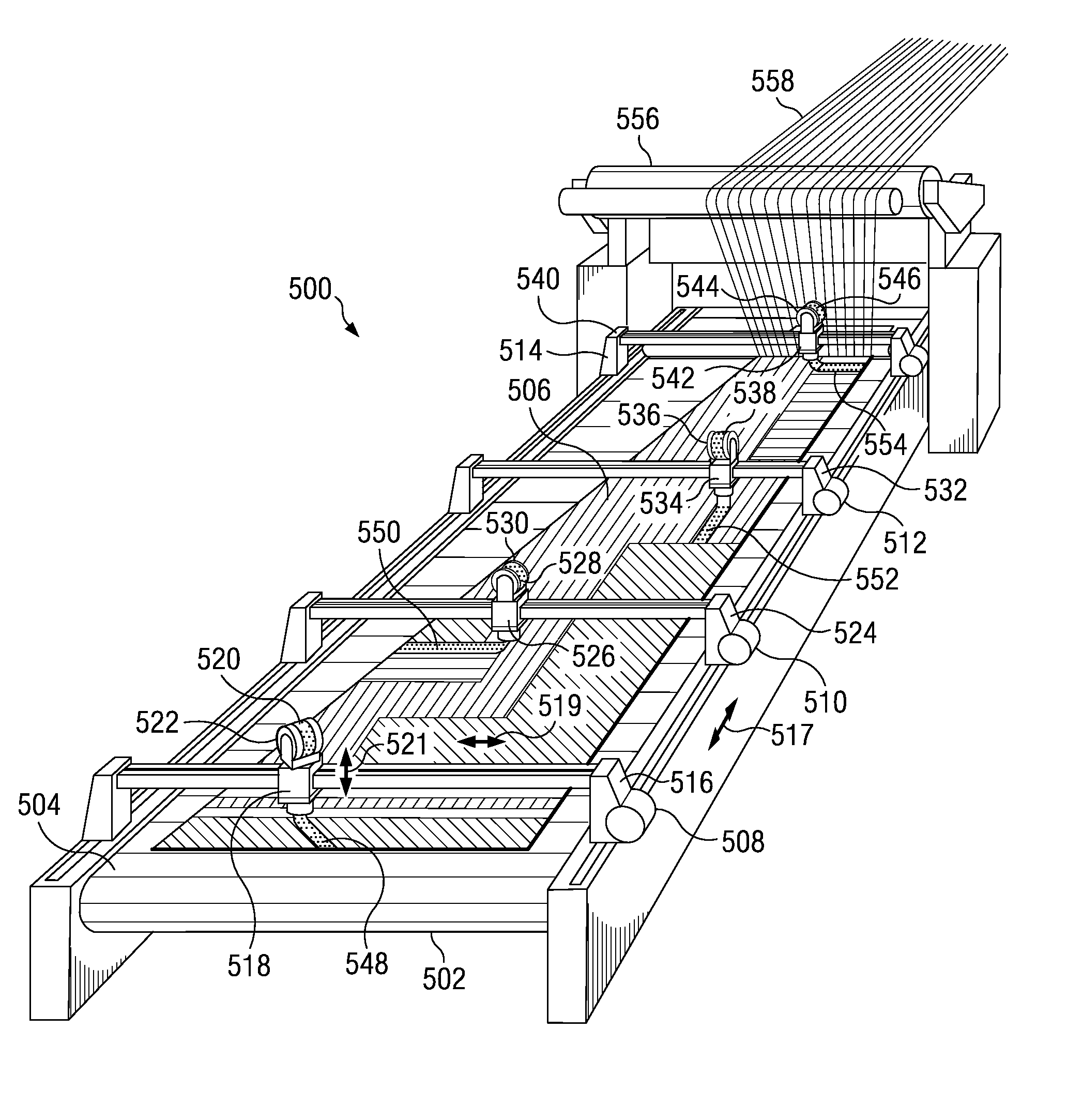

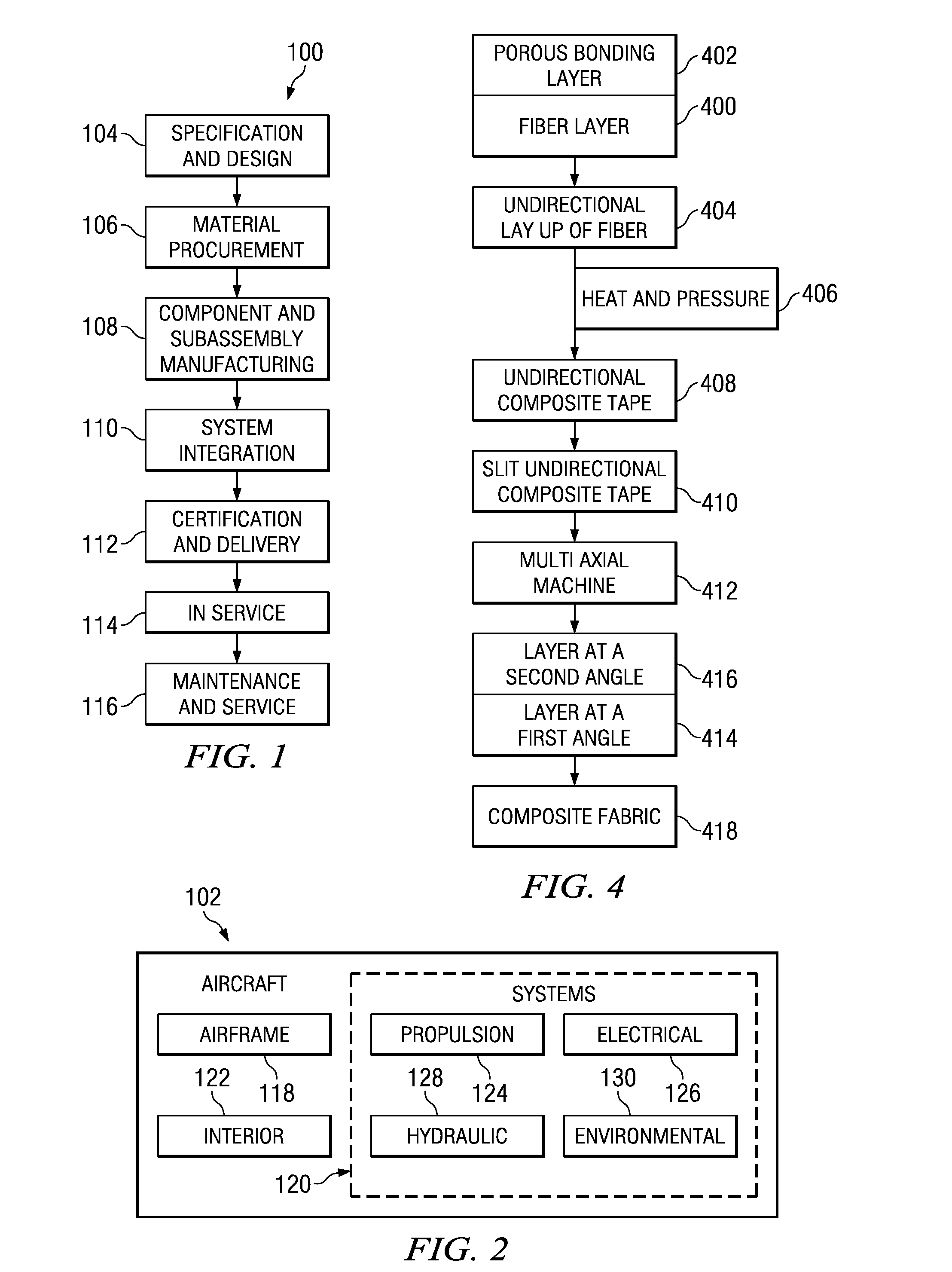

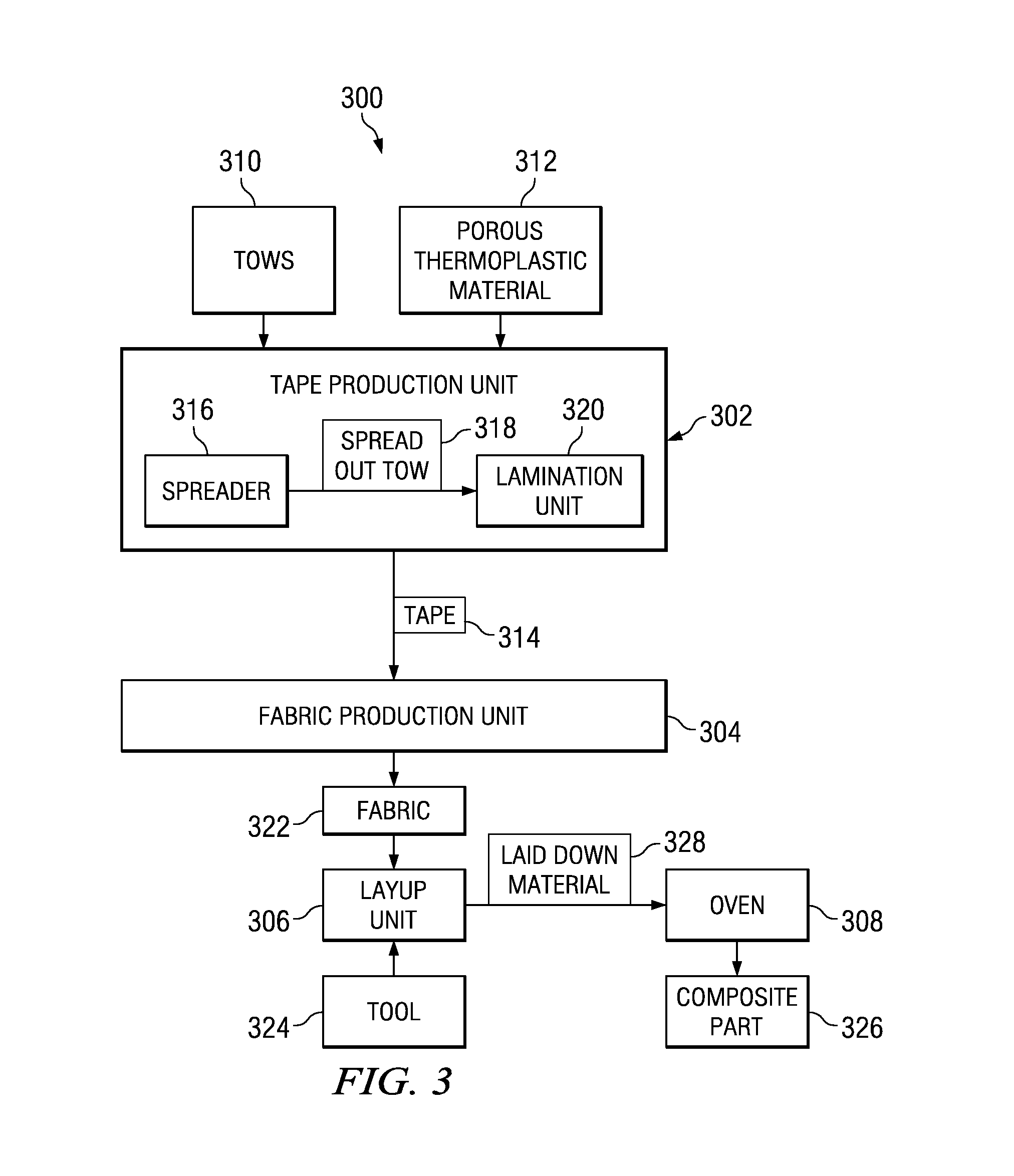

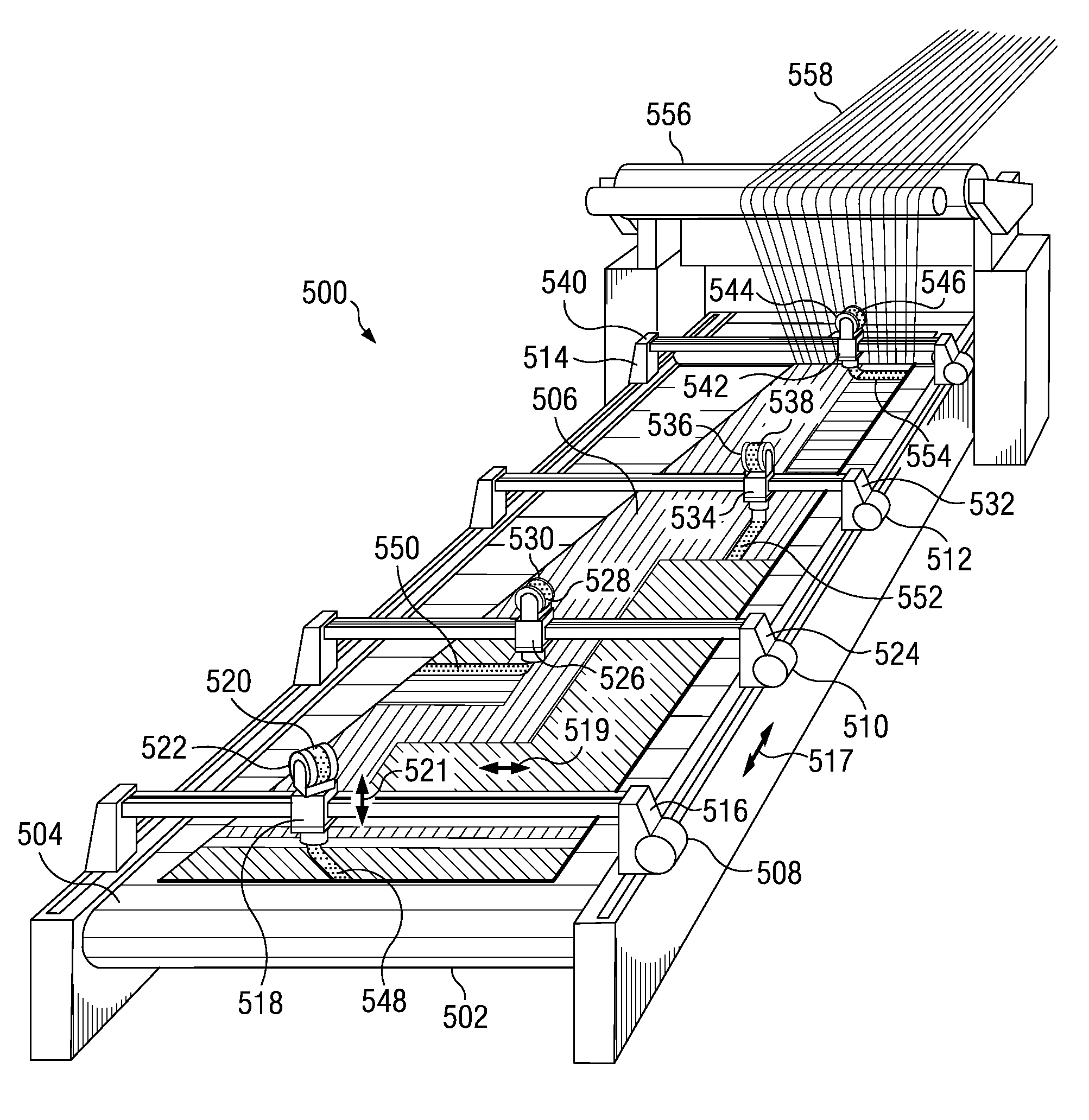

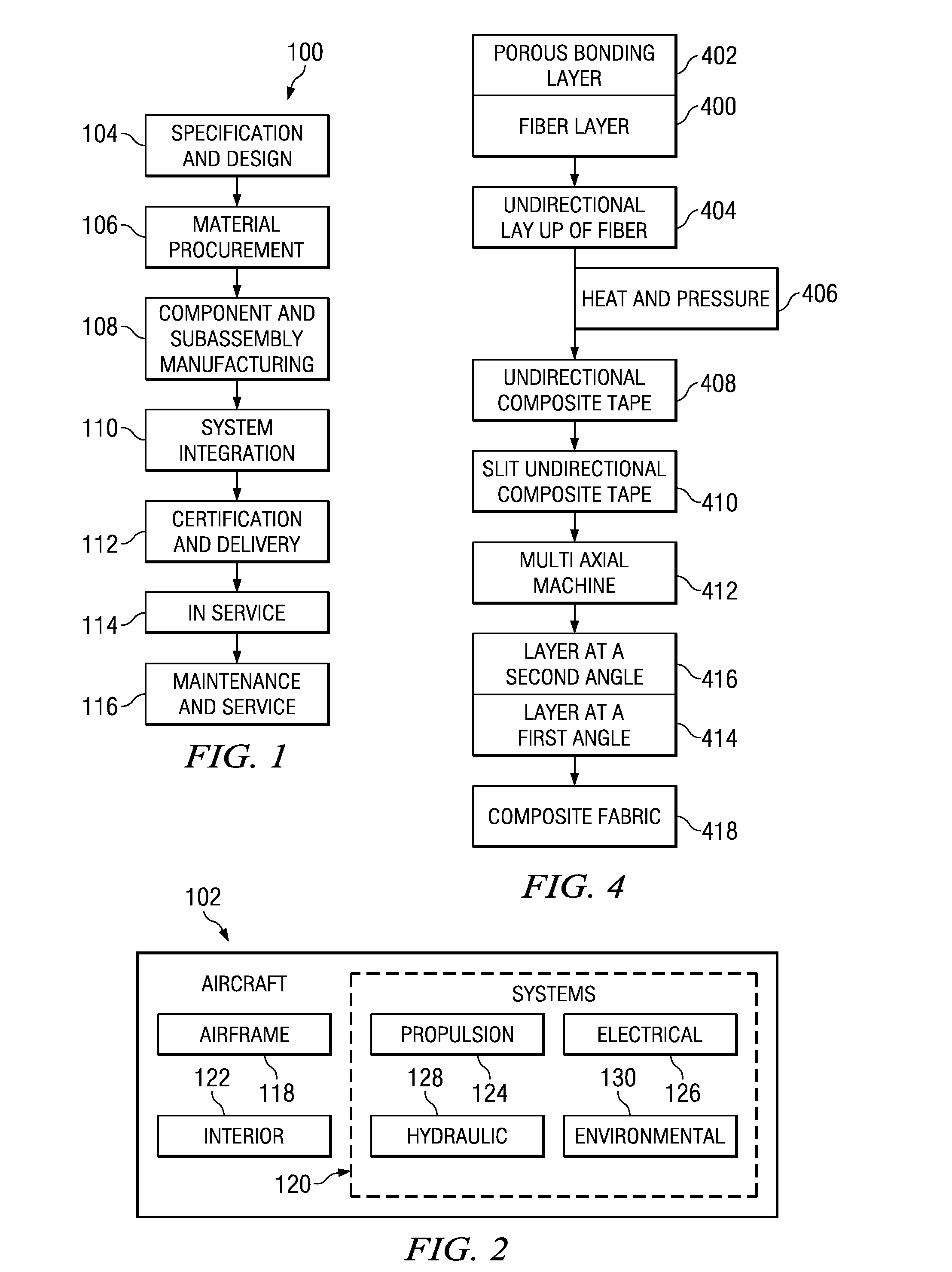

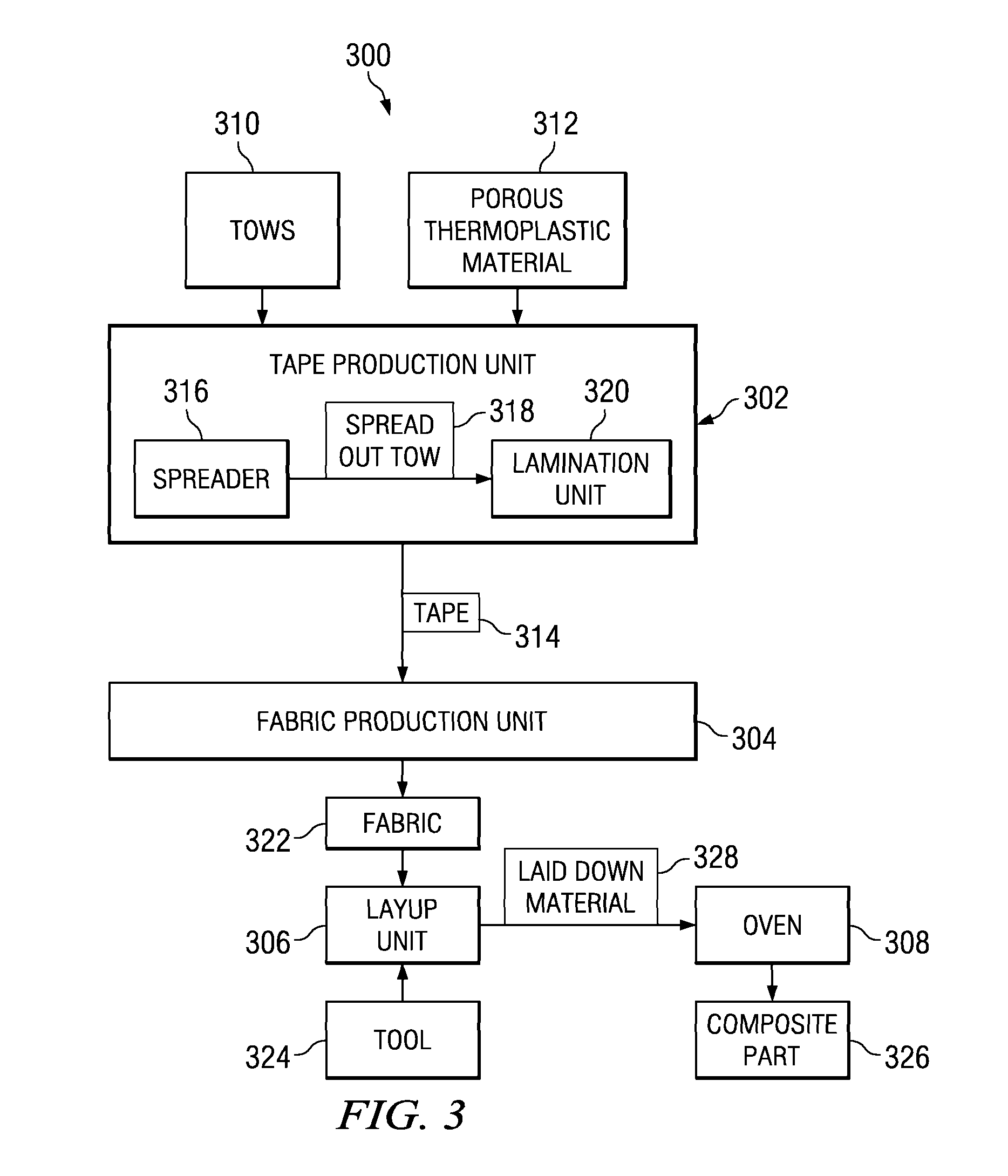

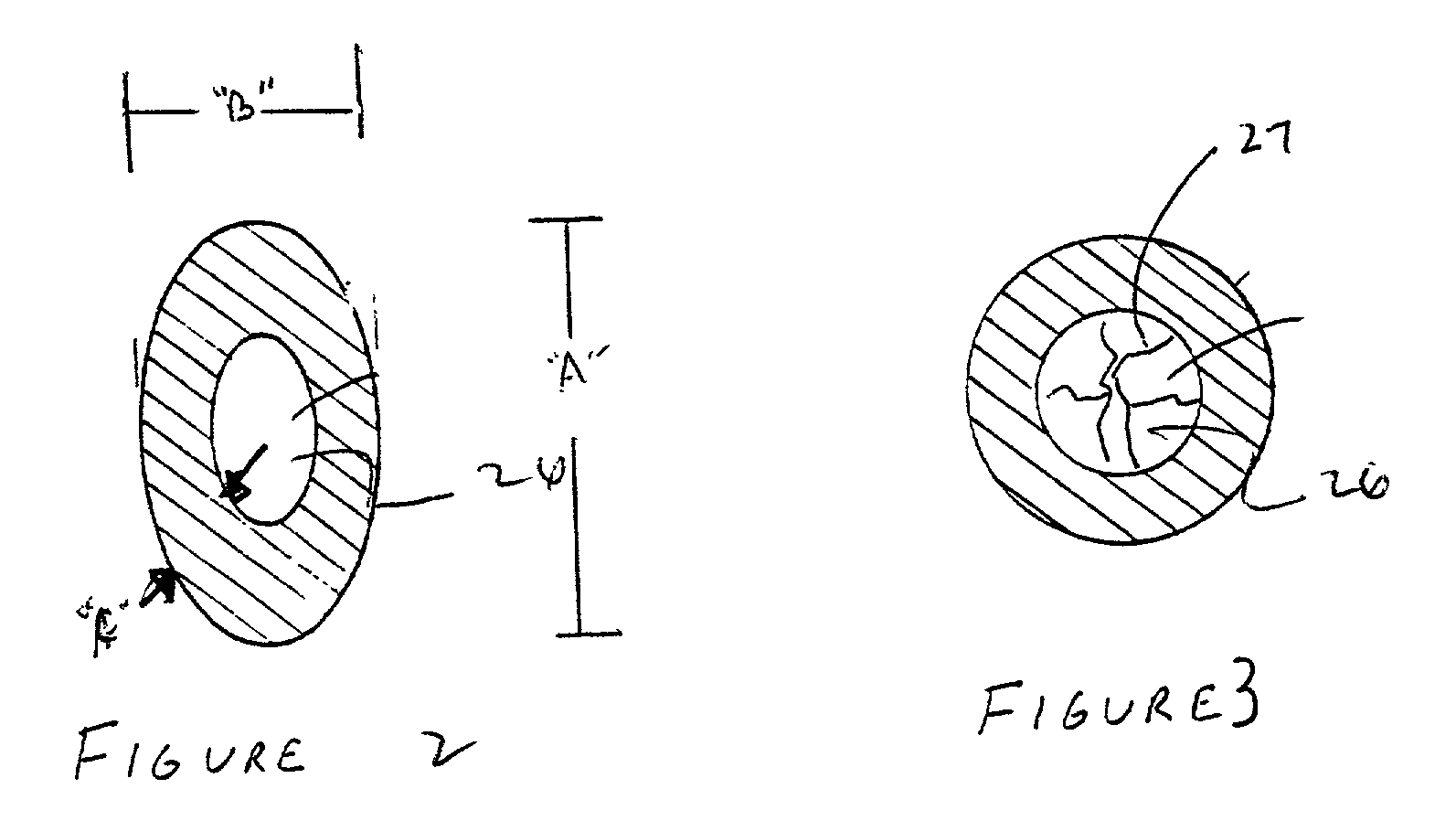

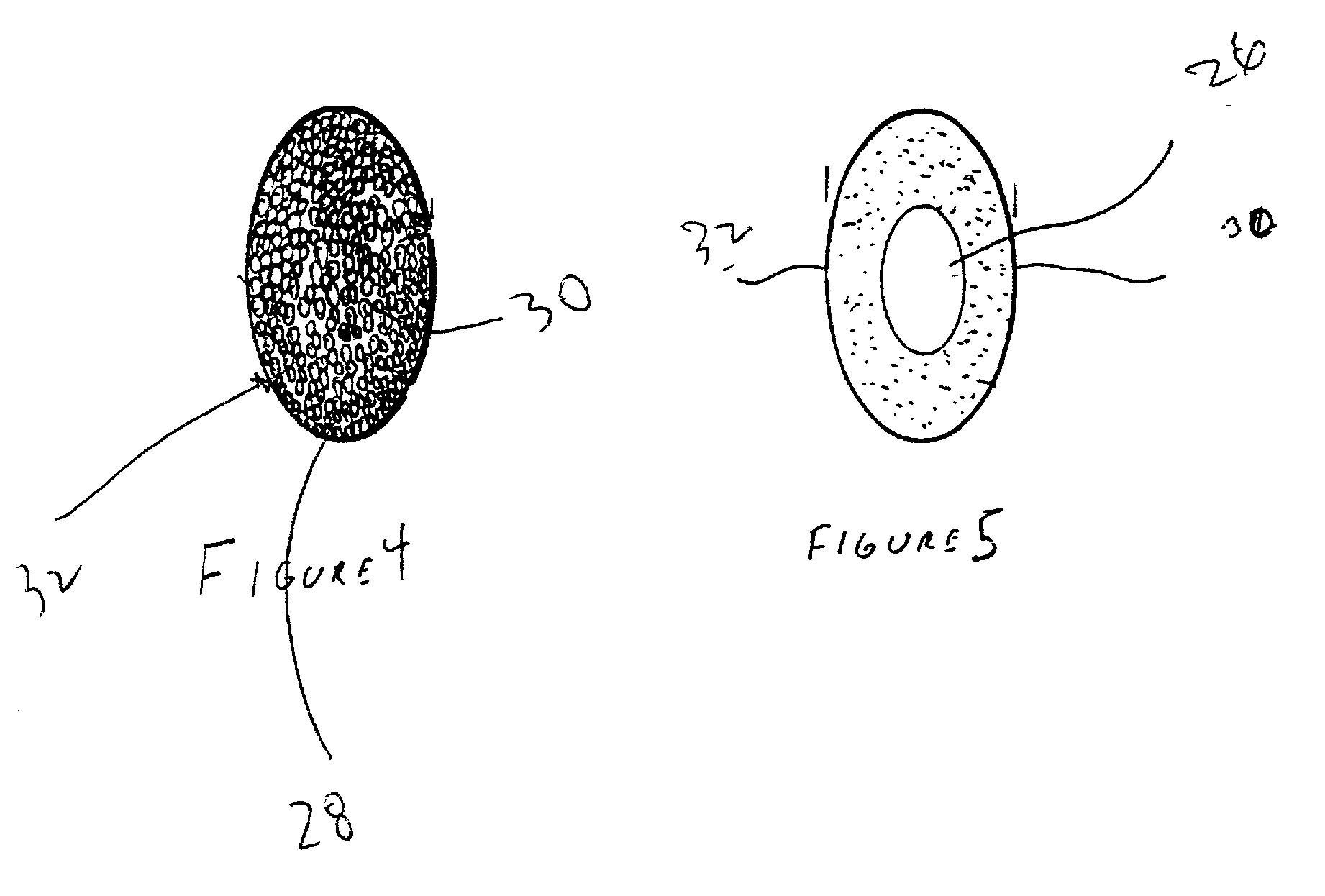

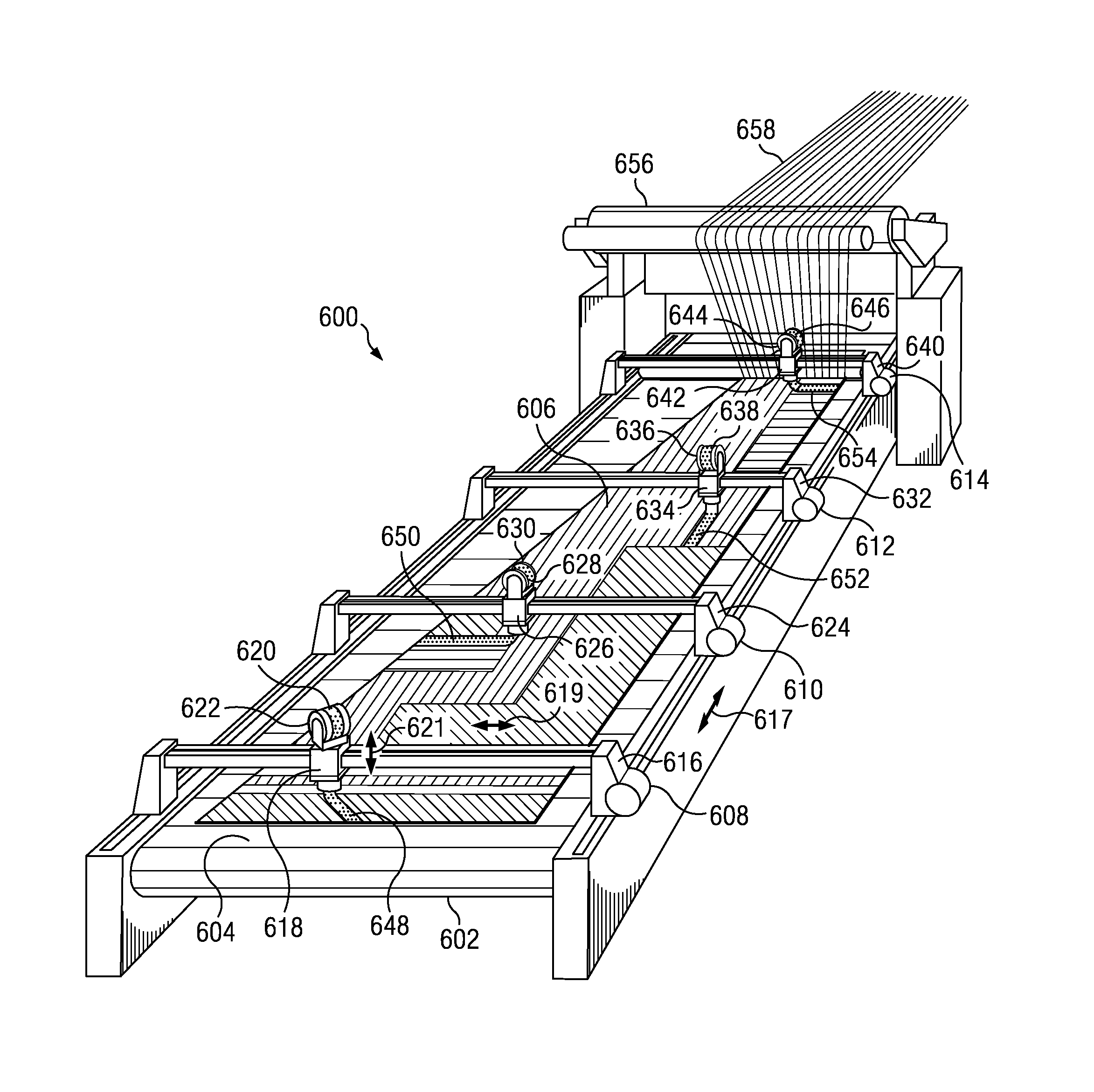

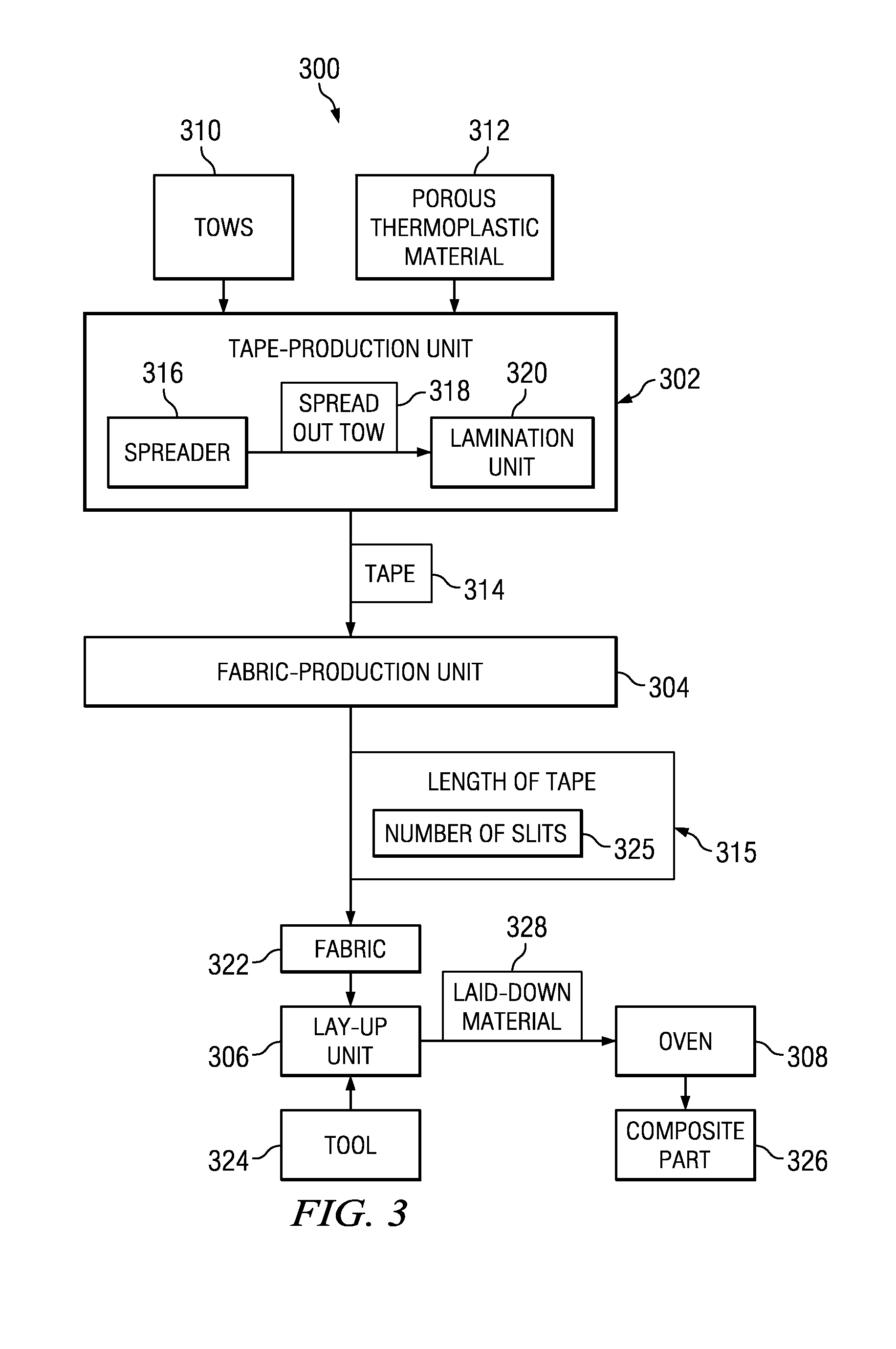

Method and apparatus for low-bulk toughened fabrics for low-pressure molding processes

ActiveUS20090120562A1Adhesive processesMechanical working/deformationShell moldingLow pressure molding

A method and apparatus for manufacturing. A fiber layer and a porous bonding layer are formed to form a unidirectional lay-up of fibers. The lay-up of fibers is heated under pressure to form a unidirectional composite tape of desired thickness to substantially maintain the fibers in a desired configuration. The unidirectional composite tape is slit to a desired width, and the slit unidirectional composite tape is loaded into a multiaxial fabric machine. A first layer is built from the composite tape in the multiaxial machine, and a second layer is built from the composite tape on the first layer at a predetermined angle from the first layer in the multiaxial machine. The first and second layers are consolidated to form a composite fabric in a continuous process.

Owner:THE BOEING CO

Pre-weakening of fabric covered airbag doors

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

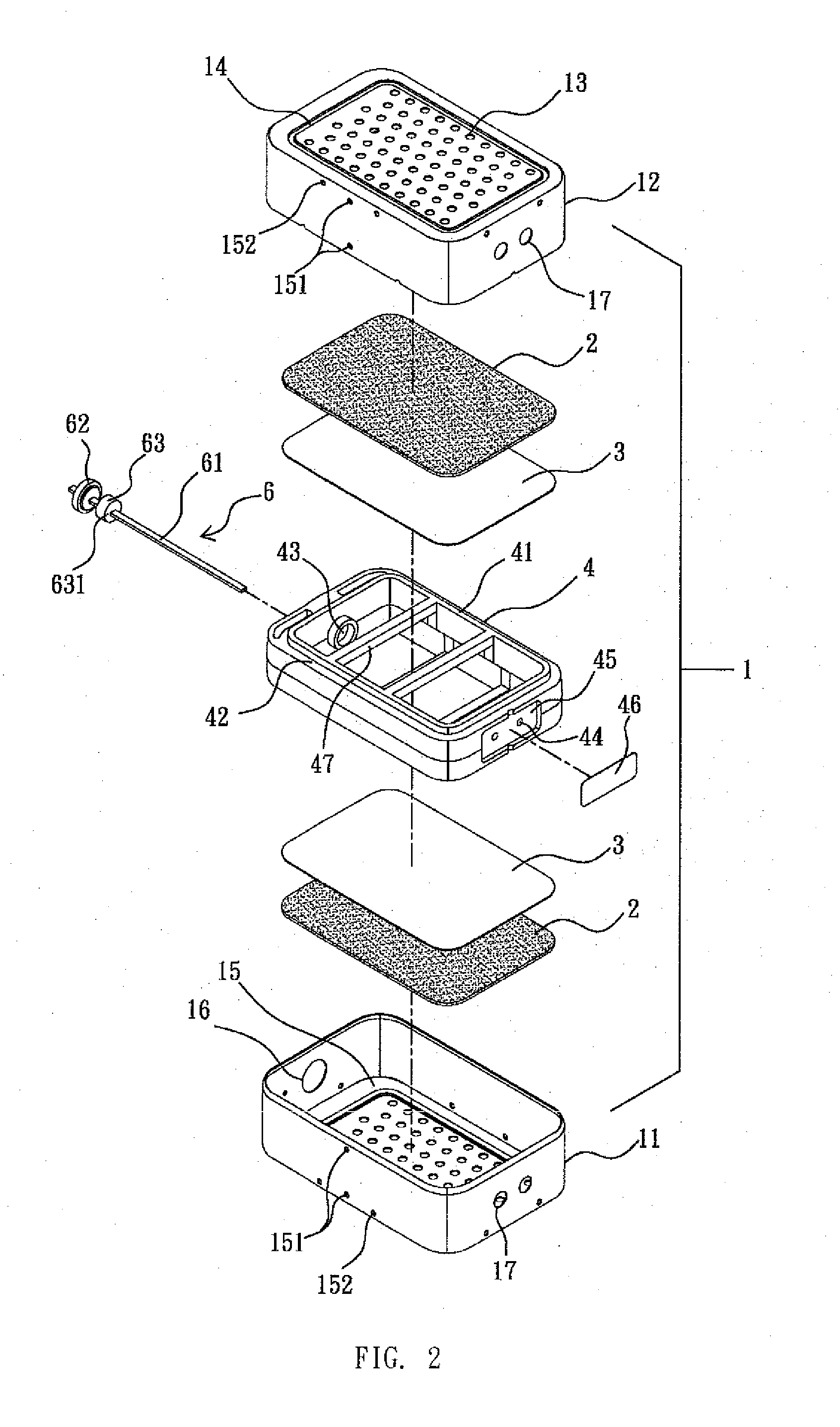

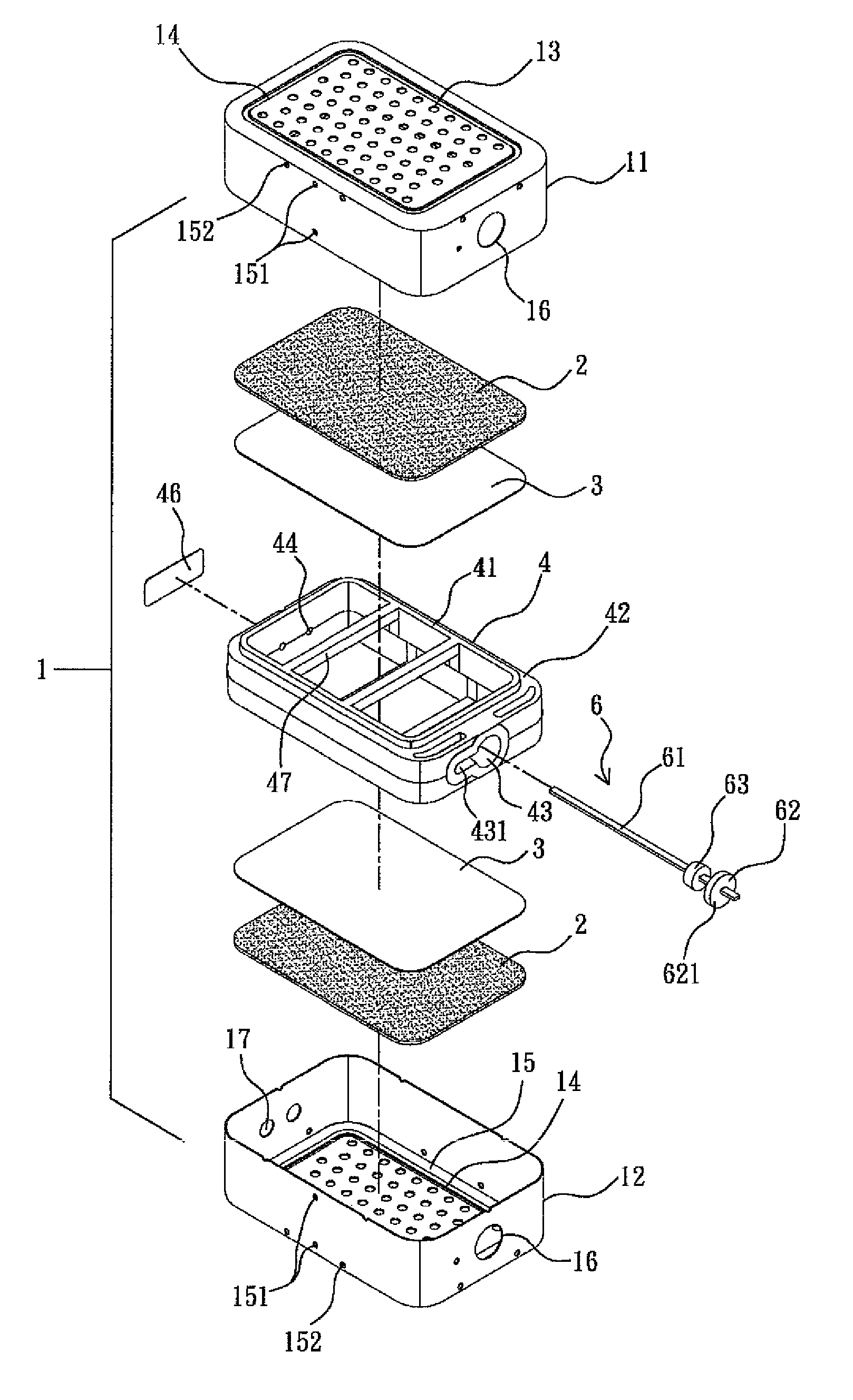

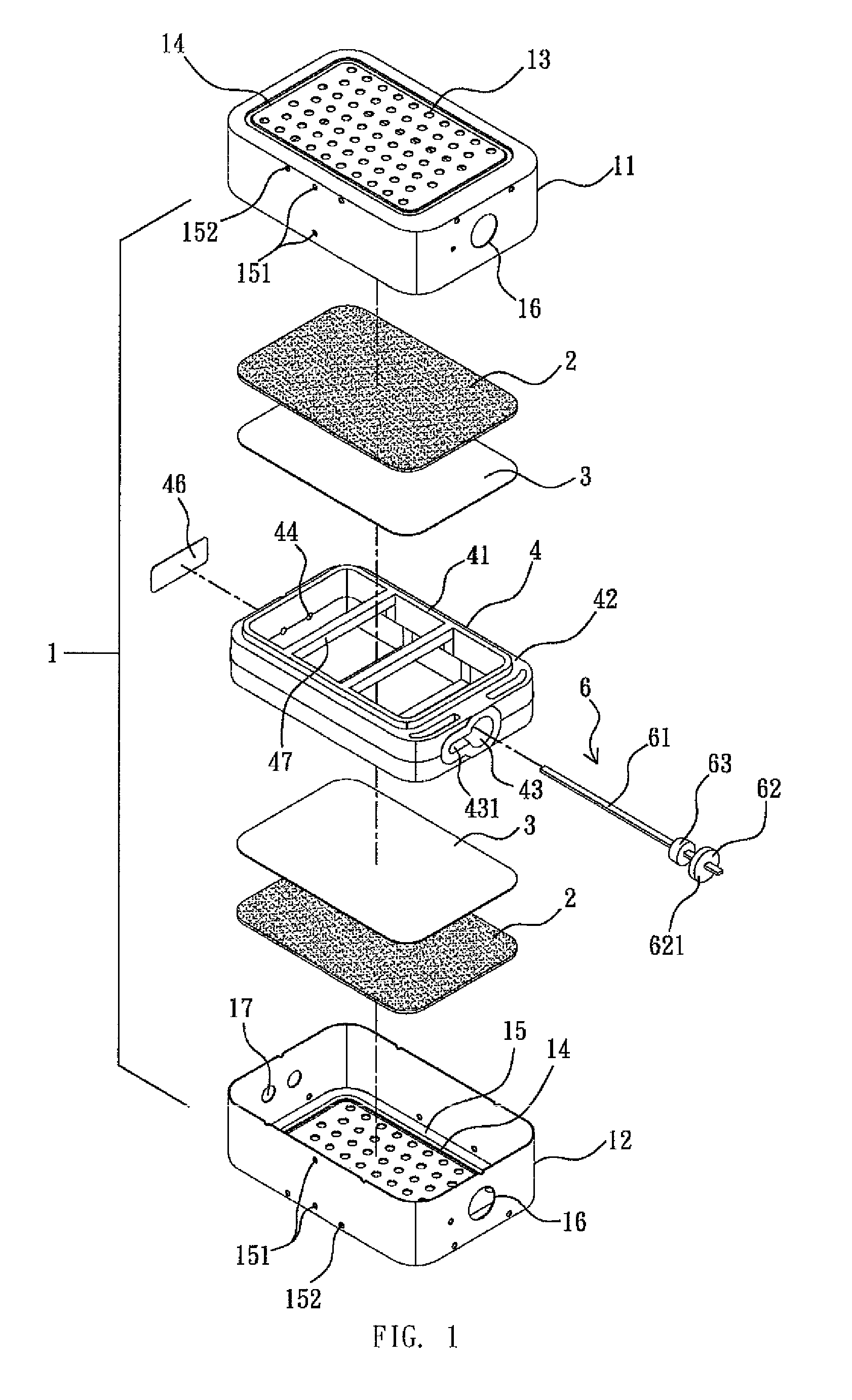

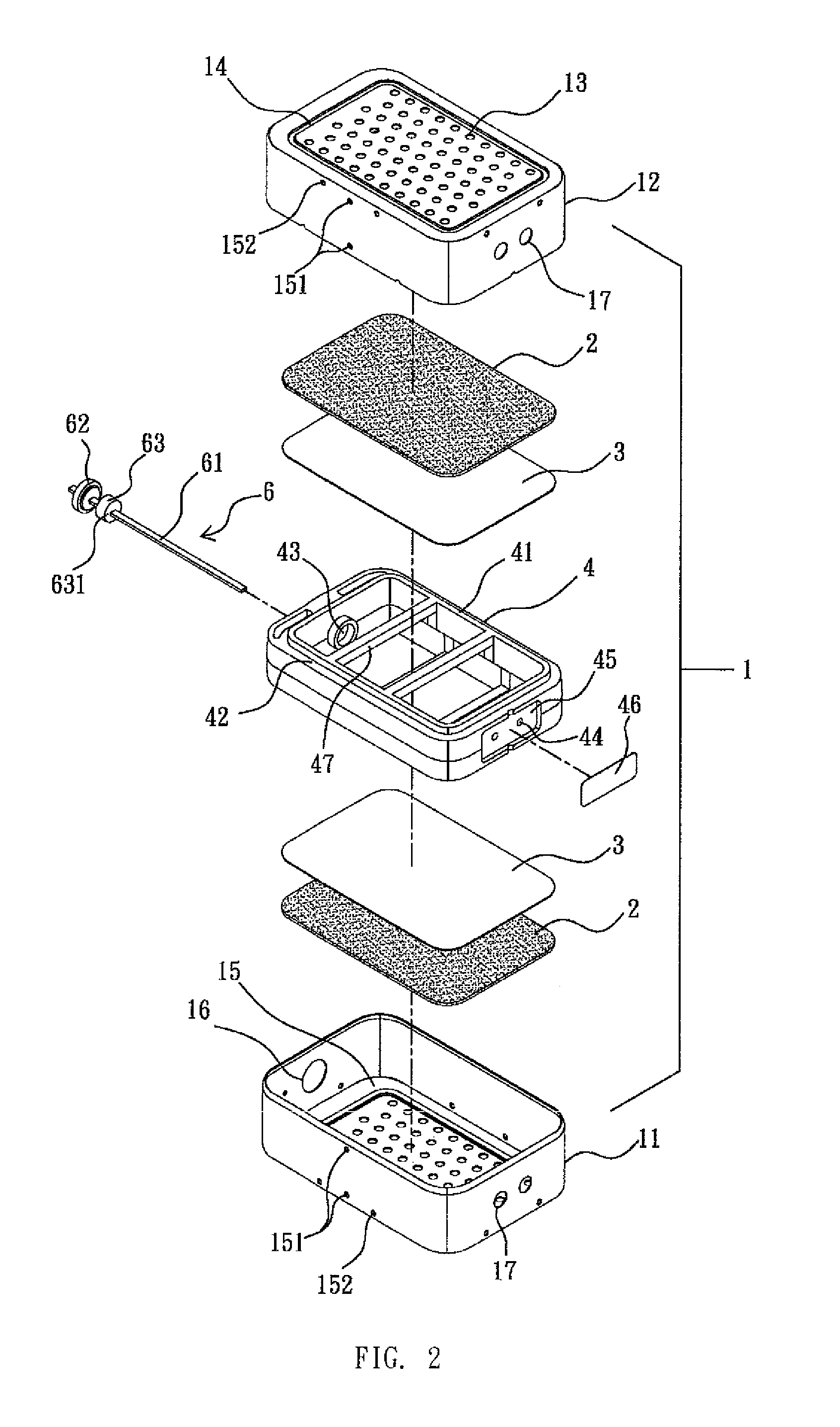

Packaging structure of low-pressure molded fuel cell

InactiveUS20100173206A1High viscosityIncrease elasticityFuel and primary cellsFuel cells groupingC sectionsFuel cells

A packaging structure of a low-pressure molded fuel cell comprises a hot melt adhesive layer, which is formed through a low-pressure molding process using a hot melt adhesive that has specific material properties and will become molten when being heated. The molten hot melt adhesive is injected into the cell via injection holes formed on a housing or a mounting element to flow through a C-sectioned flow channel, so as to tightly enclose and bond to edges of the air cathode and separator for the cell. After the hot melt adhesive is solidified, a chemical-resistant hot melt adhesive layer with good sealing and enclosing ability as well as high adhesion strength and elasticity, being bubble removed at controlled pressure and the hot melt adhesive material is formed to firmly bond to the cell components and tightly seal the cell, so as to effectively prevent electrolyte in the cell from leaking.

Owner:HIGH TECH BATTERY INC

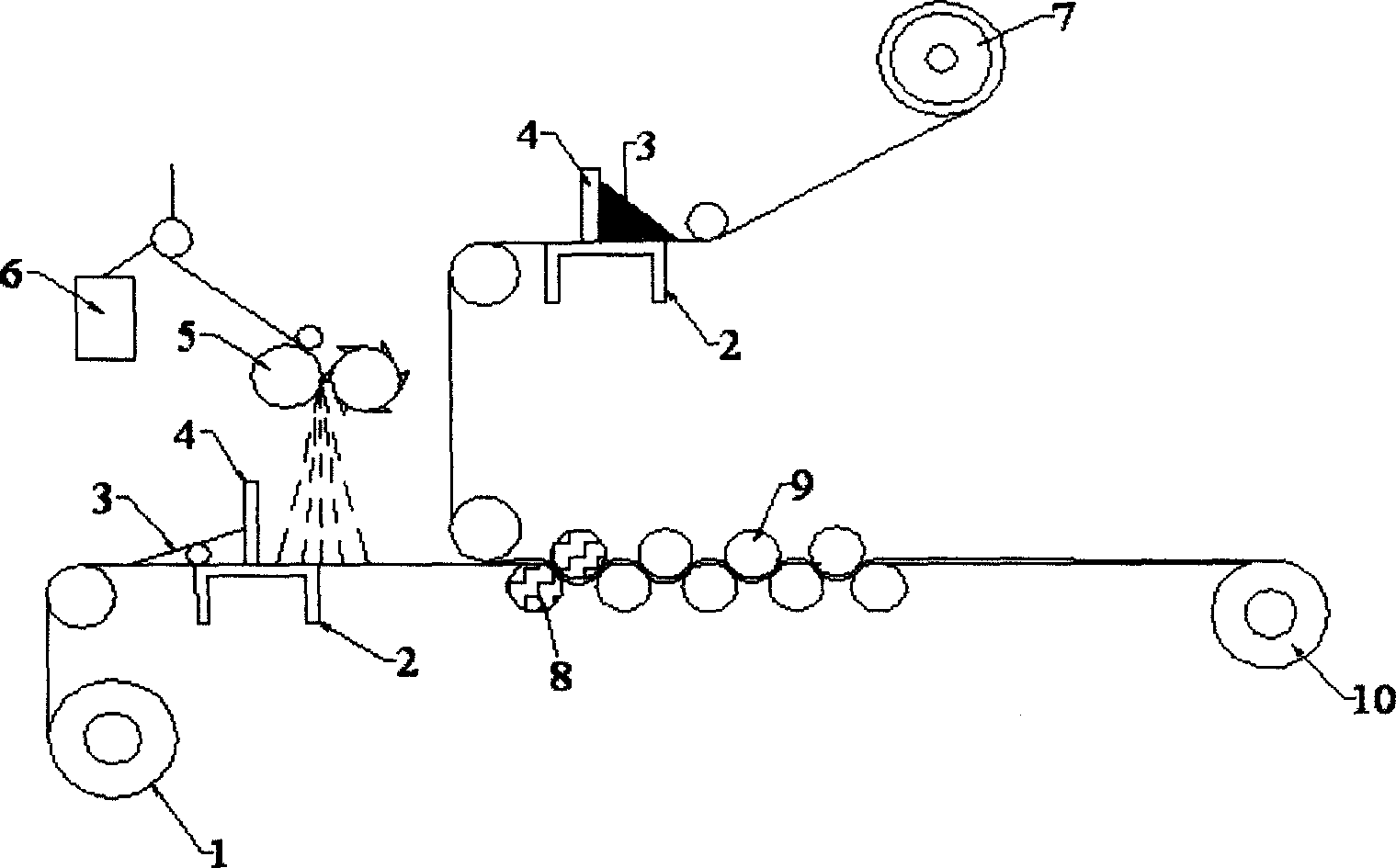

Technique and equipment for fabricating plastic sheet material produced from molding laminar die in low pressure

A plastic sheet able to be shaped by low-pressure moulding is proportionally prepared from unsaturated polyester resin, crystalline resin, low-shrinkage additive, trigger, polymerizing inhibitor, internal demoulding agent, filler and short glass fibers through mixing, thickening, shaping and packing. It can be moulded at 80-120 deg.C under 1-3 MPa for 2-3 hr.

Owner:山东海博新材料有限公司

Method and apparatus for low-bulk toughened fabrics for low-pressure molding processes

A method and apparatus for manufacturing. A fiber layer and a porous bonding layer are formed to form a unidirectional lay-up of fibers. The lay-up of fibers is heated under pressure to form a unidirectional composite tape of desired thickness to substantially maintain the fibers in a desired configuration. The unidirectional composite tape is slit to a desired width, and the slit unidirectional composite tape is loaded into a multiaxial fabric machine. A first layer is built from the composite tape in the multiaxial machine, and a second layer is built from the composite tape on the first layer at a predetermined angle from the first layer in the multiaxial machine. The first and second layers are consolidated to form a composite fabric in a continuous process.

Owner:THE BOEING CO

Method for Manufacturing Shaped Product by Low-Pressure Molding

InactiveUS20140148072A1Reduce pressureEasy to manufactureLayered productsFibre treatmentFiber bundleLow pressure molding

This method for manufacturing a shaped product is characterized in preparing a specific random mat including a thermoplastic resin and carbon fiber bundles having an average fiber length of 5-100 mm, impregnating a thermoplastic resin into the random mat, pressing the random mat in a metal mold in a range of 0.1-20 MPa, and then taking out the random mat from the metal mold.

Owner:TEIJIN LTD

LED module, and LED chain containing the same

ActiveUS7994516B2Improve thermal conductivityPoint-like light sourceElectric circuit arrangementsEngineeringLow pressure molding

The present invention discloses an LED module comprising: a waterproof enclosure; an LED accommodated in the waterproof enclosure; a wire for coupling the LED module with other LED modules and a driver; and a radiating unit set in the bottom of the waterproof enclosure and exposed to the external environment. The invention further provides an LED chain comprising the above said LED module and a driver coupled with the LED module. The LED chain according to the invention may have a high waterproof level, for example, IP65. The heat generated during the operation of the high power LED module may be transmitted to the external environment in time via a heat sink set on the LED module, thereby effective thermal management for the LED module and a long service life of the LED module may be obtained. Moreover, the finish surface of the driver may be made handsome by encapsulating the driver through the low pressure molding.

Owner:OPTOTRONIC GMBH

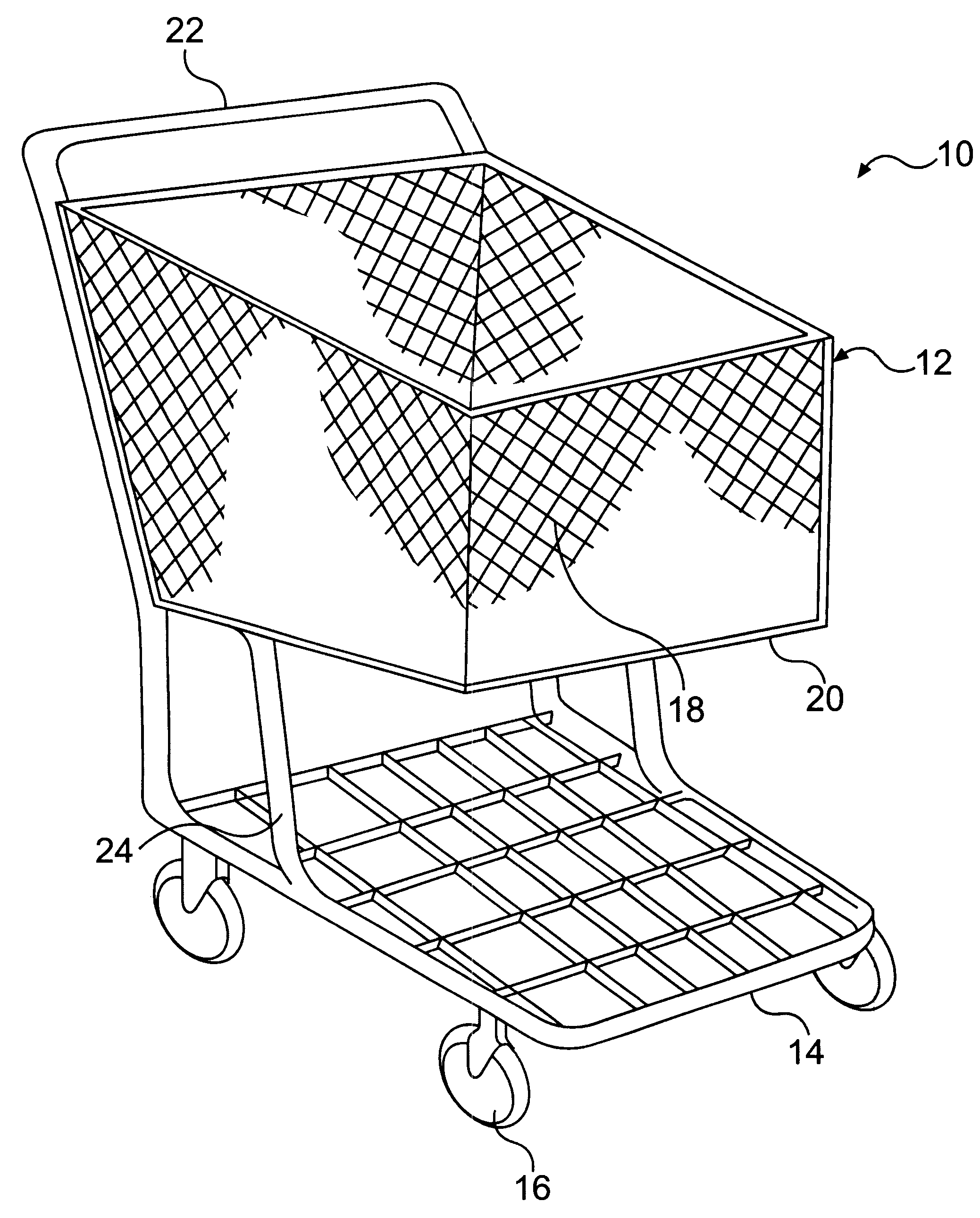

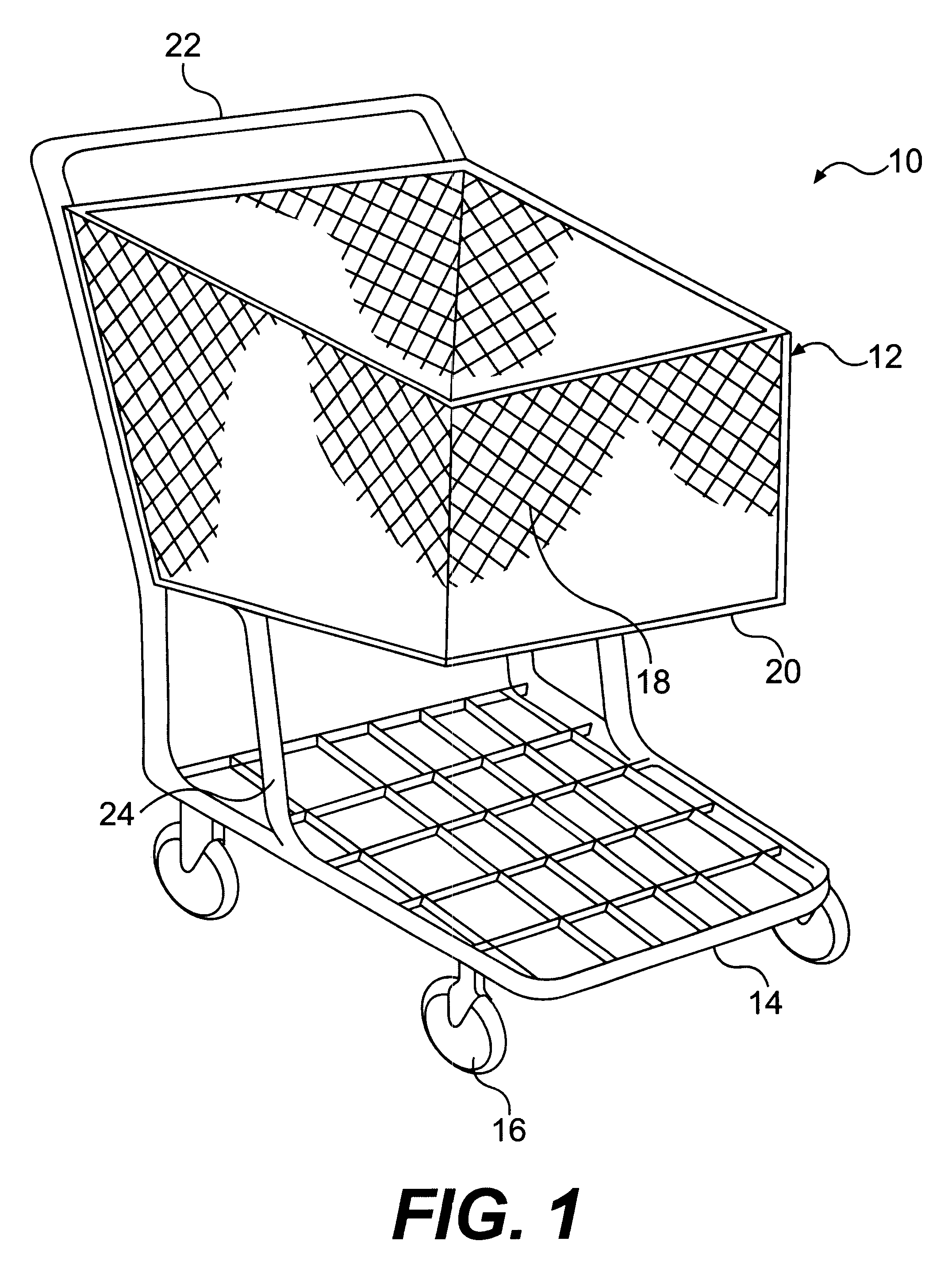

Method of molding a cart using molding processes

A method of molding components of a shopping cart using high or low pressure molding processes. The molding processes eliminate sink marks in plastic components of the shopping cart while providing structural integrity thereto. The processes used to mold the components of the shopping cart can create either or both a center channel in the molded components and / or a plurality of voids within the molded components. If hollow channels are formed in the molded components then the plurality of voids will be formed in the walls of such molded component if both processes are used together. The processes used to form the molded components are either (i) a gas assist process which provides a laminar stream of blowing agent into the stream of molten resin after the molten resin is forced into a partially filled mold or (ii) a structural foam molding process which provides a blowing agent blended into the molten resin prior to the molten resin being forced into the mold.

Owner:REHRIG INT INC +1

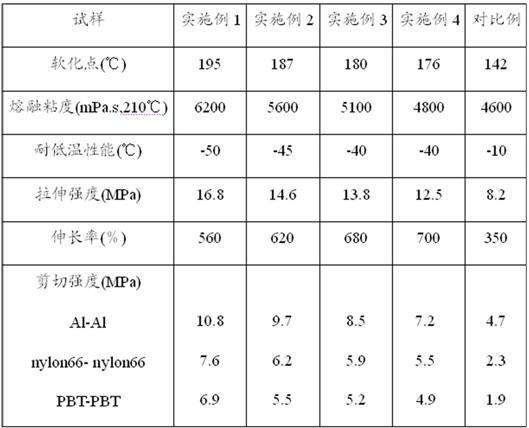

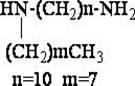

Dimer acid type polyamide hot melt adhesive and preparation method thereof

InactiveCN102220105AHigh elongationImprove low temperature resistanceAdhesivesPolymer scienceLow pressure molding

The invention relates to a dimer acid type polyamide hot melt adhesive and a preparation method thereof. The polyamide hot melt adhesive contains an N alkyl substitution diamine structure and consists of 50 percent of component A and 50 percent of component B according to mole percent, wherein the component A consists of 60-90 percent of unsaturated aliphatic dimer acid and 10-40 percent of aliphatic dicarboxylic acid according to the mole percent; the component B comprises 60-90 percent of N alkyl substituted aliphatic diamine, 10-30 percent of aliphatic diamine and 0-10 percent of heterocyclic diamine according to the mole percent. The dimer acid type polyamide hot melt adhesive has high softening point, good low-temperature resistance, high elongation, low high-temperature melting viscosity, high tensile strength and shearing intensity, and is suitable for low-pressure molding-injection forming process; and the dimer acid type polyamide hot melt adhesive has high bonding reliability and is particularly suitable for bonding of polar high polymer materials.

Owner:YANTAI DARBOND TECH

Light prepreg for unmanned aerial vehicle shell and preparation method of prepreg

The invention discloses a light prepreg for an unmanned aerial vehicle shell and a preparation method of the prepreg, relating to a prepreg and a preparation method thereof. The prepreg disclosed by the invention is made of epoxy resin system penetrated reinforcing material, wherein the epoxy resin system consists of the following components in percentage by mass: 30-80 percent of epoxy resin mixture, 1-20 percent of nano particles, 1-10 percent of hollow microspheres and 5-40 percent of curing agent system mixture; the epoxy resin mixture is prepared by mixing the components in percentage by mass: 20-60 percent of solid state or semi-solid state epoxy resin and 40-80 percent of liquid epoxy resin; and the curing agent system mixture is formed by mixing the components in percentage by mass: 40-90 percent of curing agent and 10-60 percent of curing agent. The prepreg can be cured at 60 DEG C and is suitable for low-pressure molding processes such as a vacuum bag molding process. The cured prepreg has small density, high strength and excellent dielectric properties and is suitable for preparing light and high-strength unmanned aerial vehicle shells, particularly unmanned aerial vehicle shells with wave-transparent requirements.

Owner:HARBIN GUANGLONG GENERAL AVIATION TECH

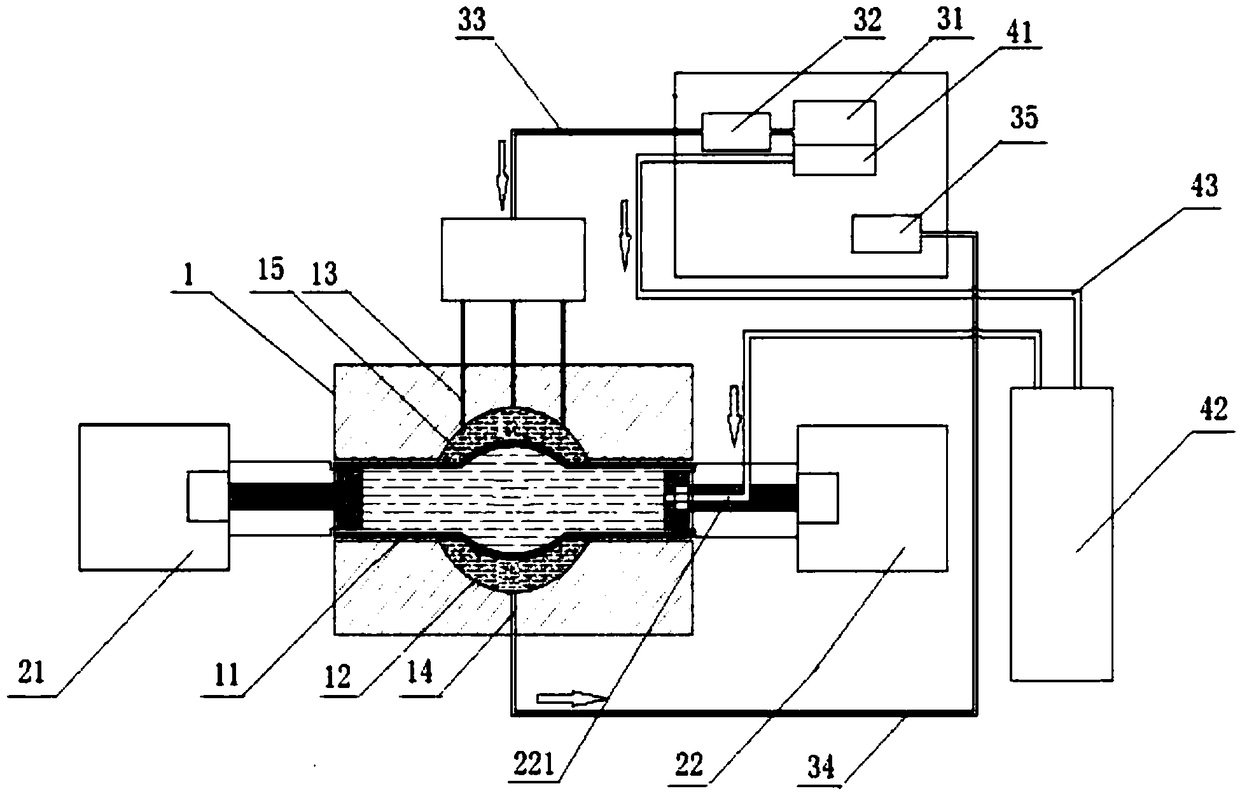

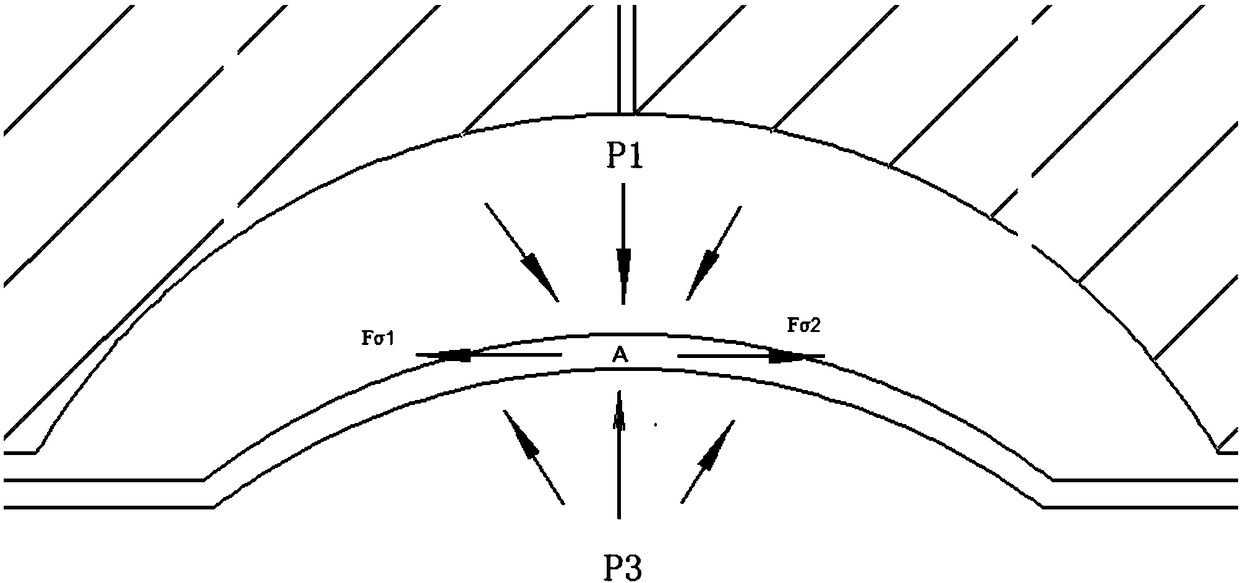

Method for forming pipe fitting with internal high pressure and external low pressure and forming machine

The invention discloses a method for forming a pipe fitting with internal high pressure and external low pressure. The method comprises the steps that a pipe fitting to be formed is put into a cavity,a swelling region is formed between the pipe fitting to be formed and the inner wall of the cavity, low pressure fluid is continuously injected into the swelling region, then high pressure fluid is injected into the inner part of the pipe fitting to be formed, the high pressure fluid forms the pressure on the outer wall of the pipe fitting to be formed, so that the pipe fitting to be formed expands to the swelling region, when the pipe fitting expands to fit the inner wall of the cavity, supplying of the low pressure fluid is stopped, the formed pie fitting is taken out, and a working cycle is completed. The invention further discloses a forming machine, and the pipe fitting is formed according to the forming machine for a pipe fitting with internal high pressure and external low pressure. According to the method for forming a pipe fitting with internal high pressure and external low pressure, a first through hole and a second through hole are formed in a die for circulating the low pressure fluid into and out of the swelling region, a certain pressure P1 is formed for pipe fitting, so that it is guaranteed that the pipe fitting can swell uniformly everywhere, and a good forming effect is achieved.

Owner:BAOLONG ANHUI AUTO PARTS

Method and apparatus for low-bulk toughened fabrics for low-pressure molding processes

A method and apparatus for manufacturing. A fiber layer and a first porous bonding layer are formed to form a unidirectional lay-up of fibers. The unidirectional lay-up of fibers is heated under pressure to form a unidirectional composite tape. A first plurality of lengths of the unidirectional composite tape is laid down to build a first layer from the unidirectional composite tape. A second plurality of lengths of the unidirectional composite tape is laid down to build a second layer from the unidirectional composite tape on the first layer at a predetermined angle from the first layer. At least one of the first and second plurality of lengths of the unidirectional composite tape are slit while laying down the first and second plurality of lengths of the unidirectional composite tape. A composite fabric is formed from the first and second layer.

Owner:THE BOEING CO

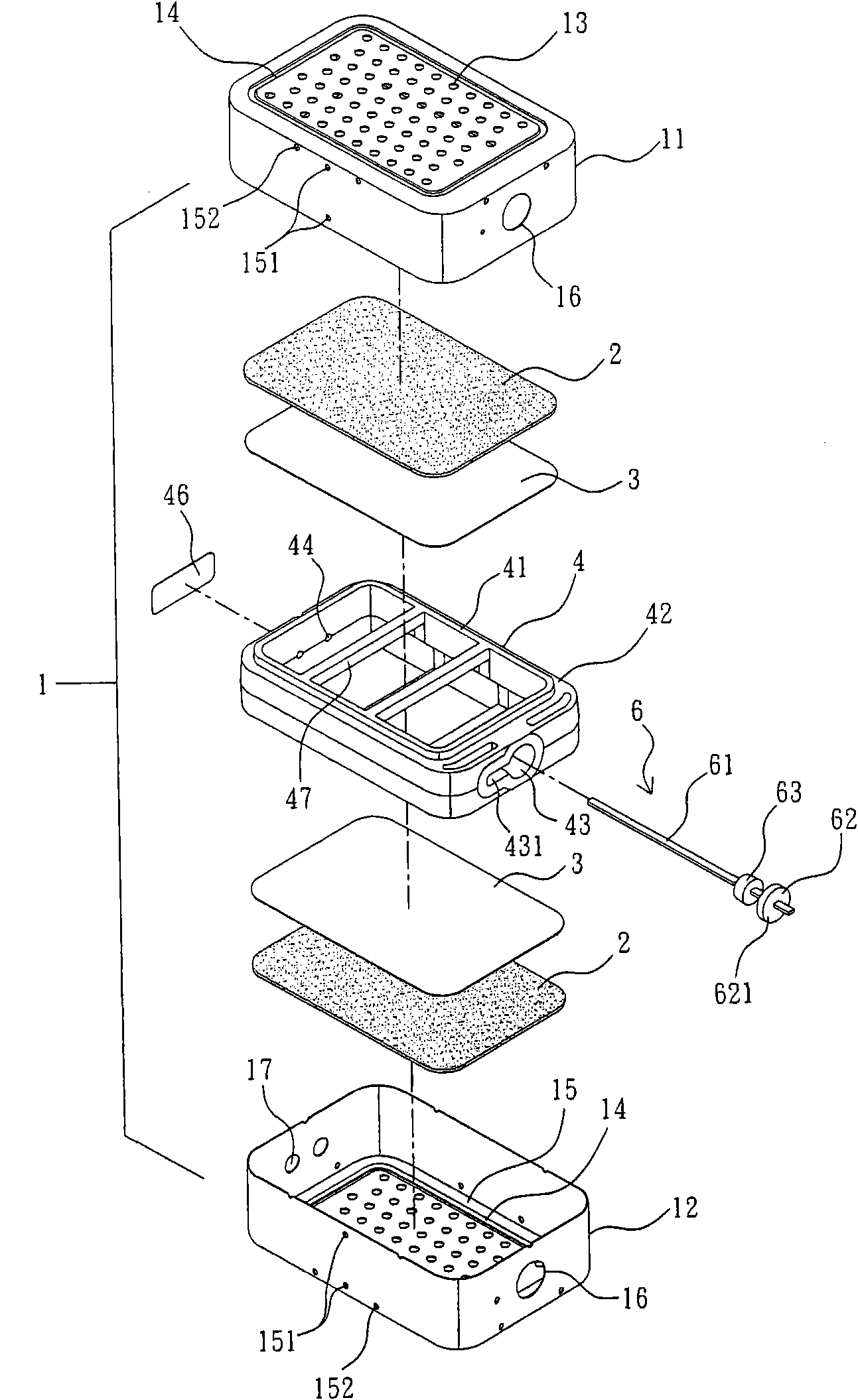

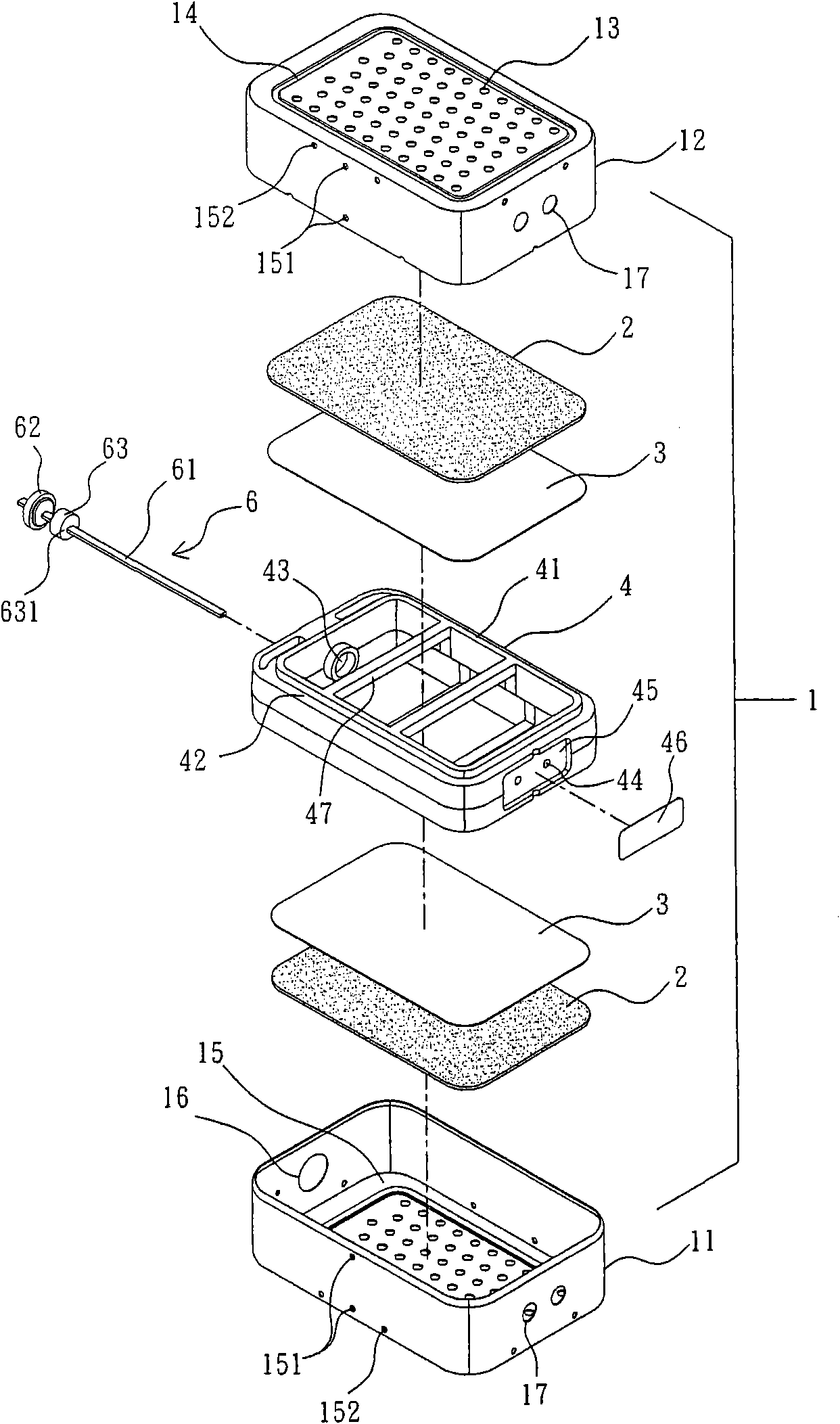

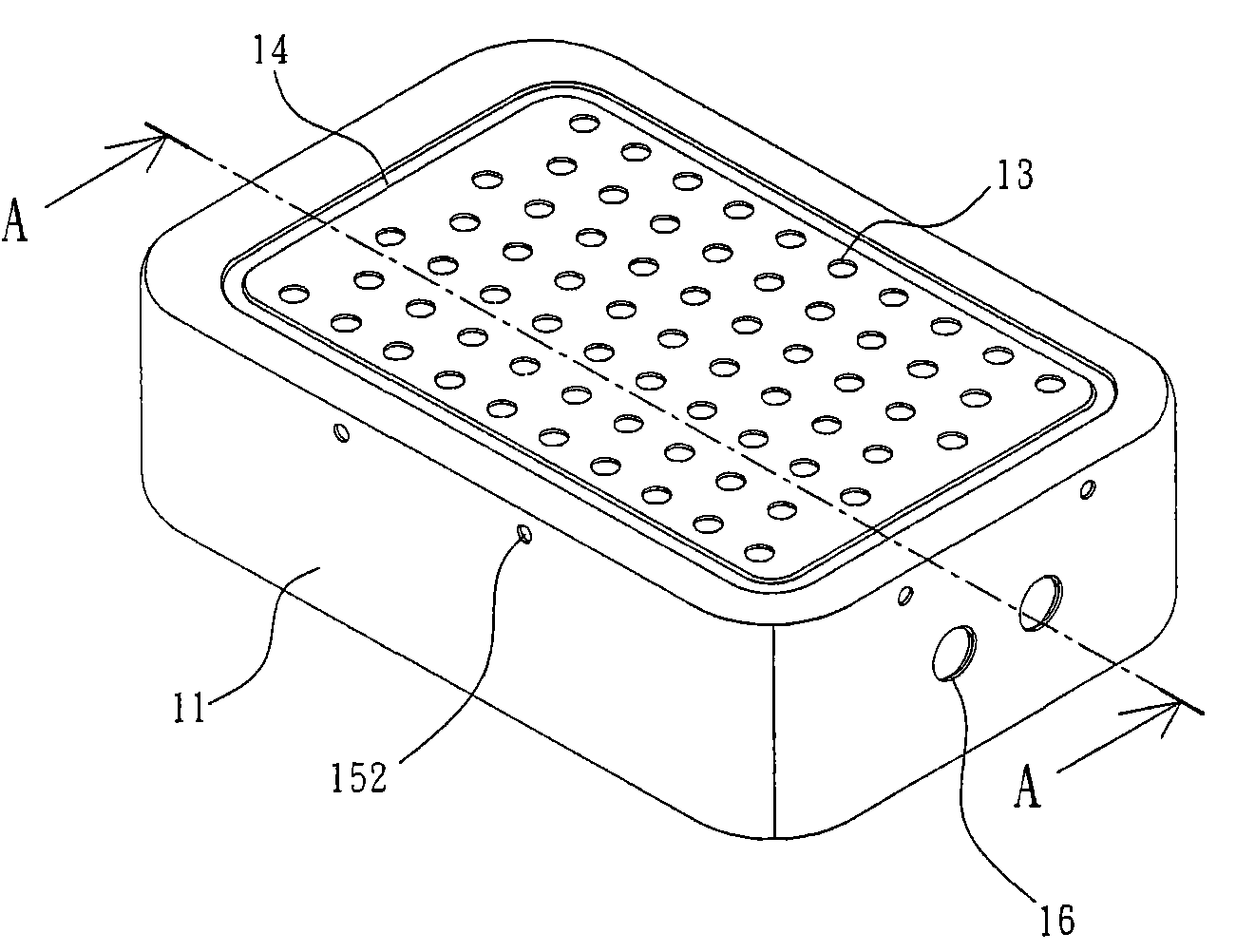

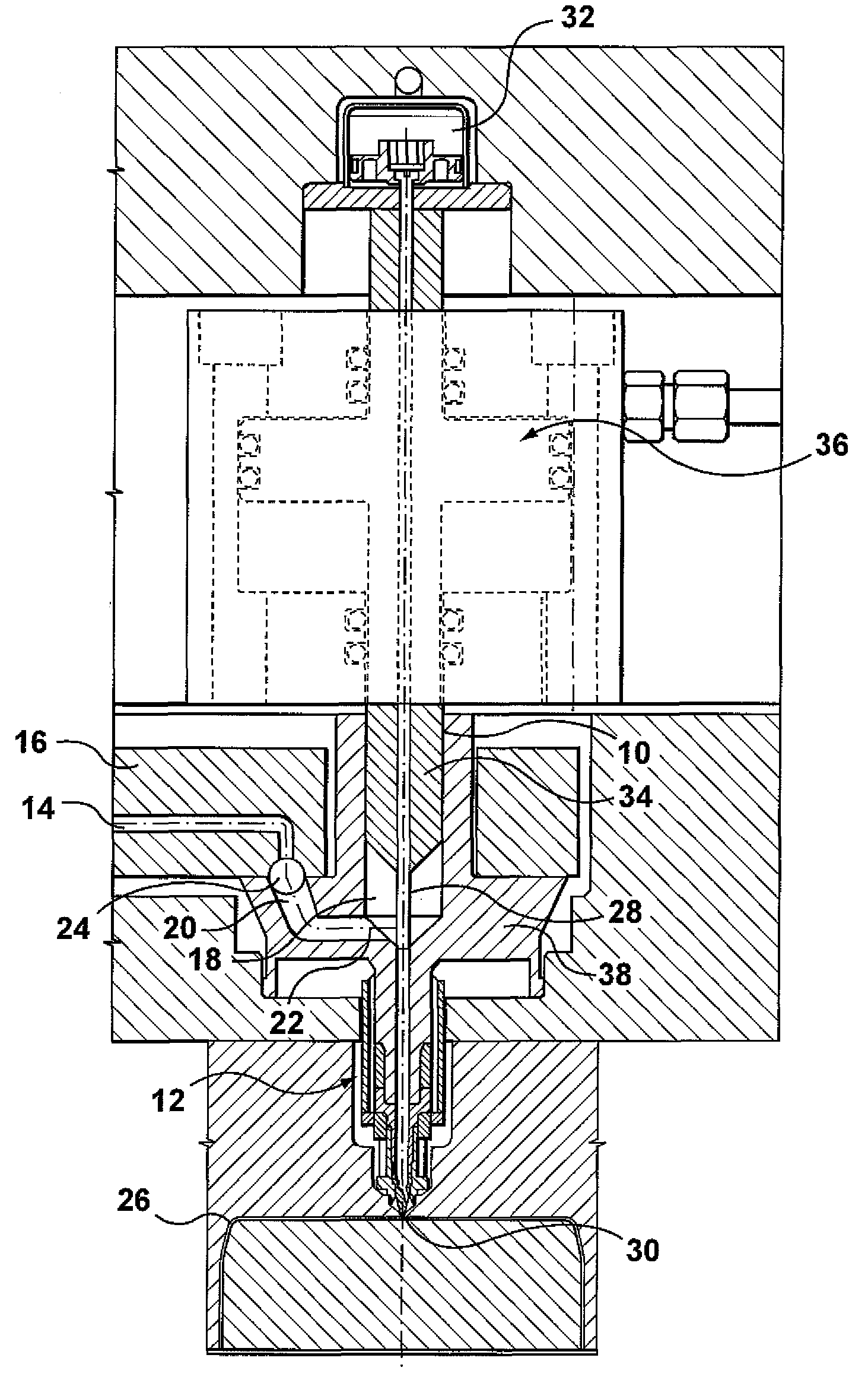

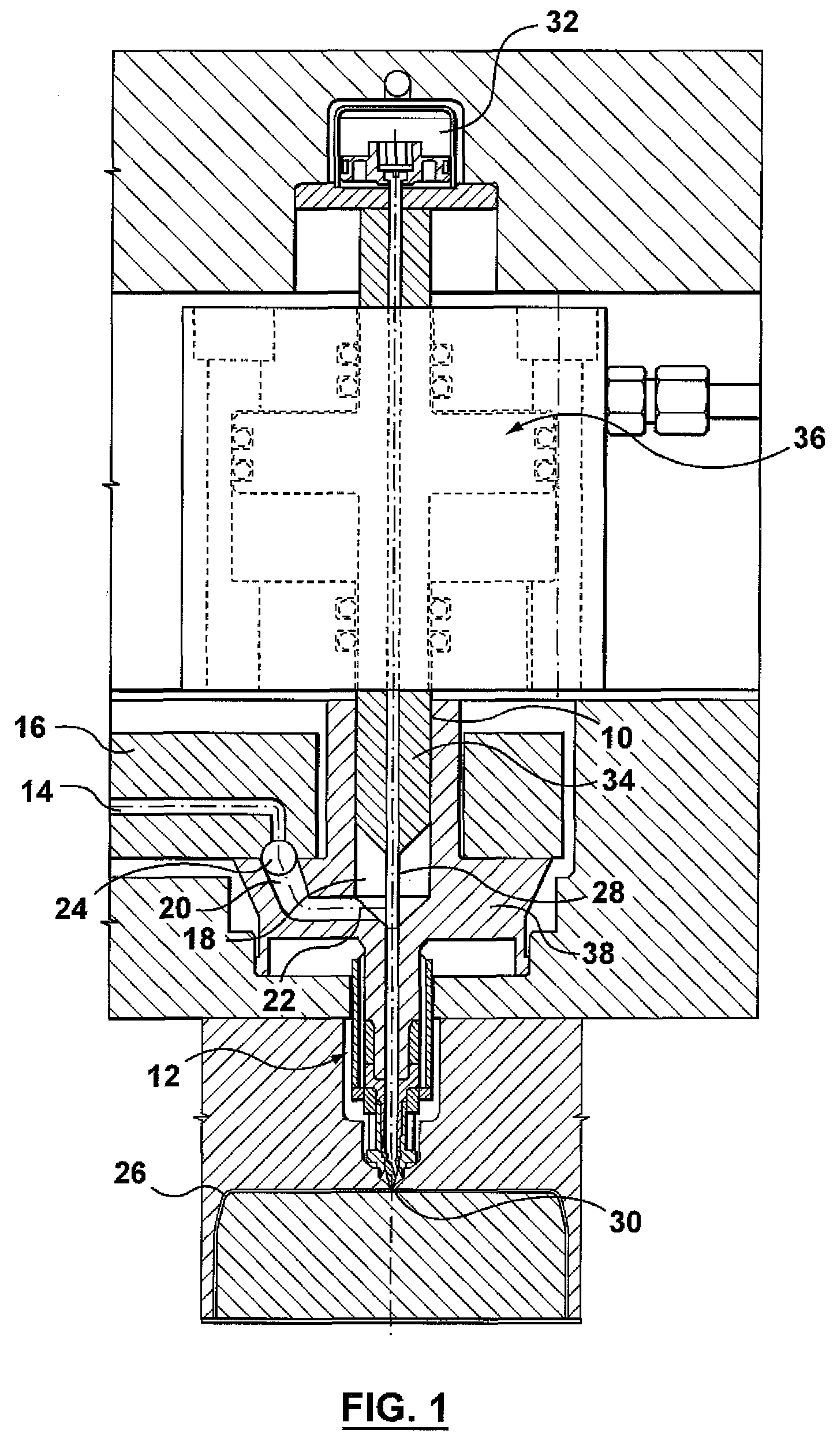

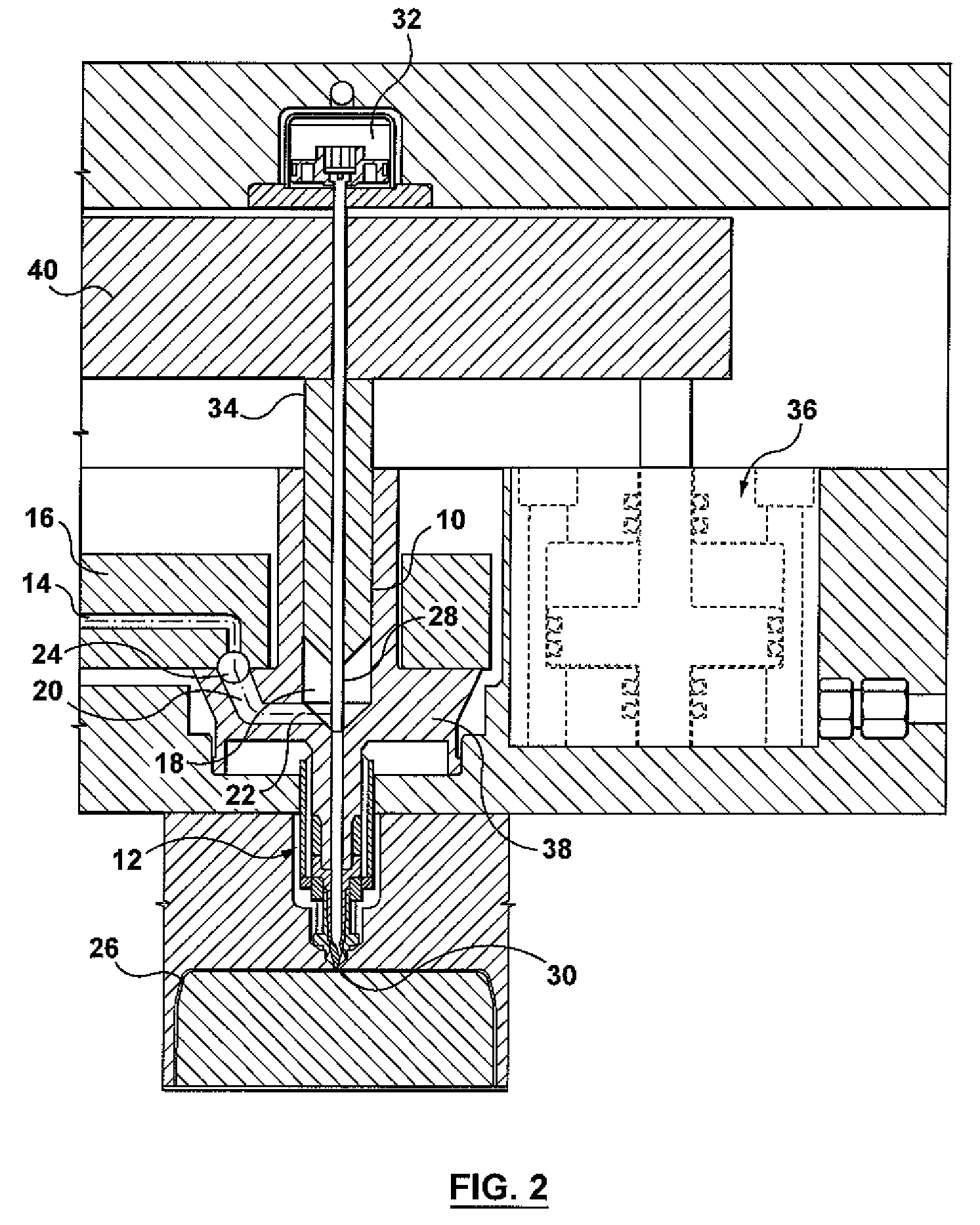

Low pressure molding package structure for fuel cell

InactiveCN101783428AEfficient exclusionAchieve airtightnessFuel and primary cellsCell component detailsMolten stateFuel cells

The invention discloses a low pressure molding package structure for a fuel cell, which comprises a shell, an air electrode and a separation film, a hollow fixing piece, and a hot melt adhesive layer. A plurality of air holes are formed on at least one surface of the shell and the periphery of an inner surface of each air hole is provided with a recessed first accommodating part. The air electrode and the separation film are superposed on the inner surfaces of the plurality of air holes. The hollow fixing piece is arranged in the shell, the surface adjacent to the separation film is provided with an annular flange in a projection mode, and a recessed second accommodating part is formed outside the annular flange. The second accommodating part and the first accommodating part enclose to form a C-shaped flow channel. A hot melt adhesive in a melting state is injected from an injection orifice of the shell or the fixing piece in a low pressure molding mode, so that the hot melt adhesive flows in the C-shaped flow channel and closely adheres and coats the edges of the air electrode and the separation film; and when the hot melt adhesive is cooled and cured, a circle of hot melt adhesive layer which has elasticity and adhesiveness and tightly compresses the air electrode is formed so as to block the leakage of the liquid in the cell.

Owner:HIGH TECH BATTERY INC

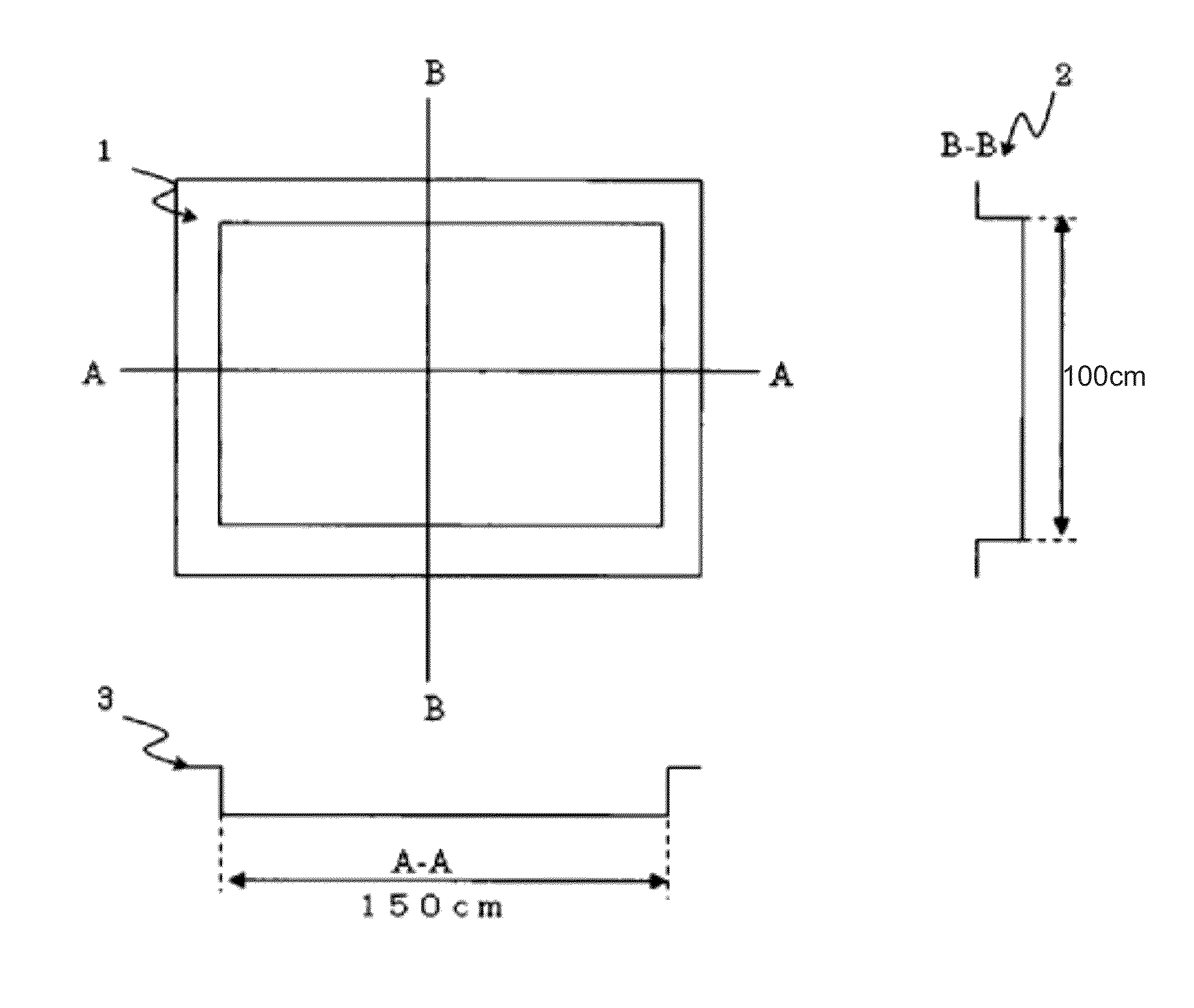

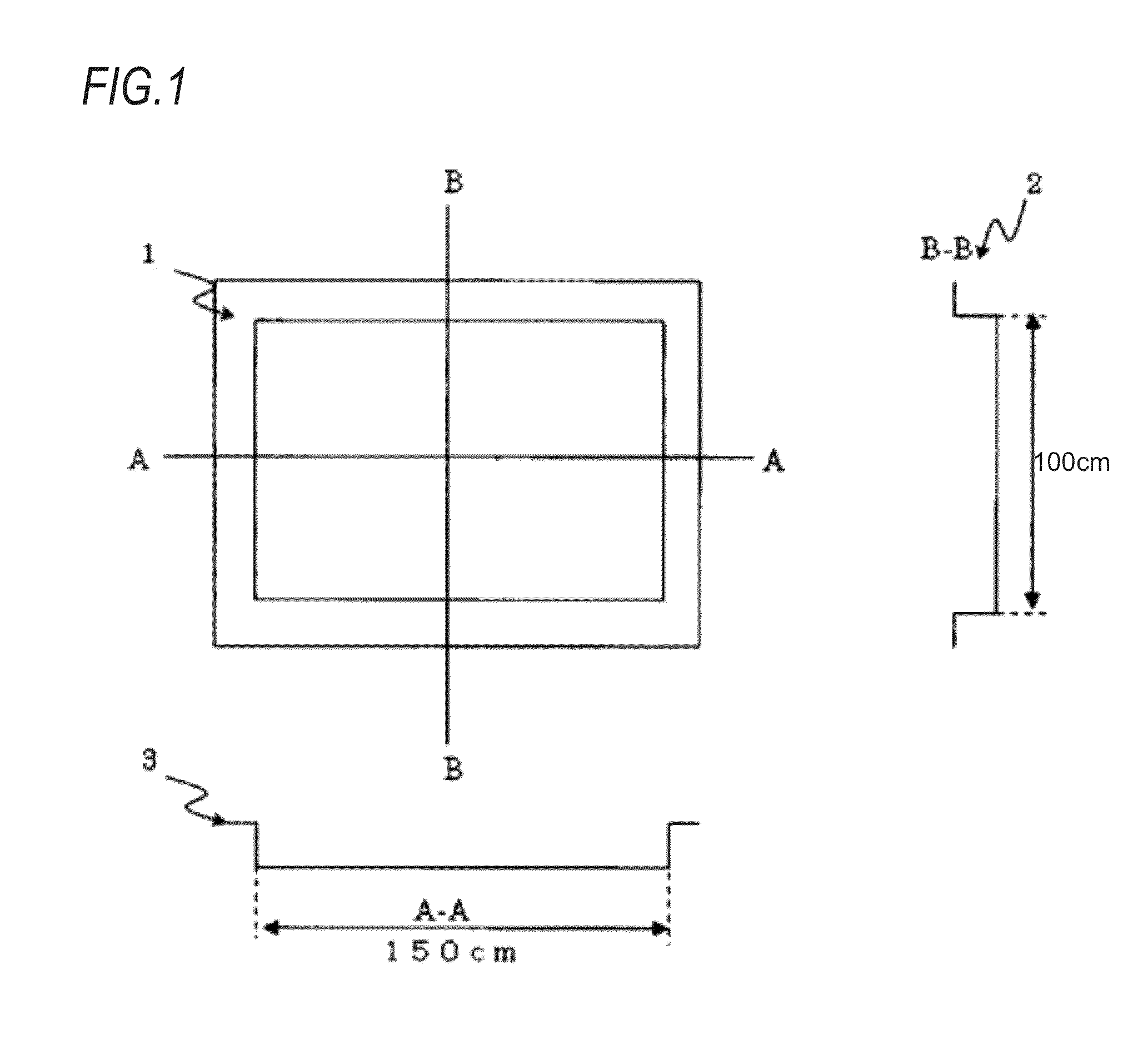

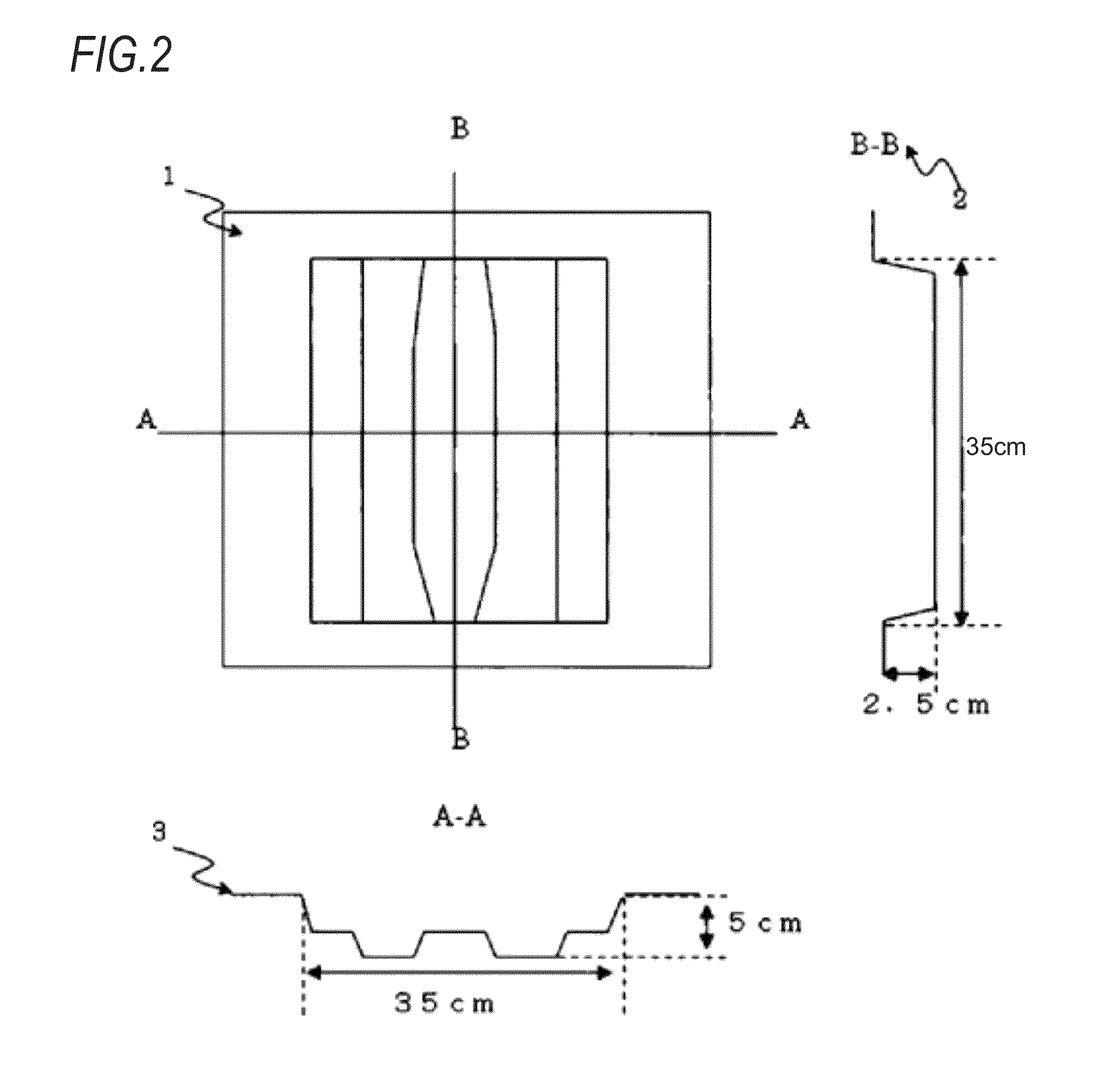

Lightweight parts molded at low pressure

InactiveUS20010053440A1Good handling characteristicsEasy to disassembleNon-woven fabricsThin material handlingEngineeringLow pressure molding

This invention is a compression molded part useful for transportation vehicles and in construction and a process for making compression molded parts. These light weight parts are molded at pressures less than 500 psi (3.5 MPa) and are made from a sheet molding composition or bulk molding composition which incorporates a thixotrope such as fumed silica.

Owner:ASHLAND LICENSING & INTPROP LLC

Multi-colored coverstock

InactiveUS6670012B2Lamination ancillary operationsSynthetic resin layered productsCompression moldingLow pressure molding

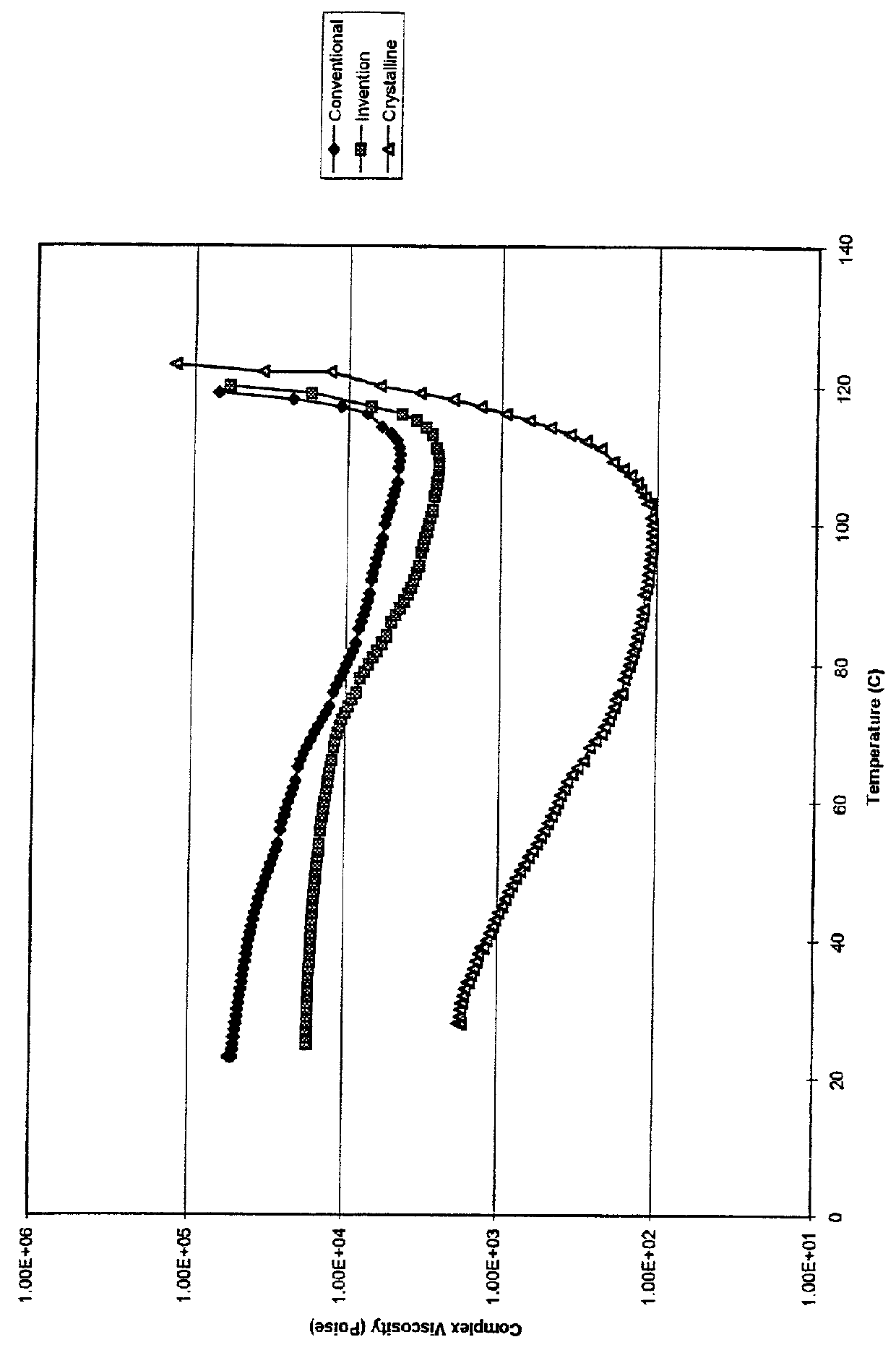

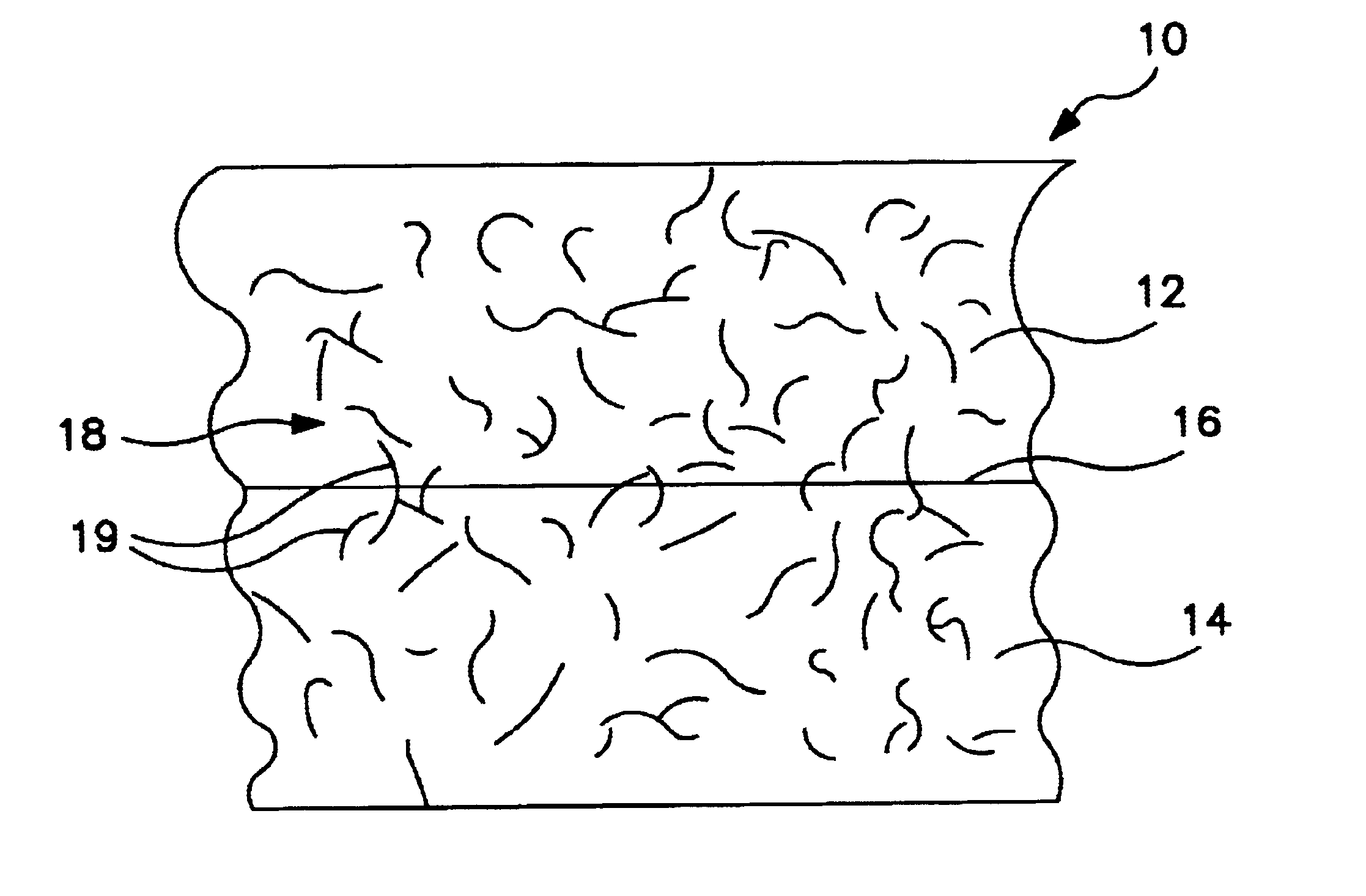

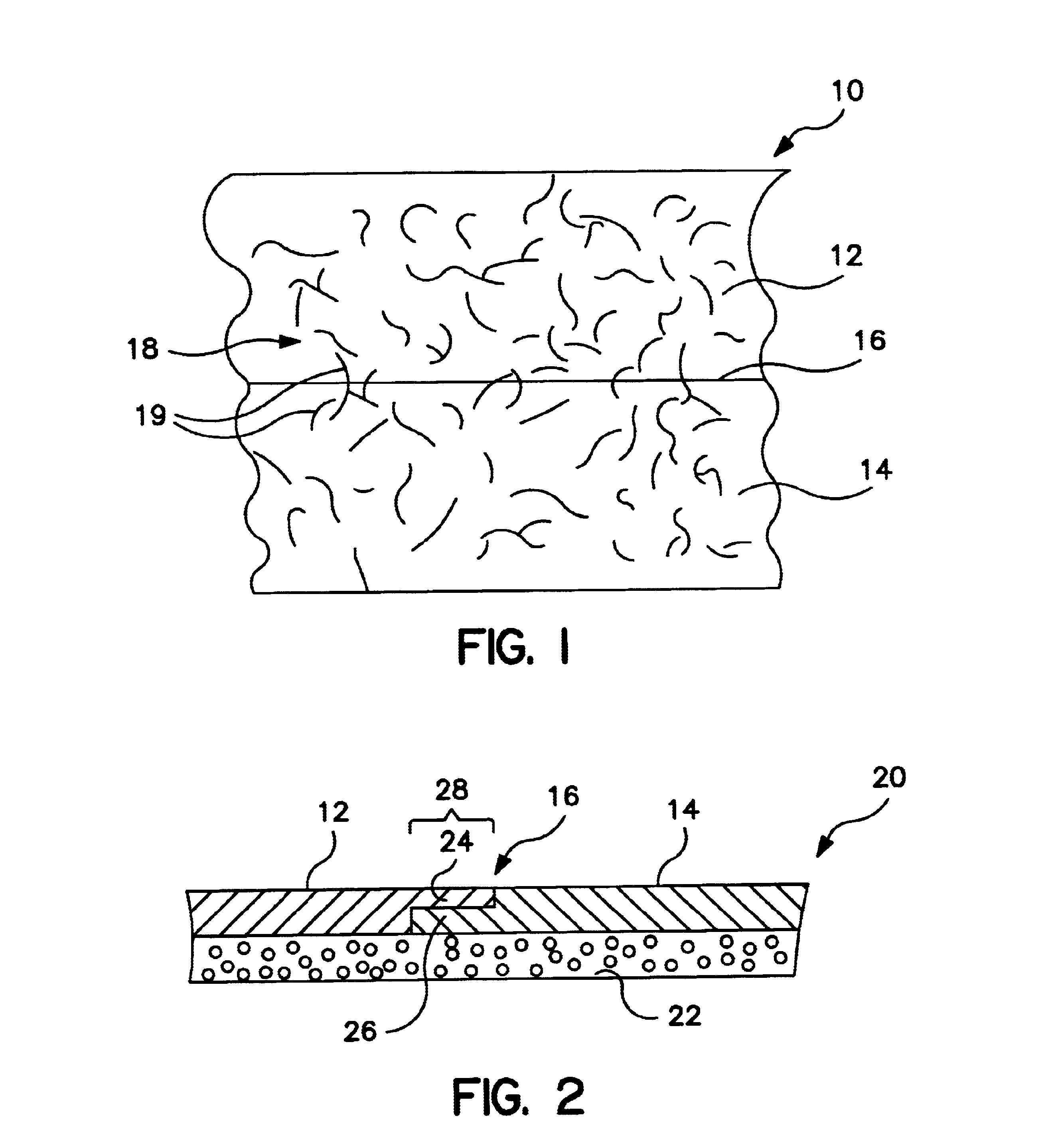

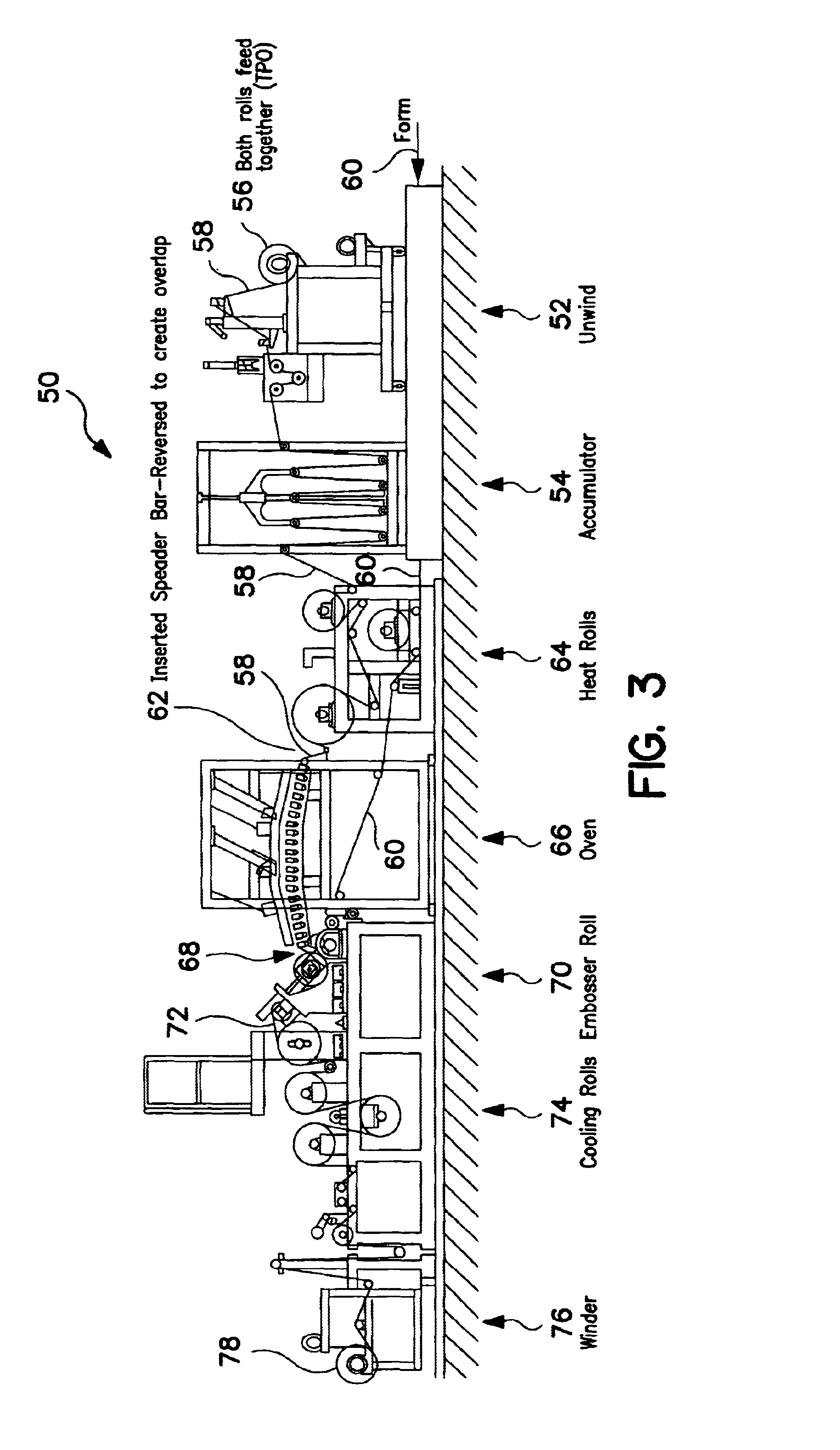

A process for producing a multicolored coverstock (10, 20, 72) providing at least two thermoplastic or thermoplastic olefin sheets (12, 14, 58). Each of the sheets includes a different color. The process includes directing the sheets into a position where the edges (24, 26) of the sheets overlap. The sheets are laminated together and are laminated to a foam substrate (22, 60) by directing the sheets and the foam substrate through an embossing nip (72). The embossing nip is further operative to impart an embossed surface in the sheets (18). The resulting laminated coverstock may be used in vacuum forming, low pressure molding, and compression molding of interior trim parts of automobiles and other vehicles.

Owner:OSULLIVAN FILMS INC

Notched pre-preg and notched pre-preg sheet

ActiveCN106715547AImprove molding stabilitySuppression of molding defects that reduce strengthSynthetic resin layered productsPaper/cardboard layered productsWrinkle skinLow pressure molding

The purpose of the present invention is to provide: an intermediate substrate that has excellent handleability and followability for complex shapes, and also achieves good yield, excellent mechanical properties and low variation thereof, as well as excellent dimensional stability as a result of strength-reducing moulding defects, such as wrinkles and voids, occurring less readily when used in a fibre-reinforced plastic, even with low-pressure moulding; and a method for manufacturing a fibre-reinforced plastic, the intermediate substrate being used in said method. This pre-preg, which has a layer that contains reinforcing fibres impregnated with a resin composition, is characterised by: being a notched pre-preg; the rate of impregnation by the resin composition in the pre-preg being within a prescribed range; comprising reinforcing fibres, at least a portion of which is of a prescribed fibre length due to a plurality of notches; and having a reinforcing-fibre volume content Vf that is within a prescribed range.

Owner:TORAY IND INC

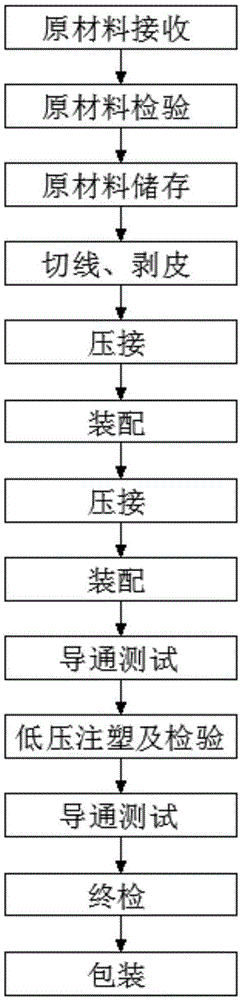

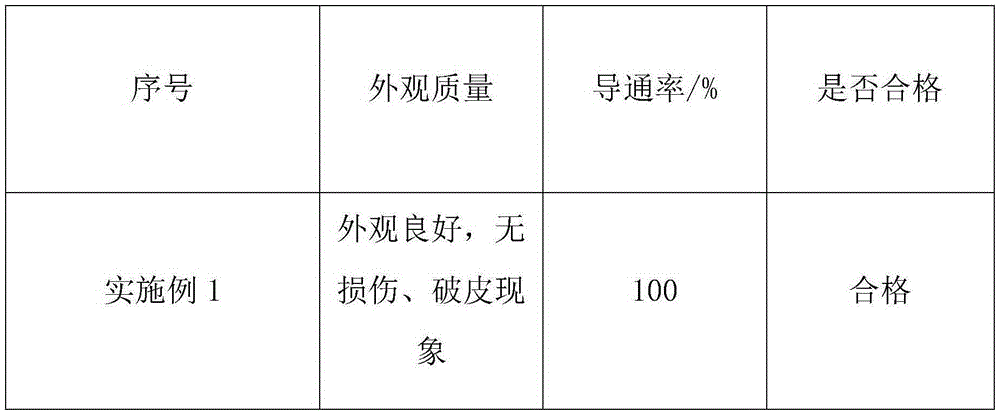

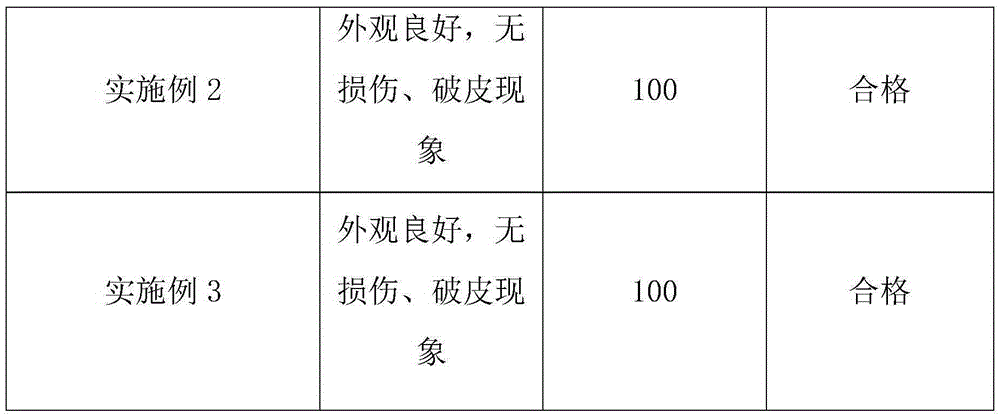

Production method of abrasion connection harness

InactiveCN105304212AGood workmanship qualityImprove standardsConductor/cable markingEconomic benefitsWire cutting

The present invention discloses a production method of an abrasion connection harness, and relates to the field of the automobile harness production technology. The production method comprises the 13 steps: reception of raw materials, examination of the raw materials, wire cutting and skinning, crimping, assembling, crimping, assembling, conduction test, low pressure molding and examination, conduction test, final inspection and package. Through the optimization of the production process, the adoption of a plurality of technologies and checking at each level, the production method of an abrasion connection harness is able to ensure that materials or provides produced by each process may reach best technology qualities; and moreover, through strict control of technological parameters, produced harness products are ensured to reach the high standard so that the rejection rate is reduced, and a pipeline operation step is employed in the crimping and assembling steps so that the production efficiency is increased, the cost of enterprises is reduced, and the economic benefit is improved.

Owner:WUHU BOKANG ELECTRICAL

Paper sludge and urban living garbage biomass environment-friendly renewable energy fuel, and preparation method thereof

InactiveCN102732350AImprove fire performanceReduced time required to burn outBiofuelsSolid fuelsCombustionSulfur

The invention discloses a paper sludge and urban living garbage biomass environment-friendly renewable energy fuel with advantages of low cost, easy combustion, high burnout rate, good desulphurization effect, and good water resistance, and a preparation method thereof. The environment-friendly renewable energy fuel is mainly composed of the components of, by mass: 40-65 parts of fine anthracite, 25-55 parts of paper sludge or urban living garbage, and 6-15 parts of additives. The preparation method comprises the steps that: the fine anthracite is screened, and dried paper sludge or urban living garbage is crushed, such that a maximal particle size is no larger than 3mm; the screened anthracite and the crushed dried paper sludge or urban living garbage are well mixed; the additives of a sulfur-fixing agent, an oxidant, and a water-proofing agent are well mixed; the mixed anthracite and the paper sludge or urban living garbage, the mixed additives, and a proper amount of water are well mixed; the mixture is molded by using a mold through wet low-pressure molding; and the molded material is cured under room temperature. The fuel provided by the invention can be widely applied in the field of environment-friendly renewable energy.

Owner:ZHUHAI HUISHENG ENERGY SOURCE TECH DEV

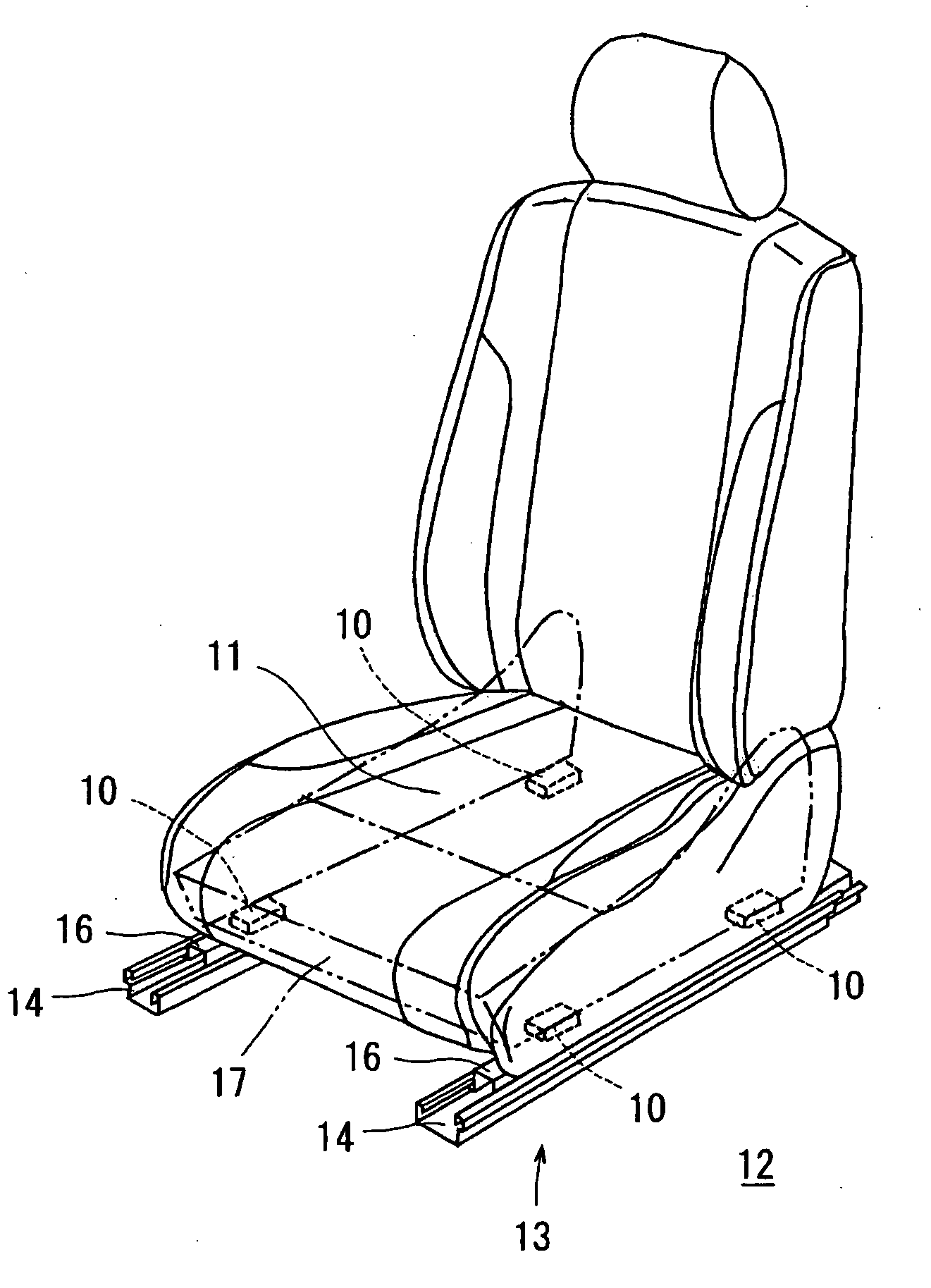

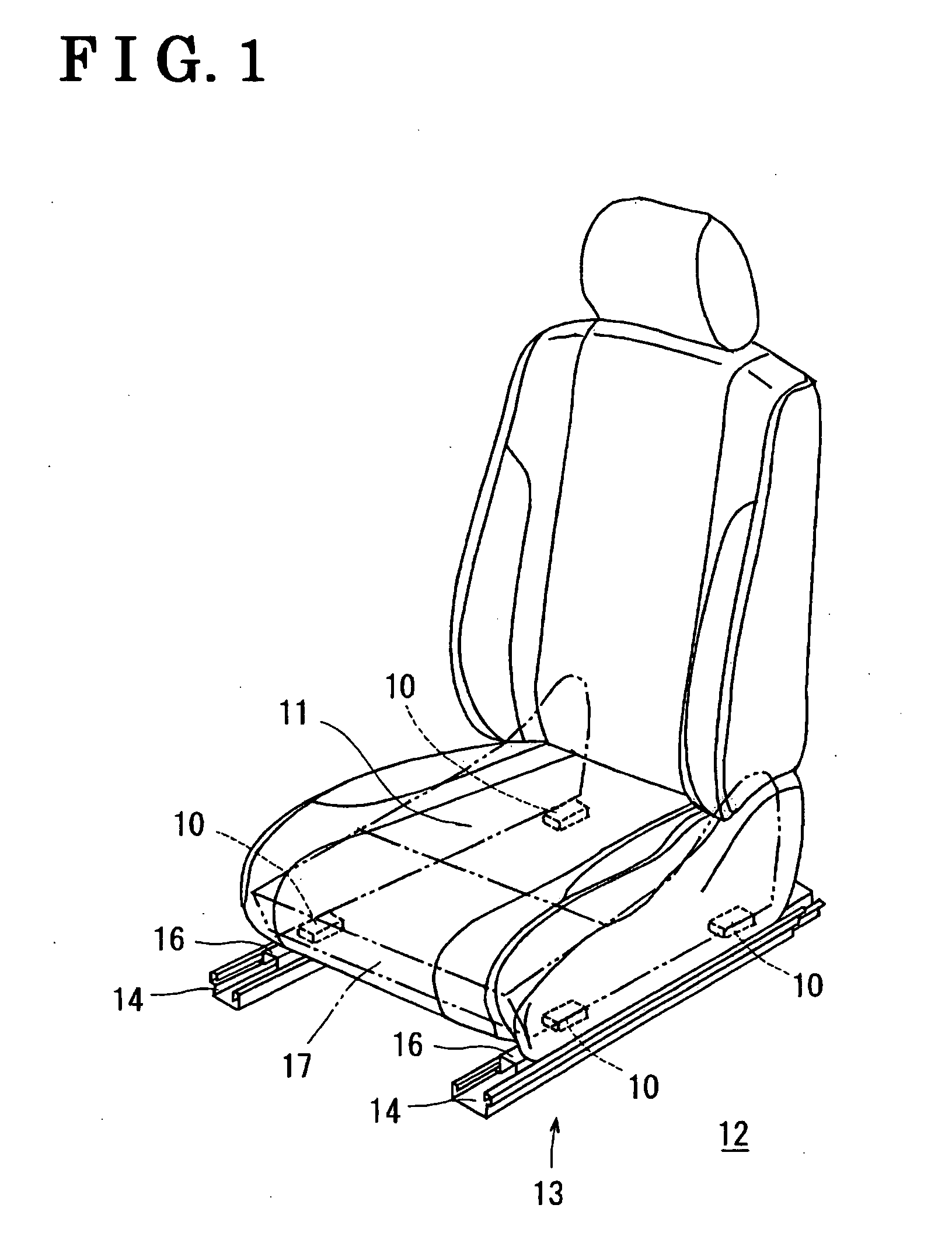

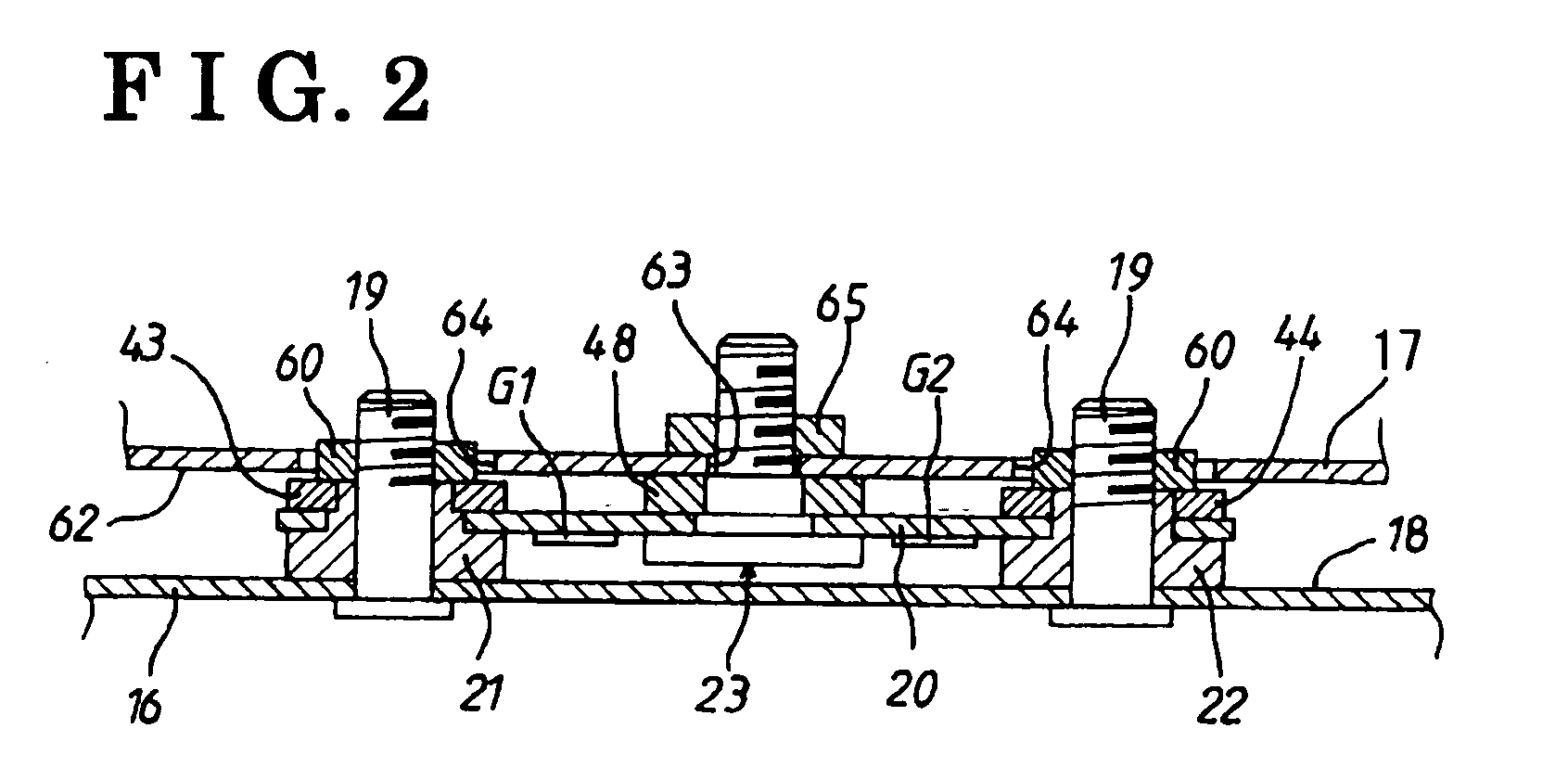

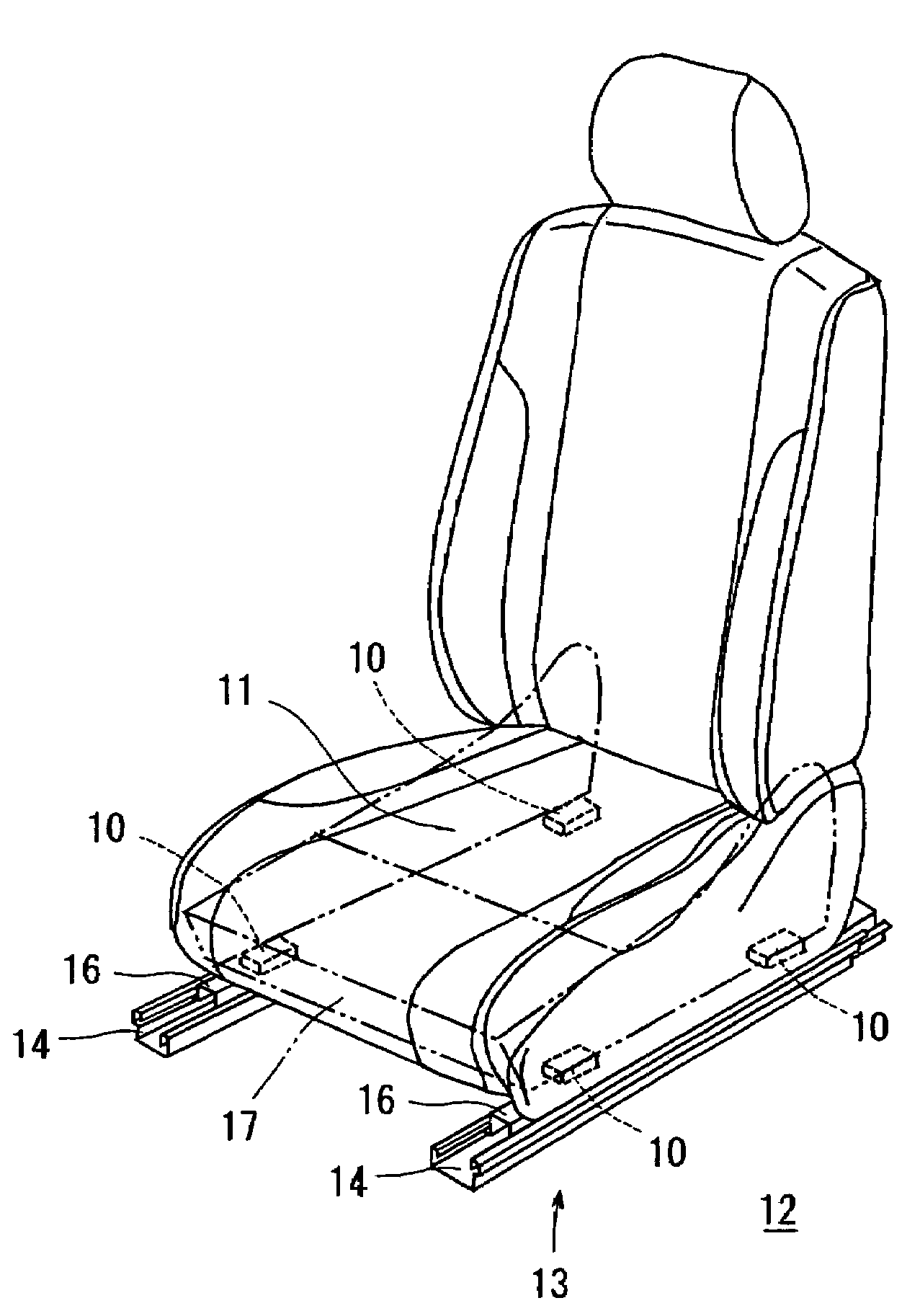

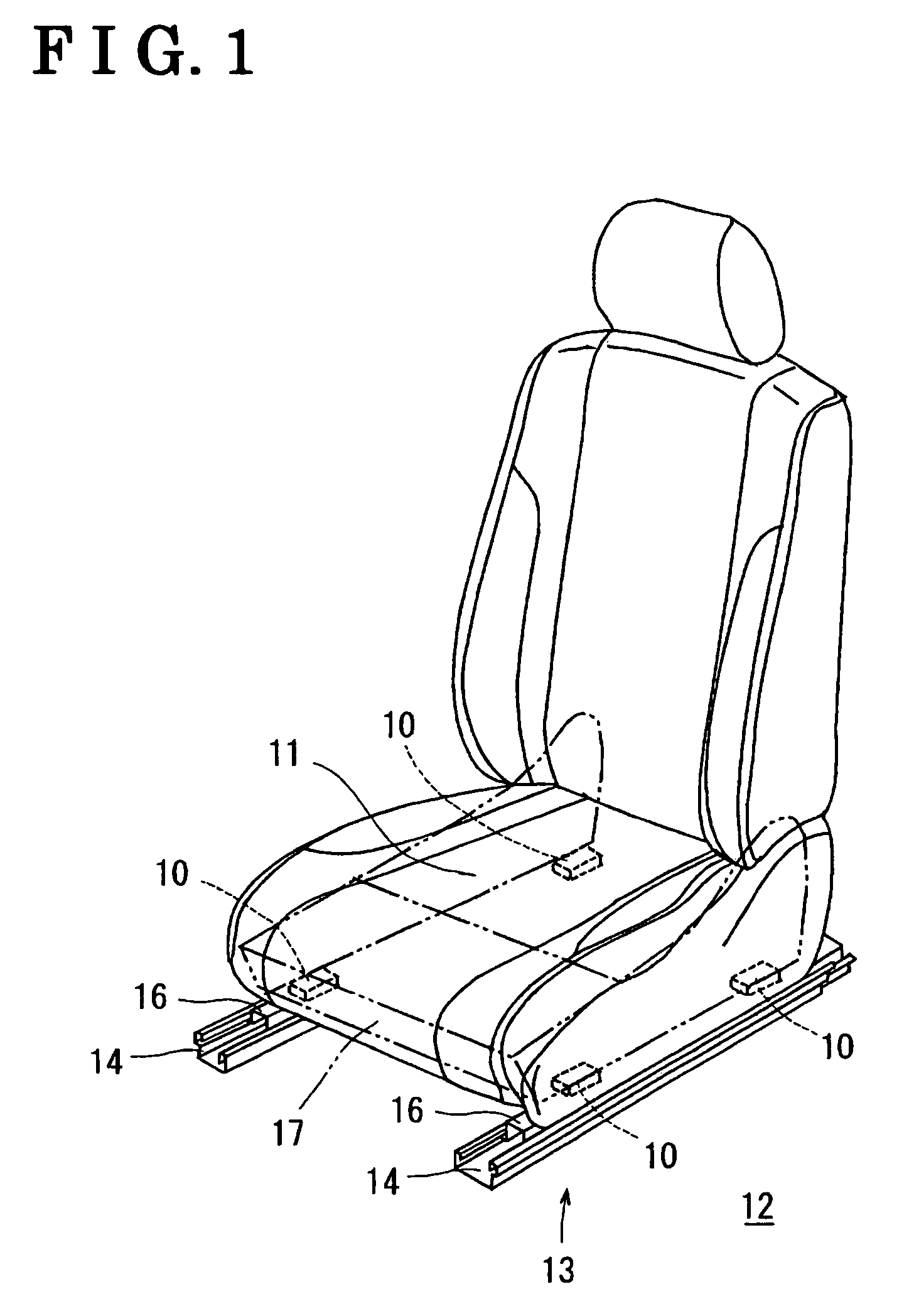

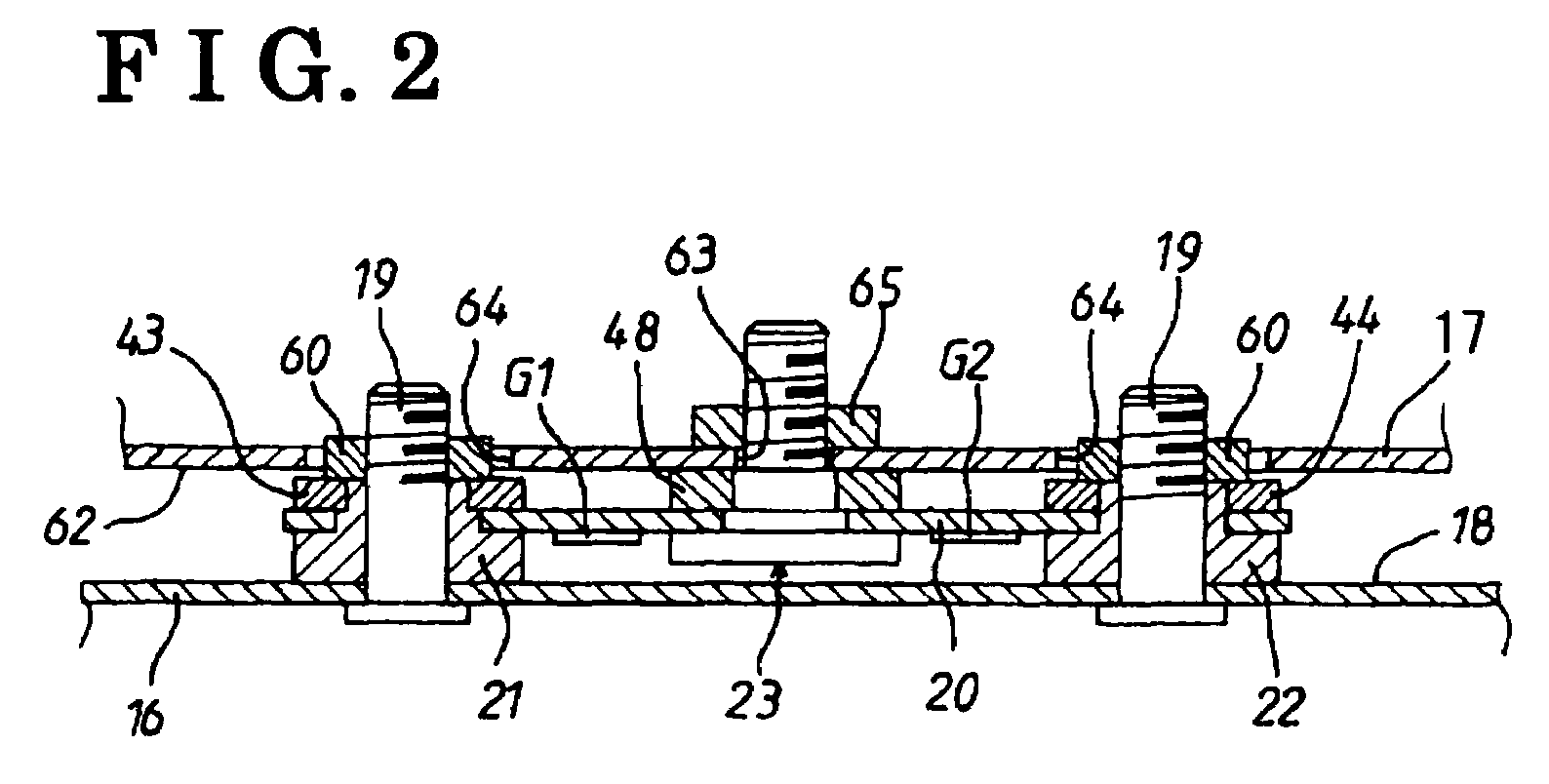

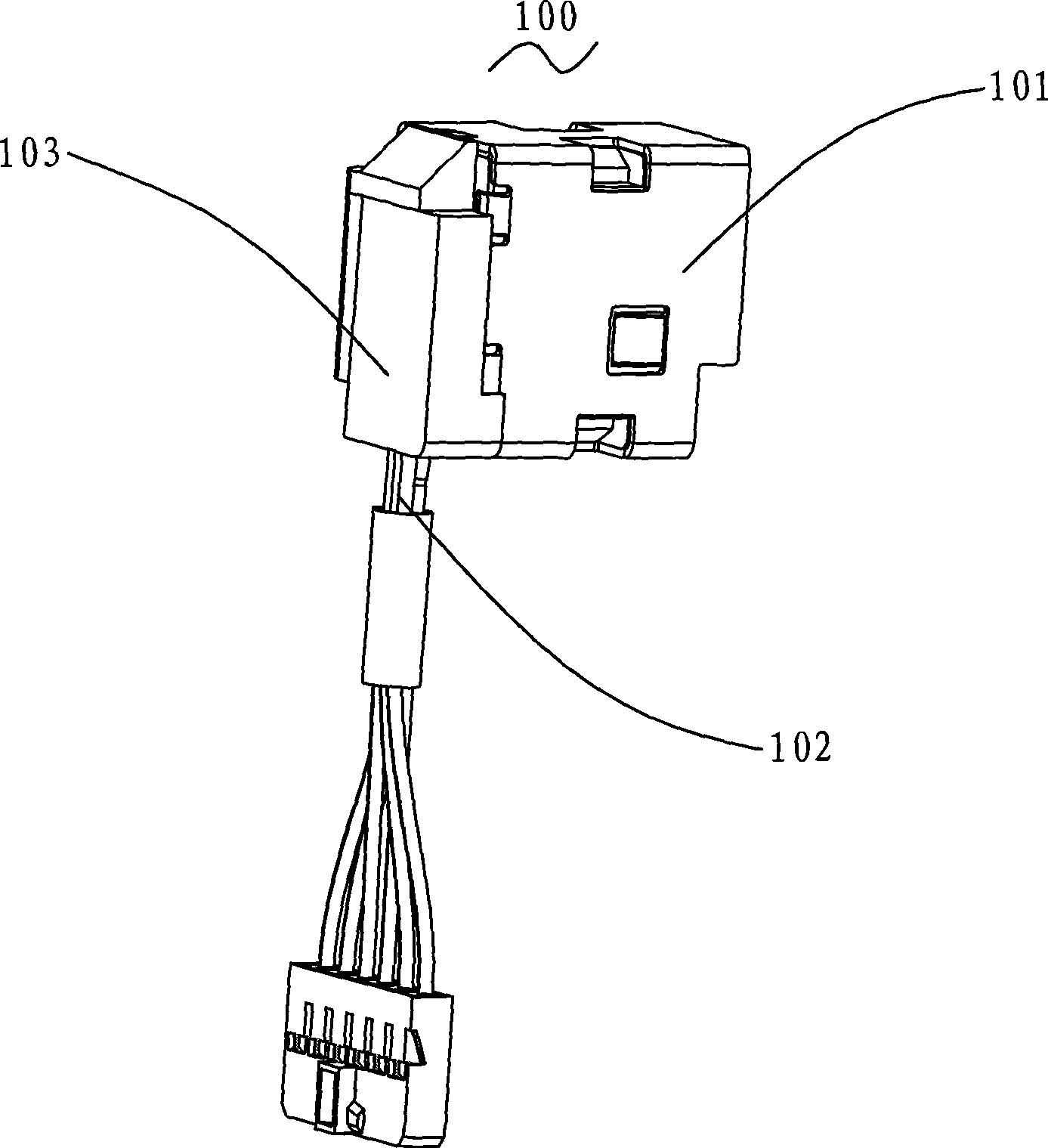

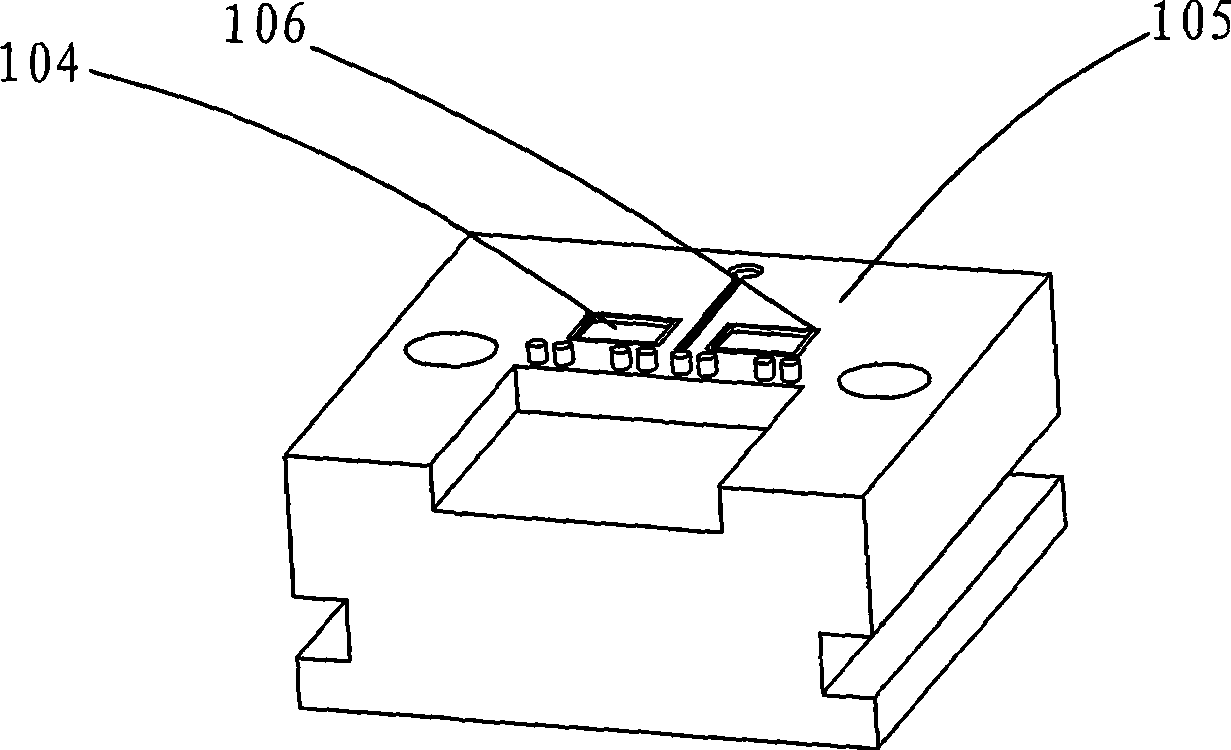

Occupant load sensor for vehicle

An occupant load sensor for a vehicle includes a strain member, a connecting member fixed at the strain member, a strain gauge attached to the strain member, an upper bracket having a fixed portion and an attachment portion connecting each fixed portion and extending at a side of the strain member in a lateral direction of the seat, an amplifier case attached to the attachment portion and arranged in parallel with the strain member, an amplifier substrate enclosed in the amplifier case and placed on an identical plane to the strain member, an FPC substrate connected to the strain gauge and the amplifier substrate, a coating portion for coating a connection portion between the FPC substrate and the strain gauge; and a low pressure molded portion molded with a hot melt resin by low pressure molding in the amplifier case to cover the amplifier substrate and the connection portion.

Owner:AISIN SEIKI KK

Formulation and process for compression molded component parts

InactiveUS7078451B2Low viscosityLow molding conditionFibre treatmentSolid ballsMedicineShell molding

A formulation for controlling the thickening profile for sheet molding compositions to a lower viscosity for use in low pressure molding conditions is provided. The B side addition of a modified alkaline earth oxide thickening system using a combination of oxides results in a sheet molding compound that is tack free at lowered viscosities. These sheet molding compounds exhibit extended shelf lives, good flowability, and excellent handling characteristics.

Owner:OCV INTELLECTUAL CAPITAL LLC

High pressure injection molding nozzle with low pressure manifold

Owner:HUSKY INJECTION MOLDING SYST LTD

Occupant load sensor for vehicle

An occupant load sensor for a vehicle includes a strain member, a connecting member fixed at the strain member, a strain gauge attached to the strain member, an upper bracket having a fixed portion and an attachment portion connecting each fixed portion and extending at a side of the strain member in a lateral direction of the seat, an amplifier case attached to the attachment portion and arranged in parallel with the strain member, an amplifier substrate enclosed in the amplifier case and placed on an identical plane to the strain member, an FPC substrate connected to the strain gauge and the amplifier substrate, a coating portion for coating a connection portion between the FPC substrate and the strain gauge; and a low pressure molded portion molded with a hot melt resin by low pressure molding in the amplifier case to cover the amplifier substrate and the connection portion.

Owner:AISIN SEIKI KK

Packaging structure of low-pressure molded fuel cell

InactiveUS8551672B2Efficient removalSimple processFuel and primary cellsFuel cells groupingC sectionsFuel cells

Owner:HIGH TECH BATTERY INC

Assembling method for DC electric connector and DC electric connector

ActiveCN101483289AImpact resistantWon't hurtRelieving strain on wire connectionContact member assembly/disassemblyEngineeringLow pressure molding

The invention relates to a direct current electric connector and an assembly method. The assembly method of the direct current electric connector comprises the following steps: 1. welding the direct current electric connector body and a wire; 2. packaging the welded direct current electric connector body and the wire through a low pressure molding forming mode so as to realize the assembly of the direct current electric connector. The direct electric connector comprises the direct current electric connector body and the wire which are connected by the low pressure molding forming mode. The invention has simple process and high production efficiency. The welding part of the direct current electric connector and the wire is packaged by the low pressure molding forming mode, which does not damage the component. The defective rate is low. The packaged products have tidy appearance, good hot-melt adhesive toughness, and high strength. The packaged wire effectively protects the welding point against the external force pulling, moreover the packaging part of the direct current connector body and the wire has efficiencies of insulation, temperature resistance, impact resistance, vibration reduction, damp proof, waterproof, dustproof and chemical resistance or the like.

Owner:SINGATRON ELECTRONICS CHINA

Unsaturated polyester resin glass fiber prepreg for low-temperature and low-pressure forming and preparation method thereof

Owner:江门市瑞祥复合材料研究院有限公司

Combining system for low pressure moulding of continuous-casting three critical parts

The invention belongs to the technical field of continuous-casting funcational refractory materials, and relates to a combining system for low pressure moulding of continuous-casting three critical parts. The combining system comprises a binding agent and a solvent. The binding agent is composed of phenolic resin powder and CarboresP, the adding amount of phenolic resin powder is 4-6 wt% of the total weight of the continuous-casting three critical parts, and the adding amount of CarboresP is 1.5-3 wt% of the total weight of the continuous-casting three critical parts. The solvent comprises alcohol and methyl mixed dicarboxylate, the adding amount of alcohol is 2-3 wt% of the total weight of the continuous-casting three critical parts, and the adding amount of methyl mixed dicarboxylate is 1.5-2.5 wt% of the total weight of the continuous-casting three critical parts. By controlling the adding amount of high-boiling-point solvents, the high-volatility composition needed by low-pressure molding of blank materials is regulated and controlled; by introducing the binding agent with high residual carbon rate, the densification of the products is guaranteed, also the high-temperature strength of the material is improved, so that the combining system has obvious economic benefit and social benefit.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com